- Page 1 and 2: SERVICE MANUAL FILE NO. A07-003 Rev

- Page 3 and 4: 7. REFRIGERANT R410A ..............

- Page 5 and 6: WARNING Check earth wires. Prohibit

- Page 7 and 8: • New Refrigerant (R410A) This ai

- Page 9 and 10: 1. SPECIFICATIONS Revised 2: Jun.,

- Page 11 and 12: Revised 2: Jun., 2008 Indoor unit

- Page 13 and 14: 1-1-2. Concealed Duct Type Model I

- Page 15 and 16: 1-1-3. Under Ceiling Type Revised

- Page 17 and 18: 1-1-4. High Wall Type Revised 2: J

- Page 19 and 20: 1-1-5. Compact 4-Way Cassette (600

- Page 21 and 22: 1-1-6. Slim Duct Type Model Coolin

- Page 23 and 24: Revised 2: Jun., 2008 Indoor unit 1

- Page 25 and 26: 1-2. Outdoor Unit Model name Outdo

- Page 27 and 28: 1-3. Operation Characteristic Curve

- Page 29 and 30: 2. CONSTRUCTION VIEWS (EXTERNAL VIE

- Page 31 and 32: Revised 2: Jun., 2008 RAV-SM1104UT-

- Page 33 and 34: - 33 - 365 17.5 17.5 74 Drain hole

- Page 35 and 36: RAV-TWP30E2, RAV-TWP50E2 (Simultane

- Page 37 and 38: 3-2. Outdoor Unit RAV-SP1104AT-E, S

- Page 39 and 40: 4-1. Slim Duct (Filter Attached) 4.

- Page 41 and 42: 5-1-2. Slim Duct Type RAV-SM404SDT-

- Page 43 and 44: - 43 - CAUTION : HIGH VOLTAGE The h

- Page 45 and 46: 6-2. Outdoor Unit (Parts Ratings) R

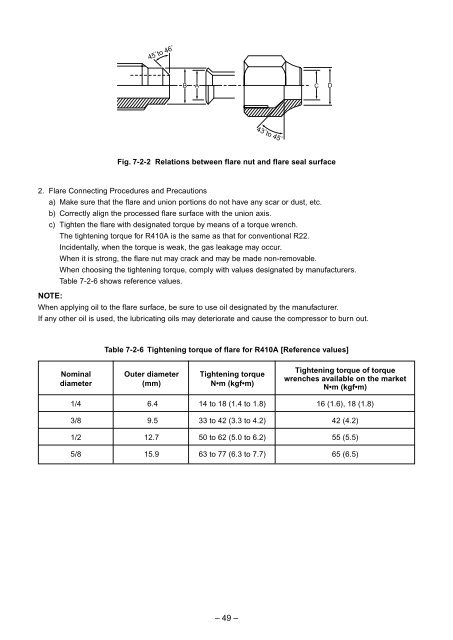

- Page 47: Table 7-2-1 Thicknesses of annealed

- Page 51 and 52: 1) Be sure to make setting so that

- Page 53 and 54: 7-6. Instructions for Re-use Piping

- Page 55 and 56: Revised 2: Jun., 2008 7-6-6. Handli

- Page 57 and 58: 7-6-8. Recovery method of refrigera

- Page 59 and 60: 8-1-2. Connection of Wireless Remot

- Page 61 and 62: 8-2. Control Specifications No. Ite

- Page 63 and 64: No. Item Outline of specifications

- Page 65 and 66: No. Item Outline of specifications

- Page 67 and 68: No. Item Outline of specifications

- Page 69 and 70: No. Item Outline of specifications

- Page 71 and 72: No. Item Outline of specifications

- Page 73 and 74: No. Item Outline of specifications

- Page 75 and 76: Optional power supply CN309 (Yellow

- Page 77 and 78: - 77 - L-phase power supply lead (B

- Page 79 and 80: 3. Outdoor fan control SP110 SP140

- Page 81 and 82: 7. Current release value shift cont

- Page 83 and 84: 1. Pulse Motor Valve (PMV) control

- Page 85 and 86: 2) Heating fan control The outdoor

- Page 87 and 88: 10-1. Summary of Troubleshooting 1

- Page 89 and 90: 10-2. Troubleshooting 10-2-1. Outli

- Page 91 and 92: 10-2-2. Others (Other than Check Co

- Page 93 and 94: - 93 - Check Code List (Outdoor) Re

- Page 95 and 96: Error mode detected by indoor unit

- Page 97 and 98: Error mode detected by outdoor unit

- Page 99 and 100:

10-2-4. Diagnostic Procedure for Ea

- Page 101 and 102:

Revised 2: Jun., 2008 [E18 error] I

- Page 103 and 104:

[P10 error] Is connection of float

- Page 105 and 106:

[F02 error] Revised 2: Jun., 2008

- Page 107 and 108:

[E03 error] (Master indoor unit) [

- Page 109 and 110:

Check code Outdoor LED display Che

- Page 111 and 112:

Check code Outdoor LED display Che

- Page 113 and 114:

Check code [L29] Outdoor LED displa

- Page 115 and 116:

Check code Outdoor LED display Che

- Page 117 and 118:

Check code Outdoor LED display Che

- Page 119 and 120:

Temperature sensor Temperature - Re

- Page 121 and 122:

Lamp indication Check code Cause of

- Page 123 and 124:

- 123 - Check Code List (Outdoor) R

- Page 125 and 126:

Error mode detected by remote contr

- Page 127 and 128:

10-2-9. Diagnostic Procedure for Ea

- Page 129 and 130:

[E18 error] Is inter-unit cable of

- Page 131 and 132:

[P10 error] Revised 2: Jun., 2008

- Page 133 and 134:

[F02 error] Revised 2: Jun., 2008

- Page 135 and 136:

[E03 error] (Master indoor unit) [

- Page 137 and 138:

Check code [F12] [Suction temp. sen

- Page 139 and 140:

Check code [P22] [Fan system error]

- Page 141 and 142:

11. REPLACEMENT OF SERVICE P.C. BOA

- Page 143 and 144:

Revised 2: Jun., 2008 Setting 4-way

- Page 145 and 146:

Revised 2: Jun., 2008 Table 1. Sett

- Page 147 and 148:

12-1. Indoor Unit 12. SETUP AT LOCA

- Page 149 and 150:

Procedure 1 2 Turn on power of the

- Page 151 and 152:

12-1-4. Function Selection Setup P

- Page 153 and 154:

DN Item Contents At shipment from f

- Page 155 and 156:

12-1-6. Monitor Function of Remote

- Page 157 and 158:

n Indoor unit power-ON sequence Pow

- Page 159 and 160:

4. Wiring specifications • Use 2-

- Page 161 and 162:

2. How to confirm the central contr

- Page 163 and 164:

4. How to set louver lock (Louver f

- Page 165 and 166:

Be sure to make ceiling setting whe

- Page 167 and 168:

12-4-3. Service Support Function (L

- Page 169 and 170:

2) Error display The error which i

- Page 171 and 172:

4) Specific operation for maintenan

- Page 173 and 174:

13. ADDRESS SETUP Revised 2: Jun.,

- Page 175 and 176:

13-2-2. Automatic Address Example f

- Page 177 and 178:

Revised 2: Jun., 2008 13-3. Remote

- Page 179 and 180:

13-5. Confirmation of Indoor Unit N

- Page 181 and 182:

14. DETACHMENTS Revised 2: Jun., 20

- Page 183 and 184:

No. Part name Procedure Remarks 4 C

- Page 185 and 186:

No. Part name Procedure Remarks 6 D

- Page 187 and 188:

No. Part name Procedure Remarks 7 F

- Page 189 and 190:

No. Part name Procedure Remarks 9 F

- Page 191 and 192:

14-1-2. Slim Duct Type RAV-SM404SDT

- Page 193 and 194:

No. Part name Procedure Remarks 5 P

- Page 195 and 196:

No. Part name Procedure Remarks 9 D

- Page 197 and 198:

No. Part name Procedure Remarks 2 D

- Page 199 and 200:

No. Part name Procedure Remarks 4 R

- Page 201 and 202:

No. Part name Procedure Remarks 6 C

- Page 203 and 204:

No. Part name Procedure Remarks 7 P

- Page 205 and 206:

No. Part name Procedure Remarks 2 F

- Page 207 and 208:

No. Part name Procedure Remarks 4 C

- Page 209 and 210:

No. Part name Procedure Remarks 7 C

- Page 211 and 212:

15. EXPLODED VIEWS AND PARTS LIST R

- Page 213 and 214:

RAV-SM564UT-E, RAV-SM804UT-E, RAV-S

- Page 215 and 216:

RBC-AX31U (W)-E, RBC-AX31U (WS)-E 3

- Page 217 and 218:

Revised 2: Jun., 2008 Location No.

- Page 219 and 220:

15-2. Outdoor Unit RAV-SP1104AT-E,

- Page 221 and 222:

RAV-SP1104AT-E, RAV-SP1104ATZ-E, RA

- Page 223 and 224:

Location No. Part No. Description 1

- Page 225 and 226:

WARNINGS ON REFRIGERANT LEAKAGE Che

![Service-Handbuch [20522 kB]](https://img.yumpu.com/23967369/1/184x260/service-handbuch-20522-kb.jpg?quality=85)

![Preisliste [3476 kB] - Krüger and Co](https://img.yumpu.com/23967351/1/184x260/preisliste-3476-kb-kra-1-4-ger-and-co.jpg?quality=85)

![Prospekt [1268 kB]](https://img.yumpu.com/23967350/1/184x260/prospekt-1268-kb.jpg?quality=85)

![Mode d'emploi [759 kB]](https://img.yumpu.com/23967349/1/184x260/mode-demploi-759-kb.jpg?quality=85)

![Mode d'emploi [4761 kB]](https://img.yumpu.com/23967346/1/184x260/mode-demploi-4761-kb.jpg?quality=85)