Modular Step-in Cold Rooms - Porkka

Modular Step-in Cold Rooms - Porkka

Modular Step-in Cold Rooms - Porkka

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Modular</strong> <strong>Step</strong>-<strong>in</strong> <strong>Cold</strong> <strong>Rooms</strong><br />

NEW DESIGN FEATURES OF OUR MODULAR STEP-IN COLD ROOM RANGE INCLUDE LOWER<br />

ENERGY CONSUMPTION COMBINED WITH IMPROVED PERFORMANCE

<strong>Porkka</strong> used daily throughout the world<br />

Cool<strong>in</strong>g units produced <strong>in</strong> our own factory have been designed to be both powerful and energy efficient. Digital temperature displays have built-<strong>in</strong><br />

high/low alarms which are both audible and visual. These can be connected via a volt free relay to a build<strong>in</strong>g management system. The controller is<br />

also equipped with HACCP features to meet the more str<strong>in</strong>gent temperature monitor<strong>in</strong>g regulations be<strong>in</strong>g enforced. The unit or units can be<br />

connected to an <strong>in</strong>dependent monitor<strong>in</strong>g server and temperatures automatically recorded via the <strong>in</strong>ternet <strong>in</strong> real time. An alarm can also be sent to<br />

GPRS enabled mobile phone, a PC or an e-mail.<br />

Carefully planned materials and details<br />

<strong>Porkka</strong> rooms are produced from modular CFC/HCFC-free polyurethane<br />

<strong>in</strong>sulated panels which are moulded with male / female jo<strong>in</strong>ts<br />

and held by eccentric action cam-locks, giv<strong>in</strong>g great all-round<br />

strength. The visible exterior surfaces of the panels are coated with<br />

durable scratch resistant polyester, which is classified as food safe.<br />

Insulation thickness with excellent thermal efficiency is 80mm as<br />

standard with an option of 100mm for freezer application if required.<br />

Doors are semi-rebated and supplied with heavy duty h<strong>in</strong>ges and a<br />

lockable door handle with emergency entrapment release. Thresholds<br />

and surrounds are produced from durable sta<strong>in</strong>less steel with a heater<br />

supplied for freezer application. Doors are already pre-mounted on a<br />

panel for ease of assembly <strong>in</strong> the field.<br />

Floors, when supplied, are <strong>in</strong>sulated and have a strong mar<strong>in</strong>e<br />

plywood surface, which is coated with a non-slip glass fibre res<strong>in</strong>.<br />

Load limit for a standard floor max. 40 KN/m 2 or max 1,0 KN/ per<br />

40mm castor. Heavy duty floor with sta<strong>in</strong>less steel surface available<br />

as an additional accessory.<br />

A newly-designed hygienic shelv<strong>in</strong>g system allows the operator to<br />

wash <strong>in</strong>dividual shelves <strong>in</strong> a commercial dishwasher whilst larger<br />

dimensions <strong>in</strong>crease storage areas with<strong>in</strong> our rooms.<br />

Select from our extensive range, for a room to suit your<br />

requirements<br />

<strong>Porkka</strong> cold rooms with volumes from 1.2 to 22m 3 .<br />

• Three temperature ranges; +2 to +8°C (adjustable <strong>in</strong> <strong>in</strong>crements of 1°C) for chilled<br />

produce. For the storage of fresh meat or fish use –2 to +5°C and for frozen select<br />

–18 to –22°C.<br />

• Insulation options of either 80 or 100mm.<br />

• Select floorless chill rooms for trolley operation. (Chill temperature only).<br />

• Medium and freezer rooms must be supplied with a floor which can be either recessed<br />

or with a ramp if a trolley is required.<br />

• Cool<strong>in</strong>g units can be manufactured for placement either to the left or right hand side of<br />

the door and can also be made for connection to a central cool<strong>in</strong>g system.<br />

• Door can be hung either left or right-h<strong>in</strong>ged or changed <strong>in</strong> the field if required.<br />

• Standard external height 2100mm (note 2140mm if 100mm <strong>in</strong>sulation selected) or<br />

2400 / 2440mm.<br />

• 4 tier fully adjustable shelv<strong>in</strong>g is supplied for either 2 or 3 walls depend<strong>in</strong>g on model<br />

selected. Standard shelves are made of ABS-plastics and can be washed <strong>in</strong> a commercial<br />

dishwasher. Sta<strong>in</strong>less steel shelves are available as an additional accessory.<br />

