Mikron M77/78 SeriesMikron M77/78 Series

Mikron M77/78 SeriesMikron M77/78 Series

Mikron M77/78 SeriesMikron M77/78 Series

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

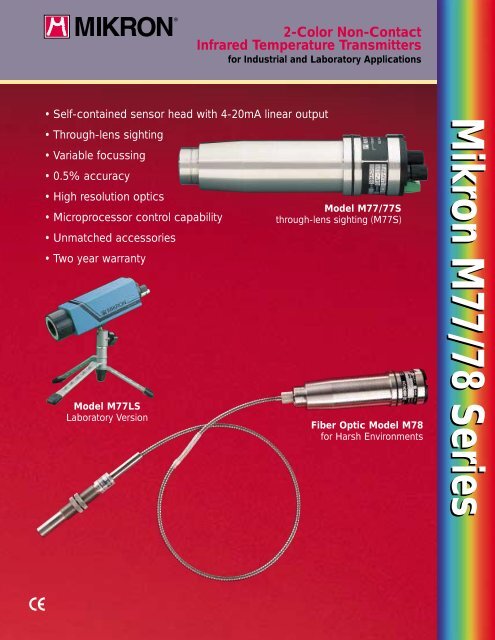

2-Color Non-Contact<br />

Infrared Temperature Transmitters<br />

for Industrial and Laboratory Applications<br />

• Self-contained sensor head with 4-20mA linear output<br />

• Through-lens sighting<br />

• Variable focussing<br />

• 0.5% accuracy<br />

• High resolution optics<br />

• Microprocessor control capability<br />

• Unmatched accessories<br />

• Two year warranty<br />

Model <strong>M77</strong>LS<br />

Laboratory Version<br />

Model <strong>M77</strong>/77S<br />

through-lens sighting (<strong>M77</strong>S)<br />

Fiber Optic Model M<strong>78</strong><br />

for Harsh Environments<br />

<strong>Mikron</strong> <strong>M77</strong>/<strong>78</strong> <strong>Series</strong>

<strong>M77</strong>/<strong>78</strong> 2-color Infrared Temperature Transmitters<br />

