CORROSION RESISTANCE OF HASTEllOY®AllOYS - Haynes ...

CORROSION RESISTANCE OF HASTEllOY®AllOYS - Haynes ...

CORROSION RESISTANCE OF HASTEllOY®AllOYS - Haynes ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

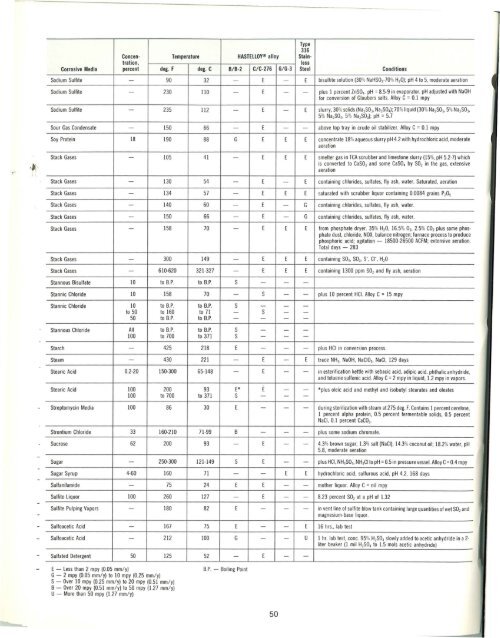

Type<br />

316<br />

Concen- Temperature HASTEllOY~ alloy Staintration.<br />

less<br />

Corrosive Media percent deg. F deg. C 8/8-2 C/C-276 G/G-3 Steel Conditions<br />

Sodium Sulfite - 90 32 - E - E bisulfite solution (30% NaHSO]" 70% H20); pH 4 to 5, moderate aeration<br />

Sodium Sulfite - 230 110 - E - - plus 1percent ZnS04. pH =: 8.5·9 in evaporator. pH adjusted with NaOH<br />

for conversion of Glaubers salts. Alloy C =: 0.1 mpy<br />

Sodium Sulfite - 235 112 - E - E slurry, 30% solids (Na2S0J, Na2S04); 70% liquid (30% Na2S0S, 5% Na2S0J,<br />

5% Na2S04, 5% Na2S03); pH =: 5.7<br />

Sour Gas Condensate - 150 66 - E - - above top tray in crude oil stabilizer. Alloy C =: 0.1 mpy<br />

Soy Protein 18 190 88 G E E E concentrate 18% aqueous slurry pH 4.2 with hydrochloric acid, moderate<br />

aeration<br />

Stack Gases - 105 41 - E E E smelter gas in TCA scrubber and limestone slurry (15%, pH 5.2-7) which<br />

is converted to CaS03 and some CaS04 by S02 in the gas, extensive<br />

aeration<br />

Stack Gases - 130 54 - E - E containing chlorides, sulfates, fly ash, water. Saturated, aeration<br />

Stack Gases - 134 57 - E E E saturated with scrubber liquor containing 0.0084 grains P20S<br />

Stack Gases - 140 60 - E - G containing chlorides, sulfates, fly ash, water.<br />

Stack Gases - 150 66 - E - G containing chlorides, sulfates, fly ash, water.<br />

Stack Gases - 158 70 - E E E from phosphate dryer. 35% H20, 16.5% 02, 2.5% CO2plus some phosphate<br />

dust, chloride, NOX, balance nitrogen; furnace process to produce<br />

phosphoric acid; agitation - 18500-26500 ACFM; extensive aeration.<br />

Total days - 283<br />

Stack Gases - 300 149 - E E E containing S04, S03, So, CI-, H2O<br />

Stack Gases - 610-620 321-327 - E E E containing 1300 ppm S02 and fly ash, aeration<br />

Stannous Bisulfate 10 to B.P. to B.P_ S - - -<br />

Stannic Chloride 10 158 70 - S - - plus 10 percent HCI. Alloy C =: 15 mpy<br />

Stannic Chloride 10 to B.P. to B.P. S - - -<br />

to 50 to 160 to 71 - S - -<br />

50 to B.P. to B.P. - - - -<br />

Stannous Chloride All to B.P. to B.P. S - - -<br />

100 to 700 to 371 S - - -<br />

Starch - 425 218 E - - - plus HCI in conversion process.<br />

Steam - 430 221 - E - E trace NHJ, NaOH, NaC103, NaCI, 129 days<br />

Stearic Acid 0.2-20 150-300 65-148 - E - - in esterification kettle with sebacic acid, adipic acid, phthalic anhydride,<br />

and toluene sulfonic acid. Alloy C=: 2 mpy in liquid, 1.2 mpy in vapors.<br />

Stearic Acid 100 200 93 E* E - - *plus oleic acid and methyl and isobutyl stearates and oleates<br />

100 to 700 to 371 S - - -<br />

Streptomycin Media 100 86 30 E - - - during sterilization with steam at275 deg. F. Contains 1percent cerelose,<br />

1 percent alpha protein, 0.5 percent fermentable solids, 0.5 percent<br />

NaCI, 0.1 percent CaC03.<br />

Strontium Chloride 33 160-210 71-99 B - - - plus some sodium chromate.<br />

Sucrose 62 200 93 - E - - 4.3% brown sugar; 1.3% salt (NaCI); 14.3% coconut oil; 18.2% water, pH<br />

5.8, moderate aeration<br />

Sugar - 250-300 121-149 S E - - plus HCI, NH4S04, NH4Clto pH =: 0.5 in pressure vessel. Alloy C=: 0.4 mpy<br />

Sugar Syrup 4-60 160 71 - - E E hydrochloric acid, sulfurous acid, pH 4.2, 168 days<br />

Sulfanilamide - 75 24 E E - - mother liquor. Alloy C =: nil mpy<br />

Sulfite Liquor 100 260 127 - E - - 8.23 percent S02 at a pH of 1.32<br />

Sulfite Pulping Vapors - 180 82 E - - - in vent line of sulfite blow tank containing large quantities of wet S02 and<br />

magnesium-base liquor.<br />

Sulfoacetic Acid - 167 75 E - - E 16 hrs., lab test<br />

Sulfoacetic Acid - 212 100 G - - U 1 hr. lab test, cone. 95% H2S04slowly added to acetic anhydride in a 2-<br />

liter beaker (1 mil H2S0 4 to 1.5 mols acetic anhydride)<br />

Sulfated Detergent 50 125 52 - E - -<br />

E - Less than 2 mpy (0.05 mm/y)<br />

G- 2 mpy (0.05 mm/y) to 10 mpy (0.25 mm/y)<br />

S - Over 10 mpy (0.25 mm/y) to 20 mpy (0.51 mm/y)<br />

B - Over 20 mpy (0.51 mm/y) to 50 mpy (1.27 mm/y)<br />

U - More than 50 mpy (1.27 mm/y)<br />

B.P. -<br />

Boiling Point<br />

50