CORROSION RESISTANCE OF HASTEllOY®AllOYS - Haynes ...

CORROSION RESISTANCE OF HASTEllOY®AllOYS - Haynes ...

CORROSION RESISTANCE OF HASTEllOY®AllOYS - Haynes ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

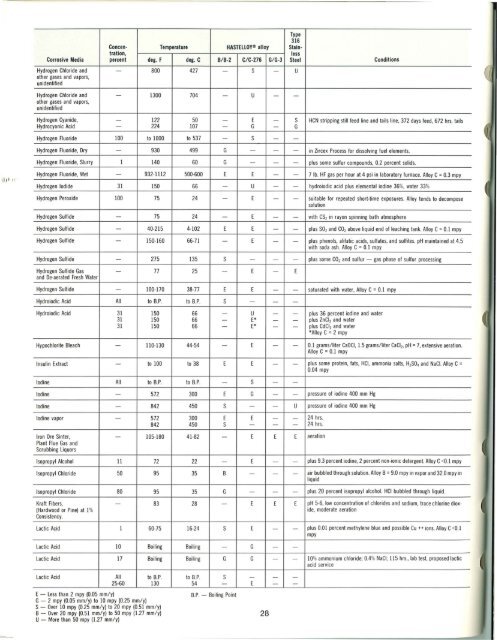

Type<br />

316<br />

Concen- Temperature HASTEllOY~ alloy Staintration.<br />

less<br />

Corrosive Media percent deg. F deg. C 8/8-2 C/C-276 G/G-3 Steel Conditions<br />

Hydrogen Chloride and - 800 427 - S - U<br />

other gases and vapors,<br />

unidentified<br />

Hydrogen Chloride and - 1300 704 - U - -<br />

other gases and vapors,<br />

unidentified<br />

Hydrogen Cyanide, - 122 50 - E - S HCN stripping still feed line and tails line, 372 days feed, 672 hrs. tails<br />

Hydrocyanic Acid - 224 107 - G - G<br />

Hydrogen Fluoride 100 to 1000 to 537 - S - -<br />

Hydrogen Fluoride, Dry - 930 499 G - - - in Zircex Process for dissolving fuel elements.<br />

Hydrogen Fluoride, Slurry 1 140 60 G - - - plus some sulfur compounds, 0.2 percent solids.<br />

Hydrogen Fluoride, Wet - 932-1112 500-600 E E - - 7 lb. HF gas per hour at 4 psi in laboratory furnace. Alloy C= 0.3 mpy<br />

Hydrogen Iodide 31 150 66 - U - - hydroiodic acid plus elemental iodine 36%, water 33%<br />

Hydrogen Peroxide 100 75 24 - E - - suitable for repeated short-time exposures. Alloy tends to decompose<br />

solution<br />

Hydrogen Sulfide - 75 24 - E - - with CSz in rayon spinning bath atmosphere<br />

Hydrogen Sulfide - 40·215 4-102 E E - - plus SOz and COz above liquid end of leaching tank. Alloy C= 0.1 mpy<br />

Hydrogen Sulfide - 150-160 66·71 - E - - plus phenols, alifatic acids, sulfates, and sulfites. pH maintained at 4.5<br />

with soda ash. Alloy C= 0.1 mpy<br />

Hydrogen Sulfide - 275 135 S - - - plus some COz and sulfur - gas phase of sulfur processing<br />

Hydrogen Sulfide Gas - 77 25 - E - E<br />

and De·aerated Fresh Water<br />

Hydrogen Sulfide - 100-170 38-77 E E - - saturated with water, Alloy C= 0.1 mpy<br />

Hydroiodic Acid All to B.P. to B.P. S - - -<br />

Hydroiodic Acid 31 150 66 - U - - plus 36 percent iodine and water<br />

31 150 66 - E* - - plus ZnClz and water<br />

31 150 66 - E* - - plus CdClz and water<br />

*Alloy C= 2 mpy<br />

Hypochlorite Bleach - 110·130 44·54 - E - - 0.1 grams/liter CaOCl, 1.5 grams/liter CaClz, pH = 7, extensive aeration.<br />

Alloy C= 0.1 mpy<br />

Insulin Extract - to 100 to 38 E E - - plus some protein, fats, HCI, ammonia salts, HzS0 4 and NaCI. Alloy C=<br />

0.04 mpy<br />

Iodine All to B.P. to B.P. - S - -<br />

Iodine - 572 300 E G - - pressure of iodine 400 mm Hg<br />

Iodine - 842 450 S - - U pressure of iodine 400 mm Hg<br />

Iodine vapor - 572 300 E E - - 24 hrs.<br />

842 450 S - - - 24 hrs.<br />

Iron Ore Sinter, - 105·180 41-82 - E E E aeration<br />

Plant Flue Gas and<br />

Scrubbing liquors<br />

Isopropyl Alcohol 11 72 22 - E - - plus 9.3 percent iodine, 2 percent non-ionic detergent. Alloy C