Reinforced Concrete Columns - MCEER

Reinforced Concrete Columns - MCEER

Reinforced Concrete Columns - MCEER

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

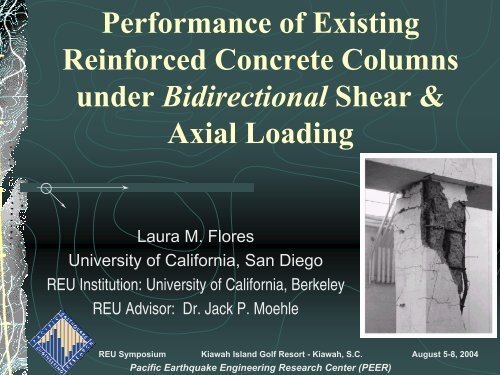

Performance of Existing<br />

<strong>Reinforced</strong> <strong>Concrete</strong> <strong>Columns</strong><br />

under Bidirectional Shear &<br />

Axial Loading<br />

Laura M. Flores<br />

University of California, San Diego<br />

REU Institution: University of California, Berkeley<br />

REU Advisor: Dr. Jack P. Moehle<br />

REU Symposium Kiawah Island Golf Resort - Kiawah, S.C. August 5-8, 2004<br />

Pacific Earthquake Engineering Research Center (PEER)

Outline<br />

Research Background & Project Objectives<br />

Design of Test Setup<br />

RC Column Specimen Material & Geometry<br />

Capacity Models<br />

Flexural, Shear and Axial Capacity<br />

Moment – Curvature Response of Column<br />

Deformation Components<br />

Lateral Deformation – Shear Failure<br />

Axial Deformation<br />

Residual Column Capacity & Damage Progression<br />

Fabrication of RC Column Specimens<br />

Sensitivity Analysis<br />

Ongoing<br />

Acknowledgments

Research Background<br />

Mechanisms leading to the collapse of existing, pre-seismic code<br />

RC frames are NOT well documented.<br />

Shake table tests are currently being conducted at PEER-UCB to<br />

observe & identify the failure components & load redistribution<br />

processes in RC bridge columns & in RC building frames under<br />

seismic & gravity loading.<br />

Identifying mechanisms causing shear failure in RC columns can<br />

be used to develop performance-based seismic design -<br />

strengthen future & existing structures against earthquake<br />

loading<br />

Column shear failure & its effect on the degradation of axial<br />

capacity in a pre-seismic code RC column is the focus of this<br />

project.

PERSONAL:<br />

Project Objectives<br />

To independently conduct research & gain extensive laboratory experience in<br />

the field of structural – earthquake engineering<br />

Opportunity to work with researchers on cutting-edge research and learn about<br />

ongoing studies in seismic design and retrofitting<br />

Opportunity to learn and apply theories of seismic design & analysis to RC<br />

columns under seismic and gravity loads<br />

RESEARCH:<br />

Identify lateral & axial deformation components leading to RC column failure<br />

Compute flexural, shear and axial capacity models of RC column<br />

Design experimental setup allowing bidirectional loading of RC column for<br />

specific loading requirements & under budget<br />

Fabricate RC column specimens based on design specs<br />

Analyze the effect of bidirectional loading on the shear and axial failure of RC<br />

