Axis Ball Bearing Catalog (PDF) - McGuire Bearing Company

Axis Ball Bearing Catalog (PDF) - McGuire Bearing Company

Axis Ball Bearing Catalog (PDF) - McGuire Bearing Company

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Contents<br />

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1<br />

Part Number Breakdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4<br />

1200 Series – Self-Aligning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5<br />

1300 Series – Self-Aligning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6<br />

1600 Series – inch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7<br />

2200 Series – Self-Aligning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8<br />

2300 Series – Self Aligning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9<br />

5200 Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10<br />

5300 Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11<br />

600 Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12<br />

6000 Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13<br />

6200 Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14<br />

6300 Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15<br />

6400 Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16<br />

6800 Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17<br />

6900 Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18<br />

M6200 Series – Max Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19<br />

M6300 Series – Max Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20<br />

7200 Series – Angular Contact . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21<br />

7200 Series – Duplex . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22<br />

7300 Series – Angular Contact . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23<br />

7300 Series – Duplex . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24<br />

7000 Series – Spindle <strong>Bearing</strong>s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25<br />

7000 Series – Spindle <strong>Bearing</strong> Pairs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26<br />

7200 Series – Spindle <strong>Bearing</strong>s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27<br />

7200 Series – Spindle <strong>Bearing</strong> Pairs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28<br />

7900 Series – Spindle <strong>Bearing</strong>s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29<br />

7900 Series – Spindle <strong>Bearing</strong> Pairs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30<br />

87000 Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31<br />

88000 Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32<br />

WC87000 Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33<br />

WC88000 Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34<br />

R Series - inch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35<br />

RLS Series - inch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36<br />

RMS Series - inch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37<br />

Snap Ring & Groove Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38-40<br />

Radial Internal Clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41<br />

www.<strong>Axis</strong><strong>Bearing</strong>.com

www.<strong>Axis</strong><strong>Bearing</strong>.com<br />

General <strong>Bearing</strong> Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42<br />

Angular Contact Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43-44<br />

Angular Contact Pairs End Play . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45<br />

Preloaded Spindle Sets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46<br />

Introduction to Shaft and Housing Fits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47<br />

Shaft Fits for Radial <strong>Bearing</strong>s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48<br />

Housing Fits for Radial <strong>Bearing</strong>s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49<br />

Shaft Fits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50-51<br />

Housing Fits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52-53<br />

<strong>Bearing</strong> Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54-55

Introduction<br />

Deep Groove <strong>Ball</strong> <strong>Bearing</strong>s<br />

At <strong>Axis</strong>, we build exceptional tolerances into our bearings. Instead of the usual ABEC 1, we manufacture every <strong>Axis</strong><br />

bearing to meet or exceed ABEC 3 tolerances. We use grade 10 balls, normally found in ABEC 5 (or better), instead<br />

of grade 25. This insures a rounder, more precise diameter ball and gives longer life because the balls share the<br />

load evenly. All <strong>Axis</strong> deep groove ball bearings are noise and vibration tested. We use Polyrex EM grease that has<br />

become the lubricant of choice for the electric motor industry. In addition, we use high strength, temperature resistant<br />

steel as standard in our retainers. All of these features add up to longer life.<br />

Angular Contact <strong>Ball</strong> <strong>Bearing</strong>s<br />

All <strong>Axis</strong> angular contact ball bearings meet or exceed ABEC 5 tolerances. They feature forged steel rings for superior<br />

grain structure. The machined bronze retainer provides superior strength and heat dissipation. They come with a<br />

40-degree contact angle for high thrust load capacity. All <strong>Axis</strong> angular contact ball bearings are universally flush<br />

ground allowing them to be paired in any configuration your application demands.<br />