Manufactured from high quality materials and comb<strong>in</strong><strong>in</strong>g low energy consumption with quiet<br />

operation. <strong>Porkka</strong> modular cold rooms are the ideal choice for the storage of perishable products.<br />

3

Decades of experience <strong>in</strong> the design, technology and production of hi<br />

Comb<strong>in</strong>ed digital temperature display with built-<strong>in</strong> control functions<br />

1. Compressor RUN light<br />

2. Automatic defrost <strong>in</strong> operation light<br />

3. Evaporator fan RUN light<br />

4. Alarm activated light<br />

5. Temperature/<strong>in</strong>formation display<br />

6. Temperature adjustment button<br />

7. Manual defrost button<br />

8. Sett<strong>in</strong>gs button<br />

9. Light switch button with light to <strong>in</strong>dicate ON mode<br />

10. ON/OFF Stand-by mode button<br />

11. Humidity control button<br />

12. Probe display button<br />

2 3<br />

1 11<br />

6<br />

7 9<br />

4 5 12 6<br />

8<br />

10<br />

Alarm functions<br />

The <strong>Porkka</strong> temperature display is supplied with a built-<strong>in</strong> high/low temperature alarm which<br />

is both audible and visual and can also be connected to a build<strong>in</strong>g management system by<br />

means of a volt free connection.<br />

HACCP<br />

Versatile, built-<strong>in</strong> HACCP (Hazard Analysis<br />

and Critical Control Po<strong>in</strong>t) properties enable<br />

cont<strong>in</strong>uous and real-time temperature monitor<strong>in</strong>g <strong>in</strong> compliance with the European Food Act be<strong>in</strong>g<br />

implemented by many governments. For further <strong>in</strong>formation about our HACCP functions see page 13.<br />

Air-cooled condenser<br />

dust filter<br />

The air <strong>in</strong>let to the condenser is on the lower<br />

part of the refrigeration unit, ensur<strong>in</strong>g the<br />

coolest air is always used help<strong>in</strong>g to reduce<br />

runn<strong>in</strong>g costs and extend<strong>in</strong>g the service life<br />

of the unit. The dust filter beh<strong>in</strong>d the air grill<br />

is easy to clean or replace. The controller<br />

provides <strong>in</strong>formation on when the filter<br />

requires clean<strong>in</strong>g or chang<strong>in</strong>g.<br />

4<br />

Advanced HACCP monitor<strong>in</strong>g features with a ready to use connection to a computer or build<strong>in</strong>g ma<strong>in</strong>tenance sys

gh quality refrigeration equipment<br />

Shelv<strong>in</strong>g system<br />

The <strong>Porkka</strong> modular cold room shelv<strong>in</strong>g system is highly<br />

practical and easy to clean. Standard shelv<strong>in</strong>g delivery <strong>in</strong>cludes<br />

four (4) tier dishwasher safe polycarbonate (food safe) <strong>in</strong>serts<br />

and support<strong>in</strong>g material. Shelv<strong>in</strong>g is supplied for either 2 or 3<br />

walls dependent on model selected.<br />

Safety<br />

The door is supplied with heavy duty h<strong>in</strong>ges and a lockable door<br />

handle with a lum<strong>in</strong>ous emergency entrapment release, which<br />

overrides the lock at all times, should someone accidentally be<br />

shut <strong>in</strong> the room. Door threshold and surround is fitted with a<br />

heater to prevent freez<strong>in</strong>g of the gasket to the frame <strong>in</strong> low<br />

temperature models. If required floor panels can also be<br />

supplied with built-<strong>in</strong> heaters to prevent freez<strong>in</strong>g or moisture<br />

damage below a larger freezer room.<br />

Trolley operation<br />

To facilitate the use of trolleys, chill rooms can be supplied<br />

without a floor. In this <strong>in</strong>stance, the room is erected on an<br />

<strong>in</strong>sulated pl<strong>in</strong>th and the door equipped with a sweeper gasket.<br />