column and compare to predictive capacity models

Simplified Model of RC Column<br />

One-third scale of existing, pre-seismic ACI code<br />

designed RC Column<br />

½ of RC column used in analysis<br />

Free end of column idealized as hinge connection<br />

with a fixed end at base of column

Simplified Model of RC Column (cont.)<br />

M(x)<br />

RC<br />

Col’n<br />

M = 0<br />

(hinge)<br />

M = M MAX<br />

(fixed)<br />

RC<br />

Col’n

Design of Test Setup<br />

Gravity Load<br />

= 10 kips<br />

Actuator / Seismic<br />

Load = 8.3 kips<br />

HINGE<br />

RC<br />

Col’n<br />

FIXED

Design of Test Setup (cont.)<br />

TEST APPARTUS<br />

1'-4 3/8"<br />

(platform<br />

width?)<br />

9"x8" flanged beam 70lb/ft.<br />

S=61.5 cu. in.<br />

1'-5"<br />

4'-6"<br />

6"x3"channel beam<br />

2'-9 7 8 "ACTUATOR<br />

POSITION<br />

A<br />

42.25"<br />

B<br />

C<br />

4" x 5" x 1" pillow<br />

block - pnt.load<br />

1/2" x 1/2" x 10"<br />

hold-in-place<br />

rods(check<br />

height&spacing?)<br />

1'-1 5 8 "<br />

lead ingot-14 bars<br />

110 lb/bar<br />

total wt. 1540 lb.<br />

4" (add<br />

spacing if<br />

needed)<br />

clamp??<br />

(H-structure) safety frame<br />

3"x2" angle iron<br />

welded construction<br />

1/2" concrete<br />

anchor bolts<br />

( ??2 places??)<br />

A<br />

base plate 2 in. thickness<br />

15 in.width and 3 ft. length<br />

FRONT VIEW<br />

CONCRETE<br />

FLOOR<br />

4'-7 7 8 "<br />

SIDE VIEW<br />

SECTION C-C

RC Column Material & Geometry

RC Column Material & Geometry (cont.)

Capacity Models of RC Column<br />

Specimen: Axial Capacity<br />

Axial Capacity of undamaged RC column:<br />

P N = 0.85*f C ’*(A g – A SL ) + f YL* A SL<br />

..where f C ’ concrete compressive strength, A g is the gross<br />

concrete area, A SL is the longitudinal reinforcement area,<br />

f YL is yield strength of longitudinal steel<br />

P N<br />

= 0.85*(3ksi)*[36in 2 -0.884in 2 ] +<br />

(70ksi)*(0.884in 2 )<br />

P N<br />

= 151.43 kips

Capacity Models of RC Column<br />

Specimen: Flexural Capacity<br />

h<br />

ε cu = .003<br />

•<br />

• ε s2<br />

• ε s3<br />

N.A.<br />

.85f C ’<br />

a<br />

T S2<br />

T S1<br />

T S3<br />

C C<br />

T S3<br />

T S2<br />

T S1<br />

•<br />

ε S1 = -00207<br />

C C<br />

M ΣM N<br />

T h/2 = 0 @Balanced Failure (Z=-1)<br />

S3<br />

P N • T -T S3<br />

*[(h/2)-d S3<br />

] - C C<br />

*[(h/2)-(a/2)] + M N<br />

-T S1<br />

*[d S1<br />

-(h/2)]<br />

S2<br />

M<br />

T N<br />

= T S3<br />

*[(h/2)-d S3<br />

] + C C<br />

*[(h/2)-(a/2)] +<br />

S1<br />

T S1<br />

*[d S1<br />

-(h/2)]<br />

..so, M N<br />

=153.3 kip-in

Capacity Models of RC Column<br />

Specimen: Shear Capacity<br />

Total shear capacity of an RC column depends on the shear<br />

capacity of the concrete, V C and the shear capacity carried by<br />

the transverse reinforcement, V ST in the column<br />

V N = (V C + V ST ) = 2*[1+(P/2000*Ag)]*√f C ’*b W *d +<br />

[(4*A ST *f YT *d)/s]<br />

..where A ST<br />

is the transverse reinforcement area, f YT<br />

is yield strength of transverse reinforcement,<br />

d is distance from compression fiber to farthest tensile reinforcement, s is transverse<br />

reinforcement spacing, b W<br />

is the width of column x-section, P is axial load<br />

V N<br />

= 2*[1+(10,000lb/(2000*35.12in 2 ))]*√(3000psi)*(6in)(5.145in) +<br />

(0.01228in 2 )(70,000psi)(5.145in)<br />

V N<br />

= 8.283 kips

Interaction Diagram of RC Column Specimen<br />

The flexural and axial capacity model for RC columns is used to derive an<br />

interaction diagram which relates the axial load column capacity with its<br />

moment capacity at any given time<br />

120<br />

100<br />

Maximum<br />

Axial Load<br />

Zero stress in tensile<br />

reinforcement, Z=0<br />

(nom inal) Axial Load Capacity, Pn (kips)<br />

80<br />

60<br />

40<br />

20<br />

0<br />

0 20 40 60 80 100 120 140 160<br />

-20<br />

Balanced<br />

Failure, Z= -1<br />

COMPRESSION<br />

TENSION<br />

-40<br />

(nominal) Moment Capacity, Mn (kip-in)