Innovative Design<br />

The <strong>M77</strong>/<strong>78</strong> series “Infraducers”<br />

represent a milestone in infrared<br />

temperature measurement technology.<br />

They are the first commercially<br />

available, completely self-contained,<br />

2-color radiometers to produce a<br />

4-20mA linear output. The “Infraducers”<br />

represent the latest in<br />

innovative technology, integrating<br />

exclusive advanced electronic design<br />

with optical and mechanical<br />

precision that are the essence of<br />

<strong>Mikron</strong> infrared products. Their<br />

design from concept to finish is<br />

based on simplicity of installation<br />

and maintenance. The <strong>M77</strong>/<strong>78</strong><br />

series, with its matchless array of<br />

accessories, demonstrates <strong>Mikron</strong>’s<br />

continuing leadership in infrared<br />

temperature measuring technology.<br />

Why 2-color<br />

Infrared Thermometry?<br />

The <strong>M77</strong>/<strong>78</strong> series are “state of the<br />

art” instruments designed for the<br />

measurement of temperatures above<br />

250°C (500°F). They utilize the<br />

2-color principle, in which the temperature<br />

measurement is made by<br />

ratioing the radiation intensities of<br />

two adjacent wavelengths rather<br />

than from absolute intensity as with<br />

single band (or single color) instruments.<br />

This design approach<br />

eliminates a number of factors that<br />

degrade the accuracy of conventional<br />

instruments. For example,<br />

temperature measurements with<br />

the <strong>M77</strong>/<strong>78</strong> are:<br />

• Independent of emissivity<br />

• Unaffected by dust and other<br />

contaminants in the field of view<br />

• Independent of target size (can<br />

produce accurate reading with<br />

only 5% of the target area<br />

within field of view)<br />

• Unaffected by moving target<br />

within field of view<br />

• Unaffected by dirty viewing<br />

windows<br />

point of failure in other instruments.<br />

Also, there are no optical<br />

or electronic adjustments to be<br />

made in the field. An invalid signal<br />

LED warns if the target radiation<br />

intensity drops to a level too low<br />

for reliable measurements.<br />

The <strong>M77</strong>S Sensor Head incorporates<br />

a high quality, high precision<br />

variable focus optical system that<br />

provides sharp focussing on the<br />

desired target from about 2” (50mm)<br />

to infinity. Focussing is executed by<br />

turning the focussing knob on the<br />

rear panel of the instrument.<br />

The <strong>M77</strong>S enables precision<br />

pinpointing of small target areas.<br />

The user simply adjusts the instrument<br />

until the desired target is<br />

clear within a reticle.<br />

<strong>M77</strong>LS for Laboratory<br />

& Research Applications<br />

The <strong>M77</strong>LS was specifically designed<br />

for research and laboratory<br />

applications and is readily adaptable<br />

for either tripod or optical<br />

bench use. Its through-lens sighting<br />

and variable focussing features<br />

permit precision pinpointing of the<br />

target area.<br />

M<strong>78</strong> for Inaccessible or<br />

Environmentally Severe<br />

Applications<br />

The fiber optics based M<strong>78</strong><br />

“Infraducer” is recommended for<br />

areas where the following conditions<br />

exist:<br />

A. When direct sighting with the<br />

<strong>M77</strong>S is impossible due to<br />

obstructions. The flexibility<br />

of the fiber optics cable overcomes<br />

this problem.<br />

B. Where RF or EMI interference<br />

is a problem, requiring the<br />

electronics to be placed at a<br />

safe distance from the source<br />

of interference.<br />

C. Where exceptionally high ambient<br />

temperatures exist. Fiber optic<br />

tips and lens assemblies can<br />

withstand temperatures up to<br />

600°F (315°C) without cooling<br />

and up to 1000°F (540°C) with<br />

air cooling.<br />

D. Where corrosive environments<br />

prohibit the use of a conventional<br />

system.<br />

E. In vacuum applications where<br />

sighting through the window<br />

is difficult or impossible, a<br />

fiber optics lens assembly can<br />

be placed inside the vacuum<br />

vessel.<br />

F. When an intrinsically safe IR<br />

temperature transmitter is<br />

mandatory.<br />

G. Environments where nuclear<br />

radiation is present. A<br />

specially designed lens and<br />

fiber optics assembly can withstand<br />

high nuclear radiation<br />

levels.<br />

<strong>M77</strong>LS Laboratory Version<br />

<strong>Mikron</strong> 77/77S<br />

for Industrial Applications<br />

The <strong>M77</strong> is housed in a compact,<br />

rugged stainless steel housing only<br />

8” (200mm) long and 2” (50mm) in<br />

diameter. Superior design not only<br />

insures accuracy and long term<br />

reliability, it also guarantees interchangeability<br />

between “Infraducers”<br />

of the same model with ±0.75%<br />

accuracy. This ensures that, should<br />

one of the “Infraducers” need to<br />

be replaced, the replacement unit<br />

would be as accurate as the original<br />

unit. The <strong>M77</strong> has absolutely no<br />

moving parts which are often the<br />

VISUAL SIGHTING<br />

RETICLE DEFINES<br />

EXACT AREA OF<br />

TEMPERATURE<br />

MEASUREMENT<br />

INVALID<br />

READING<br />

EYEPIECE<br />

QUICK<br />

DISCONNECT<br />

CONNECTOR<br />

<strong>M77</strong>LS<br />

REAR<br />

PANEL<br />

SLOPE<br />

ADJUST<br />

FOCUS<br />

2

How to Select an<br />

<strong>M77</strong> Sensor Head<br />

Since there are three <strong>M77</strong> models (<strong>M77</strong>, <strong>M77</strong>S, <strong>M77</strong>LS)<br />

as described on the previous page, it is first necessary to<br />

determine which model you require:<br />

a. <strong>M77</strong> – Fixed focus<br />

b. <strong>M77</strong>S – Variable focus, see through lens<br />

c. <strong>M77</strong>LS – Variable focus, see through lens for<br />

laboratory and research applications.<br />

After choosing the desired model follow these 4 steps.<br />

1. Select the temperature range and units (C or F) from<br />

ranges listed. Insert ranges and units in Box 1 ,<br />

filling in all blanks with zeros.<br />

2. Place letter “R” or “R1” in Box 2 for standard<br />

spectral response.<br />

3. Select signal output; (L) for standard 4-20mA linear,<br />

or (U) for others and insert in Box 3 .<br />

4. Select the correct operating distance.<br />

a. If you selected the <strong>M77</strong> fixed focus model, specify<br />

the desired focus distance in writing (See Table 1.)<br />

and enter “U” in Box 4 .<br />

b. If you selected the focussable <strong>M77</strong>S or <strong>M77</strong>LS<br />