The <strong>in</strong>stallation package conta<strong>in</strong>s all components. Medium and<br />

low temperature rooms must always be supplied with a floor. If<br />

trolley use is essential, it is possible to recess the floor, or, if<br />

above ground, supply an optional ramp. In either case, the doors<br />

are fitted with a sweeper gasket.<br />

tem.<br />

5

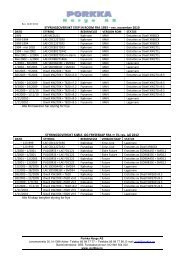

<strong>Porkka</strong> <strong>Modular</strong> <strong>Cold</strong> <strong>Rooms</strong> offer hundreds of rooms to select from<br />

Depth<br />

900 1200 1350 1500 1800 2100 2400 2700 3000 3300 3600<br />

Width<br />

mm<br />

Height 2100 or 2400mm<br />

(80mm <strong>in</strong>sulation thickness)<br />

Height 2140 or 2440mm<br />

(100mm <strong>in</strong>sulation thickness)<br />

1200<br />

1,4 B*/** 1,8 A<br />

*/**<br />

2,3 A<br />

*/**<br />

2,6 A*/** 3,1 A*/** 3,7 A*/** 4,3 A*/** 4,9 A*/** 5,4 A*/**<br />

1350<br />

1,6 B*/** 2,3 B<br />

*/**<br />

2,9 A*/** 3,6 AL*/** 4,2 AL*/**<br />

1500<br />

1,7 B** 2,6 B<br />

**<br />

2,9 B<br />

**<br />

3,5 A** 4,0 A** 4,8 A** 5,5 A** 6,1 A** 7,0 A**<br />

1800<br />

2,2 B** 3,1 B<br />

**<br />

3,6 B<br />

**<br />

4,0 B** 5,0 A** 5,9 A** 6,7 A** 7,6 A** 8,5 A 9,5 A 10,3 A<br />

2100<br />

3,7 B<br />

**<br />

4,2 B<br />

**<br />

4,8 B** 5,9 B** 6,9 A** 8,0 A** 8,9 A 10,1 A 11,2 A 12,3 A<br />

2400<br />

4,3 B<br />

**<br />

5,5 B** 6,7 B** 8,0 B** 9,0 A 10,4 A 11,6 A 12,9 A 14,2 A<br />

2700<br />

4,9 B<br />

**<br />

6,1 B** 7,6 B** 8,9 B 10,4 B 11,8 A<br />

13,3 A<br />

14,7 A 16,0 A<br />

3000<br />

5,4 B<br />

**<br />

7,0 B** 8,5 B 10,1 B 11,6 B 13,3 B<br />

14,9 A<br />

16,4 A<br />

18,0 A<br />

3300<br />

9,5 B 11,2 B 12,9 B 14,7 B<br />

16,4 B<br />

3600<br />

10,3 B 12,3 B 14,2 B 16,0 B<br />

18,0 B<br />

*Available only <strong>in</strong> 80mm <strong>in</strong>sulation thickness<br />

**Available with R290 refrigerant<br />

6<br />

Environmentally friendly all <strong>Porkka</strong> modular panels and refrigeration units are CFC/HCFC free.

Depth 900 Depth 1200 Depth 1350 Depth 1500 Depth 1800 Depth 2100<br />

Width 1200 1,4 B* 1,8 A* 2,3 A* 2,6 A* 3,1 A* 3,7 A*<br />

Width 1350<br />

1,6 B* 2,3 B* 2,9 A* 3,6 A* 4,2 A*<br />

Width 1500<br />

1,7 B* 2,6 B 2,9 B 3,5 A 4,0 A 4,8 A<br />

Width 1800<br />

2,2 B* 3,1 B 3,6 B 4,0 B 5,0 A 5,9 A<br />

Width 2100<br />

3,7 B 4,2 B 4,8 B 5,9 B 6,9 A<br />

Width 2400<br />

4,3 B 5,5 B 6,7 B 8,0 B<br />

Width 2700<br />

4,9 B 6,1 B 7,6 B 8,9 B<br />

Width 3000<br />

5,4 B 7,0 B 8,5 B 10,1 B<br />

Width 3300<br />

9,5 B 11,2 B<br />

Width 3600<br />

10,3 B 12,3 B<br />

*Available only <strong>in</strong> 80mm <strong>in</strong>sulation thickness<br />

