Requirements Balancer Adm. Robert J. Papp Jr. - KMI Media Group

Requirements Balancer Adm. Robert J. Papp Jr. - KMI Media Group

Requirements Balancer Adm. Robert J. Papp Jr. - KMI Media Group

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Dedicated to Those Who Are Always Ready<br />

<strong>Requirements</strong><br />

<strong>Balancer</strong><br />

<strong>Adm</strong>. <strong>Robert</strong> J.<br />

<strong>Papp</strong> <strong>Jr</strong>.<br />

Commandant<br />

U.S. Coast Guard<br />

www.CGF-kmi.com<br />

May 2013<br />

Volume 5, Issue 1<br />

View from<br />

the hill<br />

U.S. Representative<br />

Howard Coble<br />

(R-N.C.)<br />

Cleaner, Better Engines O Icebreakers O C4ISR Technologies<br />

Maritime Domain Awareness O Oil Spill Response O Safety

SERVING THE U.S. COAST GUARD.<br />

SUPPORTING THE FAMILIES.<br />

We serve the U.S. Coast Guard and their families. It’s what we do. It’s who we are.<br />

That’s why we provide the quality products and superior member service you deserve.<br />

With thousands of free ATMs,* 24/7 live phone support, and convenient online and<br />

Mobile Banking,** we have the benefits of membership you deserve.<br />

JOIN TODAY!<br />

navyfederal.org 1.888.842.6328<br />

Federally insured by NCUA.*There are no fees for members who use their Navy Federal Visa® Check Card at CO-OP and MoneyPass® networks, in addition to California Walgreens. **Message and data rates may apply. For more information, visit<br />

navyfederal.org. App Store SM is a service mark of Apple, Inc. Android TM is a trademark of Google, Inc. Image used for representational purposes only; does not imply government endorsement. © 2013 Navy Federal NFCU 12556 (3-13)

