EU-SICHERHEITSDATENBLATT Dieselkraftstoff ... - Schmierstoffe

EU-SICHERHEITSDATENBLATT Dieselkraftstoff ... - Schmierstoffe EU-SICHERHEITSDATENBLATT Dieselkraftstoff ... - Schmierstoffe

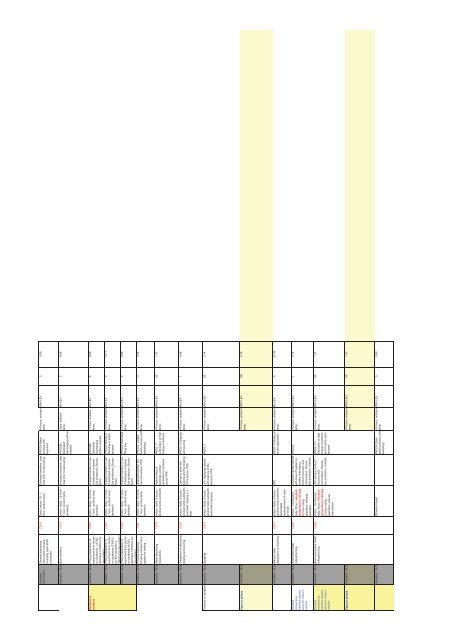

Industrial - General exposures CS16 Daily; Indoor; 15 - 1 Enclosed transfers, clear PROC4 Batch >4 hours, ambient SU3/ SU10 open batch process, hour; product temp. lines prior to decoupling process with temp. including open EDM exposure processes Industrial -SU3 Bulk transfers CS14 Indoor, Daily; 15 mins - Enclosed transfers, clear PROC8b daily; ambient 1 hour; product temp lines prior to decoupling Dedicated temp. (ambient) discharging to/from vessels Combine in Industrial -SU3 Filling preparation of CS45 Indoor, Daily; 15 mins - Pumped transfer or use PROC8b 4 hours; ambient equipment from drums 1 hour; product temp of dedicated container. blending in batch temp. or containers (CS45) - (ambient) Eye protection, Gloves, process (ATIEL identified 3 Apron PROCs for this activity) Industrial -SU3 Filling preparation of CS45 Indoor, Daily; 15 mins - Pumped transfer or use PROC9 Dedicated >4 hours, ambient equipment from drums 1 hour; product temp of dedicated container. filling line temp. or containers (ATIEL (ambient) Eye protection, Gloves, identified 3 PROCs for Apron this activity) Industrial -SU3 Process sampling. CS2 Indoor, Daily; 15 mins - Dedicated pipette. No PROC3 Closed >4 hours, ambient Drawing sample into a 1 hour; product temp hand immersion. PPE batch process (with temp. pipette for testing (ambient) sampling) Industrial -SU3 Metal Machining CS79 Indoor, Daily; 8 hours; Restrict area of PROC 17 >4 hours, ambient Operations product temp (ambient) openings; extract Lubrication at high temp. ventilation to emission energy conditions points; PPE Industrial -SU3 Treatment of articles by CS35 Indoor, Daily; 8 hours, Cabinet to allow the PROC 13 Dipping >4 hours, ambient dipping and pouring product temp (ambient), dipping and the dripping and pouring temp. automatic dipping in a of the pieces. PPE bath Combine in narrative Industrial -SU3 Spraying CS10 Indoor, Daily; 8 hours, LEV, Spraying cabinet PROC 7 >4 hours, ambient product temp (ambient), with capture of the temp. automated spraying aerosols, PPE Vapour phase Industrial -SU3 >4 hours, ambient temp. Industrial -SU3 Manual roller CS13 Indoor, Daily; 8 hours, PPE PROC 10 Roller or >4 hours, ambient application or brushing product temp (ambient), brush application temp. Automated replenishment of roller or brush Elevated Industrial -SU3 Automated metal CS80 Indoor. Continuous; Enclosed vented cabinet PROC2 >4 hours, ambient temperature rolling/forming daily; 8hour; elevated with blow off system to temp. therefore applied temperature (120 deg contain mist/vapour; value for medium C) from rolling product recovery and volatility operation; Remote recirculation; Gloves, operation eye protection, overalls. Elevated Industrial -SU3 Semi-automated metal CS83 Indoor. Continuous; LEV canopy; product PROC 17 - >4 hours, ambient temperature rolling/forming daily; 8hour; elevated recovery and lubrication at high temp. therefore applied temperature (120 deg recirculation; Gloves, energy conditions value for medium C) from rolling eye protection, overalls. and in partly open volatility operation; manual process intervention Vapour phase. Industrial -SU3 >4 hours, ambient temp. Industrial -SU3 Oil/water-based PROC4 Open >4 hours, ambient batch process (with temp. sampling) With LEV 5 0.69 No LEV 5 6.86 No LEV 5 6.86 No LEV 5 13.71 No LEV 5 6.86 No LEV 3 0.34 With LEV 50 1.37 No LEV 1 6.86 With LEV 20 2.14 With LEV 100 2.14 No LEV 5 27.43 With LEV 1 0.14 With LEV 50 1.37 With LEV 50 1.37 With LEV 5 0.69