Moment-Curvature Response of Shear-Critical RC<br />

Column under Axial & Lateral (Shear) Loading<br />

The flexural and axial capacity model for RC columns is used to derive an interaction<br />

diagram which relates the axial load column capacity with its moment capacity at any<br />

given time<br />

160<br />

M Y =V Y *l<br />

140<br />

120<br />

100<br />

80<br />

60<br />

Moment, M (kip-in)<br />

40<br />

20<br />

0<br />

-7.E-22<br />

1.E-04<br />

3.E-04<br />

4.E-04<br />

5.E-04<br />

7.E-04<br />

8.E-04<br />

9.E-04<br />

1.E-03<br />

1.E-03<br />

1.E-03<br />

1.E-03<br />

2.E-03<br />

2.E-03<br />

2.E-03<br />

2.E-03<br />

2.E-03<br />

2.E-03<br />

2.E-03<br />

3.E-03<br />

3.E-03<br />

3.E-03<br />

3.E-03<br />

3.E-03<br />

3.E-03<br />

3.E-03<br />

3.E-03<br />

4.E-03<br />

4.E-03<br />

Curvature, θ (1/in)

Deformation Components:<br />

Lateral Deflection<br />

Flexure<br />

M<br />

M ∆ FL = [(39in) 2 /6]*(7.6*10 -4 in -1 )<br />

= 0.19266 in

Flexure<br />

Deformation Components:<br />

Lateral Deflection

Deformation Components:<br />

Lateral Deflection<br />

Bar (Bond) Slip<br />

M<br />

M ∆ SL = [(39in)(0.375in)(70,000psi)(7.6*10 -4 in -1 )] /<br />

[8*6*√3000psi]<br />

= 0.2959 in

Deformation Components:<br />

Shear<br />

Lateral Deflection<br />

V<br />

V<br />

∆ SH = [2(113,000lb-in)] / (1.53*10 6 )(29.26in 2 )<br />

= 0.005048 in.

Deformation Components:<br />

Shear<br />

Lateral Deflection

Lateral Yield Deformation of RC column:<br />

Lateral yield deformation (prior to shear failure) of longitudinal<br />

reinforcement in RC column results from 3 components<br />

acting in series:<br />

Flexure, Bar (Bond) Slip, Shear<br />

(∆ LAT ) Y = ∆ Y = ( ∆ FL + ∆ SL + ∆ SH )<br />

(∆ LAT<br />

) Y<br />

= ∆ Y<br />

= (0.19266 in) + (0.2959 in) + (0.005048 in)<br />

= 0.49365 in.<br />

Flexural<br />

displacement,<br />

∆FL<br />

Slip<br />

displacement,<br />

∆SL<br />

Shear<br />

displacement,<br />

∆SH<br />

Yield<br />

displacement,<br />

∆Y<br />

0.19266 in 0.295941 in 0.005048 in 0.49365 in

Deformation Components:<br />

Shear → Axial Failure<br />

! After yielding of longitudinal<br />

reinforcement, column<br />

sustains gravity and lateral<br />

(shear) loads until shear<br />

demand on column exceeds<br />

ultimate??? shear capacity of<br />

column (V>V U ) – shear failure<br />

occurs<br />

! After shear failure occurs in<br />

column, gravity loads are<br />

supported by shear-friction<br />

forces along shear failure<br />

plane – (∆ LAT ) AX occurs<br />

θ<br />

Shear<br />

Failure<br />

Plane

Deformation Components:<br />

Shear → Axial Failure (cont.)<br />

θ<br />

Shear<br />

Failure<br />

Plane

Deformation Components:<br />

Shear → Axial Failure (cont.)<br />

Residual Axial Capacity (after shear failure) of damaged RC<br />

column:<br />

P N = tanθ*[(A ST *f YT *d C )/s]*[(1+µtanθ)/(tanθ-µ)]<br />

..where f YT is yield strength of transverse reinforcement, d C is distance b/w<br />

extreme longitudinal reinforcement., s is transverse reinforcement spacing, θ is<br />

critical crack angle, µ is effective friction coefficient, A ST is transverse<br />

reinforcement area<br />

P N<br />

= [tan65(0.01228in2)(70ksi)(4.5417in) / (4in)]*[(1+(8.28kip/10kip)*tan65) /<br />

