the handbook of food engineering practice crc press chapter 10 ...

the handbook of food engineering practice crc press chapter 10 ...

the handbook of food engineering practice crc press chapter 10 ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

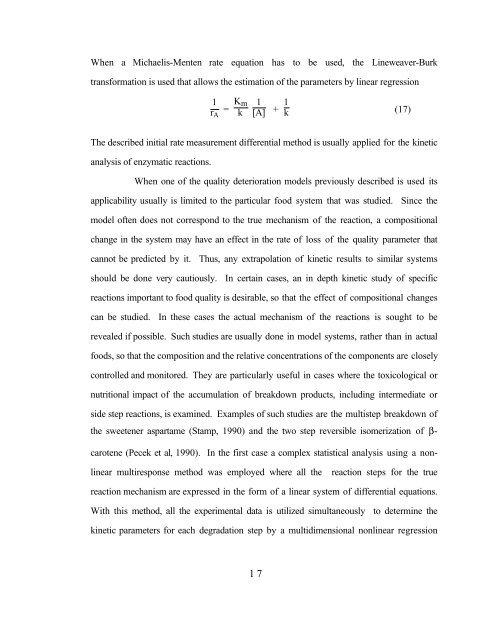

When a Michaelis-Menten rate equation has to be used, <strong>the</strong> Lineweaver-Burk<br />

transformation is used that allows <strong>the</strong> estimation <strong>of</strong> <strong>the</strong> parameters by linear regression<br />

1<br />

r A<br />

= K m<br />

k<br />

1<br />

[A] + 1 k (17)<br />

The described initial rate measurement differential method is usually applied for <strong>the</strong> kinetic<br />

analysis <strong>of</strong> enzymatic reactions.<br />

When one <strong>of</strong> <strong>the</strong> quality deterioration models previously described is used its<br />

applicability usually is limited to <strong>the</strong> particular <strong>food</strong> system that was studied. Since <strong>the</strong><br />

model <strong>of</strong>ten does not correspond to <strong>the</strong> true mechanism <strong>of</strong> <strong>the</strong> reaction, a compositional<br />

change in <strong>the</strong> system may have an effect in <strong>the</strong> rate <strong>of</strong> loss <strong>of</strong> <strong>the</strong> quality parameter that<br />

cannot be predicted by it. Thus, any extrapolation <strong>of</strong> kinetic results to similar systems<br />

should be done very cautiously. In certain cases, an in depth kinetic study <strong>of</strong> specific<br />

reactions important to <strong>food</strong> quality is desirable, so that <strong>the</strong> effect <strong>of</strong> compositional changes<br />

can be studied. In <strong>the</strong>se cases <strong>the</strong> actual mechanism <strong>of</strong> <strong>the</strong> reactions is sought to be<br />

revealed if possible. Such studies are usually done in model systems, ra<strong>the</strong>r than in actual<br />

<strong>food</strong>s, so that <strong>the</strong> composition and <strong>the</strong> relative concentrations <strong>of</strong> <strong>the</strong> components are closely<br />

controlled and monitored. They are particularly useful in cases where <strong>the</strong> toxicological or<br />

nutritional impact <strong>of</strong> <strong>the</strong> accumulation <strong>of</strong> breakdown products, including intermediate or<br />

side step reactions, is examined. Examples <strong>of</strong> such studies are <strong>the</strong> multistep breakdown <strong>of</strong><br />

<strong>the</strong> sweetener aspartame (Stamp, 1990) and <strong>the</strong> two step reversible isomerization <strong>of</strong> β-<br />

carotene (Pecek et al, 1990). In <strong>the</strong> first case a complex statistical analysis using a nonlinear<br />

multiresponse method was employed where all <strong>the</strong> reaction steps for <strong>the</strong> true<br />

reaction mechanism are ex<strong>press</strong>ed in <strong>the</strong> form <strong>of</strong> a linear system <strong>of</strong> differential equations.<br />

With this method, all <strong>the</strong> experimental data is utilized simultaneously to determine <strong>the</strong><br />

kinetic parameters for each degradation step by a multidimensional nonlinear regression<br />

17