Note: differentiated Industrial -SU3 Equipment cleaning CS39 Indoor, Daily; 1 - 4 Enclosed transfer, clear PROC8b dedicated and nondedicated facility for Dedicated facility CS81 retain drainings in sealed discharging to/from and maintenance - hours; ambient temp. lines prior to decoupling; Dedicated equipment cleaning - storage pending vessels both identified by disposal. PPE ATIEL - combined in narrative as CS39 Industrial -SU3 Equipment cleaning Indoor, Daily; 1 - 4 Collect waste and retain PROC8a and maintenance -Nondedicated facility storage pending to/from vessels hours; ambient temp. drainings in sealed Discharging (CS82) disposal. PPE Industrial -SU3 Material Storage CS67 Continuous; daily; 8hour Enclosed process; PROC1/2 Closed closed/semi-closed continuous process sampling point (sometimes with sampling) Use as binders and Industrial -SU3 Bulk transfers from CS3 Daily; 1 - 4 hours; Enclosed transfers, clear PROCs 1-3 release agents storage to mixing ambient temp. lines prior to decoupling contained vessels processes Industrial -SU3 Transfers to mixing CS8 Daily; 15 mins - 1 hour; Pumped transfer from PROC8b vessels from drums ambient temp drum to holding tanks. Discharging to/from vessels Industrial -SU3 Mixing / blending of CS29 Daily; >4 hours Enclosed or ventilated PROC3 Closed foundry sands with mixing vessel batch process (with binder sampling) Industrial -SU3 Mixing / blending of CS30 Daily; >4 hours Enhanced general PROC4 Open foundry sands with ventilation batch process (with binder sampling) Industrial -SU3 Forming moulds from CS31 Daily; >4 hours, ambient PPE PROC14 foundary sand temp Production by tabletting, compression, Combine in narrative Industrial -SU3 Emissions from casting CS32, CS108 Daily; 1 - 4 hours; Enhanced general PROC6 Open into moulds elevated temp.sufficient ventilation, PPE processing at to create fume elevated temperature Industrial -SU3 Emissions from casting CS32, CS108 Daily; 1 - 4 hours; Enhanced general PROC6 Open into moulds (vapour elevated temp.sufficient ventilation, PPE processing at phase) to create fume elevated temperature Combine in narrative Industrial -SU3 Applying release agent CS10, CS33 Daily; 1 - 4 hours; Enclosed or ventilated PROC7 to moulds and ambient temp. production line. Application by shuttering Automation. spraying Industrial -SU3 Applying release agent CS10, CS33 Daily; 1 - 4 hours; Enclosed or ventilated PROC7 to moulds and ambient temp. production line. Application by shuttering (vapour Automation. spraying phase) Industrial -SU3 Applying release agent CS13 Daily; 1 - 4 hours; PPE PROC10 Roller to moulds and ambient temp. application and