U.S. Coast guard forum<br />

May 2013<br />

Volume 5, Issue 1<br />

Features<br />

Cover / Q&A<br />

5<br />

VIEW FROMTHE HILL<br />

Despite the Coast<br />

Guard’s reputation<br />

of doing more<br />

with less, this<br />

Congressman is<br />

convinced that<br />

our current asset<br />

deployment in the<br />

Arctic Region is<br />

exceptionally inadequate.<br />

By Rep. Howard Coble (R-N.C.)<br />

23<br />

Coast Guard C4ISR<br />

Technologies<br />

The technological eyes and ears of<br />

the Coast Guard. Whether looking<br />

for the latest drug-running semisubmersible<br />

or a sailor lost at sea—it<br />

takes a keen eye with the right tools<br />

to get the job done.<br />

By Jeff Goldman<br />

16<br />

6<br />

Dirty Business<br />

An oil spill can be<br />

disastrous, but the<br />

response can be<br />

the measure of the<br />

event. Pre-planning<br />

and technology come<br />

together to drive<br />

solutions.<br />

By Peter Buxbaum<br />

9<br />

Cleaner, Better<br />

Engines<br />

Engine designers<br />

must meet emission<br />

rules, but should<br />

seek to do much<br />

more. Fuel efficiency,<br />

Departments<br />

2 Editor’s Perspective<br />

3 Nav Notes<br />

14 On The Horizon<br />

27 Resource Center<br />

reliability, low<br />

maintenance cost,<br />

size and weight<br />

are also important<br />

considerations for<br />

customers and thus<br />

engine makers.<br />

By Henry Canaday<br />

12<br />

On Thin Ice<br />

Changing Arctic<br />

sea ice patterns<br />

and traffic create<br />

greater need for<br />

icebreakers. Can the<br />

Coast Guard—and<br />

the U.S.—protect its<br />

interests with so few<br />

icebreakers?<br />

By John M. Doyle<br />

20<br />

Precaution is<br />

Key<br />

Off-load marine<br />

hooks are found<br />

on workboats and<br />

military vessels<br />

around the world and<br />

are used to launch<br />

fast rescue craft and<br />

other similar small<br />

manned boats from<br />

the deck of a ship<br />

using a davit or other<br />

similar launch and<br />

recovery system.<br />

Maintenance and<br />

certification of critical<br />

parts are key to the<br />

safety of life at sea.<br />

By Michael Gabriel<br />

Industry Interview<br />

28<br />

21<br />

Maritime Domain<br />

Awareness<br />

The U.S. Coast<br />

Guard is charged<br />

with protecting<br />

the homeland and<br />

ensuring the security<br />

of our harbors, ports<br />

and waterways. But<br />

homeland defense<br />

does not begin at the<br />

border. It begins far<br />

from home. Maritime<br />

domain awareness<br />

requires end-to-end<br />

vigilance.<br />

By Ned Lundquist<br />

William (Bill) E. Skinner<br />

Chief Executive Officer<br />

VT Halter Marine Shipyard<br />

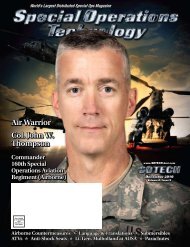

<strong>Adm</strong>iral <strong>Robert</strong> J. <strong>Papp</strong> <strong>Jr</strong>.<br />