read the section “Optical Resolution” below. Then<br />

choose the desired operating distance and insert the<br />

corresponding Code No. in Box 4 .<br />

EXAMPLE<br />

The model chosen for the instrument indicated in the<br />

selection chart is the focussable <strong>M77</strong>S with through<br />

lens sighting for a temperature range of 800° to 1800°C<br />

with spectral response of two narrow bands, with<br />

4-20mA linear output and a focussable operating<br />

distance of 350mm (14”) to infinity.<br />

Optical Resolution<br />

Three different lenses are available for the <strong>M77</strong>S. The<br />

one you should choose depends on the desired working<br />

distance of the unit. The first version is designed to<br />

measure temperature at distances of 350mm (14”) to<br />

infinity. The second version has a working area of<br />

150mm (6”) to 350mm (14”). The third version is fixed<br />

to measure temperatures at a 50mm (2”) distance.<br />

Proper focussing is achieved by mounting the unit at<br />

the desired distance and adjusting the focussing knob<br />

on the rear panel of the instrument until the target<br />

comes into clear view in the reticle. When the target is<br />

in focus to the eye, it is also in focus to the detector.<br />

Should you wish to move the instrument, remember to<br />

stay within the prescribed working distance, and simply<br />

refocus upon the target after mounting the instrument<br />

in its new location.<br />

A typical field of view diagram is shown below.<br />

Minimum Target size determined by the formula:<br />

Minimum Target Size (d) =<br />

TARGET SIZE (d)<br />

Focussed Distance (D)<br />

Field of View Ratio<br />

DISTANCE (D)<br />

Example: <strong>M77</strong>S, version 1 with 30:1 FOV focussed at<br />

381mm (15”)<br />

D 381<br />

Minimum Target Size(d) = = = 12.7mm<br />

FOV 30<br />

15”<br />

(or = = 0.5”)<br />

30<br />

Selection Chart<br />

<strong>M77</strong>S 0 8 0 0 – 1 8 0 0 C R L<br />

3<br />

1<br />

1 TEMPERATURE RANGE<br />

3<br />

FIELD OF<br />

VIEW RATIO<br />

°C °F<br />

350-800 660-1500<br />

550-1200 1025-2200 15:1<br />

600-1400 1100-2500<br />

400-1000 750-1800<br />

650-1400 1200-2500<br />

30:1<br />

450-1200 850-2200<br />

700-1400 1300-2500<br />

700-1700 1300-3100<br />

700-2000 1300-3600<br />

800-1800 1500-3300<br />

60:1<br />

800-2300 1500-4100<br />

900-1600 1800-3200<br />

500-1400 950-2550<br />

1000-2500 1800-4500<br />

1000-3000 1800-5400<br />

1100-2200 2000-4000 90:1<br />

1200-3200 2200-5800<br />

1200-3500 2200-6500<br />

Notes:<br />

1. Special temperature ranges are available upon request.<br />

2. See table 1 for availability of focus distances for FOV selection.<br />

3. Some 90:1 FOV temperature ranges are also available with a 180:1 FOV.<br />

Please consult <strong>Mikron</strong>.<br />

TABLE 1 – <strong>M77</strong><br />

MINIMUM TARGET<br />

Field of Fixed Focus<br />

View No Sighting<br />

Ratio<br />

15:1 D/15<br />

30:1 D/30<br />

60:1 D/60<br />

90:1 D/90<br />

180:1 D/180<br />

Consult <strong>Mikron</strong><br />

MINIMUM<br />

FOCUS<br />

DISTANCE<br />

2”<br />

2”<br />

6”<br />

6”<br />

14”<br />

Table 2 – <strong>M77</strong>S, <strong>M77</strong>LS Minimum target sizes are<br />

shown in the table below<br />

Field of Version 1 Version 2 Version 3<br />

View Focus 14” Focus 6” Focus at<br />

Ratio to Infinity to 14” 2”<br />

15:1 23.6mm (0.93”) 10.2mm (0.40”) 3.3mm (0.13”)<br />

at 350mm (14”) at 150mm (6”) at 50mm (2”)<br />

30:1 12mm (0.47”) 5mm (0.20”) 1.5mm (0.06”)<br />

at 350mm (14”) at 150mm (6”) at 50mm (2”)<br />

60:1 6mm (0.24”) 2.5mm (0.10”)<br />

at 350mm (14”) at 150mm (6”)<br />

N/A<br />

90:1 4mm (0.16”) 1.8mm (0.07”)<br />

at 350mm (14”) at 150mm (6”)<br />

N/A<br />

2<br />

2 SPECTRAL<br />

RESPONSE<br />

CODE<br />

R1<br />

R<br />

R1<br />

R<br />

R1<br />

TWO<br />

NARROW<br />

BANDS R<br />

NEAR<br />

INFRARED<br />

R1<br />

OUTPUT<br />

4-20mA<br />

Linear<br />

CODE<br />

L<br />

1<br />

3 4<br />

4 OPERATING<br />

DISTANCE<br />

(See note 2)<br />

CODE<br />

350mm<br />

(14”) to 1<br />

infinity<br />

150mm<br />

(6”) to<br />

350mm<br />

(14”)<br />

50mm<br />

(2”) fixed<br />

How to Select an M<strong>78</strong> Sensor Head<br />

The selection process for the M<strong>78</strong> is similar to that of the <strong>M77</strong>, with the<br />

additional requirements of the fiber optic feature. The selection steps are as follows:<br />

1. Select the temperature range and units (C or F) from ranges listed. Insert<br />

ranges and units in Box 1 , filling in all blanks with zeros.<br />

2. Place letter “R” or “R1” in Box 2 for standard spectral response.<br />

3. Select signal output; (L) for standard 4-20mA linear, or (U) for others and<br />

insert in Box 3 .<br />

4. Select the length of fiber optics cable and insert code number in Box 4 .<br />

5. Select the required lens assembly from the field of view diagrams and insert<br />

code number in Box 5 . If, however, an extension tip is to be used, the code<br />