shuttering brushing Combine in narrative Industrial -SU3 Applying release agent CS10, CS34 Daily; 1 - 4 hours; PPE, face mask PROC7 to moulds and ambient temp. Application by shuttering spraying Industrial -SU3 Applying release agent CS10, CS34 Daily; 1 - 4 hours; PPE, face mask PROC7 to moulds and ambient temp. Application by shuttering (vapours) spraying Industrial - maintenance of CS5 Daily; 1-4 hours, work methods, drain prior PROC8a SU10 equipment ambient to work, retain spills, Discharging gloves to/from vessels (non-dedicated) Industrial -SU3 Storage CS67 Daily; 8 hrs; ambient samples collected at PROC1/2 Closed temp; dedicated sample point continuous process (sometimes with li ) Oil and gas field Industrial - SU3 Bulk transfers from tote CS14 Daily; 15 - 1 hour; Enclosed transfers, clear PROCs 1-3 chemicals tanks and supply product temp (ambient). lines prior to decoupling contained vessels processes Industrial - SU3 Charge from drums CS45 Daily; 15 mins - 1 hour; Pumped transfer from PROC8b product temp (ambient) drum to holding tanks. Discharging to/from vessels (dedicated) Industrial - SU3 Drilling mud (re-) CS512 Daily; 1-4 hour; product Closed equipment, PROC3 Closed formulation temp (ambient); indoor enclosed or vented batch process with sampling points sampling Industrial - SU3 Drill floor operations CS513 Daily; 1-4 hour per PPE PROC4 Batch operator; product temp process with (ambient), outdoors exposure Combine Industrial - SU3 Operation of solids CS514 Daily; >4 hours; indoor; Local exhaust ventilation PROC4 Batch filtering equipment product temperature process with elevated temperature approx. 60 dC exposure > 4 hours daily; ambient temp. > 4 hours daily; ambient temp. daily; ambient temp. daily; ambient temp. daily; ambient temp. > 4 hours daily; ambient temp. > 4 hours daily; ambient temp. > 4 hours daily; ambient temp. > 4 hours daily; ambient temp. > 4 hours daily; ambient temp. > 4 hours daily; ambient temp. > 4 hours daily; ambient temp. > 4 hours; daily; ambient temp. > 4 hours daily; ambient temp. > 4 hours daily; ambient temp. 1-4 hours, ambient temp. daily; ambient temp. daily; ambient temp. daily; ambient temp. > 4 hours daily; ambient temp. > 4 hours daily; ambient temp. > 4 hours; daily; elevated product temperature No LEV 5 13.71 No LEV 5 13.71 outdoor activity 0.5 0.14 No LEV 3 1.37 With LEV 5 6.86 No LEV 3 1.37 No LEV 5 13.71 No LEV 5 3.43 With LEV 25 1.37 With LEV 5 1.37 With LEV 20 2.14 With LEV 100 2.14 With LEV 5 27.43 No LEV 100 42.86 No LEV 100 42.86 No LEV 5 13.71 outdoor activity 0.5 0.14 No LEV 3 1.37 With LEV 5 6.86 No LEV 3 1.37 No LEV 5 13.71 With LEV. 25 0.69