www.<strong>Axis</strong><strong>Bearing</strong>.com 1

RADIAL BALL BEARING<br />

Part Number Breakdown<br />

5208 2RS EMQ<br />

608 ZZ<br />

M6203 2RSNRPC3 EMQ<br />

Double Row <strong>Ball</strong><br />

...p. 10<br />

...p. 12<br />

Single Row <strong>Ball</strong> ...pp.13-20<br />

DESIGN CODE<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

M<br />

Blank<br />

Narrow Double Row Self-Aligning <strong>Ball</strong><br />

Double Row Self-Aligning <strong>Ball</strong><br />

Double Row Angular Contact <strong>Ball</strong><br />

Metric Width Double Row<br />

Self-Aligning <strong>Ball</strong><br />

Double Row Angular Contact <strong>Ball</strong><br />

Single Row Deep Groove <strong>Ball</strong><br />

7<br />

8<br />

9<br />

0<br />

2<br />

3<br />

4<br />

-<br />

-<br />

Max Type<br />

Standard<br />

DIAMETER/CROSS SECTION CODE<br />

Lightest<br />

Heaviest<br />

...pp. 19-20<br />

...pp. 13-18<br />

6800<br />

6900<br />

6000<br />

6200<br />

6300<br />

6400<br />

...p. 17<br />

...p. 18<br />

...p. 13<br />

...p. 14<br />

...p. 15<br />

...p. 16<br />

...pp. 5-6<br />

...pp. 8-9<br />

...pp. 10-11<br />

...pp. 13-20<br />

Blank - Standard Quality<br />

EMQ - Electric Motor Quality<br />

Noise & Vibration Checked<br />

INTERNAL CLEARANCE<br />

C2<br />

CO or Blank - Standard<br />

C3<br />

C4<br />

CAGE CODE<br />

Blank - Steel<br />

P - Plastic<br />

M - Machined Brass<br />

Least Clearance<br />

Most Clearance<br />

NR - Snap Ring on O.D.<br />

Blank - Standard (No Snap Ring)<br />

BORE DIAMETER CODE<br />

One Digit # = Bore in mm<br />

00<br />

01<br />

02<br />

03<br />

-<br />

-<br />

-<br />

-<br />

10mm<br />

12mm<br />

15mm<br />

17mm<br />

04 & Above x 5 = Bore in mm<br />

PROTECTION CODE<br />

Blank<br />

Z<br />

ZZ<br />

RS<br />

2RS<br />

-<br />

-<br />

-<br />

-<br />

-<br />

Open<br />

Shield<br />

Shields Both Sides<br />

Seal One Side<br />

Sealed Both Sides<br />

Radial Inch<br />

Dimensional <strong>Ball</strong><br />

16 02 ZZ<br />

...p. 8<br />

Blank - Open<br />

ZZ - Shielded<br />

2RS - Sealed<br />

BORE SIZE<br />

See Dimension Tables<br />

2<br />

www.<strong>Axis</strong><strong>Bearing</strong>.com

ANGULAR CONTACT BEARING<br />

Part Number Breakdown<br />

7208<br />

7004<br />

B<br />

C<br />

MP<br />

TB P4<br />

UA<br />

DUL<br />

Angular Contact<br />

Spindle <strong>Bearing</strong>s<br />

...pp. 23-26<br />

...pp. 27-32<br />

END PLAY<br />

DESIGN CODE<br />

Single Row Angular Contact<br />

<strong>Ball</strong> <strong>Bearing</strong><br />

DIAMETER/<br />

CROSS SECTION CODE<br />

UA -<br />

U0 -<br />

UL -<br />

DUL<br />

DUM<br />

DUH<br />

-<br />

-<br />

-<br />

Universally Flush Ground<br />

For Axial End Play<br />

Universally Flush Ground<br />

For No End Play<br />

Universally Flush Ground<br />

For Light Preload<br />

Duplex Pair For Light Preload<br />

Duplex Pair For Medium Preload<br />

Duplex Pair For Heavy Preload<br />

7<br />

8<br />

9<br />

0<br />

2<br />

3<br />

4<br />

Lightest<br />

Heaviest<br />

PRECISION CODE<br />

P6<br />

P5<br />

P4<br />

-<br />

-<br />

-<br />

ISO P6 / ABEC 3<br />

ISO P6 / ABEC 5<br />

ISO P4 / ABEC 7<br />

BORE DIAMETER CODE<br />

One Digit # = Bore in mm<br />

00<br />

01<br />

02<br />

03<br />

04 & Above<br />

-<br />

-<br />

-<br />

-<br />

x<br />

10mm<br />

12mm<br />

15mm<br />

17mm<br />

5 = Bore in mm<br />

CAGE CODE<br />

MP - Machine Window-Type Brass<br />

TB - Phenolic / Bakelite<br />

CONTACT ANGLE<br />

B 40°<br />

C 15°<br />

www.<strong>Axis</strong><strong>Bearing</strong>.com 3

miscellaneous<br />

Part Number Breakdown<br />

WC -<br />

Blank -<br />

Wide Cartridge<br />

(Wide Outer Race)<br />

Standard Width Outer Race<br />

Wide Width Seal<br />

WC87035<br />

Cartridge <strong>Bearing</strong>s<br />

Bore<br />

See Dimension Tables<br />

...pp. 31-34<br />

0<br />

5<br />

6<br />

- See Table<br />

- 200 Series<br />

- 300 Series<br />

...p. 31-34<br />

7 - Wide Width Shield<br />

8 - Wide Width Seal<br />

R4AZZ<br />

...p. 37<br />

Radial<br />

Inch Dimensional <strong>Ball</strong><br />

4/16”<br />

Bore in 16th<br />

of an inch<br />

Blank<br />

ZZ<br />

2RS<br />

-<br />

-<br />

-<br />

Open<br />

Shielded<br />

Sealed<br />

Larger Cross Section<br />

RLS 8<br />

...pp. 38-39<br />

RLS<br />

RMS<br />

- Light<br />

- Medium<br />

8 = 1”<br />

Bore in 1/8”<br />

4<br />

www.<strong>Axis</strong><strong>Bearing</strong>.com

<strong>Ball</strong> <strong>Bearing</strong>s<br />

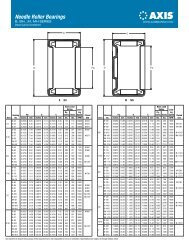

1200 Series – Self-Aligning<br />

Load Rating (Lbs.)<br />

Part Number<br />

Dimensions (mm)<br />

Dynamic Static<br />

Cylindrical Bore Tapered Bore d D B Cr Cor<br />

Limiting Speed (RPM)<br />

Grease<br />

Oil<br />

1200 1200K 10 30 9 989 216 21000 24000<br />

1201 1201K 12 32 10 1007 225 18000 22000<br />

1202 1202K 15 35 11 1340 315 16000 19000<br />

1203 1203K 17 40 12 1421 360 14000 17000<br />

1204 1204K 20 47 14 1780 468 13000 15000<br />

1205 1205K 25 52 15 2176 593 11000 13000<br />

1206 1206K 30 62 16 2806 836 9200 11000<br />

1207 1207K 35 72 17 2841 917 8000 9400<br />

1208 1208K 40 80 18 3453 1169 7100 8400<br />

1209 1209K 45 85 19 3921 1322 6400 7500<br />

1210 1210K 50 90 20 4082 1457 5800 6800<br />

1211 1211K 55 100 21 4820 1798 5300 6200<br />

1212 1212K 60 110 22 5431 2068 4900 5800<br />

1213 1213K 65 120 23 5575 2248 4500 5300<br />

1214 1214K 70 125 24 6222 2482 4200 4900<br />

1215 1215K 75 130 25 6978 2824 3900 4600<br />

1216 1216K 80 140 26 7158 3057 3700 4300<br />

www.<strong>Axis</strong><strong>Bearing</strong>.com 5

<strong>Ball</strong> <strong>Bearing</strong>s<br />

1300 Series – Self-Aligning<br />

Load Rating (Lbs.)<br />

Part Number<br />

Dimensions (mm)<br />

Dynamic Static<br />

Cylindrical Bore Tapered Bore d D B Cr Cor<br />

Limiting Speed (RPM)<br />

Grease<br />

Oil<br />

1300 10 35 11 1304 288 18000 21000<br />

1301 12 37 12 1690 387 16000 18000<br />

1302 15 42 13 1717 414 13000 16000<br />

1303 17 47 14 2250 575 12000 14000<br />

1304 1304K 20 52 15 2680 593 11000 13000<br />

1305 1305K 25 62 17 3237 899 9100 11000<br />

1306 1306K 30 72 19 3831 1133 7700 9100<br />

1307 1307K 35 80 21 4514 1412 6800 8000<br />

1308 1308K 40 90 23 5305 1744 6000 7000<br />

1309 1309K 45 100 25 6852 2284 5400 6300<br />

1310 1310K 50 110 27 7805 2536 4900 5800<br />

1311 1311K 55 120 29 9226 3219 4500 5200<br />

1312 1312K 60 130 31 10287 3741 4100 4800<br />

1313 1313K 65 140 33 11096 4118 3900 4500<br />

1314 70 150 35 13308 4982 3600 4300<br />

1315 1315K 75 160 37 14189 5459 3400 4000<br />

1316 1316K 80 170 39 15844 5935 3200 3800<br />

6<br />

www.<strong>Axis</strong><strong>Bearing</strong>.com

<strong>Ball</strong> <strong>Bearing</strong>s<br />

1600 Series – inch<br />

<strong>Bearing</strong> Size<br />

Load Rating (Lbs.)<br />

Limiting Speed (RPM)<br />

Dimensions (mm)<br />

Dynamic Static Grease Oil<br />

d D B Cr Cor 2RS ZZ/OPEN OPEN<br />

1601 3/16 11/16 1/4 600 220 28000 36000 43000<br />

1602 1/4 11/16 1/4 635 240 28000 36000 43000<br />

1603 5/16 7/8 9/32 745 310 22000 31000 36000<br />

1604 3/8 7/8 9/32 750 320 22000 31000 36000<br />

1605 5/16 29/32 5/16 745 315 18000 28000 33000<br />

1606 3/8 29/32 5/16 750 320 18000 28000 33000<br />

1607 7/16 29/32 5/16 1015 430 17000 27000 32000<br />

1614 3/8 1 1/8 3/8 1140 520 15000 25000 28000<br />

1615 7/16 1 1/8 3/8 1145 530 15000 25000 28000<br />

1616 1/2 1 1/8 3/8 1150 450 15000 25000 28000<br />

1620 7/16 1 3/8 7/16 1690 800 12000 22000 26000<br />

1621 1/2 1 3/8 7/16 1700 815 12000 22000 26000<br />

1622 9/16 1 3/8 7/16 1710 825 12000 22000 26000<br />

1623 5/8 1 3/8 7/16 1720 835 12000 22000 26000<br />

1628 5/8 1 5/8 1/2 2100 1095 10000 17000 20000<br />

1630 3/4 1 5/8 1/2 2110 1115 10000 17000 20000<br />

1633 5/8 1 3/4 1/2 2100 1120 9000 14000 16000<br />

1635 3/4 1 3/4 1/2 2110 1140 9000 14000 16000<br />

1638 3/4 2 9/16 2270 1290 7500 12000 13000<br />

1640 7/8 2 9/16 2265 1315 7500 12000 13000<br />

1641 1 2 9/16 2260 1345 7500 12000 13000<br />

1652 1 1/8 2 1/2 5/8 3603 2280 5500 9000 10000<br />

1654 1 1/4 2 1/2 5/8 3600 2300 5500 9000 10000<br />

1657 1 1/4 2 9/16 11/16 4400 2500 3000 5000 6000<br />

1658 1 5/16 2 9/16 11/16 4370 2600 3000 5000 6000<br />

www.<strong>Axis</strong><strong>Bearing</strong>.com 7

<strong>Ball</strong> <strong>Bearing</strong>s<br />

2200 Series – Self-Aligning<br />

Part Number Dimensions (mm) Load Rating (Lbs.) Limiting Speed (RPM)<br />

Cylindrical<br />

Bore Tapered Bore d D B<br />

Dynamic Static Grease Oil<br />

Cr Cor OPEN 2RS OPEN<br />

2200 10 30 14 1331 288 19000 17000 23000<br />

2201 12 32 14 1376 315 17000 16000 20000<br />

