the handbook of food engineering practice crc press chapter 10 ...

the handbook of food engineering practice crc press chapter 10 ... the handbook of food engineering practice crc press chapter 10 ...

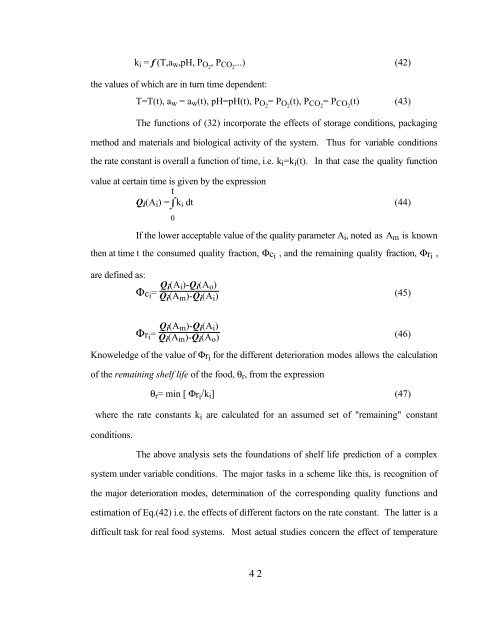

k i = f (T,a w ,pH, P O2 , P CO2 ...) (42) the values of which are in turn time dependent: T=T(t), a w = a w (t), pH=pH(t), P O2 = P O2 (t), P CO2 = P CO2 (t) (43) The functions of (32) incorporate the effects of storage conditions, packaging method and materials and biological activity of the system. Thus for variable conditions the rate constant is overall a function of time, i.e. k i =k i (t). In that case the quality function value at certain time is given by the expression t Q i (A i ) = ⌡ ⌠k i dt (44) 0 If the lower acceptable value of the quality parameter A i , noted as A m is known then at time t the consumed quality fraction, Φc i , and the remaining quality fraction, Φr i , are defined as: Φc i = Q i(A i )-Q i (A o ) Q i (A m )-Q i (A i ) (45) Φr i = Q i(A m )-Q i (A i ) Q i (A m )-Q i (A o ) (46) Knoweledge of the value of Φr i for the different deterioration modes allows the calculation of the remaining shelf life of the food, θ r , from the expression θ r = min [ Φr i /k i ] (47) where the rate constants k i are calculated for an assumed set of "remaining" constant conditions. The above analysis sets the foundations of shelf life prediction of a complex system under variable conditions. The major tasks in a scheme like this, is recognition of the major deterioration modes, determination of the corresponding quality functions and estimation of Eq.(42) i.e. the effects of different factors on the rate constant. The latter is a difficult task for real food systems. Most actual studies concern the effect of temperature 42

and variable temperature conditions, with the expressed (or implied) assumption that the other factors are constant. Controlled temperature functions like square, sine, and linear (spike) wave temperature fluctuations can be applied to verify the Arrhenius model, developed from several constant-temperature shelf life experiments . Labuza (1984) gives analytical expressions for Eq. (44) for the above temperature functions using the Q 10 approach. Similarly solutions can be given using the Arrhenius or square root models. To systematically approach the effect of variable temperature conditions the concept of effective temperature, T eff , can be introduced. T eff is a constant temperature that results in the same quality change as the variable temperature distribution over the same period of time. T eff is characteristic of the temperature distribution and the kinetic temperature dependence of the system. The rate constant at T eff is analogously termed effective rate constant, and Q i (A i ) of Eq.(44) is equall to k eff t. If T m and k m are the mean of the temperature distribution and the corresponding rate constant respectively, the ratio Γ is also characteristic of the temperature distribution and the specific system, where Γ= k eff k m (48) For some known characteristic temperature functions shown in Fig.8 analytical expressions for the Q 10 and Arrhenius models are tabulated in Table 5. 43

- Page 1 and 2: THE HANDBOOK OF FOOD ENGINEERING PR

- Page 3 and 4: It is a working definition for the

- Page 5 and 6: 10.2 KINETICS OF FOOD DETERIORATION

- Page 7 and 8: very small, allowing us to treat it

- Page 9 and 10: Data can be fitted to these equatio

- Page 11 and 12: criterion. The value of the R 2 , f

- Page 13 and 14: of reaction systems involved in foo

- Page 15 and 16: Lund, 1985). The standarized residu

- Page 17 and 18: When a Michaelis-Menten rate equati

- Page 19 and 20: ∂ ln K eq ∂ (1/T) = - ∆Eo R (

- Page 21 and 22: are available, the confidence range

- Page 23 and 24: kinetic data is compared. Its main

- Page 25 and 26: plot will give a relatively straigh

- Page 27 and 28: temperatures (Fennema et al., 1973)