**Available with R290 refrigerant<br />

7

Depth 2400 Depth 2700 Depth 3000 Depth 3300 Depth 3600<br />

4,3 A*<br />

4,9 A* 5,4 A*<br />

5,5 A<br />

6,1 A 7,0 A<br />

6,7 A<br />

7,6 A 8,5 A 9,5 A** 10,3 A**<br />

8,0 A<br />

8,9 A 10,1 A 11,2 A 12,3 A<br />

9,0 A<br />

10,4 A 11,6 A 12,9 A 14,2 A<br />

10,4 B<br />

11,8 A 13,3 A 14,7 A 16,0 A<br />

11,6 B<br />

13,3 B 14,9 A 16,4 A 18,0 A<br />

12,9 B<br />

14,7 B 16,4 B<br />

**Special shelf layout, height 2400mm<br />

14,2 B<br />

16,0 B 18,0 B<br />

9,5 A** 10,3 A**<br />

8

A large comprehensive range<br />

with volumes up to 22m 3<br />

<strong>Porkka</strong> <strong>Modular</strong> <strong>Step</strong>-<strong>in</strong> <strong>Rooms</strong> are available <strong>in</strong> a<br />

range of 81 different sizes with volumes from 1.2<br />

up to 22m 3 . All are available to select <strong>in</strong> three<br />

temperature variations with optional <strong>in</strong>sulation<br />

thickness and external heights. When this is<br />

comb<strong>in</strong>ed with unit positions and door options our<br />

range is truly massive. This is why <strong>Porkka</strong> is the<br />

perfect partner to work with as we are bound to<br />

have a storage solution to suit your requirements.<br />

<strong>Porkka</strong> refrigeration unit technical data<br />

C940 M940 F840<br />

C950 C1240 M950 M1240 F850 F1140 F1540<br />

Temperature range +2°C … +12°C +2°C … +12°C –2°C … + 5°C –2°C … + 5°C –22°C … –18°C –22°C … –18°C –22°C … –18°C<br />

Volume < 12 m 3 < 22 m 3 < 12 m 3 < 22 m 3 < 11 m 3 < 14 m 3 < 22 m 3<br />

Connection power 0.72 kW 0.96 kW 1.11 kW 1.51 kW 1.33 kW 1.76 kW 2.08 kW<br />

Connection power RHDS * 0.84 kW 1.09 kW 1.24 kW 1.64 kW 1.45 kW 1.89 kW 2.18 kW<br />

Fus<strong>in</strong>g 1 x 10 A 1 x 10 A 1 x 10 A 1 x 16 A 1 x 16 A 1 x 16 A 3 x 10 A<br />

Voltage 230 V / 50 Hz 230 V / 50 Hz 230 V / 50 Hz 230 V / 50 Hz 230 V / 50 Hz 230 V / 50 Hz 400 V / 50 Hz<br />

Cool<strong>in</strong>g effect (CC) 1 330 W 1 870 W 1 240 W 1 800 W 1 310 W 1 590 W 2 210 W<br />

Evaporat<strong>in</strong>g temperature (CC) –8°C –8°C –10°C –10°C –30°C –30°C –30°C<br />

Ambient temperature +5°C … +32°C +5°C … +32°C +5°C … +32°C +5°C … +32°C +5°C … +32°C +5°C … +32°C +5°C … +32°C<br />

Refrigerant R 404a (C940) R 404a R 404a (M940) R 404a R 404a (F840)<br />

R 290 (C950)<br />

R 290 (M950)<br />

R 290 (F850)<br />

R 404a R 404a<br />

Mach<strong>in</strong>e element acoustic pressure<br />

1m / 1,5 m ( dB re 20 µPa ) 53 dB ( A ) 53 dB ( A ) 53 dB ( A ) 53 dB ( A ) 55 dB ( A ) 58 dB ( A ) 59 dB ( A )<br />

RHDS mach<strong>in</strong>e element acoustic<br />

pressure 1m / 1,5 m ( dB re 20 µPa ) 49 dB ( A ) 49 dB ( A ) 49 dB ( A ) 49 dB ( A ) 51 dB ( A ) 54 dB ( A ) 55 dB ( A )<br />

RHDS fluid condenser RHDS 2140 RHDS 2160 RHDS 2140 RHDS 2160 RHDS 2140 RHDS 2160 2 x RHDS 2160<br />