2202 15 35 14 1385 333 15000 14000 18000<br />

2203 17 40 16 1762 432 13000 12000 16000<br />

2204 2204K 20 47 18 2266 593 12000 10000 14000<br />

2205 2205K 25 52 18 2266 629 10000 9000 12000<br />

2206 2206K 30 62 20 2806 2806 8600 7500 10000<br />

2207 2207K 35 72 23 3885 1187 7500 6300 8800<br />

2208 2208K 40 80 23 4028 1331 6700 5600 7900<br />

2209 2209K 45 85 23 4190 1466 6000 5300 7100<br />

2210 2210K 50 90 23 4190 1529 5500 4800 6400<br />

2211 2211K 55 100 25 4820 1798 5000 4300 5800<br />

2212 2212K 60 110 28 6133 2266 4600 3800 5400<br />

2213 2213K 65 120 31 7823 2949 4300 3600 5100<br />

2214 70 125 31 7895 3075 4100 3400 4700<br />

2215 2215K 75 130 31 7949 3201 3800 3200 4400<br />

2216 2216K 80 140 33 8812 3579 3300 3000 3900<br />

8<br />

www.<strong>Axis</strong><strong>Bearing</strong>.com

<strong>Ball</strong> <strong>Bearing</strong>s<br />

2300 Series – Self Aligning<br />

Part Number Dimensions (mm) Load Rating (Lbs.) Limiting Speed (RPM)<br />

Cylindrical<br />

Bore Tapered Bore d D B<br />

Dynamic Static Grease Oil<br />

Cr Cor OPEN 2RS OPEN<br />

2300 10 35 17 1673 378 17000 17000 20000<br />

2301 12 37 17 1745 414 15000 14000 17000<br />

2302 15 42 17 2176 522 13000 12000 15000<br />

2303 17 47 19 2608 647 11000 11000 14000<br />

2304 2304K 20 52 21 3237 845 10000 9500 12000<br />

2305 2305K 25 62 24 4388 1187 8500 7500 10000<br />

2306 2306K 30 72 27 5647 1573 7200 6700 8500<br />

2307 2307K 35 80 31 7086 2032 6300 5600 7400<br />

2308 2308K 40 90 33 8075 2428 5600 5000 6600<br />

2309 2309K 45 100 36 9783 3003 5000 4500 5900<br />

2310 2310K 50 110 40 11618 3651 4600 4000 5400<br />

2311 2311K 55 120 43 13542 4316 4200 3800 4900<br />

2312 2312K 60 130 46 15682 5089 3800 3600 4500<br />

2313 2313K 65 140 31 17229 5845 3300 3400 4000<br />

2314 2314K 70 150 51 16114 5701 3100 3200 3700<br />

2315 2315K 75 160 55 18524 6618 2700 3000 3200<br />

2316 2316K 80 170 58 23199 8219 2500 2800 3000<br />

www.<strong>Axis</strong><strong>Bearing</strong>.com 9

<strong>Ball</strong> <strong>Bearing</strong>s<br />

5200 Series<br />

<strong>Bearing</strong> Size<br />

Load Rating (Lbs.)<br />

Dimensions<br />

Dynamic<br />

Static<br />

d (mm) D (mm) B (inches) Cr Cor<br />

Limiting Speed (RPM)<br />

2RS<br />

ZZ/OPEN<br />

5200 10 30 9/16 1562 854 17000 24000<br />

5201 12 32 5/8 2057 1135 15000 22000<br />

5202 15 35 5/8 2248 1360 14000 18000<br />

5203 17 40 11/16 2878 1776 12000 16000<br />

5204 20 47 13/16 4271 2720 10000 14000<br />

5205 25 52 13/16 4631 3215 8500 12000<br />

5206 30 62 15/16 6429 4586 7500 10000<br />

5207 35 72 1 1/16 8543 6250 6300 9000<br />

5208 40 80 1 3/16 9554 7306 5600 8000<br />

5209 45 85 1 3/16 10791 8318 5300 7500<br />

5210 50 90 1 3/16 11465 9442 4800 7000<br />

5211 55 100 1 5/16 14163 11915 4500 6300<br />

5212 60 110 1 7/16 16074 13151 4000 5600<br />

5213 65 120 1 1/2 18771 16299 3600 4800<br />

5214 70 125 1 9/16 20345 17872 3400 4500<br />

5215 75 130 1 5/8 20233 18097 3200 4500<br />

5216 80 140 1 3/4 23830 21469 3000 3400<br />

5217 85 150 1 15/16 25178 23830 2600 3800<br />

5218 90 160 2 1/16 31473 29000 2500 3600<br />

10<br />

www.<strong>Axis</strong><strong>Bearing</strong>.com

<strong>Ball</strong> <strong>Bearing</strong>s<br />

5300 Series<br />

<strong>Bearing</strong> Size<br />

Load Rating (Lbs.)<br />

Dimensions<br />

Dynamic<br />

Static<br />

d (mm) D (mm) B (inches) Cr Cor<br />

Limiting Speed (RPM)<br />

2RS<br />

ZZ/OPEN<br />

5302 15 42 3/4 3867 2271 9900 13000<br />

5303 17 47 7/8 4586 2720 9900 12000<br />

5304 20 52 7/8 4631 2855 9000 13000<br />

5305 25 62 1 6857 4609 7500 11000<br />

5306 30 72 1 3/16 8880 6182 6300 9000<br />

5307 35 80 1 3/8 11128 7868 6000 8500<br />

5308 40 90 1 7/16 13601 9892 5000 7000<br />

5309 45 100 1 9/16 16299 12140 4800 6700<br />

5310 50 110 1 3/4 19221 14500 4000 6000<br />

5311 55 120 1 15/16 23830 18434 4000 5300<br />

5312 60 130 2 1/8 27426 21469 2720 5000<br />

5313 65 140 2 5/16 31023 24504 2560 4500<br />

5314 70 150 2 1/2 34845 28101 2240 4300<br />

5315 75 160 2 11/16 37768 31698 2080 4000<br />

www.<strong>Axis</strong><strong>Bearing</strong>.com 11

<strong>Ball</strong> <strong>Bearing</strong>s<br />

600 Series<br />

<strong>Bearing</strong> Size<br />

d<br />

Dimensions (mm) Load Rating (Lbs.) Limiting Speed (RPM)<br />

D<br />

Open<br />

B Dynamic Static Grease Oil<br />

Sealed/<br />

Shielded Cr Cor 2RS ZZ/OPEN OPEN<br />

603 3 9 3 3 100 50 42000 56000 67000<br />

604 4 12 4 4 170 80 36000 48000 56000<br />

605 5 14 5 5 230 110 30000 40000 50000<br />

606 6 17 6 6 500 185 24000 32000 40000<br />

607 7 22 7 6 525 200 26000 36000 43000<br />

608 8 22 7 7 750 315 20000 28000 34000<br />

608 5/16 7.94 22 7 7 750 315 22000 30000 36000<br />

609 9 24 7 7 750 310 24000 32000 40000<br />

623 3 10 4 4 110 50 37000 50000 60000<br />

624 4 13 5 5 290 100 24000 32000 40000<br />

625 5 16 5 5 390 140 26000 36000 43000<br />

626 6 19 6 6 525 200 29000 40000 48000<br />

626 1/4 6.35 19 6 6 525 200 23000 32000 38000<br />

627 7 22 7 7 750 300 24000 34000 40000<br />

627 1/4 6.35 22 7 7 749 300 24000 34000 40000<br />

628 8 24 8 8 690 350 20000 28000 34000<br />

629 9 26 8 8 1030 440 24000 34000 40000<br />

634 4 16 5 5 395 155 26000 36000 43000<br />

635 5 19 6 6 525 200 27000 38000 45000<br />

636 6 22 7 7 525 200 22000 30000 36000<br />

637 7 26 9 9 750 315 20000 28000 34000<br />

638 8 28 8 8 750 315 20000 28000 34000<br />

682 2 5 1.5 2.3 30 10 63000 85000 100000<br />

683 3 7 2 3 35 15 46000 63000 75000<br />

684 4 9 2.5 4 80 40 39000 53000 63000<br />

685 5 11 3 5 125 60 33000 45000 53000<br />

686 6 13 3.5 5 190 90 29000 40000 50000<br />

687 7 14 3.5 5 205 105 29000 40000 50000<br />

688 8 16 4 5 235 120 26000 36000 43000<br />

689 9 17 4 5 230 130 26000 36000 43000<br />

693 3 8 3 4 65 25 44000 60000 67000<br />

694 4 11 4 4 125 60 36000 48000 56000<br />

695 5 13 4 4 190 90 32000 43000 50000<br />

696 6 15 5 5 230 110 29000 40000 45000<br />

698 8 19 6 6 290 150 26000 36000 43000<br />

699 9 20 6 6 310 160 24000 34000 40000<br />

12<br />

www.<strong>Axis</strong><strong>Bearing</strong>.com

<strong>Ball</strong> <strong>Bearing</strong>s<br />

6000 Series<br />

Load Rating (Lbs.)<br />

Limiting Speed (RPM)<br />

Dimensions (mm)<br />

Dynamic Static Grease Oil<br />

<strong>Bearing</strong> Size<br />

d D B Cr Cor 2RS ZZ/OPEN OPEN<br />

6000 10 26 8 1030 440 28000 31000 36000<br />

6001 12 28 8 1150 540 17000 27000 32000<br />

6002 15 32 9 1260 650 14000 23000 27000<br />

6003 17 35 10 1350 740 12000 21000 25000<br />

6004 20 42 12 2120 1140 10000 17000 21000<br />

6005 25 47 12 2280 1320 9000 15000 18000<br />

6006 30 55 13 2970 1860 7500 13000 15000<br />

6007 35 62 14 3580 2320 6500 11000 13000<br />

6008 40 68 15 3760 2590 5800 10000 12000<br />

6009 45 75 16 4730 3400 5300 9200 11000<br />

6010 50 80 16 4910 3740 4800 8400 9900<br />

6011 55 90 18 6370 4770 4300 7600 8900<br />

6012 60 95 18 6610 5220 4000 7100 8400<br />

6013 65 100 18 6860 5670 3700 6600 7800<br />

6014 70 110 20 8570 6950 3500 6100 7200<br />

6015 75 115 20 8910 7540 3300 5700 6800<br />

6016 80 125 22 10710 8950 3100 5300 6300<br />

6017 85 130 22 11130 9690 2900 5000 5900<br />

6018 90 140 24 13090 11180 2700 4700 5600<br />

6019 95 145 24 13580 12120 2500 4400 5200<br />

6020 100 150 24 13540 12190 2500 4300 5100<br />

6021 105 160 26 16260 14800 2300 4000 4700<br />

6022 110 170 28 18440 16420 2200 3800 4500<br />

6024 120 180 28 19110 17830 2100 3600 4200<br />

6026 130 200 33 23830 22710 1900 3200 3800<br />

6028 140 210 33 24730 24510 1800 3000 3600<br />

6030 150 225 35 28110 28330 1600 2800 3300<br />

6032 160 240 38 30580 30350 1500 2600 3000<br />

www.<strong>Axis</strong><strong>Bearing</strong>.com 13

<strong>Ball</strong> <strong>Bearing</strong>s<br />

6200 Series<br />

<strong>Bearing</strong> Size<br />

Load Rating (Lbs.)<br />

Limiting Speed (RPM)<br />

Dimensions (mm)<br />

Dynamic Static Grease Oil<br />

d D B Cr Cor 2RS ZZ/OPEN OPEN<br />

6200 10 30 9 1150 540 16000 24000 29000<br />

6201 12 32 10 1530 690 15000 22000 27000<br />

6202 15 35 11 1720 850 13000 20000 24000<br />

6203 17 40 12 2150 1080 12000 17000 21000<br />

6204 20 47 14 2880 1500 9700 15000 17000<br />

6205 25 52 15 3150 1770 8400 13000 15000<br />

6206 30 62 16 4390 2550 7000 11000 13000<br />

6207 35 72 17 5780 3470 6000 9200 11000<br />

6208 40 80 18 6550 4010 5400 8300 10000<br />

6209 45 85 19 7360 4570 5100 7700 9200<br />

6210 50 90 20 7900 5240 4600 7100 8500<br />

6211 55 100 21 9760 6610 4100 6300 7600<br />

6212 60 110 22 11780 8140 3700 5700 6900<br />

6213 65 120 23 12860 9020 3500 5400 6400<br />

6214 70 125 24 13990 9920 3300 5100 6100<br />

6215 75 130 25 15160 10860 3100 4800 5800<br />

6216 80 140 26 16350 11920 2900 4500 5400<br />