number inserted in Box 5 should be selected from the chart under Rigid<br />

Extension Tip; both stainless steel and ceramic tips are available.<br />

2<br />

3

Selection Chart<br />

C or F<br />

M<strong>78</strong> 0 8 0 0 – 1 8 0 0 C R L<br />

S 1 2 0 3 0 S<br />

1<br />

2 3 4<br />

5 or<br />

1 TEMPERATURE RANGE<br />

See note 1<br />

°C °F<br />

450-1200 850-2200<br />

450-1200 850-2200<br />

500-1400 950-2550<br />

600-1800 1100-3300<br />

700-1400 1300-2500<br />

700-1700 1300-3100<br />

700-2000 1300-3600<br />

800-1800 1500-3300<br />

800-2300 1500-4100<br />

900-1600 1800-3200<br />

1000-2500 1800-4500<br />

1000-3000 1800-5400<br />

1100-2200 2000-4000<br />

1200-3200 2200-5800<br />

1200-3500 2200-6500<br />

FIELD<br />

OF<br />

VIEW<br />

RATIO<br />

3:1<br />

15:1<br />

30:1<br />

30:1<br />

15:1 or<br />

30:1<br />

30:1<br />

90:1<br />

MAX. FIBER<br />

OPTIC<br />

LENGTH<br />

360cm (6’)<br />

360cm (6’)<br />

540cm (6’)<br />

900cm (6’)<br />

For 15:1 –<br />

900cm (30’)<br />

For 30:1 –<br />

180cm (6’)<br />

900cm (30’)<br />

900cm (30’)<br />

See note 4<br />

2 SPECTRAL<br />

RESPONSE<br />

CODE<br />

TWO<br />

NARROW<br />

BANDS<br />

NEAR<br />

INFRARED<br />

R1<br />

R<br />

3 OUTPUT<br />

CODE<br />

4-20mA<br />

L<br />

4 FIBER OPTIC<br />

CABLE<br />

LENGTH<br />

CM FT. CODE<br />

90 3 S03<br />

180 6 S06<br />

360 12 S12<br />

540 18 S18<br />

720 24 S24<br />

900 30 S30<br />

Special Length<br />

– Customer to<br />

Specify Length<br />

in Writing<br />

SXX<br />

5 STANDARD<br />

FOCUS LENS<br />

ASSEMBLY<br />

See note 2<br />

FOV CODE<br />

15:1 015S<br />

30:1 030S<br />

90:1 090S<br />

NON-<br />

STANDARD<br />

FOCUS<br />

See note 3<br />

15:1 015U<br />

5<br />

RIGID<br />

EXTENSION TIPS<br />

See note 5<br />

STAINLESS CERAMIC<br />

STEEL<br />

LENGTH CODE LENGTH CODE<br />

76mm S033 76mm C033<br />

(3’) (3’)<br />

152mm S063 152mm C063<br />

(6’) (6’)<br />

305mm S123 305mm C123<br />

(12’) (12’)<br />

610mm S243 24mm C243<br />

(24’) (24’)<br />

30:1 030U<br />

FOV RATIO<br />

15:1<br />

TARGET DISTANCE IN.<br />

0<br />

Min.<br />

TARGET DIA. IN. 0.4<br />

Focussable<br />

Distance:<br />

5.0cm TARGET DIA. CM<br />

1.0<br />

(2.0”)<br />

TARGET DISTANCE CM<br />

0<br />

30:1<br />

Min.<br />

Focussable<br />

Distance:<br />

12.7cm<br />

(5.0”)<br />

90:1<br />

Min.<br />

Focussable<br />

Distance:<br />

12.7cm<br />

(5.0”)<br />

Standard Lens Assembly<br />

TARGET DISTANCE IN.<br />

TARGET DIA. IN.<br />

0<br />

.40<br />

TARGET DIA. CM<br />

0<br />

TARGET DISTANCE CM<br />

0<br />

0<br />

TARGET DISTANCE IN.<br />

TARGET DIA. IN. .40<br />

TARGET DIA. CM<br />

1.0<br />

TARGET DISTANCE CM<br />

0<br />

FIELD OF VIEW DIAGRAMS<br />

15<br />

1.0<br />

2.5<br />

38<br />

30<br />

1.0<br />

2.5<br />

76<br />

90<br />

1.0<br />

2.5<br />

230<br />

30<br />

2.4<br />

6.1<br />

76<br />

60<br />

2.5<br />

6.0<br />

150<br />

180<br />

2.5<br />

6.0<br />

460<br />

EXAMPLE<br />

The model number for the M<strong>78</strong> “Infraducer” indicated in the boxes<br />

designates a unit with a temperature range of 800° to 1800°C with a<br />

4-20mA linear output using 360cm (12’) length of fiber optics cable,<br />

a standard lens assembly with an FOV ratio of 30:1 focussed at<br />

760mm (30”).<br />

Notes:<br />

90:1 090U<br />

1. Special ranges are available upon request.<br />

2. All standard focussing distances match their respective FOV<br />

distance, i.e. 30:1 = 30”.<br />

3. When non-standard focus distance is desired, such as close focus,<br />

insert code “U” instead of “S” and describe desired focus distance<br />

in writing.<br />

4. Longer length fiber optic available upon request.<br />

5. All Rigid Extension Tips provide a 3:1 FOV<br />

6. Minimum focus distance for standard lens assembly is 2” for 15:1<br />

FOV and 5” for all others.<br />

7. 6’ fiber cable max. Consult factory for any other configurations.<br />

CLOSE FOCUS FOV*<br />

FOV RATIO 15:1 FOV RATIO 30:1 FOV RATIO 90:1<br />

CODE 015U CODE 030U CODE 090U EXTENSION TIP FIELD OF VIEW (3:1)<br />

D<br />

dø<br />

20°<br />

Tip<br />

*Min Target Size (d) =<br />

Focussed Distance (D)<br />

FOV Ratio 20°<br />

1.5 (.06)<br />

EXTENSION TIP ASSEMBLY<br />

3Ø<br />

(.125)<br />

13<br />

(.50)<br />

64<br />

(2.50)<br />

13<br />

(.50)<br />

19<br />

(.75)<br />

LENGTH<br />

1/2-20 THD 3/4-16 THD<br />

(2) JAM NUTS<br />

LENS ASSEMBLY<br />

All mounting hardware is supplied by <strong>Mikron</strong><br />

114<br />

(4.50)<br />

76<br />

(3.00)<br />

(2) JAM NUTS<br />

STAINLESS STEEL<br />

FLEXIBLE FIBER OPTICS<br />

CABLE (50 (2.00) MIN.<br />

BEND RADIUS)<br />

LENGTH<br />

193<br />

(7.61)<br />

M<strong>78</strong> SENSOR HEAD<br />

51<br />

(2.00)<br />

Four Holes<br />

5 (0.200)<br />

MOUNTING BLOCK<br />

64<br />

(2.50)<br />

25<br />

(1.00)<br />

All dimensions are mm (in.)<br />

4

How to Select an<br />

<strong>M77</strong>E/77EM Electronics<br />

Step No.<br />

A. Insert in box “A” the basic model. Select either<br />

<strong>M77</strong>EM for a single electronics processor or <strong>M77</strong>E<br />