Commandant<br />

U.S. Coast Guard<br />

“From an<br />

operational<br />

perspective, the<br />

Coast Guard’s<br />

most pressing<br />

need is to invest<br />

in recapitalization<br />

of the offshore<br />

cutter fleet.<br />

Given the<br />

condition of our<br />

fleet—many<br />

older than 45<br />

years—we<br />

must continue<br />

to recapitalize<br />

cutters, boats<br />

and aircraft.”<br />

- <strong>Adm</strong>. <strong>Robert</strong> J.<br />

<strong>Papp</strong>

Border Threat Prevention and CBRNE Response<br />

<strong>Adm</strong>inistration<br />

Wide Area Aerial Surveillance O Hazmat Disaster Response<br />

Tactical Communications O P-3 Program<br />

SPECIAL SECTION:<br />

www.BCD-kmi.com<br />

June 2012<br />

Volume 1, Issue 1<br />

Leadership Insight:<br />

<strong>Robert</strong> S. Bray<br />

Assistant <strong>Adm</strong>inistrator for<br />

Law Enforcement<br />

Director of the Federal Air<br />

Marshal Service<br />

Transportation Security<br />

U.S. Coast Guard<br />

Forum<br />

Volume 5, Issue 1 • May 2013<br />

Dedicated to Those Who<br />

Are Always Ready<br />

Editorial<br />

Editor-In-Chief<br />

Jeff McKaughan jeffm@kmimediagroup.com<br />

Managing Editor<br />

Harrison Donnelly harrisond@kmimediagroup.com<br />

Copy Editors<br />

Sean Carmichael seanc@kmimediagroup.com<br />

Laural Hobbes lauralh@kmimediagroup.com<br />

Correspondents<br />

Peter Buxbaum • Henry Canaday • Kelly Fodel<br />

Steve Hirsh • William Murray<br />

Art & Design<br />

Art Director<br />

Jennifer Owers jennifero@kmimediagroup.com<br />

Senior Graphic Designer<br />

Jittima Saiwongnuan jittimas@kmimediagroup.com<br />

Graphic Designers<br />

Scott Morris scottm@kmimediagroup.com<br />

Eden Papineau edenp@kmimediagroup.com<br />

Amanda Paquette amandak@kmimediagroup.com<br />

Kailey Waring kaileyw@kmimediagroup.com<br />

Account Executive<br />

Rena Pensky renap@kmimediagroup.com<br />

<strong>KMI</strong> <strong>Media</strong> <strong>Group</strong><br />

Publisher<br />

Kirk Brown kirkb@kmimediagroup.com<br />

Chief Executive Officer<br />

Jack Kerrigan jack@kmimediagroup.com<br />

Chief Financial Officer<br />

Constance Kerrigan connik@kmimediagroup.com<br />

Executive Vice President<br />

David Leaf davidl@kmimediagroup.com<br />

Editor-In-Chief<br />

Jeff McKaughan jeffm@kmimediagroup.com<br />

Controller<br />

Gigi Castro gcastro@kmimediagroup.com<br />

Marketing & Communications Manager<br />

Holly Winzler hollyw@kmimediagroup.com<br />

Operations Assistant<br />

Casandra Jones casandraj@kmimediagroup.com<br />

Trade Show Coordinator<br />

Holly Foster hollyf@kmimediagroup.com<br />

Operations, Circulation & Production<br />

Operations <strong>Adm</strong>inistrator<br />

Bob Lesser bobl@kmimediagroup.com<br />

Circulation & Marketing <strong>Adm</strong>inistrator<br />

Duane Ebanks duanee@kmimediagroup.com<br />

Circulation<br />

Barbara Gill barbg@kmimediagroup.com<br />

Data Specialists<br />

Summer Walker summerw@kmimediagroup.com<br />

Raymer Villanueva raymerv@kmimediagroup.com<br />

EDITOR’S PERSPECTIVE<br />

The Coast Guard is proud of its support in Operation Arctic, an interagency<br />

effort that saw them deploy a national security cutter (NSC), two ice-capable<br />

buoy tenders and two helicopters 300 miles north of the Arctic Circle. The NSC<br />

performed as expected and was a linchpin to the successful operations.<br />

The fiscal year 2014 budget provides a request for the seventh national<br />

security cutter. The ship is critical because of the capabilities that it delivers to<br />

the fleet, but also to fill the gap left by the decommissioning of high endurance<br />

cutters as they reach the end of their useful service life. As has been discussed in<br />

the pages of Coast Guard Forum many times in the past, while the replacement<br />

of cutters is not being done on a one-for-one basis, what the NSCs and the fast<br />

response cutters bring to the operational toolkit exceeds what the older cutters<br />

Jeffrey D. McKaughan<br />

Editor-IN-CHIEF<br />

could provide. While the numbers may decline, overall mission capabilities should increase—so long as the<br />

numbers of ships in the fleet never fall below a critical mass.<br />

On the other hand, is nine years a long time or not? That’s about how long the Coast Guard has to<br />

sustain the Polar Star until the next-generation icebreaker is projected to be ready. Reacquisition activities<br />

are currently being funded (see the chart on page 13) and the Coast Guard and Congress seem committed to<br />

moving the project forward. The Coast Guard has allies on the Hill; Representative Howard Coble—himself<br />

a former Coastie—is concerned about the country’s ability to project and protect its national interests in the<br />

polar arctic region if we are one of the few nations competing in that area without a true heavy icebreaker. As<br />

he puts it, we can’t keep doing something with nothing!<br />

Turning inward a little, <strong>KMI</strong> <strong>Media</strong> <strong>Group</strong> is working on the launch of our 12th title, Navy Air/Sea PEO<br />

Forum, a magazine focused on the U.S. Navy program executive offices that work the projects that fly and<br />

float. Rear <strong>Adm</strong>iral Thomas Moore, PEO Carriers, will be featured on the inaugural cover. We are still building<br />

the distribution list for this title, so please reach out to us if this is another of <strong>KMI</strong> <strong>Media</strong> <strong>Group</strong>’s magazines<br />

that is in your wheelhouse.<br />

<strong>KMI</strong> MedIa <strong>Group</strong> LeadershIp MaGazInes and WebsItes<br />

Border & CBRNE<br />

Defense<br />

Ground<br />

Combat<br />

Technology<br />

Geospatial<br />

Intelligence<br />

Forum<br />

Military<br />

Advanced<br />

Education<br />

Military<br />

Information<br />

Technology<br />

A Proud Member of:<br />

Integrated<br />

Fixed Towers<br />

Subscription Information<br />

U.S. Coast Guard Forum<br />

ISSN 2152-6990<br />

is published four times a year by<br />

<strong>KMI</strong> <strong>Media</strong> <strong>Group</strong>. All Rights Reserved.<br />