6217 85 150 28 18890 13920 2700 4200 5000<br />

6218 90 160 30 21610 16080 2600 3900 4700<br />

6219 95 170 32 24510 18420 2400 3700 4400<br />

6220 100 180 34 27430 20930 2300 3500 4200<br />

6221 105 190 36 29900 23610 2200 3300 3900<br />

6222 110 200 38 32380 26310 2000 3100 3700<br />

6224 120 215 40 34850 29450 1900 2900 3400<br />

6226 130 230 40 37550 32830 1800 2700 3200<br />

6228 140 250 42 37320 33730 1600 2400 2900<br />

14<br />

www.<strong>Axis</strong><strong>Bearing</strong>.com

<strong>Ball</strong> <strong>Bearing</strong>s<br />

6300 Series<br />

<strong>Bearing</strong> Size<br />

Load Rating (Lbs.)<br />

Limiting Speed (RPM)<br />

Dimensions (mm)<br />

Dynamic Static Grease Oil<br />

d D B Cr Cor 2RS ZZ/OPEN OPEN<br />

6300 10 35 11 1830 780 16000 22000 27000<br />

6301 12 37 12 2190 950 15000 20000 25000<br />

6302 15 42 13 2570 1230 12000 17000 20000<br />

6303 17 47 14 3060 1500 10000 15000 18000<br />

6304 20 52 15 3580 1770 9500 14000 17000<br />

6305 25 62 17 4640 2550 7500 11000 13000<br />

6306 30 72 19 6010 3380 6400 9600 12000<br />

6307 35 80 21 7510 4340 5700 8500 10000<br />

6308 40 90 23 9150 5400 5100 7700 9200<br />

6309 45 100 25 11000 6640 4500 6800 8100<br />

6310 50 110 27 13940 8620 4100 6100 7300<br />

6311 55 120 29 16100 10120 3700 5600 6700<br />

6312 60 130 31 18420 11740 3500 5200 6200<br />

6313 65 140 33 20840 13470 3200 4800 5800<br />

6314 70 150 35 23380 15340 3000 4500 5400<br />

6315 75 160 37 25410 17360 2800 4200 5000<br />

6316 80 170 39 27660 19500 2700 3900 4700<br />

6317 85 180 41 29900 21770 2500 3700 4400<br />

6318 90 190 43 32150 24060 2400 3500 4200<br />

6319 95 200 45 34400 26760 2200 3300 4000<br />

6320 100 215 47 38900 31700 2100 3000 3600<br />

6321 105 225 49 41370 34400 2000 2900 3500<br />

6322 110 240 50 46090 40470 1900 2700 3200<br />

6324 120 260 55 46540 41590 1800 2500 3000<br />

6326 130 280 58 51490 48110 1600 2300 2700<br />

6328 140 300 62 56880 55310 1500 2100 2500<br />

www.<strong>Axis</strong><strong>Bearing</strong>.com 15

<strong>Ball</strong> <strong>Bearing</strong>s<br />

6400 Series<br />

<strong>Bearing</strong> Size<br />

Load Rating (Lbs.)<br />

Limiting Speed (RPM)<br />

Dimensions (mm)<br />

Dynamic Static Grease Oil<br />

d D B Cr Cor 2RS ZZ/OPEN OPEN<br />

6403 17 62 17 5000 1450 9600 14000 16000<br />

6404 20 72 19 7000 3350 8400 12000 14000<br />

6405 25 80 21 8000 4300 7200 10000 12000<br />

6406 30 90 23 9800 5300 6000 8600 10000<br />

6407 35 100 35 12200 6900 5400 7800 9000<br />

6408 40 110 27 14300 8200 4920 7000 8200<br />

6409 45 120 29 17000 1000 4440 6300 7400<br />

6410 50 130 31 19200 11500 3990 5700 6650<br />

6411 55 140 33 22200 13800 3660 5200 6100<br />

6412 60 150 35 24000 15000 3420 4750 5700<br />

6413 65 160 37 26200 17000 3180 4500 5300<br />

6414 70 180 42 32000 23000 3000 4000 5000<br />

6415 75 190 45 34300 25500 2700 3900 4500<br />

6416 80 200 48 36500 28100 2520 3650 4200<br />

6417 85 210 52 39200 30600 2400 3450 4000<br />

6418 90 225 54 41800 33700 2280 3000 3800<br />

16<br />

www.<strong>Axis</strong><strong>Bearing</strong>.com

<strong>Ball</strong> <strong>Bearing</strong>s<br />

6800 Series<br />

Load Rating (Lbs.)<br />

Limiting Speed (RPM)<br />

Dimensions (mm)<br />

Dynamic Static Grease Oil<br />

<strong>Bearing</strong> Size<br />

d D B Cr Cor 2RS ZZ/OPEN OPEN<br />

6800 10 19 5 410 208 22800 32000 38000<br />

6801 12 21 5 429 233 21000 29000 35000<br />

6802 15 24 5 466 282 18600 26000 31000<br />

6803 17 26 5 630 385 16800 24000 28000<br />

6804 20 32 7 902 554 15000 21000 25000<br />

6805 25 37 7 968 660 12600 18000 21000<br />

6806 30 42 7 1060 815 10800 15000 18000<br />

6807 35 47 7 1100 900 9600 13000 16000<br />

6808 40 52 7 1140 985 8400 12000 14000<br />

6809 45 58 7 1440 1270 7200 11000 12000<br />

6810 50 65 7 1480 1400 6600 9600 11000<br />

6811 55 72 9 1980 1900 6000 8700 10000<br />

6812 60 78 10 2570 2460 5640 8000 9400<br />

6813 65 85 10 2680 2710 5220 7400 8700<br />

6814 70 90 10 2710 2860 4860 6900 8100<br />

6815 75 95 10 2820 3100 4560 6400 7600<br />

6816 80 100 10 2840 3230 4260 6000 7100<br />

6817 85 110 13 4270 4710 3780 5400 6300<br />

6819 95 120 13 4330 4750 3540 5000 5900<br />

6820 100 125 13 4400 4750 3360 4800 5600<br />

6822 110 140 16 4440 5370 3060 4300 5100<br />

6824 120 150 16 6290 7370 2820 4000 4700<br />

6826 130 165 18 8030 8030 2580 3700 4300<br />

6828 140 175 18 8250 9790 2400 3400 4000<br />

6830 150 190 20 10700 10900 2220 3100 3700<br />

6832 160 200 20 10900 13800 2040 2900 3400<br />

6834 170 215 22 13400 16800 1920 2700 3200<br />

6836 180 225 22 13600 17600 1800 2600 3000<br />

www.<strong>Axis</strong><strong>Bearing</strong>.com 17

<strong>Ball</strong> <strong>Bearing</strong>s<br />

6900 Series<br />

<strong>Bearing</strong> Size<br />

Load Rating (Lbs.)<br />

Limiting Speed (RPM)<br />

Dimensions (mm)<br />

Dynamic Static Grease Oil<br />

d D B Cr Cor 2RS ZZ/OPEN OPEN<br />

6900 10 22 6 605 280 22800 32000 38000<br />

6901 12 24 6 650 330 21600 30000 36000<br />

6902 15 28 7 970 510 18000 26000 30000<br />

6903 17 30 7 1050 570 16800 24000 28000<br />

6904 20 37 9 1430 825 13800 19000 23000<br />

6905 25 42 9 1570 1010 11400 16000 19000<br />

6906 30 47 9 1630 1130 10200 14000 17000<br />

6907 35 55 10 2510 1670 9000 12000 15000<br />

6908 40 62 12 3250 2300 7800 11000 13000<br />

6909 45 68 12 3400 2530 7200 9800 12000<br />

6910 50 72 12 3500 2750 6600 8900 11000<br />

6911 55 80 13 3590 2970 5760 8200 9600<br />

6912 60 85 13 4360 3650 5340 7600 8900<br />

6913 65 90 13 3890 3610 4920 7000 8200<br />

6914 70 100 16 5320 4750 4620 6500 7700<br />

6915 75 105 16 5460 5060 4440 6100 7400<br />

6916 80 110 16 5590 5390 4020 5700 6700<br />

6917 85 120 18 7150 6600 3780 5400 6300<br />

6918 90 125 18 7370 7040 3600 5100 6000<br />

6919 95 130 18 7590 7480 3420 4800 5700<br />

6920 100 140 20 9570 9350 3180 4500 5300<br />

6921 105 145 20 9790 9460 3180 4300 5300<br />

6922 110 150 20 11900 10000 3000 4300 5000<br />

6924 120 165 22 14600 12100 2640 3800 4400<br />

6926 130 180 24 14600 15100 2460 3500 4100<br />

6928 140 190 24 15000 16100 2280 3200 3800<br />

6930 150 210 28 19000 20200 2100 3000 3500<br />

6932 160 220 28 19500 21600 1980 2800 3300<br />

6934 170 230 28 19300 21700 1860 2600 3100<br />

6936 180 250 33 26600 28800 1740 2400 2900<br />

6938 190 260 33 25300 28600 1620 2300 2700<br />

6940 200 280 38 32100 35400 1560 2200 2600<br />

18<br />

www.<strong>Axis</strong><strong>Bearing</strong>.com

<strong>Ball</strong> <strong>Bearing</strong>s<br />

M6200 Series – Max Type<br />

<strong>Bearing</strong> Size<br />

Load Rating (Lbs.)<br />

Dimensions (mm)<br />

Dynamic<br />

Static<br />

d D B Cr Cor<br />

Limiting Speed (RPM)<br />

OPEN<br />

ZZ<br />

M6206 30 62 16 5148 3889 12000 10000<br />

M6207 35 72 17 6677 5126 11000 8500<br />

M6208 40 80 18 7554 5957 9500 7500<br />

M6209 45 80 19 8902 7306 9000 7000<br />

M6210 50 90 20 8790 7756 8000 6700<br />

M6211 55 100 21 10881 9892 7500 6000<br />

M6212 60 110 22 12612 11240 6700 5300<br />

M6213 65 120 23 13601 13151 6000 4800<br />

M6214 70 125 24 14837 14725 6000 4500<br />

M6215 75 130 25 16209 16186 5600 4500<br />

M6216 80 140 26 19783 19109 5300 4000<br />

M6217 85 150 28 21761 22481 4800 3800<br />

M6218 90 160 30 25178 25628 4500 3600<br />

M6219 95 170 32 27202 27426 4300 4300<br />

M6220 100 180 34 30124 31473 4000 3200<br />

www.<strong>Axis</strong><strong>Bearing</strong>.com 19

<strong>Ball</strong> <strong>Bearing</strong>s<br />

M6300 Series – Max Type<br />

<strong>Bearing</strong> Size<br />

Load Rating (Lbs.)<br />

Dimensions (mm)<br />

Dynamic<br />

Static<br />

d D B Cr Cor<br />

Limiting Speed (RPM)<br />

OPEN<br />

ZZ<br />

M6305 25 62 17 5148 3507 13000 10000<br />

M6306 30 62 19 6564 4676 11000 9000<br />

M6307 35 80 21 8790 6407 10000 8000<br />

M6308 40 90 23 10521 8093 9000 7000<br />

M6309 45 100 25 13354 10454 8000 6300<br />

M6310 50 110 27 14478 11690 7000 5600<br />

M6311 55 120 29 17805 15062 6700 5300<br />

M6312 60 130 31 20525 17535 6000 4800<br />

M6313 65 140 33 22930 20233 5600 4500<br />

M6314 70 150 35 25628 22930 5000 4000<br />

M6315 75 160 37 28101 26078 4800 3800<br />

M6316 80 170 39 31023 29000 4500 3600<br />

M6317 85 180 41 33047 32822 4300 3400<br />

M6318 90 190 43 35295 35969 4000 3200<br />

20<br />

www.<strong>Axis</strong><strong>Bearing</strong>.com

<strong>Ball</strong> <strong>Bearing</strong>s<br />

7200 Series – Angular Contact<br />

Contact Angle (a) – the angle between the radial plane and a line joining<br />

the two contact points of the inner and outer race.<br />

Angular contact bearings have races with high shoulders allowing the<br />

balls to operate at higher contact angles giving them increased one directional<br />

