IMPORTANT NOTES! WARNING - Ramsey Winch

IMPORTANT NOTES! WARNING - Ramsey Winch

IMPORTANT NOTES! WARNING - Ramsey Winch

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

INSTALLATION INSTRUCTIONS FOR<br />

WRAPAROUND KIT #295356<br />

ON 1999-2004 FORD F250 – F550<br />

WITH RPH 12,000 FRONT MOUNT WINCH # 123305<br />

NOTICE<br />

<strong>Ramsey</strong> kits are designed for use with <strong>Ramsey</strong> <strong>Winch</strong>es only.<br />

Use or sales of kits for other winches or applications voids warranty.<br />

<strong>WARNING</strong><br />

<strong>Ramsey</strong> offers mounting kits and winches for various vehicles. In crash tests on a limited number<br />

of automotive manufacturer's vehicles, winches/mounting kits, which have been properly<br />

mounted, have not interfered with air bag operation.<br />

The user/customer, or their installer, must verify that the mounting kit does not interfere with the<br />

factory air bag sensors, which must not be relocated or modified in any way.<br />

The user/customer should follow the vehicle manufacturer's recommendations and those of a<br />

qualified mechanic to determine if the winch/mounting kit might interfere with the air bag<br />

operation. The user/customer should then determine the suitability of a winch/mounting kit on a<br />

particular vehicle.<br />

PLEASE BE ADVISED THAT THE VEHICLE'S AIR BAG SYSTEM MAY NOT OPERATE<br />

PROPERLY IF THE WINCH/MOUNTING KIT IS NOT MOUNTED IN COMPLIANCE WITH THE<br />

VEHICLE MANUFACTURER'S RECOMMENDATIONS.<br />

DO NOT ATTACH TOW HOOK TO ANY PART OF MOUNTING KIT UNLESS INSTRUCTED TO<br />

DO SO.<br />

DO NOT SUBSTITUTE ATTACHING HARDWARE ITEMS (BOLTS, NUTS, OR WASHERS).<br />

READ AND UNDERSTAND WINCH OWNER'S MANUAL BEFORE INSTALLATION AND<br />

OPERATION OF WINCH. SEE <strong>WARNING</strong>S, CAUTIONS, AND OPERATION.<br />

<strong>IMPORTANT</strong> <strong>NOTES</strong>!<br />

1. RIGHT AND LEFT HAND DIRECTIONS AS IF SEATED BEHIND STEERING WHEEL.<br />

2. ALL FASTENING HARDWARE MUST BE LOOSELY ASSEMBLED UNTIL DIRECTED TO TIGHTEN.<br />

RAMSEY WINCH COMPANY<br />

P.O. BOX 581510<br />

TULSA, OKLAHOMA 74158<br />

KI-913344-0803-D

STEP 1<br />

Unfasten plastic splashguard from radiator support bracket. Remove vehicle tow hooks and vehicle<br />

bumper. Remove and discard shims hanging from front of vehicle frame.<br />

Enlarge rectangular cutout in bumper bracket by 1/2" at top and 1/4” at bottom. See REAR VIEW OF<br />

BUMPER below.<br />

Attach nut plate #4 to inside of bracket assembly #7 & #8 using (2) 1/2-13NC x 1-1/4 lg. capscrews<br />

#16 with lockwashers #21, and flatwashers #22, in the two front holes each side.<br />

You will need assistance for this step.<br />

While holding bumper in place, install end of R.H. and L.H. bracket assemblies through bumper and<br />

bumper brackets and into ends of R.H. and L.H. vehicle frame. Secure brackets to front of frame<br />

using (2) 1/2-13NC x 1-1/2 lg. capscrews #13, with lockwashers #21, nuts #19 and nut strips #1, each<br />

side. DO NOT TIGHTEN HARDWARE COMPLETELY.<br />

1

STEP 2<br />

Remove (4) bumper bracket bolts from each side of bumper. This allows bumper to move forward to<br />

provide access to lower bracket bolts. Use (3) 1/2-13NC x 1-1/2 lg. capscrews #13, with lockwashers<br />

#21 through bottom of vehicle frame and into nut plate attached to bracket assemblies, each side.<br />

Tighten hardware to full torque. (See torque value chart, page 6).<br />

Reattach bumper to bumper brackets and tighten all hardware to full torque. Use bracket assembly<br />

#7 & #8 as a template to drill (2) 9/16 DIA. holes through bumper brackets, as shown below. Install<br />

(2) 1/2-13NC x 1-1/2lg. capscrews #13, with lockwashers #21, nuts #19 and nut strips #1, each side.<br />

Reattach vehicle tow hooks to underside of bracket assembly #7 & #8 using M12 x 1.75 x 50mm<br />

capscrews. Discard the existing bolts. Tighten to full torque. (See torque value chart, page 6).<br />

Reattach splashguard.<br />

2

STEP 3<br />

Place frame assembly #3 between bracket assemblies #7 & #8 and R.H. & L.H. side plates #2 to the<br />

outsides of bracket assemblies. Use (3) 1/2-13NC x 1-1/2 lg. carriage bolts #15 and (1) 1/2-13NC x<br />

