- Page 1 and 2: EU-SICHERHEITSDATENBLATT gemäß Ve

- Page 3 and 4: EU-SICHERHEITSDATENBLATT gemäß Ve

- Page 5 and 6: EU-SICHERHEITSDATENBLATT gemäß Ve

- Page 7 and 8: EU-SICHERHEITSDATENBLATT gemäß Ve

- Page 9 and 10: EU-SICHERHEITSDATENBLATT gemäß Ve

- Page 11 and 12: EU-SICHERHEITSDATENBLATT gemäß Ve

- Page 13 and 14: EU-SICHERHEITSDATENBLATT gemäß Ve

- Page 15 and 16: Vacuum Gas Oils, Hydrocracked Gas O

- Page 17 and 18: Vacuum Gas Oils, Hydrocracked Gas O

- Page 19 and 20: Vacuum Gas Oils, Hydrocracked Gas O

- Page 21 and 22: Vacuum Gas Oils, Hydrocracked Gas O

- Page 23 and 24: Vacuum Gas Oils, Hydrocracked Gas O

- Page 25 and 26: Vacuum Gas Oils, Hydrocracked Gas O

- Page 27 and 28: Vacuum Gas Oils, Hydrocracked Gas O

- Page 29 and 30: Vacuum Gas Oils, Hydrocracked Gas O

- Page 31 and 32: Vacuum Gas Oils, Hydrocracked Gas O

- Page 33 and 34: Vacuum Gas Oils, Hydrocracked Gas O

- Page 35 and 36: Vacuum Gas Oils, Hydrocracked Gas O

- Page 37 and 38: Vacuum Gas Oils, Hydrocracked Gas O

- Page 39 and 40: Vacuum Gas Oils, Hydrocracked Gas O

- Page 41 and 42: Vacuum Gas Oils, Hydrocracked Gas O

- Page 43: Vacuum Gas Oils, Hydrocracked Gas O

- Page 47 and 48: Vacuum Gas Oils, Hydrocracked Gas O

- Page 49 and 50: Vacuum Gas Oils, Hydrocracked Gas O

- Page 51 and 52: Vacuum Gas Oils, Hydrocracked Gas O

- Page 53 and 54: Vacuum Gas Oils, Hydrocracked Gas O

- Page 55 and 56: Vacuum Gas Oils, Hydrocracked Gas O

- Page 57 and 58: Vacuum Gas Oils, Hydrocracked Gas O

- Page 59 and 60: Vacuum Gas Oils, Hydrocracked Gas O

- Page 61 and 62: Vacuum Gas Oils, Hydrocracked Gas O

- Page 63 and 64: Vacuum Gas Oils, Hydrocracked Gas O

- Page 65 and 66: Vacuum Gas Oils, Hydrocracked Gas O

- Page 67 and 68: Vacuum Gas Oils, Hydrocracked Gas O

- Page 69 and 70: Vacuum Gas Oils, Hydrocracked Gas O

- Page 71 and 72: Vacuum Gas Oils, Hydrocracked Gas O

- Page 73 and 74: Vacuum Gas Oils, Hydrocracked Gas O

- Page 75 and 76: Vacuum Gas Oils, Hydrocracked Gas O

- Page 77 and 78: Vacuum Gas Oils, Hydrocracked Gas O

- Page 79 and 80: Vacuum Gas Oils, Hydrocracked Gas O

- Page 81 and 82: Vacuum Gas Oils, Hydrocracked Gas O

- Page 83 and 84: Vacuum Gas Oils, Hydrocracked Gas O

- Page 85 and 86: Vacuum Gas Oils, Hydrocracked Gas O

- Page 87 and 88: Vacuum Gas Oils, Hydrocracked Gas O

- Page 89 and 90: Vacuum Gas Oils, Hydrocracked Gas O

- Page 91 and 92: Vacuum Gas Oils, Hydrocracked Gas O

- Page 93 and 94: Vacuum Gas Oils, Hydrocracked Gas O

- Page 95 and 96:

Vacuum Gas Oils, Hydrocracked Gas O

- Page 97 and 98:

Vacuum Gas Oils, Hydrocracked Gas O

- Page 99 and 100:

Vacuum Gas Oils, Hydrocracked Gas O

- Page 101 and 102:

Vacuum Gas Oils, Hydrocracked Gas O

- Page 103 and 104:

Vacuum Gas Oils, Hydrocracked Gas O

- Page 105 and 106:

Vacuum Gas Oils, Hydrocracked Gas O

- Page 107 and 108:

Vacuum Gas Oils, Hydrocracked Gas O

- Page 109 and 110:

Vacuum Gas Oils, Hydrocracked Gas O

- Page 111 and 112:

Vacuum Gas Oils, Hydrocracked Gas O

- Page 113 and 114:

Vacuum Gas Oils, Hydrocracked Gas O

- Page 115 and 116:

Vacuum Gas Oils, Hydrocracked Gas O

- Page 117 and 118:

Vacuum Gas Oils, Hydrocracked Gas O

- Page 119 and 120:

Vacuum Gas Oils, Hydrocracked Gas O

- Page 121 and 122:

Vacuum Gas Oils, Hydrocracked Gas O

- Page 123 and 124:

Gas Oils (Vacuum) 4 DNEL (inhalatio

- Page 125 and 126:

Industrial - Tabletting, CS100 Indo

- Page 127 and 128:

Combined Professional - Manual spra

- Page 129 and 130:

Industrial - Bulk transfers CS14 Da

- Page 131 and 132:

Professional - Maintenance and CS77

- Page 133 and 134:

Note: differentiated Industrial -SU

- Page 135 and 136:

Professional - Treatment and dispos

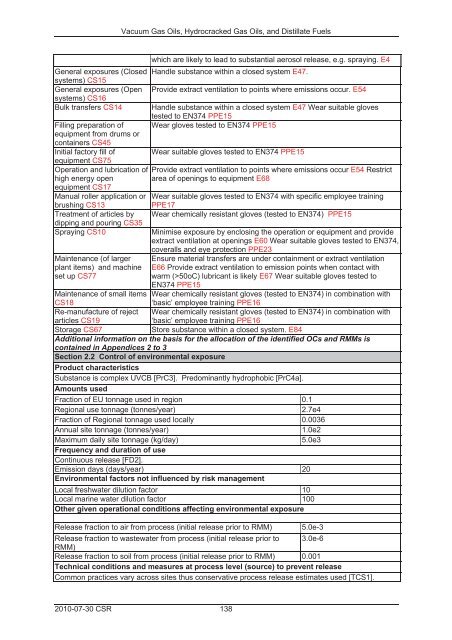

- Page 137 and 138:

Industrial - operation of open CS16

- Page 139 and 140:

Vacuum Gas Oils, Hydrocracked Gas O

- Page 141 and 142:

Vacuum Gas Oils, Hydrocracked Gas O

- Page 143 and 144:

Vacuum Gas Oils, Hydrocracked Gas O

- Page 145 and 146:

Gas Oils (Vacuum) 4 DNEL (inhalatio

- Page 147 and 148:

Industrial - Tabletting, CS100 Indo

- Page 149 and 150:

Combined Professional - Manual spra

- Page 151 and 152:

Industrial - Bulk transfers CS14 Da

- Page 153 and 154:

Professional - Maintenance and CS77

- Page 155 and 156:

Note: differentiated Industrial -SU

- Page 157 and 158:

Professional - Treatment and dispos

- Page 159 and 160:

Industrial - operation of open CS16

- Page 161 and 162:

Vacuum Gas Oils, Hydrocracked Gas O

- Page 163 and 164:

Vacuum Gas Oils, Hydrocracked Gas O

- Page 165 and 166:

This tool is provided for informati

- Page 167 and 168:

An Evaluation of the Persistence, B

- Page 169 and 170:

Table of Contents Executive Summary

- Page 171 and 172:

2.0 Outline of PBT/vPvB Assessment

- Page 173 and 174:

3.0 Persistence Assessment of Petro

- Page 175 and 176:

100.0 Half-life predicted (days) 10

- Page 177 and 178:

2,3-dimethylheptane 9 7.7 6.2 7.4 2

- Page 179 and 180:

ioHCwin half-life (days) 10000.0 10

- Page 181 and 182:

criterion. It can be concluded that

- Page 183 and 184:

ioHCwin half-life (days) 100000.0 1

- Page 185 and 186:

Hydrocarbon C nr BioHCwin Predicted

- Page 187 and 188:

ioHCwin half-life (days) 1000000.0

- Page 189 and 190:

ioHCwin half-life (days) 1000.0 100

- Page 191 and 192:

Hydrocarbon C nr BioHCwin Predicted

- Page 193 and 194:

enzo[a]pyrene 20 421.6 16.5 Table 1

- Page 195 and 196:

(see Appendix 2). Since BCF predict

- Page 197 and 198:

10000 BCF (Arnot) 1000 100 10 1 n-P

- Page 199 and 200:

exhibit BMFs near unity (Figure 28)

- Page 201 and 202:

2,2,4,4,6,8,8- heptamethyl nonane 1

- Page 203 and 204:

Hydrocarbon C BMF BCF (Arnot) Dieta

- Page 205 and 206:

BCF (regression) 100000 10000 1000

- Page 207 and 208:

4.5 Polynaphthenic hydrocarbons Reg

- Page 209 and 210:

Experimental BMF 10 1 Polynaphth. D

- Page 211 and 212:

enzene n-octylbenzene 14 0.034 403

- Page 213 and 214:

10000 1000 BCF (Arnot) 100 10 1 NMA

- Page 215 and 216:

and appears to be an outlier. This

- Page 217 and 218:

4-ethylbiphenyl 14 863 1039 C Yakat

- Page 219 and 220:

100000 BCF (regression) 10000 1000

- Page 221 and 222:

10 Experimental BMF 1 0.1 NDiAr Die

- Page 223 and 224:

Hydrocarbon C BMF Arnot BCF Dietary

- Page 225 and 226:

Hydrocarbon C BMF Arnot BCF Dietary

- Page 227 and 228:

Acenaphthene Acenaphthylene Benz(a)

- Page 229 and 230:

5.0 Summary of Persistence and Bioa

- Page 231 and 232:

lower water solubility, it is possi

- Page 233 and 234:

properties of petroleum hydrocarbon

- Page 235 and 236:

8.0 References Anonymous (2004). Fi

- Page 237 and 238:

EMBSI (2007c). Fish, dietary bioacc

- Page 239 and 240:

Prince RC, Walters CC. (2007). Biod

- Page 241 and 242:

Appendix 1. Hydrocarbon structures

- Page 243 and 244:

iP 14 2,4,10-Trimethylundecane CC(C

- Page 245 and 246:

MN 7 1,2-Dimethylcyclopentane CC1C(

- Page 247 and 248:

MN 14 n-Nonylcyclopentane CCCCCCCCC

- Page 249 and 250:

MN 29 MN 29 MN 30 n-Tetracosylcyclo

- Page 251 and 252:

hexahydroindane DN 20 2,4-dimethylo

- Page 253 and 254:

PN 27 Phenanthrene 2,6-dimethylhept

- Page 255 and 256:

MAr 13 1-Methyl-3-hexylbenzene Cc1c

- Page 257 and 258:

NMAr 12 n-Propylindan c1ccc2CC(CCC)

- Page 259 and 260:

NMAr 24 c1cc(CC(C)CCCC(C)CCCCC)c2CC

- Page 261 and 262:

NMAr 29 NMAr 29 NMAr 29 NMAr 29 NMA

- Page 263 and 264:

DAr 16 2-Hexylnaphthalene CCCCCCc1c

- Page 265 and 266:

NDAr 16 n-Butylacenaphthene c12cccc

- Page 267 and 268:

NDAr 26 Dimethyloctyl-1,2,3,6,7,8-

- Page 269 and 270:

PAr 19 Ethylbenzo(a)fluorene C3c1cc

- Page 271 and 272:

PAr 22 n-Pentylbenzo(a)fluorene C3c

- Page 273 and 274:

PAr 28 Isohexyl-octadecahydro-picen

- Page 275 and 276:

Appendix 3. CONCAWE Position Paper

- Page 277 and 278:

probabilities are adjusted to best

- Page 279 and 280:

1.2.2 OASIS LMC Models: Toxicologic

- Page 281 and 282:

environmental chemicals (database o

- Page 283 and 284:

dihydrodiol. These dihydroxylated i

- Page 285 and 286:

Table 1 : PBT assessment of C15 str

- Page 287 and 288:

1: The following structures were pr

- Page 289 and 290:

Dimitrov SD, Dimitrova N, Mekenyan

- Page 291 and 292:

hydrocarbons and azaarenes original

- Page 293 and 294:

Verhaar HJM, van Leeuwen CJ, Hermen

- Page 295 and 296:

CONCAWE AQUATIC TOXICITY PREDICTION

- Page 297 and 298:

CONTENTS (Continued) Section Page 1

- Page 299 and 300:

1-2 The model predictions include m

- Page 301 and 302:

2-1 SECTION 2 2 SUMMARY OF COMPOSIT

- Page 303 and 304:

4-1 SECTION 4 4 SUMMARY OF COMPOSIT

- Page 305 and 306:

6-1 SECTION 6 6 SUMMARY OF COMPOSIT

- Page 307 and 308:

8-1 SECTION 8 8 SUMMARY OF COMPOSIT

- Page 309 and 310:

10-1 SECTION 10 10 SUMMARY OF COMPO

- Page 311 and 312:

12-1 SECTION 12 12 SUMMARY OF COMPO

- Page 313 and 314:

14-1 SECTION 14 14 SUMMARY OF COMPO

- Page 315 and 316:

16-1 SECTION 16 16 SUMMARY OF COMPO

- Page 317 and 318:

18-1 SECTION 18 18 SUMMARY OF COMPO

- Page 319:

20-1 SECTION 20 20 SUMMARY OF COMPO