Fluid condenser acoustic pressure<br />

at location 10m ( dB re 20 µPa ) 34 dB ( A ) 34 dB ( A ) 34 dB ( A ) 34 dB ( A ) 34 dB ( A ) 34 dB ( A ) 37 dB ( A )<br />

Permitted temperature range<br />

at fluid condenser location –40°C … +35°C –40°C … +35°C –40°C … +35°C –40°C … +35°C –40°C … +35°C –40°C … +35°C –40°C … +35°C<br />

Note: If there is a lack of ventilation or ambient temperatures are likely to rema<strong>in</strong> above or below recommended levels for considerable periods of time please contact us for solutions.<br />

*Includes RHDS fluid condenser<br />

(E) = Available with R290 refrigerant (1.1.2012)<br />

9

New Unique <strong>Porkka</strong> Shelv<strong>in</strong>g System<br />

<strong>Porkka</strong> has designed a totally new shelv<strong>in</strong>g system for our standard range of<br />

rooms. We have focused on improved hygiene features, flexibility and greater<br />

surface area, for more storage space. The support pilasters are fixed to the<br />

<strong>in</strong>sulated wall panels, which are positioned to allow easy all round clean<strong>in</strong>g of<br />

the floor.<br />

Four (4) tier shelv<strong>in</strong>g is supplied as standard. In rooms with a width up to<br />

1500mm, shelv<strong>in</strong>g is supplied to two (2) walls and <strong>in</strong> rooms with greater<br />

width, shelv<strong>in</strong>g is fitted to three (3) walls.<br />

Installation is simple and quick. Place shelf support brackets at desired height,<br />

fit support bars horizontally <strong>in</strong>to the ready made open<strong>in</strong>gs and place shelv<strong>in</strong>g<br />

<strong>in</strong>serts between the bars. The tough, strong <strong>in</strong>serts are produced from plastic<br />

that is approved for use with foodstuffs. Even the largest shelv<strong>in</strong>g <strong>in</strong>sert 300 x<br />

462mm can fit <strong>in</strong>to most commercial dishwashers.<br />

It is also possible to purchase additional shelves which can be easily added at<br />

a later date to facilitate further storage space.<br />

The depth of rear wall shelv<strong>in</strong>g will be 488mm and dependent on room<br />

model, the total depth of side wall shelv<strong>in</strong>g will be either 398 or 488mm.<br />

The shelv<strong>in</strong>g can be evenly loaded with up to 70Kg per meter run i.e. 280 Kg<br />

per 4 tier shelv<strong>in</strong>g meter run.<br />

Shelf support brackets<br />

together with horizontal<br />

bars are simple and quick to<br />

<strong>in</strong>stall and are designed to<br />

be strong and durable<br />

under heavy loads.<br />

Shelf <strong>in</strong>serts have been<br />

produced from high density,<br />

durable plastic, which is<br />

approved for use with<br />

foodstuffs. They can be easily<br />

taken out and washed <strong>in</strong> a<br />

dishwasher or by hand for<br />

improved hygiene.<br />

Pilasters affixed to wall.<br />

Note that shelv<strong>in</strong>g can now<br />

be placed much closer to<br />

the floor level than <strong>in</strong> the<br />

previous range. Sufficient<br />

space is still available to<br />

allow clean<strong>in</strong>g of the floor.<br />

10<br />

Easy-to-adjust shelves are strong and mach<strong>in</strong>e washable.

<strong>Porkka</strong> Remote Heat Disposal System (RHDS)<br />

When plac<strong>in</strong>g <strong>Porkka</strong> modular rooms with<strong>in</strong> a build<strong>in</strong>g, lack of<br />

ventilation can cause heat to build up and <strong>in</strong>crease runn<strong>in</strong>g costs. The<br />

solution is to use the <strong>Porkka</strong> Remote Heat Disposal System. <strong>Porkka</strong>’s<br />