Reproduction without permission is strictly<br />

forbidden. © Copyright 2013.<br />

U.S. Coast Guard Forum is free to<br />

qualified members of the U.S. military,<br />

employees of the U.S. government and<br />

non-U.S. foreign service based in the U.S.<br />

All others: $65 per year.<br />

Foreign: $149 per year.<br />

Corporate Offices<br />

<strong>KMI</strong> <strong>Media</strong> <strong>Group</strong><br />

15800 Crabbs Branch Way, Suite 300<br />

Rockville, MD 20855-2604 USA<br />

Telephone: (301) 670-5700<br />

Fax: (301) 670-5701<br />

Web: www.CGF-kmi.com<br />

Border<br />

Protector<br />

Michael J.<br />

Fisher<br />

Chief<br />

U.S. Border Patrol<br />

U.S. Customs and<br />

Border Protection<br />

Military Logistics<br />

Forum<br />

www.MLF-kmi.com<br />

www.BCD-kmi.com<br />

Military Medical<br />

& Veterans<br />

Affairs Forum<br />

www.M2VA-kmi.com<br />

www.GCT-kmi.com<br />

Military Training<br />

Technology<br />

www.MT2-kmi.com<br />

www.GIF-kmi.com<br />

Special<br />

Operations<br />

Technology<br />

www.SOTECH-kmi.com<br />

www.MAE-kmi.com<br />

Tactical ISR<br />

Technology<br />

www.TISR-kmi.com<br />

www.MIT-kmi.com<br />

U.S. Coast Guard<br />

Forum<br />

www.CGF-kmi.com

NAV NOTES<br />

Compiled by <strong>KMI</strong> <strong>Media</strong> <strong>Group</strong> staff<br />

