CORROSION RESISTANCE OF HASTEllOY®AllOYS - Haynes ...

CORROSION RESISTANCE OF HASTEllOY®AllOYS - Haynes ...

CORROSION RESISTANCE OF HASTEllOY®AllOYS - Haynes ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

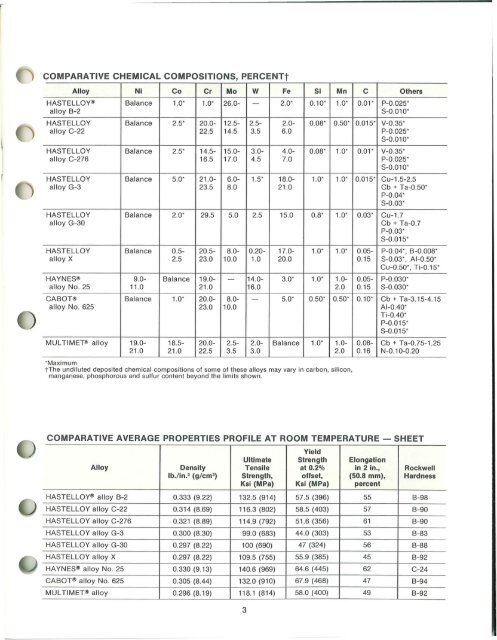

COMPARATIVE CHEMICAL COMPOSITIONS, PERCENTt<br />

Alloy Ni Co Cr Mo W Fe Si Mn C Others<br />

HA8TELLOY® Balance 1.0* 1.0* 26.0- - 2.0* 0.10* 1.0* 0.01* P-0.025*<br />

alloy B-2 8-0.010*<br />

HA8TELLOY Balance 2.5* 20.0- 12.5- 2.5- 2.0- 0.08* 0.50* 0.015* V-0.35*<br />

alloy C-22 22.5 14.5 3.5 6.0 P-0.025*<br />

8-0.010*<br />

HA8TELLOY Balance 2.5* 14.5- 15.0- 3.0- 4.0- 0.08* 1.0* 0.01* V-0.35*<br />

alloy C-276 16.5 17.0 4.5 7.0 P-0.025*<br />

8-0.010*<br />

HA8TELLOY Balance 5.0* 21.0- 6.0- 1.5* 18.0- 1.0* 1.0* 0.015* Cu-1.5-2.5<br />

alloy G-3 23.5 8.0 21.0 Cb + Ta-0.50*<br />

P-0.04*<br />

8-0.03*<br />

HA8TELLOY Balance 2.0* 29.5 5.0 2.5 15.0 0.8* 1.0* 0.03* Cu-1.7<br />

alloy G-30<br />

Cb + Ta-0.7<br />

P-0.03*<br />

8-0.015*<br />

HA8TELLOY Balance 0.5- 20.5- 8.0- 0.20- 17.0- 1.0* 1.0* 0.05- P-0.04*, B-0.008*<br />

alloy X 2.5 23.0 10.0 1.0 20.0 0.15 8-0.03*, AI-0.50*<br />

Cu-0.50*, Ti-0.15*<br />

HAYNE8® 9.0- Balance 19.0- - 14.0- 3.0* 1.0* 1.0- 0.05- P-0.030*<br />

alloy No. 25 11.0 21.0 16.0 2.0 0.15 8-0.030*<br />

CABOT® Balance 1.0* 20.0- 8.0- - 5.0* 0.50* 0.50* 0.10* Cb + Ta-3.15-4.15<br />

alloy No. 625 23.0 10.0 AI-0.40*<br />

Ti-0.40*<br />

P-0.015*<br />

8-0.015*<br />

MULTIMET~ alloy 19.0- 18.5- 20.0- 2.5- 2.0- Balance 1.0* 1.0- 0.08- Cb + Ta-0.75-1.25<br />

21.0 21.0 22.5 3.5 3.0 2.0 0.16 N-0.10-0.20<br />

'Maximum<br />

tThe undiluted deposited chemical compositions of some of these alloys may vary in carbon, silicon,<br />

manganese, phosphorous and sulfur content beyond the limits shown.<br />

COMPARATIVE AVERAGE PROPERTIES PR<strong>OF</strong>ILE AT ROOM TEMPERATURE -<br />

SHEET<br />

Yield<br />

Ultimate Strength Elongation<br />

Alloy Density Tensile at 0.2% in 2 in., Rockwell<br />

Ib./in. 3 (g/cm 3 ) Strength, offset, (50.8 mm), Hardness<br />

Ksi (MPa) Ksi (MPa) percent<br />

HA8TELLOY~ alloy B-2 0.333 (9.22) 132.5 (914) 57.5 (396) 55 B-98<br />

HA8TELLOY alloy C-22 0.314 (8.69) 116.3 (802) 58.5 (403) 57 B-90<br />

HA8TELLOY alloy C-276 0.321 (8.89) 114.9 (792) 51.6 (356) 61 B-90<br />

HA8TELLOY alloy G-3 0.300 (8.30) 99.0 (683) 44.0 (303) 53 B-83<br />

HA8TELLOY alloy G-30 0.297 (8.22) 100 (690) 47 (324) 56 B-88<br />

HA8TELLOY alloy X 0.297 (8.22) 109.5 (755) 55.9 (385) 45 B-92<br />

HAYN E8l!ll alloy No. 25 0.330 (9.13) 140.6 (969) 64.6 (445) 62 C-24<br />

CABOT~ alloy No. 625 0.305 (8.44) 132.0 (910) 67.9 (468) 47 B-94<br />

MULTIMETllll alloy 0.296 (8.19) 118.1 (814) 58.0 (400) 49 B-92<br />

3