- Page 29 and 30: Glass transition phenomena are also

- Page 31 and 32: i.e. if T ∞ is chosen correctly,

- Page 33 and 34: A number of recent publications deb

- Page 35 and 36: The study of the temperature depend

- Page 37 and 38: and bakery goods, upon losing moist

- Page 39 and 40: ambient temperatures (e.g loss of c

- Page 41: temperature and is an area of curre

- Page 45 and 46: Figure 8. Characteristic fluctuatin

- Page 47 and 48: 10.3 APPLICATION OF FOOD KINETICS I

- Page 49 and 50: time at each selected temperature.

- Page 51 and 52: TTI can be used to monitor the temp

- Page 53 and 54: 10.4 EXAMPLES OF APPLICATION OF KIN

- Page 55 and 56: Figure 10. Thiamin retention of a m

- Page 57 and 58: S = SS {1+ N p n-Np F[N p, n-N p ,

- Page 59 and 60: 10.4.2. Examples of shelf life mode

- Page 61 and 62: In Fig. 12a aspartame concentration

- Page 63 and 64: the approach to follow to increase

- Page 65 and 66: REFERENCES Arabshashi, A. (1982). E

- Page 67 and 68: Fennema, O., Powrie, W. D., Marth,

- Page 69 and 70: Labuza, T. P. (1975) Oxidative chan

- Page 71 and 72: Mohr, P. W., Krawiec, S. (1980) Tem

- Page 73 and 74: Sapru, V., and T.P. Labuza (1992) G

- Page 75: Yoshioka, S., Aso, Y., Uchiyama, M.

k i = f (T,a w ,pH, P O2 , P CO2 ...) (42)<br />

<strong>the</strong> values <strong>of</strong> which are in turn time dependent:<br />

T=T(t), a w = a w (t), pH=pH(t), P O2 = P O2 (t), P CO2 = P CO2 (t) (43)<br />

The functions <strong>of</strong> (32) incorporate <strong>the</strong> effects <strong>of</strong> storage conditions, packaging<br />

method and materials and biological activity <strong>of</strong> <strong>the</strong> system. Thus for variable conditions<br />

<strong>the</strong> rate constant is overall a function <strong>of</strong> time, i.e. k i =k i (t). In that case <strong>the</strong> quality function<br />

value at certain time is given by <strong>the</strong> ex<strong>press</strong>ion<br />

t<br />

Q i (A i ) = ⌡ ⌠k i dt (44)<br />

0<br />

If <strong>the</strong> lower acceptable value <strong>of</strong> <strong>the</strong> quality parameter A i , noted as A m is known<br />

<strong>the</strong>n at time t <strong>the</strong> consumed quality fraction, Φc i , and <strong>the</strong> remaining quality fraction, Φr i ,<br />

are defined as:<br />

Φc i = Q i(A i )-Q i (A o )<br />

Q i (A m )-Q i (A i ) (45)<br />

Φr i = Q i(A m )-Q i (A i )<br />

Q i (A m )-Q i (A o ) (46)<br />

Knoweledge <strong>of</strong> <strong>the</strong> value <strong>of</strong> Φr i for <strong>the</strong> different deterioration modes allows <strong>the</strong> calculation<br />

<strong>of</strong> <strong>the</strong> remaining shelf life <strong>of</strong> <strong>the</strong> <strong>food</strong>, θ r , from <strong>the</strong> ex<strong>press</strong>ion<br />

θ r = min [ Φr i /k i ] (47)<br />

where <strong>the</strong> rate constants k i are calculated for an assumed set <strong>of</strong> "remaining" constant<br />

conditions.<br />

The above analysis sets <strong>the</strong> foundations <strong>of</strong> shelf life prediction <strong>of</strong> a complex<br />

system under variable conditions. The major tasks in a scheme like this, is recognition <strong>of</strong><br />

<strong>the</strong> major deterioration modes, determination <strong>of</strong> <strong>the</strong> corresponding quality functions and<br />

estimation <strong>of</strong> Eq.(42) i.e. <strong>the</strong> effects <strong>of</strong> different factors on <strong>the</strong> rate constant. The latter is a<br />

difficult task for real <strong>food</strong> systems. Most actual studies concern <strong>the</strong> effect <strong>of</strong> temperature<br />

42