Bollinger Shipyards Inc. has delivered the<br />

Margaret Norvell, the fifth fast response cutter<br />

(FRC), to the U.S. Coast Guard. The announcement<br />

was made by Bollinger Executive Vice President of<br />

New Construction, Chris Bollinger. “We are very<br />

pleased to announce another successful on-time<br />

delivery to the Coast Guard. The Margaret Norvell<br />

was delivered to the 7th Coast Guard District<br />

in Key West, Fla., and will be stationed at USCG<br />

Sector Miami. We are all looking forward to the<br />

vessel’s commissioning, as well as honoring and<br />

celebrating the heroic acts of Margaret Norvell.”<br />

The 154-foot patrol craft Margaret Norvell<br />

is the fifth vessel in the Coast Guard’s Sentinelclass<br />

FRC program. To build the FRC, Bollinger<br />

Shipyards used a proven, in-service parent craft<br />

design based on the Damen Stan Patrol Boat<br />

4708. It has a flank speed of 28 knots, state of<br />

the art command, control, communications and<br />

computer technology, and a stern launch system<br />

for the vesse’ls 2- foot cutter boat. The FRC has<br />

been described as an operational game changer,<br />

by senior Coast Guard officials.<br />

Newest FRC Delivered<br />

The Coast Guard took delivery March 21,<br />

2013, in Key West, Fla., and is scheduled to<br />

commission the vessel in New Orleans, Louisiana<br />

in June 2013.<br />

Each FRC is named for an enlisted Coast<br />

Guard hero who distinguished him or herself<br />

in the line of duty. This vessel is named after<br />

Coast Guard hero Margaret Norvell for serving<br />

admirably for 41 years with the U.S. Lighthouse<br />

Service in Louisiana from 1891 to 1932. Her<br />

devotion to duty saved the lives of countless<br />

sailors as she vigilantly stood the watch. Norvell<br />

served as keeper of both the Port Ponchartrain<br />

Light and the West End Light.<br />

Contractor Support<br />

for Sentinel Cutter<br />

Build<br />

The contract award for 18 Sentinel-class<br />

cutters has required the establishment of a project<br />

residence office (PRO) at the contractors’ facility<br />

in Lockport, La. The requested billet structure will<br />

remain unfulfilled as a result of limited USCG<br />

personnel resources. The Coast Guard, therefore,<br />

has issued a solicitation for on-site contractor<br />

support services for the PRO. The contractor shall<br />

provide design review and validation services in<br />

support of the Sentinel-class patrol craft project.<br />

The contractor will also provide support tasks to<br />

include test inspection and quality assurance for<br />

the cutters during construction, shipyard trials,<br />

delivery and post-delivery warranty periods.<br />

The Coast Guard uses Fleet Broadband<br />

(FB), Swift-64 and BGAN (Broadband, Swift<br />

Broadband) services to support underway<br />

cutters, aircraft and Portable SIPRNET<br />

Kits (PSK). These services are part of the<br />

Inmarsat family of services available<br />

commercially. The aviation Swift-64 service<br />

is a dial-on-demand service and is being<br />

upgraded to the Swift Broadband (SB)<br />

Inmarsat service. All Inmarsat services<br />

to the Coast Guard are supported 24/7<br />

by the InmarsatGov Network Operations<br />

Security Center (NOSC). Each Coast Guard<br />

asset with an Inmarsat terminal has a<br />

unique subscriber identity module (SIM)<br />

that allows tracking of air time. Inmarsat<br />

provides a database to the Coast Guard<br />

customer that allows tracking of SIM MB<br />

levels and performance and activity state of<br />

any Coast Guard terminal SIM.<br />

The USCG C4IT Service Center,<br />

Telecommunications Information Systems<br />

Command has a requirement to provide<br />

connectivity to the Coast Guard Data<br />

Network (CGONE) to mobile assets (cutters,<br />

Broadband Services<br />

airplanes and portable networking kits).<br />

These assets when underway, airborne<br />

or deployed abroad leverage Inmarsat’s<br />

Advances Services (Fleet BGAN) portfolio<br />

of air time and support services to provide<br />

the path to the Coast Guard Multi-Protocol<br />

Labeled Switching GuardianNet network.<br />

The GuardianNet network then backhauls<br />

all Inmarsat Advances Services connections<br />

to the CGONE network. The entire path<br />

thus allows our forward deployed units<br />

the ability to conduct their multi-mission<br />

tasking. This design and connectivity path<br />

is installed and has been in effect since<br />

2009.<br />

The Coast Guard is seeking a contract<br />

to obtain Inmarsat Advanced Service (Fleet<br />

Broadband, Swift Broadband, BGAN) data<br />

single corporate access plans (SCAPs). It<br />

is the Coast Guard’s intension to purchase<br />

air time for up to 50 cutters and up to 40<br />

aircraft. There will be airtime SCAPS for<br />

each service (FB, SB, BGAN) and the NOSC<br />

and database SIM/SCAP tracking will not<br />

be charged.<br />

www.CGF-kmi.com CGF 5.1 | 3

NAV NOTES<br />

Compiled by <strong>KMI</strong> <strong>Media</strong> <strong>Group</strong> staff<br />