1-1/4 lg. carriage bolt #14, with lockwashers #21, and nuts #19 (each side), as shown, to attach side<br />

plates and brackets to frame assembly. DO NOT TIGHTEN HARDWARE.<br />

Install (1) tube assembly #6 at top between side plates #2, placing shims #23 between side plates<br />

and ends of tube. Secure using (1) 3/8-16 NC X 3/4 lg. hex socket button head capscrew #17 at<br />

each end. Attach light tube assemblies #9 to side plates, as shown. Use (2) 3/8-16NC x 1 lg.<br />

carriage bolts #10, with lockwashers #20 and nuts #18, each side.<br />

3

STEP 4<br />

Remove base tie bars from bottom of winch end bearings. Place winch in cavity of frame #3 on top of<br />

mounting plate. Place (2) base tie bars between the rear winch feet and the mounting plate. Place<br />

the other two base tie bars between the front winch feet and the mounting platform. Secure using (8)<br />

1/2-13NC X 1-1/2 lg. hex hd. capscrews inserted through 1/2” lockwashers then through mounting<br />

plate, base tie bars, and into tapped holes in winch feet. Tighten securely. (See torque value chart,<br />

page 6).<br />

Install remaining bottom tube assembly #6 between side plates #2, placing shims #23 between side<br />

plates and ends of tube. Secure using (1) 3/8-16 NC X 3/4 lg. hex socket button head capscrew #17<br />

at each end. Tighten all hardware to proper torque value (see Torque value chart, page 6).<br />

4

STEP 5<br />

Place roller fairlead over holes in mounting plate. Install (2) 3/8-16 NC X 1 lg. capscrews #11 through<br />

(2) 3/8” lockwashers #20, then through inside holes in mounting plate and into the threaded holes in<br />

bottom of roller guide. Install (2) 3/8-16 NC X 1-1/2 lg. capscrews #12 through outside holes of<br />

mounting plate and roller guide and secure using (2) 3/8 lockwashers #20, and (2) nuts #18. Tighten<br />

hardware to proper torque value (see Torque value chart, page 6).<br />

SEE PAGE 2 OF WINCH OWNER’S MANUAL FOR CABLE INSTALLATION, PAGE 3 FOR<br />

HYDRAULIC SCHEMATICS, AND PAGE 14 (VIEW A-A) FOR HYDRAULIC LINES INSTALLATION.<br />

REFER TO WINCH OWNER'S MANUAL FOR PROPER OPERATIONS.<br />

5

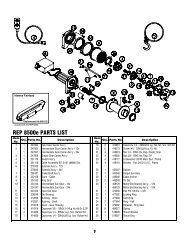

PARTS LIST FOR KIT #295356 (BLACK)<br />

ITEM NO. QTY. PART NO. DESCRIPTION<br />

1 4 364165 NUT STRIP<br />

2 2 265073 SIDE PLATE R.H. & L.H.-BLACK<br />

3 1 265083 FRAME ASSEMBLY-WINCH MNTG.<br />

4 2 350666 PLATE-NUT<br />

6 2 395272 TUBE ASSEMBLY (BLACK)<br />

7 1 395380 BRACKET ASSEMBLY-R.H.<br />

8 1 395381 BRACKET ASSEMBLY-L.H.<br />

9 2 395386 LIGHT TUBE ASSEMBLY (BLACK)<br />

10 4 414220 CARRIAGE BOLT 3/8-16NC X 1 LG. GR.5 BLACK<br />

11 2 414321 CAPSCREW 3/8-16NC X 1" LG. HX. HD. GR.5 BLACK<br />

12 2 414322 CAPSCREW 3/8-16NC X 1-1/2 LG. HX. HD. GR.5 BLACK<br />

13 14 414551 CAPSCREW 1/2-13NC X 1-1/2 LG. HX. HD. GR.5 BLACK<br />

14 2 414559 CARRIAGE BOLT 1/2-13NC X 1-1/4 LG. GR.5 BLACK<br />

15 6 414560 CARRIAGE BOLT 1/2-13NC X 1-1/2 LG. GR.5 BLACK<br />

16 4 414592 CAPSCREW 1/2-13NC x 1-1/4 LG. HX. HD. GR.5 BLACK<br />

17 4 414937 CAPSCREW 3/8-16NC X 3/4 LG. HX. SOC. BUTTON HD. BLK.<br />

18 6 418033 NUT 3/8-16NC HX. REG.-BLACK<br />

19 16 418072 NUT 1/2-13NC HX. REG.-BLACK<br />

20 8 418175 LOCKWASHER 3/8 MED. SECT.-BLACK<br />

21 26 418216 LOCKWASHER 1/2 MED. SECT.-BLACK<br />

22 4 418229 WASHER 1/2 FLAT<br />

23 4 488011 SHIM-PLASTIC<br />

24 6 415311 CAPSCREW M12 X 1.75 X 50 HX HD GR8.8 Z/P<br />

TORQUE VALUE CHART<br />

SIZE TORQUE FT./LB. NM<br />

3/8-16 39 52<br />

1/2-13 87 118<br />

6