thrust capacity over the same size conrad style (deep groove)<br />

bearing. Greater clearances between the balls and the raceways allows<br />

for higher contact angles.<br />

Standard contact angles:<br />

B – 40°<br />

C – 15°<br />

Load Rating (Lbs.)<br />

Limiting Speed (RPM)<br />

Dimensions (mm)<br />

Dynamic<br />

Static<br />

<strong>Bearing</strong> Size<br />

d D B Cr Cor<br />

Grease<br />

Oil<br />

7200 B 10 30 9 1300 600 26000 34000<br />

7201 B 12 32 10 1550 720 20000 27000<br />

7202 B 15 35 11 1780 950 18000 24000<br />

7203 B 17 40 12 2430 1240 16000 20000<br />

7204 B 20 47 14 2990 1740 13000 17000<br />

7205 B 25 52 15 3150 1960 12000 15000<br />

7206 B 30 62 16 4370 2820 9600 13000<br />

7207 B 35 72 17 5760 3830 8300 11000<br />

7208 B 40 80 18 6880 4790 7500 10000<br />

7209 B 45 85 19 7720 5470 7000 9400<br />

7210 B 50 90 20 8030 6010 6400 8500<br />

7211 B 55 100 21 9920 7600 5700 7600<br />

7212 B 60 110 22 12010 9360 5100 6900<br />

7213 B 65 120 23 13700 11090 4800 6400<br />

7214 B 70 125 24 14210 11380 4600 6100<br />

7215 B 75 130 25 16120 13340 4300 5800<br />

7216 B 80 140 26 17340 14620 4000 5400<br />

7217 B 85 150 28 20060 17090 3800 5000<br />

7218 B 90 160 30 22940 19790 3500 4700<br />

7219 B 95 170 32 24960 21140 3300 4400<br />

7220 B 100 180 34 27880 24060 3100 4200<br />

7221 B 105 190 36 30350 27210 2900 3900<br />

7222 B 110 200 38 33050 30350 2800 3700<br />

7224 B 120 215 40 35520 33950 2600 3400<br />

7226 B 130 230 40 39800 40470 2400 3200<br />

7228 B 140 250 42 44290 47890 2200 2900<br />

7230 B 150 270 45 50590 57110 2000 2700<br />

B = 40° contact angle<br />

www.<strong>Axis</strong><strong>Bearing</strong>.com 21

<strong>Ball</strong> <strong>Bearing</strong>s<br />

7200 Series – Duplex<br />

<strong>Bearing</strong> Size<br />

Duplex Load Rating (Lbs.)<br />

Dimensions (mm)<br />

Dynamic<br />

Static<br />

d D B1 Cr Cor<br />

Duplex Limiting Speed (RPM)<br />

Grease<br />

Oil<br />

7200 BUA 10 30 18 2080 1200 17000 25000<br />

7201 BUA 12 32 20 2480 1440 16000 23000<br />

7202 BUA 15 35 22 2850 1900 15000 21000<br />

7203 BUA 17 40 24 3890 2480 13000 18000<br />

7204 BUA 20 47 28 4860 3470 10000 14000<br />

7205 BUA 25 52 30 5110 3920 9200 12000<br />

7206 BUA 30 62 32 7110 5630 7700 10000<br />

7207 BUA 35 72 34 9360 7670 6600 8800<br />

7208 BUA 40 80 36 11180 9600 6000 8000<br />

7209 BUA 45 85 38 12550 10930 5600 7500<br />

7210 BUA 50 90 40 13040 12030 5100 6800<br />

7211 BUA 55 100 42 16100 15200 4600 6100<br />

7212 BUA 60 110 44 19520 18730 4100 5500<br />

7213 BUA 65 120 46 22260 22190 3900 5200<br />

7214 BUA 70 125 48 23160 22710 3700 4900<br />

7215 BUA 75 130 50 26080 26760 3500 4600<br />

7216 BUA 80 140 52 28110 29230 3200 4300<br />

7217 BUA 85 150 56 32600 34180 3000 4000<br />

7218 BUA 90 160 60 37320 39570 2800 3800<br />

7219 BUA 95 170 64 40470 42270 2700 3500<br />

7220 BUA 100 180 68 45420 48110 2500 3300<br />

7221 BUA 105 190 72 49460 54180 2300 3100<br />

7222 BUA 110 200 76 53510 60700 2200 3000<br />

7224 BUA 120 215 80 57780 67900 2100 2800<br />

7226 BUA 130 230 80 64750 80940 1900 2500<br />

7228 BUA 140 250 84 71940 95770 1700 2300<br />

7230 BUA 150 270 90 82060 114430 1600 2100<br />

B = 40° contact angle<br />

UA* = Flush ground for slight axial end play<br />

UO = Flush ground for no end play<br />

* Usually supplied UA. Usually supplied with MP bronze cage.<br />

22<br />

www.<strong>Axis</strong><strong>Bearing</strong>.com

<strong>Ball</strong> <strong>Bearing</strong>s<br />

7300 Series – Angular Contact<br />

Contact Angle (a) – the angle between the radial plane and a line joining<br />

the two contact points of the inner and outer race.<br />

Angular contact bearings have races with high shoulders allowing the<br />

balls to operate at higher contact angles giving them increased one<br />

directional thrust capacity over the same size conrad style (deep groove)<br />

bearing. Greater clearances between the balls and the raceways allows<br />

for higher contact angles.<br />

Standard contact angles:<br />

B – 40°<br />

C – 15°<br />

<strong>Bearing</strong> Size<br />

Load Rating (Lbs.)<br />

Dimensions (mm)<br />

Dynamic<br />

Static<br />

d D B Cr Cor<br />

Limiting Speed (RPM)<br />

Grease<br />

Oil<br />

7301 B 12 37 12 2360 1100 19000 25000<br />

7302 B 15 42 13 2790 1460 16000 21000<br />

7303 B 17 47 14 3170 1820 15000 19000<br />

7304 B 20 52 15 3650 1960 13000 17000<br />

7305 B 25 62 17 5150 2990 10000 14000<br />

7306 B 30 72 19 6210 3920 8700 12000<br />

7307 B 35 80 21 7310 4550 7700 10000<br />

7308 B 40 90 23 8930 5670 6900 9200<br />

7309 B 45 100 25 11380 7670 6200 8200<br />

7310 B 50 110 27 14480 9960 5500 7300<br />

7311 B 55 120 29 16710 11690 5000 6700<br />

7312 B 60 130 31 20240 14800 4600 6200<br />

7313 B 65 140 33 21610 15580 4300 5800<br />

7314 B 70 150 35 24280 17740 4000 5400<br />

7315 B 75 160 37 26530 20060 3800 5000<br />

7316 B 80 170 39 28560 22490 3500 4700<br />

7317 B 85 180 41 30800 25180 3300 4400<br />

7318 B 90 190 43 33280 27880 3100 4200<br />

7319 B 95 200 45 35520 30800 3000 4000<br />

7320 B 100 215 47 37770 33280 2700 3600<br />

7321 B 105 225 49 42940 39800 2600 3500<br />

7322 B 110 240 50 47890 46760 2400 3200<br />

B = 40° contact angle<br />

www.<strong>Axis</strong><strong>Bearing</strong>.com 23

<strong>Ball</strong> <strong>Bearing</strong>s<br />

7300 Series – Duplex<br />

<strong>Bearing</strong> Size<br />

Duplex Load Rating (Lbs.)<br />

Dimensions (mm)<br />

Dynamic<br />

Static<br />

d D B1 Cr Cor<br />

Duplex Limiting Speed (RPM)<br />

Grease<br />

Oil<br />

7301 BUA 12 37 24 3780 2200 15000 22000<br />

7302 BUA 15 42 26 4460 2920 14000 20000<br />

7303 BUA 17 47 28 5070 3640 12000 17000<br />

7304 BUA 20 52 30 5920 3920 10000 13000<br />

7305 BUA 25 62 34 8370 5980 8300 11000<br />

7306 BUA 30 72 38 10100 7810 6900 9200<br />

7307 BUA 35 80 42 11850 9110 6200 8200<br />

7308 BUA 40 90 46 14510 11360 5500 7400<br />

7309 BUA 45 100 50 18460 15340 4900 6600<br />

7310 BUA 50 110 54 23610 19920 4400 5800<br />

7311 BUA 55 120 58 27210 23380 4000 5400<br />

7312 BUA 60 130 62 31030 27210 3700 5000<br />

7313 BUA 65 140 66 35070 31250 3500 4600<br />

7314 BUA 70 150 70 39350 35520 3200 4300<br />

7315 BUA 75 160 74 42940 40020 3000 4000<br />

7316 BUA 80 170 78 46540 44970 2800 3800<br />

7317 BUA 85 180 82 50140 50140 2700 3500<br />

7318 BUA 90 190 86 53960 55760 2500 3300<br />

7319 BUA 95 200 90 57560 61380 2400 3200<br />

7320 BUA 100 215 94 61600 66770 2200 2900<br />

7321 BUA 105 225 98 69700 79810 2100 2800<br />

7322 BUA 110 240 100 77790 93520 1900 2600<br />

B = 40° contact angle<br />

UA* = Flush ground for slight axial end play<br />

UO = Flush ground for no end play<br />

* Usually supplied UA. Usually supplied with MP bronze cage.<br />

24<br />

www.<strong>Axis</strong><strong>Bearing</strong>.com

<strong>Ball</strong> <strong>Bearing</strong>s<br />

7000 Series – Spindle <strong>Bearing</strong>s<br />

<strong>Bearing</strong><br />

Size<br />

Load Rating (Lbs.)<br />

Dimensions (mm)<br />

Dynamic Static<br />

d D B Cr Cor<br />

Limiting Speeds (RPM)<br />

Grease<br />

Oil<br />

7004 CT.P4.UL 20 42 12 2630 1596 36000 53000<br />

7005 CT.P4.UL 25 47 12 2900 1933 30000 45000<br />

7006 CT.P4.UL 30 55 13 3417 2315 26000 40000<br />

7007 CT.P4.UL 35 62 14 4316 3080 22000 36000<br />

7008 CT.P4.UL 40 68 15 4811 3777 20000 34000<br />

7009 CT.P4.UL 45 75 16 5710 4586 18000 30000<br />

7010 CT.P4.UL 50 80 16 5845 4901 17000 28000<br />

7011 CT.P4.UL 55 90 18 7059 6182 15000 24000<br />

7012 CT.P4.UL 60 95 18 7418 6901 14000 22000<br />

7013 CT.P4.UL 65 100 18 7553 7284 13000 20000<br />

7014 CT.P4.UL 70 110 20 10880 10116 12000 19000<br />

7015 CT.P4.UL 75 115 20 11128 10745 12000 19000<br />

7016 CT.P4.UL 80 125 22 13196 12409 11000 18000<br />

7017 CT.P4.UL 85 130 22 13533 13173 10000 17000<br />

7018 CT.P4.UL 90 140 24 16096 15511 9500 16000<br />

7019 CT.P4.UL 95 145 24 16523 16455 9000 15000<br />

7020 CT.P4.UL 100 150 24 16927 17355 8500 14000<br />

7021 CT.P4.UL 105 160 26 18546 19243 8000 13000<br />

7022 CT.P4.UL 110 170 28 21491 22098 7500 12000<br />

7024 CT.P4.UL 120 180 28 23547 24486 6700 10000<br />

www.<strong>Axis</strong><strong>Bearing</strong>.com 25

<strong>Ball</strong> <strong>Bearing</strong>s<br />

7000 Series – Spindle <strong>Bearing</strong><br />

Pairs<br />

<strong>Bearing</strong><br />

Size<br />

Duplex Load Rating (Lbs.)<br />

Dimensions (mm)<br />

Dynamic Static<br />

d D B Cr Cor<br />

Duplex Limiting Speeds (RPM)<br />

Grease<br />

Oil<br />

7004 CTBP4DUL 20 42 24 4261 3192 28800 42400<br />

7005 CTBP4DUL 25 47 24 4698 3866 24000 36000<br />

7006 CTBP4DUL 30 55 26 5536 4630 20800 32000<br />

7007 CTBP4DUL 35 62 28 6992 6160 17600 28800<br />

7008 CTBP4DUL 40 68 30 7794 7554 16000 27200<br />

7009 CTBP4DUL 45 75 32 9250 9172 14400 24000<br />

7010 CTBP4DUL 50 80 32 9469 9802 13600 22400<br />

7011 CTBP4DUL 55 90 36 11436 12364 12000 19200<br />

7012 CTBP4DUL 60 95 36 12017 13802 11200 17600<br />

7013 CTBP4DUL 65 100 36 12236 14568 10400 16000<br />

7014 CTBP4DUL 70 110 40 17626 20232 9600 15200<br />

7015 CTBP4DUL 75 115 40 18027 21490 9600 15200<br />

7016 CTBP4DUL 80 125 44 21378 24818 8800 14400<br />

7017 CTBP4DUL 85 130 44 21923 26346 8000 13600<br />

7018 CTBP4DUL 90 140 48 26076 31022 7600 12800<br />

7019 CTBP4DUL 95 145 48 26767 32910 7200 12000<br />

7020 CTBP4DUL 100 150 48 27422 34710 6800 11200<br />

7021 CTBP4DUL 105 160 52 30045 38486 6400 10400<br />