(tan65-(8.28kip/10kip))]<br />

= 4.4 kips<br />

!When gravity loads exceed shear-friction forces, axial failure occurs in<br />

column (column loses ALL shear capacity) → total collapse of structure

Deformation Components:<br />

Shear → Axial Failure (cont.)<br />

Axial Failure of<br />

Column<br />

Total Collapse of<br />

Column

Damage Progression in Column – Drift<br />

Capacity Model<br />

Progression of damage in a shear-critical RC column can be<br />

quantified using an empirical drift capacity model based on the<br />

column’s lateral displacement (i.e. ‘drift’)<br />

Drift Ratio at Yielding of<br />

Longitudinal Reinforcement<br />

(∆/L) Y<br />

= 0.00494<br />

Drift Ratio at Shear Failure<br />

(∆/L) SH<br />

= 0.026248<br />

Drift Ratio at Axial Failure<br />

L<br />

(∆/L) AX<br />

= 0.035183<br />

L

Damage Progression in Column – EPP<br />

Backbone Model<br />

Elastic-Perfectly-Plastic (EPP) backbone model approximates the<br />

shear load vs. lateral displacement behavior of shear-critical RC<br />

columns via. a ‘shear-failure surface’<br />

EPP backbone model utilizes the calculated column drift ratios at<br />

yielding, shear & axial failure, as well as the yield moment derived<br />

from the column moment-curvature response to generate the<br />

column’s ‘shear failure surface’ under lateral and gravity loading

Shear-Critical RC column Shear Hysteretic (forcedisplacement)<br />

Response w/ EPP shear-drift backbone<br />

∆ Y<br />

∆ SH<br />

∆ AX<br />

EPP-predicted<br />

shear failure<br />

surface

Fabrication of RC Column Specimens<br />

Column Forms –<br />

plywood, 2x4’s<br />

6”<br />

2’-4 5/8”<br />

RC<br />

Col’n<br />

1’-1 5/8”<br />

1’-10”

Fabrication of RC Column Specimens (cont.)<br />

Steel Cages /<br />

Longitudinal &<br />

Transverse<br />

Reinforcement<br />

– 60 Grade #3 & #5<br />

rebar, tie wires, 1/8”<br />

diameter stirrups

Fabrication of RC Column Specimens (cont.)<br />

Casting of<br />

Column<br />

Specimens<br />

– f C ’ = 3 ksi

Fabrication of RC Column Specimens<br />

(cont.) – Sensitivity Analysis<br />

Sensitivity of RC Column Moment Capacity to Increasing 28-day Compressive Strength of<br />

<strong>Concrete</strong>.<br />

200<br />

180<br />

(nominal) Moment Capacity, Mn (kip-in)<br />

160<br />

140<br />

120<br />

100<br />

80<br />

60<br />

40<br />

fy constant<br />

20<br />

0<br />

1.5 2 2.5 3 3.5 4 4.5<br />

<strong>Concrete</strong> Compressive Strength, fc' (ksi)

Fabrication of RC Column Specimens<br />

(cont.) – Sensitivity Analysis<br />

Sensitivity of RC Column Axial Load Capacity to Increasing 28-day Compressive Strength of<br />

<strong>Concrete</strong>.<br />

70<br />

60<br />

(nominal) Axial Load Capacity, Pn (kips)<br />

50<br />

40<br />

30<br />

20<br />

fy constant<br />

10<br />

0<br />

1.5 2 2.5 3 3.5 4 4.5<br />

<strong>Concrete</strong> Compressive Strength, fc' (ksi)

-Ongoing-<br />

My Research Objectives to be completed:<br />

" Fabrication of experimental setup<br />

" Testing of RC column specimens<br />

" Comparing observed RC column hysteretic response under axial & shear<br />

loading w/ that response predicted by capacity models<br />

Overall Research Objectives to be completed:<br />

" Using results to calibrate existing OpenSees analytical model<br />

that is based on RC structure deformation components &<br />

capacity models<br />

" Using revised OpenSees analytical model to predict hysteretic<br />

response of existing RC building structure (composed of several<br />

column-beam components) to seismic & gravity loading<br />

" Fabrication & testing of large-scale RC building frame<br />

" Additional verification studies of OpenSees analytical model

Acknowledgments<br />

Research conducted as part of the 2004 Pacific Earthquake<br />

Engineering Research Center (PEER) Research Experience for<br />

Undergraduates & funded by the National Science Foundation<br />

Special thanks to my PEER advisor, Professor Jack P. Moehle for<br />

his guidance in the direction of my project and working hard to<br />

secure the funding which made this research experience possible<br />

Thanks to UC Berkeley graduate students, Wassim Michael<br />

Ghannoum & Yoon Bong Shin for their assistance in every aspect<br />

of this project<br />

Thanks to Richmond Field Station – PEER headquarters lab<br />

personnel for their assistance in the design & fabrication of my<br />

experimental setup