CORROSION RESISTANCE OF HASTEllOY®AllOYS - Haynes ...

CORROSION RESISTANCE OF HASTEllOY®AllOYS - Haynes ...

CORROSION RESISTANCE OF HASTEllOY®AllOYS - Haynes ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

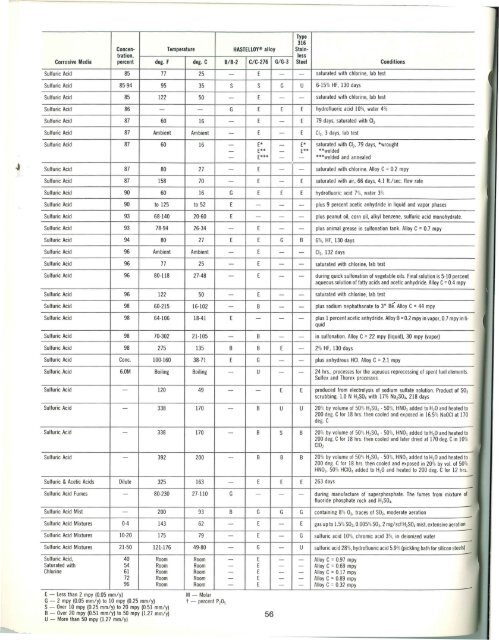

Type<br />

316<br />

Concen- Temperature HASTELlOY3 alloy Staintration,<br />

less<br />

Corrosive Media percent deg. F deg. C 8/8-2 C/C-276 G/G-3 Steel Conditions<br />

Sulfuric Acid 85 77 25 - E - - saturated with chlorine, lab test<br />

Sulluric Acid 85·94 95 35 S S G U 6·15% HF, 130 days<br />

Sulfuric Acid 85 122 50 - E - - saturated with chlorine, lab test<br />

Sulfuric Acid 86 - - G E E E hydrofluoric acid 10%, water 4%<br />

Sulfuric Acid 87 60 16 - E - E 79 days, saturated with CI2<br />

Sulfuric Acid 87 Ambient Ambient - E - E C12, 3 days, lab test<br />

'.<br />

Sulfuric Acid 87 60 16 - E* - E* saturated with CI2, 79 days, *wrought<br />

- E** - E** **welded<br />

- E*** - - ***welded and annealed<br />

Sulfuric Acid 87 80 27 - E - - saturated with chlorine. Alloy C=0.2 mpy<br />

Sulfuric Acid 87 158 70 - E - E saturated with air, 66 days, 4.1 ft./sec. flow rate<br />

Sulfuric Acid 90 60 16 G E E E hydrofluoric acid 7%, water 3%<br />

Sulfuric Acid 90 to 125 to 52 E - - - plus 9 percent acetic anhydride in liquid and vapor phases<br />

Sulfuric Acid 93 68·140 20·60 E - - - plus peanut oil, corn oil, alkyl benzene, sulfuric acid monohydrate.<br />

Sulfuric Acid 93 78-94 26-34 - E - - plus animal grease in sulfonation tank. Alloy C=0.7 mpy<br />

Sulfuric Acid 94 80 27 E E G B 6%, HF, 130 days<br />

Sulfuric Acid 96 Ambient Ambient - E - - C12, 132 days<br />

Sulfuric Acid 96 77 25 - E - - saturated with chlorine, lab test<br />

Sulfuric Acid 96 80-118 27·48 - E - - during quick sulfonation of vegetable oils. Final solution is 5-10 percent<br />

aqueous solution of fatty acids and acetic anhydride. Alloy C=0.4 mpy<br />

Sulfuric Acid 96 122 50 - E - - saturated with chlorine, lab test<br />

Sulfuric Acid 98 60·215 16-102 - B - - plus sodium nephathanate to 3 0 Be. Alloy C=44 mpy<br />

Sulfuric Acid 98 64-106 18·41 E - - - plus 1 percent acetic anhydride. Alloy B=0.2 mpy in vapor, 0.7 mpy in liquid<br />

Sulfuric Acid 98 70·302 21-105 - B - - in sulfonation. Alloy C=22 mpy (liquid). 30 mpy (vapor)<br />

Sulfuric Acid 98 275 135 B B E - 2% HF, 130 days<br />

Sulfuric Acid Cone. 100·160 38·71 E G - - plus anhydrous HCI. Alloy C=2.1 mpy<br />

Sulfuric Acid 6.0M Boiling Boiling - U - - 24 hrs., processes for the aqeuous reprocessing of spent fuel elements.<br />

Sulfex and Thorex processes<br />

Sulfuric Acid - 120 49 - - E E produced from electrolysis of sodium sulfate solution. Product of S02<br />

scrubbing. 1.0 N H 2 S04with 17% Na2S04, 218 days<br />

Sulfuric Acid - 338 170 - B U U 20% by volume of 50% H2S04- 50%, HNO) added to H20 and heated to<br />

200 deg. Cfor 18 hrs. then cooled and exposed in 16.5% NaOCI at 170<br />

deg. C<br />

Sulfuric Acid - 338 170 - B S B 20% by volume of 50% H 2 S04, 50%, HNO) added to H 2 0 and heated to<br />

200 deg. C for 18 hrs. then cooled and later dried at 170 deg. Cin 10%<br />

CI02<br />

Sulfuric Acid - 392 200 - B B B 20% by volume of 50% H2S04- 50%, HNO) added to H 2 0 and heated to<br />

200 deg. C for 18 hrs. then cooled and exposed in 20% by vol. of 50%<br />

HNO). 50% HCI04 added to H20 and heated to 200 deg. C for 12 hrs.<br />

Sulfuric & Acetic Acids Dilute 325 163 - E E E 263 days<br />

Sulfuric Acid Fumes - 80-230 27-110 G - - - during manufacture of superphosphate. The fumes from mixture of<br />

fluoride phosphate rock and H2SO4.<br />

Sulfuric Acid Mist - 200 93 B G G G containing 8% O2, traces of S02, moderate aeration<br />

Sulfuric Acid Mixtures 0·4 143 62 - E - E gas up to 1.5% S02, 0.005% SO), 2mg/scf H2S04mist, extensive aeration<br />

Sulfuric Acid Mixtures 10-20 175 79 - E - G sulfuric acid 10%, chromic acid 3%, in deionized water<br />

Sulfuric Acid Mixtures 21-50 121-176 49·80 - G - U sulfuric acid 28%, hydrofluoric acid 5.9% (pickling bath for silicon steels)_<br />

Sulfuric Acid, 40 Room Room - E - - Alloy C=0.97 mpy<br />

Saturated with 54 Room Room - E - - Alloy C=0.69 mpy<br />

Chlorine 61 Room Room - E - - Alloy C=0.17 mpy<br />

72 Room Room - E - - Alloy C=0.89 mpy<br />

E - Less than 2 mpy (0.05 mm/y)<br />

G - 2 mpy (0.05 mm/y) to 10 mpy (0.25 mm/y)<br />

S - Over 10 mpy (0.25 mm/y) to 20 mpy (0.51 mm/y)<br />

B - Over 20 mpy (0.51 mm/y) to 50 mpy (1.27 mm/y)<br />

U - More than 50 mpy (1.27 mm/y)<br />

96 Room Room - E - - Alloy C=0.32 mpy<br />

-<br />

M -<br />

Molar<br />

t - percent P20 S<br />

56<br />

-<br />

-