7022 CTBP4DUL 110 170 56 34815 44196 6000 9600<br />

7024 CTBP4DUL 120 180 56 38146 48972 5360 8000<br />

26<br />

www.<strong>Axis</strong><strong>Bearing</strong>.com

<strong>Ball</strong> <strong>Bearing</strong>s<br />

7200 Series – Spindle <strong>Bearing</strong>s<br />

<strong>Bearing</strong><br />

Size<br />

Load Rating (Lbs.)<br />

Dimensions (mm)<br />

Dynamic Static<br />

d D B Cr Cor<br />

Limiting Speeds (RPM)<br />

Grease<br />

Oil<br />

7204 CT.P4.UL 20 47 14 3484 2001 32000 48000<br />

7205 CT.P4.UL 25 52 15 3934 2495 28000 43000<br />

7206 CT.P4.UL 30 62 16 5463 3574 24000 38000<br />

7207 CT.P4.UL 35 72 17 7216 4878 20000 34000<br />

7208 CT.P4.UL 40 80 18 8183 5665 18000 30000<br />

7209 CT.P4.UL 45 85 19 9644 6969 17000 28000<br />

7210 CT.P4.UL 50 90 20 10094 7643 16000 26000<br />

7211 CT.P4.UL 55 100 21 12476 9621 14000 22000<br />

7212 CT.P4.UL 60 110 22 15062 11802 13000 20000<br />

7213 CT.P4.UL 65 120 23 15669 12948 12000 19000<br />

7214 CT.P4.UL 70 125 24 16388 13376 11000 18000<br />

7215 CT.P4.UL 75 130 25 17062 14458 11000 18000<br />

7216 CT.P4.UL 80 140 26 19265 16995 10000 17000<br />

7217 CT.P4.UL 85 150 28 21693 18906 9000 15000<br />

7218 CT.P4.UL 90 160 30 25088 22075 8500 14000<br />

7219 CT.P4.UL 95 170 32 28635 25492 8000 13000<br />

7220 CT.P4.UL 100 180 34 32506 29179 7500 12000<br />

7221 CT.P4.UL 105 190 36 36530 33113 7000 11000<br />

7222 CT.P4.UL 110 200 38 39790 37294 6700 10000<br />

7224 CT.P4.UL 120 215 40 44600 43207 6000 9000<br />

www.<strong>Axis</strong><strong>Bearing</strong>.com 27

<strong>Ball</strong> <strong>Bearing</strong>s<br />

7200 Series – Spindle <strong>Bearing</strong><br />

Pairs<br />

<strong>Bearing</strong><br />

Size<br />

Duplex Load Rating (Lbs.)<br />

Dimensions (mm)<br />

Dynamic Static<br />

d D B Cr Cor<br />

Duplex Limiting Speeds (RPM)<br />

Grease<br />

Oil<br />

7204 CTBP4DUL 20 47 28 5644 4002 25600 38400<br />

7205 CTBP4DUL 25 52 30 6373 4990 22400 34400<br />

7206 CTBP4DUL 30 62 32 8850 7148 19200 30400<br />

7207 CTBP4DUL 35 72 34 11690 9756 16000 27200<br />

7208 CTBP4DUL 40 80 36 13256 11330 14400 24000<br />

7209 CTBP4DUL 45 85 38 15623 13938 13600 22400<br />

7210 CTBP4DUL 50 90 40 16352 15286 12800 20800<br />

7211 CTBP4DUL 55 100 42 20211 19242 11200 17600<br />

7212 CTBP4DUL 60 110 44 24400 23604 10400 16000<br />

7213 CTBP4DUL 65 120 46 25384 25896 9600 15200<br />

7214 CTBP4DUL 70 125 48 26549 26752 8800 14400<br />

7215 CTBP4DUL 75 130 50 27640 28916 8800 14400<br />

7216 CTBP4DUL 80 140 52 31209 33990 8000 13600<br />

7217 CTBP4DUL 85 150 56 35143 37812 7200 12000<br />

7218 CTBP4DUL 90 160 60 40643 44150 6800 11200<br />

7219 CTBP4DUL 95 170 64 46389 50984 6400 10400<br />

7220 CTBP4DUL 100 180 68 52660 58358 6000 9600<br />

7221 CTBP4DUL 105 190 72 59179 66226 5600 8800<br />

7222 CTBP4DUL 110 200 76 64460 74588 5360 8000<br />

7224 CTBP4DUL 120 215 80 72252 86414 4800 7200<br />

28<br />

www.<strong>Axis</strong><strong>Bearing</strong>.com

<strong>Ball</strong> <strong>Bearing</strong>s<br />

7900 Series – Spindle <strong>Bearing</strong>s<br />

<strong>Bearing</strong><br />

Size<br />

Load Rating (Lbs.)<br />

Dimensions (mm)<br />

Dynamic Static<br />

d D B Cr Cor<br />

Limiting Speeds (RPM)<br />

Grease<br />

Oil<br />

7905 CT.P4.UL 25 42 9 1843 1304 32000 48000<br />

7906 CT.P4.UL 30 47 9 1866 1416 28000 43000<br />

7907 CT.P4.UL 35 55 10 3192 2450 24000 38000<br />

7908 CT.P4.UL 40 62 16 3260 2653 22000 36000<br />

7909 CT.P4.UL 45 68 12 3305 2832 19000 32000<br />

7910 CT.P4.UL 50 72 12 3372 3012 18000 30000<br />

7911 CT.P4.UL 55 80 13 4159 3799 16000 26000<br />

7912 CT.P4.UL 60 85 13 4361 4181 15000 24000<br />

7913 CT.P4.UL 65 90 13 4429 4384 14000 22000<br />

7914 CT.P4.UL 70 100 16 5373 5418 13000 20000<br />

7915 CT.P4.UL 75 105 16 6587 6811 12000 19000<br />

7916 CT.P4.UL 80 110 16 7756 8093 12000 19000<br />

7917 CT.P4.UL 85 120 18 8992 9487 11000 18000<br />

7918 CT.P4.UL 90 125 18 9127 9914 10000 17000<br />

7919 CT.P4.UL 95 130 18 9262 10273 9500 16000<br />

7920 CT.P4.UL 100 140 20 11597 12656 9000 15000<br />

7921 CT.P4.UL 105 145 20 11802 13196 8500 14000<br />

7922 CT.P4.UL 110 150 20 11982 13690 8000 13000<br />

7924 CT.P4.UL 120 165 22 15129 17602 7000 11000<br />

www.<strong>Axis</strong><strong>Bearing</strong>.com 29

<strong>Ball</strong> <strong>Bearing</strong>s<br />

7900 Series – Spindle <strong>Bearing</strong><br />

Pairs<br />

<strong>Bearing</strong><br />

Size<br />

Duplex Load Rating (Lbs.)<br />

Dimensions (mm)<br />

Dynamic Static<br />

d D B Cr Cor<br />

Duplex Limiting Speeds (RPM)<br />

Grease<br />

Oil<br />

7905 CTBP4DUL 25 42 9 2986 2608 25600 38400<br />

7906 CTBP4DUL 30 47 9 3023 2832 22400 34400<br />

7907 CTBP4DUL 35 55 10 5171 4900 19200 30400<br />

7908 CTBP4DUL 40 62 16 5281 5306 17600 28800<br />

7909 CTBP4DUL 45 68 12 5354 5664 15200 25600<br />

7910 CTBP4DUL 50 72 12 5463 6024 14400 24000<br />

7911 CTBP4DUL 55 80 13 6738 7598 12800 20800<br />

7912 CTBP4DUL 60 85 13 7065 8362 12000 19200<br />

7913 CTBP4DUL 65 90 13 7175 8768 11200 17600<br />

7914 CTBP4DUL 70 100 16 8704 10836 10400 16000<br />

7915 CTBP4DUL 75 105 16 10671 13622 9600 15200<br />

7916 CTBP4DUL 80 110 16 12565 16186 9600 15200<br />

7917 CTBP4DUL 85 120 18 14567 18974 8800 14400<br />

7918 CTBP4DUL 90 125 18 14786 19828 8000 13600<br />

7919 CTBP4DUL 95 130 18 15004 20546 7600 12800<br />

7920 CTBP4DUL 100 140 20 18787 25312 7200 12000<br />

7921 CTBP4DUL 105 145 20 19119 26392 6800 11200<br />

7922 CTBP4DUL 110 150 20 19411 27380 6400 10400<br />

7924 CTBP4DUL 120 165 22 24509 35204 5600 8800<br />

30<br />

www.<strong>Axis</strong><strong>Bearing</strong>.com

<strong>Ball</strong> <strong>Bearing</strong>s<br />

87000 Series<br />

<strong>Bearing</strong> Size<br />

Dimensions (mm) Dimensions (inches) Load Rating (Lbs.)<br />

d<br />

D<br />

B1 B2 Dynamic Cr Static Cor<br />

mm inch mm inch B<br />

outer inner Cr Cor<br />

Limiting<br />

Speed (RPM)<br />

Grease<br />

87035 5 0.1969 19 0.7480 0.406 0.315 0.386 524 198 18400<br />

87036 6 0.2362 19 0.7480 0.406 0.315 0.386 524 198 18400<br />

87006 6 0.2362 24 0.9449 0.406 0.315 0.386 747 314 18400<br />

87037 7 0.2756 22 0.8661 0.406 0.315 0.386 740 306 18400<br />

87007 7 0.2756 24 0.9449 0.406 0.315 0.386 747 317 18400<br />

87038 8 0.3150 22 0.8661 0.406 0.315 0.386 740 306 18400<br />

87008 8 0.3150 24 0.9449 0.406 0.315 0.386 747 317 18400<br />

87009 9 0.3543 30 1.1811 0.500 0.354 0.480 1025 438 13600<br />

87500 10 0.3937 30 1.1811 0.500 0.354 0.480 1047 465 13600<br />

87011 11 0.4331 32 1.2598 0.500 0.394 0.480 1047 465 12000<br />

87501 12 0.4724 32 1.2598 0.500 0.394 0.480 1375 626 12000<br />

87013 13 0.5118 32 1.2598 0.500 0.394 0.480 1375 626 12000<br />

87014 14 0.5512 35 1.3780 0.500 0.433 0.480 1375 626 10400<br />

87502 15 0.5906 35 1.3780 0.500 0.433 0.480 1525 747 10400<br />

87016 16 0.6299 35 1.3780 0.500 0.433 0.480 1525 747 10400<br />

87602 15 0.6299 35 1.3780 0.500 0.433 0.480 1525 747 3200<br />

87503 17 0.6693 40 1.5748 0.563 0.472 0.538 1940 976 9600<br />

87603 17 0.6693 47 1.8504 0.630 0.551 0.591 1940 976 8800<br />

87504 20 0.7874 47 1.8504 0.625 0.551 0.600 2885 1494 8000<br />

87604 20 0.7874 52 2.0472 0.748 0.591 0.709 2885 1494 8000<br />

87505 25 0.9843 52 2.0472 0.625 0.591 0.625 3150 1785 7120<br />

87605 25 0.9843 62 2.4409 0.827 0.669 0.827 3150 1785 6480<br />

87026 26 1.0236 52 2.0472 0.625 0.591 0.600 3150 1785 7120<br />

87606 30 1.1811 62 2.8346 0.906 0.748 0.906 1970 1140 4640<br />

87507 35 1.3780 72 2.8346 0.827 0.669 0.787 1970 1140 5040<br />

87607 35 1.3780 80 3.1496 0.984 0.827 0.984 2120 1330 4800<br />

87508 40 1.5748 80 3.1496 0.945 0.827 0.945 2960 1820 4480<br />

87608 40 1.5748 90 3.5433 1.063 0.906 1.063 2960 1820 4240<br />

87509 45 1.7717 85 3.3465 0.945 0.827 0.945 3300 2050 4160<br />

87609 45 1.7717 100 3.9370 1.181 0.984 1.181 3300 2050 3760<br />

87510 50 1.9685 90 3.5433 1.024 0.866 1.024 3560 2350 3760<br />

87511 55 2.1654 100 3.9370 1.063 0.906 1.063 4390 2970 3440<br />

www.<strong>Axis</strong><strong>Bearing</strong>.com 31

<strong>Ball</strong> <strong>Bearing</strong>s<br />

88000 Series<br />

<strong>Bearing</strong> Size<br />

Dimensions (mm) Dimensions (inch) Load Rating (Lbs.)<br />

d D B1 B2 Dynamic Static<br />

mm inch mm inch outer inner Cr Cor<br />

Limiting Speed<br />

(RPM)<br />

Grease<br />

88006 6 0.2362 24 0.9449 0.3150 0.4970 747 314 14400<br />

88007 7 0.2756 24 0.9449 0.3150 0.4970 747 317 14400<br />

88008 8 0.3150 24 0.9449 0.3150 0.4970 747 317 14400<br />

88009 9 0.3543 30 1.1811 0.3543 0.6457 1025 438 10800<br />

88011 11 0.4331 32 1.2598 0.3937 0.6063 1047 465 9600<br />

88013 13 0.5118 32 1.2598 0.3937 0.6063 1375 626 9600<br />

88014 14 0.5512 35 1.3780 0.4331 0.5669 1375 626 9000<br />

88016 16 0.6299 35 1.3780 0.4331 0.5669 1525 747 9000<br />

88026 26 1.0236 52 2.0472 0.5906 0.6594 3150 1785 5340<br />

88035 5 0.1969 19 0.7480 0.3150 0.4970 524 198 18000<br />

88036 6 0.2362 19 0.7480 0.3150 0.4970 524 198 18000<br />

88037 7 0.2756 22 0.8661 0.3150 0.4970 740 306 13800<br />

88038 8 0.3150 22 0.8661 0.3150 0.4970 740 306 13800<br />

88500 10 0.3937 30 1.1811 0.3543 0.6457 1047 465 10800<br />

88501 12 0.4724 32 1.2598 0.3937 0.6063 1375 626 9600<br />

88502 15 0.5906 35 1.3780 0.4331 0.5669 1525 747 9000<br />

88503 17 0.6693 40 1.5748 0.4620 0.6536 1940 976 7200<br />

88504 20 0.7874 47 1.8504 0.5512 0.6988 2885 1494 6000<br />

88505 25 0.9843 52 2.0472 0.5906 0.6594 3150 1785 5340<br />

88506 30 1.1811 62 2.4409 0.6299 0.9449 3150 1785 4380<br />