RHDS offers an easy and <strong>in</strong>expensive method of transferr<strong>in</strong>g waste<br />

heat produced by the refrigeration systems to either an external area<br />

or an area where the warm air could be utilised. It is easy and quick to<br />

<strong>in</strong>stall, with the additional benefit of be<strong>in</strong>g much quieter than fitt<strong>in</strong>g a<br />

conventional condens<strong>in</strong>g unit.<br />

The RHDS system is similar to the standard <strong>Porkka</strong> unit with the<br />

addition of a liquid condenser, header tank and pump. Water pipes are<br />

then connected from the remote condenser to the refrigeration unit.<br />

After connect<strong>in</strong>g the system it is filled with a water glycol solution that<br />

will operate <strong>in</strong> both summer and w<strong>in</strong>ter conditions. The multi-fix<br />

condenser can be positioned either with<strong>in</strong> an area that will benefit<br />

from heat <strong>in</strong>put or externally. The unit can be floor or wall mounted. In<br />

addition the equipment benefits the environment by utilis<strong>in</strong>g a very<br />

small refrigerant charge and reduc<strong>in</strong>g runn<strong>in</strong>g costs.<br />

The <strong>Porkka</strong> RHDS unit is equipped with<br />

a refrigerant-to-liquid heat exchanger.<br />

Waste refrigeration heat is transferred<br />

to the water solution where it is<br />

circulated to the condenser where the<br />

heat is given up to the ambient air.<br />

Installation of the equipment is quick and easy and can be undertaken<br />

by competent <strong>in</strong>stallers that do not necessarily have to be qualified<br />

refrigeration eng<strong>in</strong>eers, though they are recommended. The RHDS can<br />

be used throughout our standard range of rooms and at all<br />

temperatures i.e. chilled, medium or freezer versions. For a standard<br />

<strong>in</strong>stallation, a pipe can be run as much as 25 meters horizontally with<br />

a maximum vertical lift of 4.5 meters with<strong>in</strong> the run, the height of<br />

which is measured from the pump with<strong>in</strong> the refrigeration unit.<br />

RHDS liquid to air condenser can be<br />

wall, floor or roof mounted either<br />

externally or ideally with<strong>in</strong> an area<br />

where the heat can be utilised such<br />

as a warehouse, etc. Noise levels are<br />

kept low as only fans are run on the<br />

external unit.<br />

C940 C1240 M940 M1240 F840 F1140 F1540<br />

Mach<strong>in</strong>e element acoustic pressure<br />

1m / 1,5 m ( dB re 20 µPa ) 53 dB ( A ) 53 dB ( A ) 53 dB ( A ) 53 dB ( A ) 55 dB ( A ) 58 dB ( A ) 59 dB ( A )<br />

RHDS mach<strong>in</strong>e element acoustic<br />

pressure 1m / 1,5 m ( dB re 20 µPa ) 49 dB ( A ) 49 dB ( A ) 49 dB ( A ) 49 dB ( A ) 51 dB ( A ) 54 dB ( A ) 55 dB ( A )<br />

RHDS fluid condenser RHDS 2140 RHDS 2160 RHDS 2140 RHDS 2160 RHDS 2140 RHDS 2160 2 x RHDS 2160<br />

Fluid condenser acoustic pressure<br />

at location 10m ( dB re 20 µPa ) 34 dB ( A ) 34 dB ( A ) 34 dB ( A ) 34 dB ( A ) 34 dB ( A ) 34 dB ( A ) 37 dB ( A )<br />

Permitted temperature range<br />

at fluid condenser location –40°C … +35°C –40°C … +35°C –40°C … +35°C –40°C … +35°C –40°C … +35°C –40°C … +35°C –40°C … +35°C<br />

The RHDS system is efficient, silent and environment-friendly.<br />

11

<strong>Porkka</strong> <strong>Modular</strong> <strong>Step</strong>-<strong>in</strong> <strong>Cold</strong> <strong>Rooms</strong> are easy<br />

and quick to assemble<br />

<strong>Porkka</strong> modular <strong>in</strong>sulated panels are<br />

produced with male/female jo<strong>in</strong>ts which<br />

are equipped with eccentric action<br />

cam-locks. This ensures good air-tight<br />

jo<strong>in</strong>ts.<br />

Two people are required to <strong>in</strong>stall a room<br />

and they should follow good health and<br />

safety practices dur<strong>in</strong>g assembly. Full<br />

<strong>in</strong>-stallation <strong>in</strong>structions and components<br />