if a complete control package is required.<br />

B. Select the desired control function and insert code<br />

no. in box “B”.<br />

C. Specify the supply voltage and insert code no. in<br />

box “C”.<br />

D. Designate the desired auxiliary code no. in box “D”.<br />

EXAMPLE<br />

An <strong>M77</strong>E electronics with current proportioning 3 mode PID<br />

digital controller with 4-20mA output. Supply voltage of<br />

120VAC with option of automatic tuning.<br />

A<br />

BASIC B CONTROL FUNCTION<br />

MODEL (<strong>M77</strong>E ONLY) CODE<br />

<strong>M77</strong>EM<br />

Processor<br />

<strong>M77</strong>E<br />

Processor/<br />

Controller<br />

A<br />

None<br />

(Mandatory with <strong>M77</strong>EM) 00<br />

Digital Indicator Only<br />

On-Off or Time Proportioning<br />

3 mode indicating controller<br />

Current Proportioning<br />

3 mode controller with 4-20mA output<br />

Position Proportioning<br />

3 mode indicating controller<br />

Time Proportional Duplex<br />

with two time proportioning outputs<br />

Current Proportioning Duplex<br />

with two current proportioning outputs<br />

Current/Relay Duplex<br />

(Relay = Heat)<br />

Current/Relay Duplex<br />

(Relay = Cool)<br />

<strong>M77</strong>E D 9 1 1<br />

C<br />

SUPPLY<br />

VOLTAGE<br />

C<br />

CODE<br />

120VAC 1<br />

240VAC 2<br />

100VAC 3<br />

D<br />

D<br />

B<br />

CONTROL OPTION<br />

NONE (MANDATORY<br />

WITH <strong>M77</strong>EM)<br />

D1<br />

D7<br />

D9<br />

D4<br />

D5<br />

D6<br />

D8<br />

D2<br />

CODE<br />

AUTO TUNE 1<br />

REMOTE SET POINT 2<br />

AUXILIARY OUTPUT 3<br />

RS422<br />

COMMUNICATIONS LINK<br />

DIGITAL INPUT 5<br />

SET POINT RAMP/SOAK<br />

PROGRAMMING<br />

0<br />

4<br />

6<br />

General Specifications<br />

<strong>M77</strong>/<strong>78</strong> Sensor Heads<br />

Accuracy: ±0.5% of full scale for temperature below 3200°F<br />

(1700°C); ±0.75% of full scale for temperature scales above 3200°F<br />

(1700°C)<br />

Resolution: ±0.10% of full scale span (FSS)<br />

Repeatability: ±0.25% of full scale span (FSS)<br />

Output: 4-20mA linear standard<br />

Slope Adjust: Adjustable from .85 to +1.15. Field switchable to<br />

Tungsten Lamp characteristic.<br />

Input Voltage: ±15VDC regulated 200mA min. (External supply<br />

available from <strong>Mikron</strong> 77E/77EM or a separate power supply.)<br />

Load Resistance: 500 ohms max. for 4-20mA<br />

Input Signal Reduction: Up to 95% of reduction in incoming<br />

radiation can be tolerated due to low emissivity, target size<br />

reduction or obscuration for temperature above 1500°F (815°C).<br />

Response Time: 40mS to 10 sec. field adjustable. Response time<br />

defined as time required for output to reach 95% of its final value.<br />

Electrical Connections: Compression type for <strong>M77</strong>, <strong>M77</strong>S and<br />

M<strong>78</strong>. Quick disconnect for <strong>M77</strong>LS.<br />

Operating Ambient Temperature: A) Model <strong>M77</strong> and M<strong>78</strong><br />

sensor head. Without Cooling Jacket: 32 - 120°F (0 - 50°C). With<br />

Cooling Jacket: Up to 600°F (315°C). B) Model M<strong>78</strong> lens and tip<br />

assembly. Without Cooling Jacket: 32 to 600°F (0 to 315°C). With<br />

Cooling Jacket: Up to 900°F (480°C).<br />

Material: Stainless steel.<br />

Weight: 2 lbs. (0.90kg)<br />

Mounting: Support block with four .200” (5mm) dia. holes and<br />

“U” clamp. For more secure mounting use of protective jacket is<br />

recommended.<br />

<strong>M77</strong>/<strong>78</strong>E/EM Electronics<br />

Input Signal Requirements: From <strong>M77</strong> or M<strong>78</strong> of same<br />

tem-perature range 4-20mA (linear)<br />

Slope Adjust: .85 to 1.15<br />

Response Time Adjust: 40mS to 10 sec. Field adjustable.<br />

Peak Picker Decay Rate: (Valley Picker optional) Continuously<br />

adjustable between 0.01 and 10% of full scale/second<br />

Peak Picker Controls: (Valley Picker optional) On, Cancel and<br />

Reset from front panel. Remote Reset actuated by external SPST<br />

switch (customer supplied).<br />

Standard Outputs (Linear): 0-1V Full Scale; 0-50mVDC Full<br />

Scale; 1mV/°F or C; 4-20mADC, 650 ohms max.<br />

Optional Outputs (specify one): In lieu of 0-1VDC or 1mV/°,<br />

0-5VDC full scale; or 0-10VDC full scale<br />

Output Supply Voltage: ±15VDC regulated 200mA min. to power<br />

<strong>M77</strong>/<strong>78</strong> sensor heads<br />

Ambient Temperature Range: 0°C to 50°C (32°F to 120°F)<br />

Size: Front outline <strong>M77</strong>E: 160mm x 128mm (6.5 in. x 5.0 in.) Front<br />