88507 35 1.3780 72 2.8346 0.6693 0.9843 1970 1140 3780<br />

88508 40 1.5748 80 3.1496 0.8268 1.0630 2960 1820 3360<br />

88509 45 1.7717 85 3.3465 0.8268 1.0630 3300 2050 3120<br />

88510 50 1.9685 90 3.5433 0.8661 1.1811 3560 2350 2820<br />

88511 55 2.1654 100 3.9370 0.9055 1.2205 4390 2970 2580<br />

88603 17 0.6693 47 1.8504 0.5510 0.7807 1940 976 6600<br />

88604 20 0.7874 52 2.0472 0.5910 0.9055 2885 1494 6000<br />

88605 25 0.9843 62 2.4409 0.6690 0.9843 3150 1785 4860<br />

88606 30 1.1811 72 2.8346 0.7480 1.0630 1970 1140 3960<br />

88607 35 1.3780 80 3.1496 0.9843 1.1417 2120 1330 3600<br />

88608 40 1.5748 90 3.5433 1.0630 1.2205 2960 1820 3360<br />

88609 45 1.7717 100 3.9370 1.1811 1.3780 3300 2050 2820<br />

88612 16 0.6299 35 1.3780 0.5000 0.5669 1525 747 2280<br />

32<br />

www.<strong>Axis</strong><strong>Bearing</strong>.com

<strong>Ball</strong> <strong>Bearing</strong>s<br />

WC87000 Series<br />

<strong>Bearing</strong> Size<br />

Dimensions (mm) Dimensions (inch) Load Rating (Lbs.)<br />

d D B1 B2 Dynamic Static<br />

mm inch mm inch outer inner Cr Cor<br />

Limiting Speed<br />

(RPM)<br />

Grease<br />

WC87006 6 0.2362 24 0.9449 0.406 0.386 747 317 18400<br />

WC87007 7 0.2756 24 0.9449 0.406 0.386 747 317 18400<br />

WC87008 8 0.3150 24 0.9449 0.406 0.386 747 317 18400<br />

WC87009 9 0.3543 30 1.1811 0.500 0.480 1047 465 13600<br />

WC87011 11 0.4331 32 1.2598 0.500 0.480 1375 626 12000<br />

WC87013 13 0.5118 32 1.2598 0.500 0.480 1375 626 12000<br />

WC87014 14 0.5512 35 1.3780 0.500 0.480 1525 747 10400<br />

WC87016 16 0.6299 35 1.3780 0.500 0.480 1525 747 10400<br />

WC87026 26 1.0236 52 2.0472 0.625 0.600 3150 1785 7120<br />

WC87035 5 0.1969 19 0.7480 0.406 0.386 524 198 18400<br />

WC87036 6 0.2362 19 0.7480 0.406 0.386 524 198 18400<br />

WC87037 7 0.2756 22 0.8661 0.406 0.386 740 306 18400<br />

WC87038 8 0.3150 22 0.8661 0.406 0.386 740 306 18400<br />

WC87039 9 0.3543 26 1.0236 0.406 0.386 1025 438 13600<br />

WC87500 10 0.3937 30 1.1811 0.500 0.480 1047 465 13600<br />

WC87501 12 0.4724 32 1.2598 0.500 0.480 1375 626 12000<br />

WC87502 15 0.5906 35 1.3780 0.500 0.480 1525 747 10400<br />

WC87503 17 0.6693 40 1.5748 0.563 0.538 2149 1075 9600<br />

WC87603 17 0.6693 47 1.8504 0.630 0.709 3050 1470 6600<br />

WC87504 20 0.7874 47 1.8504 0.625 0.600 2885 1494 8000<br />

WC87604 20 0.7874 52 2.0472 0.748 0.906 3600 1770 6000<br />

WC87505 25 0.9843 52 2.0472 0.625 0.600 3150 1785 7120<br />

WC87506 30 1.1811 62 2.4409 0.787 0.748 3363 2256 7120<br />

WC87507 35 1.3780 72 2.8346 0.827 0.787 2120 1330 6400<br />

WC87508 40 1.5748 80 3.1496 0.945 0.945 2960 1820 6000<br />

WC87509 45 1.7717 85 3.3465 0.945 0.945 3300 2050 5280<br />

WC87510 50 1.9685 90 3.5433 1.024 1.024 3560 2350 3600<br />

WC87511 55 2.1654 100 3.9370 1.063 1.063 4390 2970 3440<br />

www.<strong>Axis</strong><strong>Bearing</strong>.com 33

<strong>Ball</strong> <strong>Bearing</strong>s<br />

WC88000 Series<br />

<strong>Bearing</strong> Size<br />

Dimensions (mm) Dimensions (inch) Load Rating (Lbs.)<br />

d D B1 B2 Dynamic Static<br />

mm inch mm inch outer inner Cr Cor<br />

Limiting Speed<br />

(RPM)<br />

Grease<br />

WC88006 6 0.2362 24 0.9449 0.406 0.4970 747 317 13800<br />

WC88007 7 0.2756 24 0.9449 0.406 0.4970 747 317 13800<br />

WC88008 8 0.3150 24 0.9449 0.406 0.4970 747 317 13800<br />

WC88009 9 0.3543 30 1.1811 0.500 0.6457 1047 465 10200<br />

WC88011 11 0.4331 32 1.2598 0.500 0.6457 1375 626 9000<br />

WC88013 13 0.5118 32 1.2598 0.500 0.6457 1375 626 9000<br />

WC88014 14 0.5512 35 1.3780 0.500 0.6457 1525 747 7800<br />

WC88016 16 0.6299 35 1.3780 0.500 0.6457 1525 747 7800<br />

WC88026 26 1.0236 52 2.0472 0.625 0.6988 3150 1785 5340<br />

WC88035 5 0.1969 19 0.7480 0.406 0.4970 524 198 13800<br />

WC88036 6 0.2362 19 0.7480 0.406 0.4970 524 198 13800<br />

WC88037 7 0.2756 22 0.8661 0.406 0.4970 740 306 13800<br />

WC88038 8 0.3150 22 0.8661 0.406 0.4970 740 306 13800<br />

WC88039 9 0.3543 26 1.0236 0.406 0.4970 1025 438 10200<br />

WC88500 10 0.3937 30 1.1811 0.500 0.6457 1047 465 10200<br />

WC88501 12 0.4724 32 1.2598 0.500 0.6457 1375 626 9000<br />

WC88502 15 0.5906 35 1.3780 0.500 0.6457 1525 747 7800<br />

WC88503 17 0.6693 40 1.5748 0.563 0.6536 2149 1075 7200<br />

WC88603 17 0.6693 47 1.8504 0.630 0.7087 3050 1470 6600<br />

WC88504 20 0.7874 47 1.8504 0.625 0.6988 2885 1494 6000<br />

WC88604 20 0.7087 52 2.0472 0.748 0.9055 3600 1770 6000<br />

WC88505 25 0.9843 52 2.0472 0.625 0.6988 3150 1785 5340<br />

WC88506 30 1.1811 62 2.4409 0.787 0.9449 3363 2256 4380<br />

WC88507 35 1.3780 72 2.8346 0.827 0.9843 2120 1330 3780<br />

WC88508 40 1.5748 80 3.1496 0.945 1.0630 2960 1820 3360<br />

WC88509 45 1.7717 85 3.3465 0.945 1.0630 3300 2050 3120<br />

WC88510 50 1.9685 90 3.5433 1.024 1.1811 3560 2350 2820<br />

WC88511 55 2.1654 100 3.9370 1.063 1.2205 4390 2970 2580<br />

34<br />

www.<strong>Axis</strong><strong>Bearing</strong>.com

<strong>Ball</strong> <strong>Bearing</strong>s<br />

R Series - inch<br />

B Load Rating (Lbs.) Limiting Speed (RPM)<br />

<strong>Bearing</strong> Size d D<br />

Open (Inch)<br />

Sealed /<br />

Shielded (Inch)<br />

Dynamic Static Grease Oil<br />

Cr Cor 2RS ZZ/OPEN OPEN<br />

R2 1/8 3/8 0.1562 0.1562 140 49 29400 58000 49000<br />

R2A 1/8 1/2 0.1719 0.1719 255 90 19200 51000 32000<br />

R3 3/16 1/2 0.1562 0.196 292 109 24600 48000 41000<br />

R3A 3/16 1/2 0.196 0.196 292 109 24600 48000 41000<br />

R4 1/4 5/8 0.196 0.196 360 150 21600 43000 36000<br />

R4A 1/4 3/4 0.2188 0.2812 590 239 20400 40000 34000<br />

R6 3/8 7/8 0.2188 0.2812 750 315 18600 27000 31000<br />

R8 1/2 1 1/8 0.25 0.3125 1150 540 15600 20000 26000<br />

R10 5/8 1 3/8 0.2812 0.3438 1340 728 12000 13000 20000<br />

R12 3/4 1 5/8 0.3125 0.4375 2110 1120 10800 21000 18000<br />

R14 7/8 1 7/8 0.375 0.5 2270 1310 9000 18000 15000<br />

R16 1 2 0.375 0.5 2270 1310 8400 16000 14000<br />

R18 1 1/8 2 1/8 0.375 0.5 2980 1860 7800 1500 13000<br />

R20 1 1/4 2 1/4 0.375 0.5 2980 1860 7200 12000 14000<br />

R22 1 3/8 2 1/2 0.4375 0.5625 3590 2320 7500 12500 11000<br />

R24 1 1/2 2 5/8 0.4375 0.5625 3770 2590 6900 11500 10000<br />

www.<strong>Axis</strong><strong>Bearing</strong>.com 35

<strong>Ball</strong> <strong>Bearing</strong>s<br />

RLS Series - inch<br />

Dimensions (inch)<br />

Dynamic<br />

Load Rating (Lbs.)<br />

Static<br />

Limiting Speed<br />

(RPM)<br />

<strong>Bearing</strong> Size<br />

d D B<br />

Cr<br />

Cor<br />

OPEN<br />

RLS4 1/2 1 5/16 3/8 316 703 32000<br />

RLS5 5/8 1 9/16 7/16 459 976 24000<br />

RLS6 3/4 1 7/8 9/16 633 1296 20000<br />

RLS7 7/8 2 9/16 765 1541 19000<br />

RLS8 1 2 1/4 3/8 898 1816 17000<br />

RLS9 1 1/8 2 1/2 3/8 1020 1990 15000<br />

RLS10 1 1/4 2 3/4 11/16 1204 2296 14000<br />

RLS11 1 3/8 3 11/16 1398 2602 13000<br />

RLS12 1 1/2 3 1/4 3/4 1694 3133 11000<br />

RLS13 1 5/8 3 1/2 3/4 1898 3388 11000<br />

RLS14 1 3/4 3 3/4 13/16 2000 3582 10000<br />

RLS16 2 4 13/16 2551 4449 10000<br />

RLS18 2 1/4 4 1/2 7/8 2857 4847 8000<br />

RLS20 2 1/2 5 15/16 3327 6306 7000<br />

RLS22 2 3/4 5 1/4 15/16 4133 6765 6400<br />

RLS24 3 5 3/4 1 1/16 4592 7163 6000<br />

RLS26 3 1/4 6 1 1/16 5408 8490 5800<br />

RLS28 3 1/2 6 1/2 1 1/8 6327 9755 5300<br />

RLS30 3 3/4 6 3/4 1 1/8 7092 11020 5000<br />

RLS32 4 7 1/4 1 1/4 8163 12653 4700<br />

RLS34 4 1/4 7 1/2 1 1/4 8316 12653 4500<br />

RLS36 4 1/2 8 1 5/16 8827 13265 4300<br />

RLS38 4 3/4 8 1/4 1 5/16 9694 14082 4100<br />

RLS40 5 9 1 3/8 11020 15102 3800<br />

RLS44 5 1/2 9 1/2 1 3/8 11837 15918 3600<br />

RLS48 6 10 1/2 1 9/16 13980 17755 3200<br />

RLS52 6 1/2 11 1 9/16 15306 18980 3000<br />

36<br />

www.<strong>Axis</strong><strong>Bearing</strong>.com

<strong>Ball</strong> <strong>Bearing</strong>s<br />

RMS Series - inch<br />

<strong>Bearing</strong> Size<br />

Load Rating (Lbs.)<br />

Dimensions (inch)<br />

Dynamic<br />

Static<br />

d D B Cr Cor<br />

Limiting Speed<br />

(RPM)<br />

OPEN<br />

RMS4 1/2 1 5/8 5/8 510 1163 23000<br />

RMS5 5/8 1 13/16 5/8 668 1378 22000<br />

RMS6 3/4 2 11/16 796 1622 19000<br />

RMS7 7/8 2 1/4 11/16 934 1898 18000<br />

RMS8 1 2 1/2 3/4 1163 2296 16000<br />

RMS9 1 1/8 2 13/16 13/16 1490 2867 13000<br />

RMS10 1 1/4 3 1/8 7/8 1837 3388 12000<br />

RMS11 1 3/8 3 1/2 7/8 2286 4184 11000<br />

RMS12 1 1/2 3 3/4 15/16 2286 4184 11000<br />

RMS13 1 5/8 4 15/16 3061 5378 9500<br />

RMS14 1 3/4 4 1/4 1 1/16 3673 6306 8500<br />

RMS15 1 7/8 4 1/2 1 1/16 3622 6306 6800<br />

RMS16 2 4 1/2 1 1/16 3673 6306 6700<br />

RMS18 2 1/4 5 1 1/4 4898 8357 7000<br />

RMS20 2 1/2 5 1/2 1 1/4 5714 9418 6700<br />

RMS22 2 3/4 6 1/4 1 3/8 6429 10612 6300<br />

RMS24 3 7 1 9/16 8163 12653 5300<br />

RMS26 3 1/4 7 1/2 1 9/16 10000 14592 5000<br />

RMS27 3 3/8 7 1/2 1 9/16 10000 14592 5000<br />

RMS28 3 1/2 8 1/8 1 3/4 11224 15612 4500<br />

RMS30 3 3/4 8 1/4 1 3/4 11020 15612 4400<br />

RMS32 4 8 1/2 1 3/4 13469 17755 4300<br />

RMS34 4 1/4 8 3/4 1 3/4 13469 17755 4000<br />

RMS36 4 1/2 9 3/8 2 16936 20714 3800<br />

www.<strong>Axis</strong><strong>Bearing</strong>.com 37

Engineering Section<br />

Snap Ring & Groove Dimensions<br />

t<br />

d<br />

x<br />

A<br />

a<br />

b<br />

s<br />

Basic <strong>Bearing</strong><br />

6900 6000 6200 6300<br />

Dimensions of Ring, Groove and Housing<br />

Groove Ring Counter-bore<br />

a b s d t x<br />

inch mm inch mm<br />

+/-<br />

0.002<br />

+/-<br />

0.05 Minimum<br />

max min max min max min max min inch mm inch mm inch mm inch mm<br />

6900 0.041 0.035 1.05 0.90 0.041 0.031 1.05 0.80 0.008 0.20 0.98 25.0 0.026 0.65 1.016 25.8<br />