are supplied with the room.<br />

Eccentric action cam-locks make<br />

<strong>in</strong>stallation quick and easy.<br />

1 2<br />

Measure room will fit <strong>in</strong>to area selected and<br />

check floor is clear and level before unpack<strong>in</strong>g<br />

room. If ok, place floor panels and/or fix pl<strong>in</strong>th<br />

on the floor.<br />

Cont<strong>in</strong>ue by <strong>in</strong>stall<strong>in</strong>g wall panels to the rear of<br />

the room. (Please note: read plan provided to<br />

ensure that shelv<strong>in</strong>g pilaster are <strong>in</strong> the correct<br />

position).<br />

3 4<br />

Jo<strong>in</strong> the cam-locks with the allen key provided.<br />

Build the walls then <strong>in</strong>stall the refrigeration unit.<br />

The roof is added last. At this po<strong>in</strong>t, tighten<br />

cam-locks to floor and ceil<strong>in</strong>g. (Please note:<br />

cam-locks are provided on the refrigeration unit.<br />

These must also be tightened).<br />

Install shelv<strong>in</strong>g system and fit handle and<br />

emergency entrapment release. Fill silicon mastic<br />

(provided) <strong>in</strong> jo<strong>in</strong>ts and smooth. Clean surfaces<br />

with solvent provided. Connect cool<strong>in</strong>g unit to<br />

suitable power supply and monitor fall<strong>in</strong>g<br />

temperature.<br />

12<br />

Quick to assemble. Components and <strong>in</strong>structions <strong>in</strong>cluded.

<strong>Porkka</strong> XWEB HACCP monitor<strong>in</strong>g<br />

<strong>Porkka</strong> XWEB is an <strong>in</strong>dependent monitor<strong>in</strong>g and alarm<br />

warn<strong>in</strong>g control system for refrigeration equipment. XWEB is<br />

a compact powerful computer that operates as an<br />

<strong>in</strong>dependent network server complete with its own<br />

ready-made web page. Information can be accessed either by<br />

the <strong>in</strong>ternet, browser or a GPRS-enabled mobile phone.<br />

<strong>Porkka</strong> can offer several versions to suit small to large<br />

operators.<br />

The XWEB allows 24/7 monitor<strong>in</strong>g, controll<strong>in</strong>g and adjust<strong>in</strong>g<br />

<strong>in</strong> real time. It cont<strong>in</strong>uously records temperature and alarm<br />

data and will notify specific personnel of equipment failure.<br />

The system can be accessed from any computer as software is<br />

not required to ga<strong>in</strong> entry to the programme.<br />

Simple supervision<br />

Compared to traditional, passive monitor<strong>in</strong>g the <strong>Porkka</strong><br />

XWEB offers real time temperature monitor<strong>in</strong>g and alarm<br />

notification, which can be <strong>in</strong>tegrated with<strong>in</strong> an exist<strong>in</strong>g BMS<br />

(Build<strong>in</strong>g Monitor<strong>in</strong>g System). Browser facilities enable access<br />

for holders with a username and password at several levels if<br />

required. Information distribution to all relevant personnel is<br />

also quick and easy.<br />

Reduced operat<strong>in</strong>g costs<br />

Monitor<strong>in</strong>g real time temperature data can give quick and<br />

effective <strong>in</strong>formation on how a particular item of equipment<br />

is be<strong>in</strong>g used. This <strong>in</strong> turn can allow the operator to control<br />

the operation of the equipment more effectively and reduce<br />

energy consumption. Ma<strong>in</strong>tenance personnel can also ga<strong>in</strong><br />

valuable <strong>in</strong>formation from data, such as when servic<strong>in</strong>g is<br />

required. This also has the effect of reduc<strong>in</strong>g ma<strong>in</strong> component<br />

failure which reduces overall runn<strong>in</strong>g costs.<br />

Intelligence = knowledge<br />

<strong>Porkka</strong> XWEB allows the operator to use the refrigeration<br />

equipment be<strong>in</strong>g monitored more effectively which is better<br />

for the environment. The system can, for example, record door<br />

open<strong>in</strong>gs (for devices fitted with a door switch), defrost cycles<br />

etc. This <strong>in</strong> turn can highlight critical po<strong>in</strong>ts <strong>in</strong> the operation of<br />