outline <strong>M77</strong>EM: 64mm x 128mm (2.5 in. x 5.0 in.)<br />

Depth Behind Panel: 230mm (9.0 in.)<br />

Panel Cutout: <strong>M77</strong>E: 154mm x 108mm (6.062 in. x 4.25 in.)<br />

<strong>M77</strong>EM: 57.1mm x 108mm (2.25 in. x 4.25 in.)<br />

Electrical Connections: Compression type at rear of instrument<br />

— behind rear cover<br />

Peak Picker Outputs: (Valley Picker optional) All standard<br />

outputs are routed through peak picker.<br />

Electrical Connections: Compression type terminals<br />

Conduit Knockout: 4 holes - 22mm (.875 in.)<br />

Controller (<strong>M77</strong>E only)<br />

Physical Description: Housed in a metal case in a 1/4 DIN<br />

cutout. Modular construction of the plug-in chassis allows easy<br />

access to the controller board and its various option boards. All<br />

power, input, and output wiring are connected to screw terminals<br />

on the rear terminal panel.<br />

Digital Displays: Vacuum fluorescent, alphanumeric. A six digit<br />

display dedicated to the process variable. Alternate information<br />

displayed during configuration mode. An eight digit display shows<br />

key selected operating parameters. Also provides guidance during<br />

controller configuration.<br />

Note 1: Accuracy is stated for targets having grey body<br />

or tungsten lamp characteristics.<br />

Note 2: Certificate of NIST traceability will be provided<br />

upon special request.<br />

5

<strong>M77</strong>EM<br />

<strong>M77</strong>EM CUTOUT<br />

7.84<br />

(200)<br />

6.86<br />

(174)<br />

1.75<br />

(45)<br />

<strong>M77</strong>/<strong>M77</strong>S SENSOR HEAD<br />

INVALID<br />

READING<br />

EYEPIECE<br />

2.00<br />

(51)<br />

SLOPE<br />

ADJUST<br />

FOCUS<br />

OUTPUT<br />

CONNECTOR<br />

5.04<br />

(128)<br />

2.52<br />

(64)<br />

7.75<br />

(198)<br />

1.4<br />

(36)<br />

4.25<br />

(108)<br />

2.12<br />

(54)<br />

1.14<br />

(29) 2.28<br />

(58)<br />

6.62<br />

(168)<br />

.62<br />

(16)<br />

INVALID<br />

READING<br />

2.00<br />

(51)<br />

SLOPE<br />

ADJUST<br />

CONTROLLER<br />

<strong>M77</strong>E<br />

PROCESSOR<br />

<strong>M77</strong>E CUTOUT<br />

4.12<br />

(105)<br />

1.00<br />

(25.4)<br />

1/4 -20<br />

(2) MOUNTING HOLES<br />

<strong>M77</strong>LS SENSOR HEAD<br />

WITH LABORATORY STAND<br />

EYEPIECE<br />

1.50<br />

(38)<br />

2.00<br />

(51)<br />

FOCUS<br />

OUTPUT<br />

CONNECTOR<br />

5.04<br />

(128)<br />

4.250<br />

(108)<br />

2.125<br />

(54)<br />

DIMENSIONS IN INCHES (MILLIMETERS)<br />

6.3<br />

(160)<br />

3.031<br />

(77) 6.067<br />

(154)<br />

Indicators: Alarm Relay Status (ALM 1<br />

or 2), Control Mode (A or MAN), temperature<br />

Units (F or C), Remote Set Point<br />

Active (RSP), Control Relay Status (OUT<br />

1 or 2), Set Point Program RUN or HOLD<br />

(R or H).<br />

Bargraph: 21 segment, color coded<br />

Deviation bargraph —<br />

GREEN = On control<br />

RED = Deviation to ±10% of PV span<br />

Modes of Operation: Manual, Automatic<br />

with local set point, Automatic with<br />

remote set point (2-input units only).<br />

Configurable Parameters and<br />

Setting Range or Selection<br />

(a) Tuning<br />

Gain or PB(%): 0.1 to 999.9<br />

Rate: 0.08 to 10 minutes<br />

Reset: 0.02 to 50.00 minutes/repeat<br />

or repeats/minute<br />

Manual: -100 to 100 (% of Output)<br />

Cycle Time: 1 to 120 seconds<br />

Lockout: None to Maximum<br />

(b) Set Point Ramp<br />

Time: 0 to 255 minutes<br />

Final Set Point: Within the set point<br />

limits<br />

(c) Auto Tune<br />

Step Size: -105 to 105 (% of Output)<br />

(d) Algorithm<br />

Control Algorithm/Output Algorithm:<br />

On-Off, PID-A, PID-B, PD + MR, 3<br />

Position Step/Time Proportional<br />

simplex or duplex, Current Proportional<br />

simplex or duplex, Position<br />

proportional, Current-Relay duplex<br />

(relay = Heat or Cool)<br />

Relay Contact Ratings: Resistive<br />

Load: 5 amperes at 120VAC, 2.5 amperes<br />

at 240VAC. Inductive Load: 50VA at<br />

120VAC or 240VAC<br />

Inputs: 0 to 1VDC from <strong>M77</strong>EM.<br />

A second input provides a remote set<br />

point function and accepts a 4 to 20mA<br />

or a 1 to 5VDC range that can be<br />

characterized.<br />

Control Algorithm: Depending on<br />

the control output type specified, the<br />

controller can be configured for the<br />

following control algorithms: On-Off,<br />

PID-A, PID-B, PD with Manual Reset,<br />

Three Position Step Control<br />

Outputs: The controller is available<br />

with one of the output types listed below:<br />

Time Proportional: Provides On-Off<br />

or Time Proportional (Relay) output.<br />

Current Proportional: Supplies<br />

proportional direct current output for<br />

final control elements which require a<br />

4-20mA signal.<br />

Position Proportional: Positions<br />

a reversible motor with a feedback<br />

slide-wire in proportion to the output<br />

of the control algorithm.<br />

Time Proportional Duplex:<br />

Depending on which control algorithm<br />

you select, can provide On-Off Duplex,<br />

Time Proportional Duplex, or 3 Position<br />

Step Control. The time proportional<br />

duplex output provides independent<br />

PID tuning constants and two time<br />

proportional outputs: one for heat zone<br />

above, and one for the cool zone below<br />

50% output.<br />

Current Proportional Duplex:<br />

Similar to current proportional but<br />

provides a second set of tuning parameters<br />

and a second current output via the<br />

Auxiliary output option, for the heat and<br />

cool zones.<br />

Current Relay Duplex (Relay =<br />

Heat): A variation of Duplex with<br />

Current active for 0 to 50% output<br />

(Tuning Set 2) and Relay active 50<br />

to 100% output (Tuning Set 1).<br />

Current/Relay Duplex (Relay =<br />

Cool): A variation of Duplex with<br />

Current active for 50 to 100% output<br />

and Relay is active for 0 to 50% output.<br />

Configuration: You decide how the<br />

controller is to interact with the process<br />

by selecting, through simple keystrokes,<br />

the functions you want. Internal programs<br />

prompt the operator step-bystep<br />

through the configuration process<br />

assuring quick and accurate entry of all<br />

configurable parameters.<br />