- Page 81 and 82: Vacuum Gas Oils, Hydrocracked Gas O

- Page 83 and 84: Vacuum Gas Oils, Hydrocracked Gas O

- Page 85 and 86: Vacuum Gas Oils, Hydrocracked Gas O

- Page 87 and 88: Vacuum Gas Oils, Hydrocracked Gas O

- Page 89 and 90: Vacuum Gas Oils, Hydrocracked Gas O

- Page 91 and 92: Vacuum Gas Oils, Hydrocracked Gas O

- Page 93 and 94: Vacuum Gas Oils, Hydrocracked Gas O

- Page 95 and 96: Vacuum Gas Oils, Hydrocracked Gas O

- Page 97 and 98: Vacuum Gas Oils, Hydrocracked Gas O

- Page 99 and 100: Vacuum Gas Oils, Hydrocracked Gas O

- Page 101 and 102: Vacuum Gas Oils, Hydrocracked Gas O

- Page 103 and 104: Vacuum Gas Oils, Hydrocracked Gas O

- Page 105 and 106: Vacuum Gas Oils, Hydrocracked Gas O

- Page 107 and 108: Vacuum Gas Oils, Hydrocracked Gas O

- Page 109 and 110: Vacuum Gas Oils, Hydrocracked Gas O

- Page 111 and 112: Vacuum Gas Oils, Hydrocracked Gas O

- Page 113 and 114: Vacuum Gas Oils, Hydrocracked Gas O

- Page 115 and 116: Vacuum Gas Oils, Hydrocracked Gas O

- Page 117 and 118: Vacuum Gas Oils, Hydrocracked Gas O

- Page 119 and 120: Vacuum Gas Oils, Hydrocracked Gas O

- Page 121 and 122: Vacuum Gas Oils, Hydrocracked Gas O

- Page 123 and 124: Gas Oils (Vacuum) 4 DNEL (inhalatio

- Page 125 and 126: Industrial - Tabletting, CS100 Indo

- Page 127 and 128: Combined Professional - Manual spra

- Page 129 and 130: Industrial - Bulk transfers CS14 Da

- Page 131: Professional - Maintenance and CS77

- Page 135 and 136: Professional - Treatment and dispos

- Page 137 and 138: Industrial - operation of open CS16

- Page 139 and 140: Vacuum Gas Oils, Hydrocracked Gas O

- Page 141 and 142: Vacuum Gas Oils, Hydrocracked Gas O

- Page 143 and 144: Vacuum Gas Oils, Hydrocracked Gas O

- Page 145 and 146: Gas Oils (Vacuum) 4 DNEL (inhalatio

- Page 147 and 148: Industrial - Tabletting, CS100 Indo

- Page 149 and 150: Combined Professional - Manual spra

- Page 151 and 152: Industrial - Bulk transfers CS14 Da

- Page 153 and 154: Professional - Maintenance and CS77

- Page 155 and 156: Note: differentiated Industrial -SU

- Page 157 and 158: Professional - Treatment and dispos

- Page 159 and 160: Industrial - operation of open CS16

- Page 161 and 162: Vacuum Gas Oils, Hydrocracked Gas O

- Page 163 and 164: Vacuum Gas Oils, Hydrocracked Gas O

- Page 165 and 166: This tool is provided for informati

- Page 167 and 168: An Evaluation of the Persistence, B

- Page 169 and 170: Table of Contents Executive Summary

- Page 171 and 172: 2.0 Outline of PBT/vPvB Assessment

- Page 173 and 174: 3.0 Persistence Assessment of Petro

- Page 175 and 176: 100.0 Half-life predicted (days) 10

- Page 177 and 178: 2,3-dimethylheptane 9 7.7 6.2 7.4 2

- Page 179 and 180: ioHCwin half-life (days) 10000.0 10

- Page 181 and 182: criterion. It can be concluded that

Industrial - General exposures CS16 Daily; Indoor; 15 - 1 Enclosed transfers, clear PROC4 Batch >4 hours, ambient<br />

SU3/ SU10 open batch process,<br />

hour; product temp. lines prior to decoupling process with temp.<br />

including open EDM<br />

exposure<br />

processes<br />

Industrial -SU3 Bulk transfers CS14 Indoor, Daily; 15 mins - Enclosed transfers, clear PROC8b<br />

daily; ambient<br />

1 hour; product temp lines prior to decoupling Dedicated temp.<br />

(ambient)<br />

discharging to/from<br />

vessels<br />

Combine in Industrial -SU3 Filling preparation of CS45 Indoor, Daily; 15 mins - Pumped transfer or use PROC8b 4 hours; ambient<br />