the equipment, for example, when doors are kept open for<br />

too long when goods are be<strong>in</strong>g received. After tra<strong>in</strong><strong>in</strong>g,<br />

energy cost can be reduced.<br />

Device <strong>in</strong>formation<br />

With<strong>in</strong> the <strong>Porkka</strong> digital temperature display is a<br />

circuit board equipped with a TTL connection.<br />

A RS485 adapter is available as an optional extra.<br />

The control unit uses Modbus RTU data transmission<br />

protocol. Items of refrigeration equipment are<br />

connected to a <strong>Porkka</strong> XWEB computer (operat<strong>in</strong>g<br />

system L<strong>in</strong>ux). You may select from several models<br />

which can monitor cont<strong>in</strong>uously up to 12 units, the<br />

largest able to cope with up to 230 units. There are<br />

also software solutions to cater for different<br />

requirements.<br />

A good idea is to digitally photograph each item of<br />

equipment when <strong>in</strong>stalled, then the graphic user<br />

<strong>in</strong>terface can display real time <strong>in</strong>formation on the<br />

equipment’s temperature and operation.<br />

To connect to a network use a RJ-45 cable and<br />

specify it to a fixed IP address. This will allow<br />

cont<strong>in</strong>uous connection for several users. Smaller<br />

users can connect the system to a telephone plug<br />

via a modem, but only one user can access at any<br />

one time.<br />

Makes system surveillance easy, guides to energy efficient usage...<br />

13

<strong>Porkka</strong> F<strong>in</strong>land Oy is an <strong>in</strong>ternationally recognised<br />

designer and manufacturer of refrigeration equipment<br />

<strong>Porkka</strong> F<strong>in</strong>land Oy is an <strong>in</strong>ternationally<br />

recognised designer and manufacturer of<br />

refrigeration equipment. Major clients <strong>in</strong>clude<br />

commercial kitchens, restaurants, fast food outlets,<br />

hotels, <strong>in</strong>dustrial canteens, hospitals, laboratories<br />

and retailers throughout Europe.<br />

Our ma<strong>in</strong> markets outside of F<strong>in</strong>land <strong>in</strong>clude<br />

Scand<strong>in</strong>avia, United K<strong>in</strong>gdom, Germany,<br />

Switzerland, Holland, Belgium, Russia and the<br />

Baltic regions. 80% of the companies turnover is<br />

derived from foreign transactions and exports.<br />

Ongo<strong>in</strong>g and adaptive development supported by<br />

numerous foreign subsidiaries and representatives<br />

ensures our cont<strong>in</strong>ued success.<br />

<strong>Porkka</strong>’s cont<strong>in</strong>ued success is based on decades of<br />

experience, customer focused design and<br />

cont<strong>in</strong>uous product development. New <strong>in</strong>novative<br />

products are launched each year.<br />

<strong>Porkka</strong> F<strong>in</strong>land Oy is part of the Huurre Group.<br />

<strong>Porkka</strong> F<strong>in</strong>land Oy design and manufactures to a quality standard<br />

ISO 9001 which is controlled and certified by Lloyd's Register<br />

Quality Assurance. We also hold the environmental certificate ISO<br />

14001 which also has been issued by LRQA, where environmental<br />

impact <strong>in</strong> production is kept to a m<strong>in</strong>imum.<br />

-marked products. The manufacturer through cont<strong>in</strong>uous<br />

research and development reserves the right to change technical<br />

specification and design without notice.<br />

<strong>Porkka</strong> F<strong>in</strong>land Oy reserves the right to make any changes without<br />

prior notice.<br />

Briiffi - 7460 - 03/12<br />

<strong>Porkka</strong> F<strong>in</strong>land Oy<br />

Soisalmentie 3<br />

FI-15860 Hollola, F<strong>in</strong>land<br />

Tel. +358 20 5555 12<br />

Fax +358 20 5555 497<br />

e-mail: porkka@huurre.com<br />

www.porkka.fi<br />

<strong>Porkka</strong> (U.K.) Limited<br />

Unit 5, Olds Approach,<br />

Tolpits Lane, Watford<br />

Hertfordshire, WD18 9RG, UK<br />

Tel. +44 1923 77 99 29<br />

Fax +44 1923 72 51 65<br />

e-mail: sales@porkka.co.uk<br />

www.porkka.co.uk