Control Modes: Manual or Automatic<br />

control with bumpless, balanceless<br />

transfer between modes is a standard<br />

feature. In the manual mode, the<br />

6<br />

operator directly controls the controller<br />

output level. In the automatic mode, the<br />

controller will operate from a local set<br />

point, or a remote set point at the second<br />

input.<br />

Alarms: One or two alarm relays are<br />

available to activate external equipment<br />

when preset alarm set points are<br />

reached. Each of the two alarms can<br />

be set to monitor two independent set<br />

points. Each set point can be a high<br />

or low alarm. The alarm type can be<br />

selected to be either of the inputs, the<br />

PV, Deviation, Output, or Shed from the<br />

communications. It can also be used as<br />

an On or Off event at the beginning or<br />

end of a Ramp/Soak segment.<br />

Optional Features<br />

Auto Tune: When enabled, this feature<br />

will automatically calculate and enter<br />

into memory the optimum tuning<br />

parameters required for your process.<br />

A “Short Tune” feature lets you obtain<br />

approximate tuning constants.<br />

Remote Set Point: Isolated high level<br />

input available for remote set point signal.<br />

Auxiliary Output: Can be scaled<br />

from 4-20mA for 0 to 100% for any<br />

range desired. It can be configured<br />

to represent Input 1, Input 2, PV, Set<br />

Point, Deviation, or the Control Output.<br />

Communications: Provides an<br />

RS422 ASCII communication link to a<br />

host computer permitting reading and<br />

writing data transfer type transactions<br />

to the list of configurable parameters.<br />

Digital Input: Allows remote switch<br />

selection of: Local or Remote set point,<br />

Local set point 1 or Local set point 2,<br />

Manual or Automatic control mode, Direct<br />

or Reverse controller action, reset of<br />

Limit Controller, or Run or Hold of<br />

Set Point programming function.<br />

Set Point Ramp/Soak Programming:<br />

Enables you to program and store<br />

6 Ramp and 6 Soak segments for set<br />

point programming. Run or Hold of<br />

program is keyboard or remote switch<br />

selectable.

Support Electronics —<br />

A Complete Process Control Package<br />

<strong>M77</strong> Electronics<br />

Completing the total <strong>M77</strong>/M<strong>78</strong> Infrared Temperature<br />

Measurement System is the auxiliary electronics<br />

module. Two different packages are available, both<br />

of which include a variety of signal outputs.<br />

<strong>M77</strong>EM<br />

Electronics Processor<br />

The <strong>Mikron</strong> 77EM provides remote<br />

adjustment of slope and peak/<br />

valley picker with adjustable decay<br />

rate. Maintenance adjustments,<br />

though not directly exposed, are<br />

easily accessible when needed.<br />

A variety of signal outputs are<br />

provided as standard.<br />

steam or machinery<br />

• When the hottest or coldest temperature of a large<br />

piece is desired<br />

<strong>M77</strong> Control System<br />

The <strong>M77</strong>E Electronics is an integrated system with the<br />

versatility to meet any control application. It is a<br />

combination of the <strong>M77</strong>EM processor and an exceptionally<br />

versatile microprocessor based controller which<br />

offers outstanding features. See pages 5 and 6 for details.<br />

Peak/Valley Picker<br />

The peak/valley picker circuitry<br />

allows a fast system response to<br />

temperature change with adjustable<br />

slow decay of output. This<br />

feature is invaluable in applications where wide temperature<br />

variations are encountered, such as:<br />

• When hot moving objects are separated by cool spaces<br />

between them<br />

• When line of sight of sensor head intermittently or<br />

periodically is obstructed by such things as smoke,<br />

Applications<br />

The unique features of 2-color<br />

infrared thermometry make the <strong>M77</strong>/<strong>78</strong><br />

“Infraducers” ideal for a wide range of<br />

temperature measurement and control<br />

applications above 250°C (500°F). These<br />

include metal melting operations, heat<br />

treating, ore smelting, wire and rod<br />

forming, vacuum furnaces, ceramic kilns,<br />

induction heating and crystal growing.<br />

Two applications are illustrated at right.<br />

Fig. 1<br />

Fiber Optics<br />

Lens Assembly<br />

M<strong>78</strong><br />

Infraducer<br />

Figure 1:<br />

Induction Heating<br />

The illustration indicates how the M<strong>78</strong>,<br />

with its fiber optic feature, can be used<br />

at multiple locations along the length of<br />

the object being heated to measure the<br />

temperature at critical points to assure<br />

uniformity of treatment.<br />

Figure 2:<br />

Vacuum Melting<br />

In vacuum furnaces often sighting through<br />

a window is difficult or undesirable. In<br />

this application a fiber optic lens assembly<br />

is placed inside the vessel, using a vacuum<br />

bushing. Since the M<strong>78</strong> is independent of<br />

emissivity it is also ideal for direct sighting<br />

temperature measurement of molten metal<br />

in other metal furnace applications.<br />

7<br />

Fig. 2<br />

Fiber<br />

Optics<br />

Cable<br />

M<strong>78</strong><br />

Infraducer<br />

Vacuum or<br />

High Pressure<br />

Bushing

Accessories<br />

Protective Jacket<br />

This NEMA 4 rated cast aluminum<br />

jacket and end cap protect the sensor<br />

head from physical damage in heavy<br />

industry environments and dampen<br />

the effect of rapid ambient changes.<br />

The jacket features a quickly removable<br />

end cap which provides easy<br />

access to the eye piece and focussing<br />

knob without disturbing the electrical<br />

connections. In ambients exceeding<br />

the maximum rated temperature of<br />

the sensor head, a protective cooling<br />

jacket is mandatory. While air flow<br />

alone is sufficient for light cooling,<br />

water must be used for moderate and<br />

heavy cooling.<br />

To order: Specify Part No. 11609-7<br />

for protective jacket. Specify Part<br />

No. 11609-8 for protective cooling<br />

jacket.<br />

Air Purge Assembly<br />

This assembly performs two important functions - purging and localized cooling.<br />