equipment from drums<br />

1 hour; product temp of dedicated container. blending in batch temp.<br />

or containers (CS45) -<br />

(ambient)<br />

Eye protection, Gloves, process<br />

(ATIEL identified 3<br />

Apron<br />

PROCs for this activity)<br />

Industrial -SU3 Filling preparation of CS45 Indoor, Daily; 15 mins - Pumped transfer or use PROC9 Dedicated >4 hours, ambient<br />

equipment from drums<br />

1 hour; product temp of dedicated container. filling line temp.<br />

or containers (ATIEL<br />

(ambient)<br />

Eye protection, Gloves,<br />

identified 3 PROCs for<br />

Apron<br />

this activity)<br />

Industrial -SU3 Process sampling. CS2 Indoor, Daily; 15 mins - Dedicated pipette. No PROC3 Closed >4 hours, ambient<br />

Drawing sample into a<br />

1 hour; product temp hand immersion. PPE batch process (with temp.<br />

pipette for testing<br />

(ambient)<br />

sampling)<br />

Industrial -SU3 Metal Machining<br />

CS79 Indoor, Daily; 8 hours; Restrict area of PROC 17 >4 hours, ambient<br />

Operations<br />

product temp (ambient) openings; extract Lubrication at high temp.<br />

ventilation to emission energy conditions<br />

points; PPE<br />

Industrial -SU3 Treatment of articles by CS35 Indoor, Daily; 8 hours, Cabinet to allow the PROC 13 Dipping >4 hours, ambient<br />

dipping and pouring<br />

product temp (ambient), dipping and the dripping and pouring temp.<br />

automatic dipping in a of the pieces. PPE<br />

bath<br />

Combine in narrative Industrial -SU3 Spraying CS10 Indoor, Daily; 8 hours, LEV, Spraying cabinet PROC 7<br />

>4 hours, ambient<br />

product temp (ambient), with capture of the<br />

temp.<br />

automated spraying aerosols, PPE<br />

Vapour phase Industrial -SU3 >4 hours, ambient<br />

temp.<br />

Industrial -SU3 Manual roller<br />

CS13 Indoor, Daily; 8 hours, PPE PROC 10 Roller or >4 hours, ambient<br />

application or brushing<br />

product temp (ambient),<br />

brush application temp.<br />

Automated<br />

replenishment of roller<br />

or brush<br />

Elevated<br />

Industrial -SU3 Automated metal<br />

CS80 Indoor. Continuous; Enclosed vented cabinet PROC2 >4 hours, ambient<br />

temperature<br />

rolling/forming<br />

daily; 8hour; elevated with blow off system to<br />

temp.<br />

therefore applied<br />

temperature (120 deg contain mist/vapour;<br />

value for medium<br />

C) from rolling<br />

product recovery and<br />

volatility<br />

operation; Remote recirculation; Gloves,<br />

operation<br />

eye protection, overalls.<br />

Elevated<br />

Industrial -SU3 Semi-automated metal CS83 Indoor. Continuous; LEV canopy; product PROC 17 - >4 hours, ambient<br />

temperature<br />

rolling/forming<br />

daily; 8hour; elevated recovery and<br />

lubrication at high temp.<br />

therefore applied<br />

temperature (120 deg recirculation; Gloves, energy conditions<br />

value for medium<br />

C) from rolling<br />

eye protection, overalls. and in partly open<br />

volatility<br />

operation; manual<br />

process<br />

intervention<br />

Vapour phase. Industrial -SU3 >4 hours, ambient<br />

temp.<br />

Industrial -SU3 Oil/water-based PROC4 Open >4 hours, ambient<br />

batch process (with temp.<br />

sampling)<br />

With LEV 5 0.69<br />

No LEV 5 6.86<br />

No LEV 5 6.86<br />

No LEV 5 13.71<br />

No LEV 5 6.86<br />

No LEV 3 0.34<br />

With LEV 50 1.37<br />

No LEV 1 6.86<br />

With LEV 20 2.14<br />

With LEV 100 2.14<br />

No LEV 5 27.43<br />

With LEV 1 0.14<br />

With LEV 50 1.37<br />

With LEV 50 1.37<br />

With LEV 5 0.69