6901 0.041 0.035 1.05 0.90 0.041 0.031 1.05 0.80 0.008 0.20 1.06 27.0 0.026 0.65 1.094 27.8<br />

6902 0.051 0.045 1.30 1.15 0.047 0.037 1.20 0.95 0.010 0.25 1.20 30.6 0.031 0.80 1.234 31.3<br />

6001 0.068 0.062 1.73 1.57 0.047 0.037 1.20 0.95 0.016 0.40 1.20 30.6 0.031 0.80 1.234 31.3<br />

6903 0.051 0.045 1.30 1.15 0.047 0.037 1.20 0.95 0.010 0.25 1.28 32.5 0.031 0.80 1.312 33.3<br />

6200 0.081 0.075 2.06 1.90 0.065 0.053 1.65 1.35 0.016 0.40 1.36 34.5 0.042 1.07 1.391 35.3<br />

6002 6201 0.081 0.075 2.06 1.90 0.065 0.053 1.65 1.35 0.016 0.40 1.44 36.5 0.042 1.07 1.469 37.3<br />

6003 6202 6300 0.081 0.075 2.06 1.90 0.065 0.053 1.20 1.35 0.016 0.40 1.55 39.3 0.042 1.07 1.578 40.0<br />

6904 0.067 0.061 1.70 1.55 0.047 0.037 1.65 0.95 0.010 0.25 1.56 39.7 0.031 0.80 1.594 40.5<br />

6301 0.081 0.075 2.06 1.90 0.065 0.053 1.65 1.35 0.016 0.40 1.61 40.9 0.042 1.07 1.641 41.7<br />

6203 0.081 0.075 2.06 1.90 0.065 0.053 1.20 1.35 0.016 0.40 1.75 44.5 0.042 1.07 1.781 45.2<br />

6905 0.067 0.061 1.70 1.55 0.047 0.037 1.65 0.95 0.010 0.25 1.75 44.5 0.031 0.80 1.781 45.2<br />

6004 6302 0.081 0.075 2.06 1.90 0.065 0.053 1.65 1.35 0.016 0.40 1.81 46.0 0.042 1.07 1.844 46.8<br />

6906 0.067 0.061 1.70 1.55 0.047 0.037 1.20 0.95 0.010 0.25 1.95 49.6 0.031 0.80 1.984 50.4<br />

6005 0.081 0.075 2.06 1.90 0.065 0.053 1.65 1.35 0.016 0.40 2.06 52.4 0.042 1.07 2.094 53.2<br />

6204 6303 0.097 0.091 2.46 2.31 0.065 0.053 1.65 1.35 0.016 0.40 2.06 52.4 0.042 1.07 2.094 53.2<br />

6205 6304 0.097 0.091 2.46 2.31 0.065 0.053 1.65 1.35 0.016 0.40 2.27 57.6 0.042 1.07 2.297 58.3<br />

6907 0.067 0.061 1.70 1.55 0.047 0.037 1.20 0.95 0.010 0.25 2.28 57.9 0.031 0.80 2.312 58.7<br />

6006 0.082 0.074 2.08 1.88 0.065 0.053 1.65 1.35 0.016 0.40 2.38 60.3 0.042 1.07 2.406 61.1<br />

6908 0.067 0.061 1.70 1.55 0.047 0.037 1.20 0.95 0.010 0.25 2.56 65.1 0.031 0.80 2.594 65.9<br />

6007 0.082 0.074 2.08 1.88 0.087 0.075 2.20 1.90 0.024 0.60 2.66 67.5 0.065 1.65 2.688 68.3<br />

6206 6305 0.129 0.121 3.28 3.07 0.087 0.075 2.20 1.90 0.024 0.60 2.66 67.5 0.065 1.65 2.688 68.3<br />

6909 0.067 0.061 1.70 1.55 0.047 0.037 1.20 0.95 0.010 0.25 2.80 71.0 0.031 0.80 2.828 71.8<br />

6008 0.098 0.090 2.49 2.20 0.087 0.075 2.20 1.90 0.024 0.60 2.92 74.2 0.065 1.65 2.984 75.8<br />

6910 0.067 0.061 1.70 1.55 0.047 0.037 1.20 0.95 0.010 0.25 2.95 75.0 0.031 0.80 2.984 75.8<br />

6207 6306 0.129 0.121 3.28 3.07 0.087 0.075 2.20 1.90 0.024 0.60 3.08 78.2 0.065 1.65 3.141 79.8<br />

6009 0.098 0.090 2.49 2.20 0.087 0.075 2.20 1.90 0.024 0.60 3.20 81.4 0.065 1.65 3.266 83.0<br />

6911 0.083 0.075 2.11 1.90 0.063 0.051 1.60 1.30 0.016 0.40 3.31 84.1 0.042 1.07 3.375 85.7<br />

38<br />

www.<strong>Axis</strong><strong>Bearing</strong>.com

Engineering Section<br />

Snap Ring & Groove Dimensions<br />

t<br />

d<br />

x<br />

A<br />

a<br />

b<br />

s<br />

Basic <strong>Bearing</strong><br />

6900 6000 6200 6300<br />

Dimensions of Ring, Groove and Housing<br />

Groove Ring Counter-bore<br />

a b s d t x<br />

inch mm inch mm<br />

+/-<br />

0.002<br />

+/-<br />

0.05 Minimum<br />

max min max min max min max min inch mm inch mm inch mm inch mm<br />

6010 0.098 0.090 2.49 2.20 0.087 0.075 2.20 1.90 0.024 0.60 3.40 86.5 0.065 1.65 3.469 88.1<br />

6208 6307 0.129 0.121 3.28 3.07 0.087 0.075 2.20 1.90 0.024 0.60 3.40 86.5 0.065 1.65 3.469 88.1<br />

6912 0.083 0.075 2.10 1.90 0.063 0.051 1.60 1.30 0.016 0.40 3.52 89.3 0.042 1.07 3.578 90.9<br />

6209 0.129 0.121 3.28 3.07 0.087 0.075 2.20 1.90 0.024 0.60 3.59 91.3 0.065 1.65 3.656 92.9<br />

6913 0.083 0.075 2.10 1.90 0.063 0.051 1.60 1.30 0.016 0.40 3.70 94.1 0.042 1.07 3.766 95.7<br />

6011 0.113 0.105 2.87 2.67 0.118 0.106 3.00 2.70 0.024 0.60 3.80 96.4 0.095 2.41 3.859 98.0<br />

6210 6308 0.129 0.121 3.28 3.07 0.118 0.106 3.00 2.70 0.024 0.60 3.80 96.4 0.095 2.41 3.859 98.0<br />

6012 0.113 0.105 2.87 2.67 0.118 0.106 3.00 2.70 0.024 0.60 3.98 101.2 0.095 2.41 4.047 102.9<br />

6914 0.098 0.090 2.50 2.30 0.063 0.051 1.60 1.30 0.016 0.40 4.11 104.4 0.042 1.07 4.172 106.0<br />

6013 0.113 0.105 2.87 2.67 0.118 0.106 3.00 2.70 0.024 0.60 4.19 106.4 0.095 2.41 4.250 108.0<br />

6211 6309 0.129 0.121 3.28 2.67 0.118 0.106 3.00 2.70 0.024 0.60 4.19 106.4 0.095 2.41 4.250 108.0<br />

6915 0.098 0.090 2.50 2.30 0.063 0.051 1.60 1.30 0.016 0.40 4.36 110.7 0.042 1.07 4.422 112.3<br />

6916 0.098 0.090 2.50 2.30 0.063 0.051 1.60 1.30 0.016 0.40 4.55 115.5 0.042 1.07 4.609 117.1<br />

6014 0.113 0.105 2.87 2.67 0.118 0.106 3.00 2.70 0.024 0.60 4.58 116.3 0.095 2.41 4.641 117.9<br />

6212 6310 0.129 0.121 3.28 3.07 0.118 0.106 3.00 2.70 0.024 0.60 4.58 116.3 0.095 2.41 4.641 117.9<br />

6015 0.113 0.105 2.87 2.67 0.118 0.106 3.00 2.70 0.024 0.60 4.78 121.4 0.095 2.41 4.844 123.0<br />

6917 0.130 0.122 3.30 3.10 0.063 0.051 1.60 1.30 0.016 0.40 4.94 125.4 0.042 1.07 5.000 127.0<br />

6213 6311 0.160 0.152 4.06 3.86 0.134 0.122 3.40 3.10 0.024 0.60 5.09 129.4 0.109 2.77 5.156 131.0<br />

6918 0.130 0.122 3.30 3.10 0.063 0.051 1.60 1.30 0.016 0.40 5.14 130.6 0.042 1.07 5.203 132.2<br />

6016 0.113 0.105 2.87 2.67 0.134 0.122 3.40 3.10 0.024 0.60 5.30 134.5 0.109 2.77 5.359 136.1<br />

6214 0.160 0.152 4.06 3.86 0.134 0.122 3.40 3.10 0.024 0.60 5.30 134.5 0.109 2.77 5.359 136.1<br />

6919 0.130 0.122 3.30 2.10 0.063 0.051 1.60 1.30 0.016 0.40 5.33 135.3 0.042 1.07 5.391 136.9<br />

6017 0.113 0.105 2.87 2.67 0.134 0.122 3.40 3.10 0.024 0.60 5.50 139.7 0.109 2.77 5.562 141.3<br />

6215 6312 0.160 0.152 4.06 3.86 0.134 0.122 3.40 3.10 0.024 0.60 5.50 139.7 0.109 2.77 5.562 141.3<br />

6920 0.130 0.122 3.30 3.10 0.087 0.075 2.20 1.90 0.024 0.60 5.73 145.7 0.065 1.65 5.797 147.2<br />

6018 0.113 0.136 3.71 3.45 0.134 0.122 3.40 3.10 0.024 0.60 5.89 149.6 0.109 2.77 5.953 151.2<br />

6216 6313 0.193 0.183 4.90 4.65 0.134 0.122 3.40 3.10 0.024 0.60 5.89 149.6 0.109 2.77 5.953 151.2<br />

www.<strong>Axis</strong><strong>Bearing</strong>.com 39

Engineering Section<br />

Snap Ring & Groove Dimensions<br />

t<br />

d<br />

x<br />

A<br />

a<br />

b<br />

s<br />

Basic <strong>Bearing</strong><br />

6900 6000 6200 6300<br />

Dimensions of Ring, Groove and Housing<br />

Groove Ring Counter-bore<br />

a b s d t x<br />

inch mm inch mm<br />

+/-<br />

0.002<br />

+/-<br />

0.05 Minimum<br />

max min max min max min max min inch mm inch mm inch mm inch mm<br />

6921 0.130 0.122 3.30 3.10 0.087 0.075 2.50 1.90 0.024 0.60 5.92 150.4 0.065 1.65 5.984 152.0<br />

6019 0.146 0.136 3.71 3.45 0.134 0.122 3.40 3.10 0.024 0.60 6.08 154.4 0.109 2.77 6.141 156.0<br />

6922 0.130 0.122 4.90 3.10 0.087 0.075 2.20 1.90 0.024 0.60 6.13 155.6 0.065 1.65 6.188 157.2<br />

6020 0.146 0.136 3.30 3.45 0.134 0.122 3.40 3.10 0.024 0.60 6.28 159.5 0.109 2.77 6.344 161.1<br />

6217 6314 0.193 0.183 3.71 4.65 0.134 0.122 3.40 3.10 0.024 0.60 6.28 159.5 0.109 2.77 6.344 161.1<br />