Air purging of the optics is extremely important when airborne contaminants can<br />

build up on the lens and eventually “blind” the sensor head.<br />

The <strong>Mikron</strong> air purge assembly has been carefully engineered to prevent<br />

contaminant build up. A flow of only 75 CFH (2 CMH) of normally clean industrial<br />

air will keep the optics clean under most conditions.<br />

The cooling plate section of the air purge assembly allows the coolant to<br />

circulate in a stainless steel chamber which cools the sensor head up to an<br />

ambient temperature of 250°F (120°C) using 10 gallons/hour (38 liters/hour).<br />

To order: Specify Part No. 11524-L.<br />

.50 (13) ø<br />

(4) MOUNTING HOLES EQ. SP.<br />

ON A 4.7500 (121) Ø B.C. 1/8 NPT<br />

COOLANT IN<br />

6.00 ø<br />

(152)<br />

2.31 ø<br />

(59)<br />

3.00<br />

(76)<br />

.45<br />

(11)<br />

1.00<br />

(25)<br />

AIR PURGE ASSY<br />

14.35<br />

(364)<br />

5.60<br />

(142)<br />

1/8 NPT<br />

COOLANT IN<br />

1/8 NPT<br />

COOLANT OUT<br />

3.25<br />

(83)<br />

REMOVABLE CAP<br />

OUTPUT<br />

CABLE<br />

REMOVABLE<br />

CAP<br />

1.90 ø<br />

(48)<br />

2.81 ø<br />

(71)<br />

2.88 ø<br />

(73)<br />

MOUNTING<br />

BRACKET<br />

COOLANT IN<br />

(JACKET)<br />

COOLANT OUT<br />

(ADDITIONAL)<br />

AIR PURGE<br />

ASSEMBLY<br />

SPRING LOADED<br />

AIMING FLANGE<br />

MOUNT<br />

COOLANT<br />

OUT<br />

(JACKET)<br />

PROTECTIVE<br />

COOLING<br />

JACKET<br />

COOLANT IN<br />

(ADDITIONAL)<br />

SIGHT TUBE<br />

AIR<br />

PURGE<br />

IN<br />

NOTES<br />

1. ALL CASTINGS AND FLANGES ARE<br />

ALUMINUM UNLESS OTHERWISE SPECIFIED<br />

2. ALL HARDWARES ARE STAINLESS STEEL<br />

3. ALL DIMENSIONS ARE IN INCHES (MM)<br />

AIR PURGE<br />

SIGHT TUBE<br />

MOUNTING FLANGE<br />

ADJUSTABLE SPRINGS<br />

ANGLE OF<br />

ADJUSTMENT<br />

(X-Y) AXIS<br />

Aiming Flange Assembly<br />

Used in installations requiring mounting of<br />

the sensor assembly while allowing adjustment<br />

of the optical path to a maximum of 5<br />

degrees in any direction.<br />

To order: Specify Part No. 11649-2.<br />

A protective cooling jacket and air purge<br />

assembly for the M<strong>78</strong> fiber optic unit is<br />

shown below.<br />

To order: Specify Part No. 12220-1.<br />

10˚<br />

1/8 NPT AIR<br />

PURGE IN<br />

1/8 NPT<br />

COOLANT OUT<br />

PROTECTIVE JACKET<br />

COOLING (OPTIONAL)<br />

1.94<br />

1.50<br />

(49)<br />

(38) 1/2 NPT<br />

2.50<br />

(63)<br />

OUTPUT CABLE<br />

BUSHING<br />

9.41<br />

(239)<br />

1/4 - 20 TAP X .375 DP.<br />

(2) HOLES<br />

MOUNTING SURFACE<br />

Fiber Optic Target<br />

Illuminator (Optional)<br />

<strong>Mikron</strong> offers a fiber optic illuminator<br />

for precision illumination<br />

of the target areas when used in<br />

conjunction with fiber optics and<br />

lens assembly.<br />

To order: Specify Part No.<br />

12110-1A for 115VAC.<br />

Specify Part No. 12110-2B<br />

for 220VAC.<br />

Power Supplies<br />

A low profile, sealed and rugged package<br />

suitable for chassis mounting. The<br />

front-mounted terminal barrier strip is<br />

perfect for isolation between input and<br />

output voltages. A current limiting feature<br />

protects the power supply when<br />

short circuit occurs. Four tapped holes<br />

are provided for mounting.<br />

Output Voltage: ±15VDC, 300mA max.<br />

Operating Temperature: -15 to 160°<br />

F(-25 to 70° C).<br />

Dimensions: (W x H x D) 2.5” x 1.56”<br />

x 3.5” (64 x 39 x 107mm)<br />

To order: Specify Part No. 11846-6<br />

for 115VAC input. Specify Part No.<br />

11846-7 for 220VAC input.<br />

(48)<br />

AIR<br />

1.9<br />

DIA.<br />

OUT<br />

inches (mm)<br />

1.00<br />

(25)<br />

.40<br />

(10)<br />

COOLANT<br />

OUT<br />

PURGE AIR IN<br />

COOLANT IN<br />

7.81 (198)<br />

PROTECTIVE CAP<br />

FIBER OPTIC CABLE<br />

ADJUSTABLE FLANGE MOUNT (OPTIONAL)<br />

PROTECTIVE<br />

FLEXIBLE HOSE<br />

.50 INSIDE<br />

DIAMETER<br />

(OPTIONAL)<br />

Made in U.S.A. The <strong>M77</strong>/<strong>78</strong> <strong>Series</strong> are designed and manufactured in the U.S.A.<br />

ISO 9001