Sniper Simulation<br />

Laser Shot provides a sniper simulator known<br />

as the long range precision shooting simulator<br />

(LRPSS). The simulated rifle which has the ability<br />

to come with recoil or non-recoil functions contains<br />

sensors to allow for trigger pressure, butt stock<br />

pressure, the canting of the weapon, ammunition<br />

loaded or unloaded, etc. The Laser Shot’s Series<br />

II weapon technology allows for customization of<br />

various sniper rifles based on customer needs. The<br />

rifle can facilitate two types of modified optics, the<br />

simulated ACOG and the simulated rifle scope and<br />

can be built in custom mountable scopes. There is<br />

also an optional simulated spotter scope.<br />

The combined optics give the sniper a high<br />

definition 1280x1024 in-optic micro-display that<br />

emulates a real world tactical environment.<br />

LRPSS uses Virtual Battlespace 2 (VBS2) simulation<br />

software, which uses real-world ballistics<br />

effects built into its engine, including bullet drop,<br />

windage, variety of calibers, shooters angle, and the<br />

capability for Laser Shot to customize the ballistic<br />

engine to the snipers requirements.<br />

Coast Guard Academy<br />

Christens New<br />

Research Vessel<br />

On April 26, the U.S. Coast Guard Academy christened<br />

the Michael J. Greeley, a new research vessel.<br />

The vessel will greatly expand the academy’s capabilities<br />

to conduct oceanographic research that will<br />

enhance the marine science curriculum. The Michael<br />

J. Greeley is capable of performing long-distance<br />

trips, enabling coursework to take place not only in<br />

the Thames River but also in Long Island Sound and<br />

beyond. Expanded field operations are expected to<br />

translate into expanded laboratory operations, which<br />

will enhance hands-on learning opportunities for<br />

cadets.<br />

The vessel was acquired as a gift from the U.S.<br />

Coast Guard Academy Class of ‘61 through the U.S.<br />

Coast Guard Academy Alumni Association. The engines<br />

and hydraulic equipment was supplied by the U.S.<br />

Coast Guard Academy. The boat was designed by<br />

Response Marine, Inc., Newburyport, Mass., and built<br />

by Viking Welding and Fabrication in Kensington, N.H.<br />

The vessel will be operated by personnel, active<br />

duty and civilian, who successfully complete the qualification<br />

training program.<br />

Aids to Navigation Team’s New Facility<br />

The commander of Coast Guard Sector Charleston, Captain Michael White, and members<br />

of Coast Guard Aids to Navigation Team (ANT) Georgetown formally celebrated the completion<br />

of the ANT’s new facility, located adjacent to Station Georgetown, during a building<br />

dedication ceremony.<br />

Members of ANT Georgetown previously shared a small one-room workspace with Station<br />

Georgetown.<br />

Improvements include offices for each member of the ANT Georgetown command, ample<br />

space to conduct training and an enclosed garage bay with a machine shop where the ANT’s<br />

boat can be maintained and repaired in any weather.<br />

The new building will enable ANT Georgetown to improve its service to the community<br />

and is more conducive to daily operations, said ANT Georgetown Officer in Charge, Petty<br />

Officer 1st Class David Browne. It was custom-built to support the ANT’s primary mission<br />

of servicing and maintaining roughly 250 navigational aids used by mariners to mark safe<br />

passages.<br />

This is the first time ANT Georgetown has been in its own building, and during the<br />

ceremony White told the ANT members the new building is their home, highlighting the fact<br />

that they now have the right spaces with the right equipment.<br />

The entire process, from planning to completion, took about five years, said Browne.<br />

H-65 Automatic Flight Control System<br />

The Coast Guard operates a fleet of 101<br />

H-65 aircraft. In 2004, a major acquisition to<br />

modernize the USCG’s H-65 helicopter was initiated<br />

as part of the Deepwater Project. This project<br />

was later subdivided into six discrete segments to<br />

increase capability and extend the life expectancy<br />

of the H-65 aircraft. The final phase of the<br />

project, known as Discrete Segment 6 (DS 6),<br />

addresses the remaining subsystem obsolescence<br />

issues including installation of the common<br />

avionics architecture system and modernizing<br />

the aging and increasingly unreliable analog<br />

automatic flight control system (AFCS) in the<br />

H-65. This procurement to upgrade the AFCS<br />

system is one of the last steps in the modernization<br />

process. The improved aircraft will be<br />

designated as the MH-65E.<br />

A system specification has been developed<br />

for the acquisition of a replacement AFCS for<br />

the H-65 aircraft. The replacement AFCS will<br />

be installed, tested, and refined in accordance<br />

with a government defined integration plan. The<br />

Coast Guard is seeking a contractor that has and<br />

can install a new AFCS system, ideally a drop-in<br />

installation capable of being done by a field team<br />

at an operational unit.<br />

4 | CGF 5.1<br />

www.CGF-kmi.com

VIEW FROM THE HILL<br />

Doing Something<br />

with Nothing<br />

By Rep. Howard Coble (R-N.C.)<br />

During my tenure in Congress, I have had many opportunities<br />

to reflect on my career in the United States Coast Guard. As a past<br />

chairman and longtime member of the Coast Guard and Maritime<br />

Transportation Subcommittee in the House Committee on Transportation<br />

and Infrastructure, [I know that] decisions are regularly made<br />

regarding mission analysis and strategic asset capabilities. Memories of<br />

one of my most enjoyable mission assignments also lead me to articulate<br />

a great concern with our high-latitude region presence. Despite<br />

the Coast Guard’s reputation of doing more with less, I am convinced<br />

that our current asset deployment in the Arctic Region is exceptionally<br />

inadequate.<br />

In June 1956, I was able to utilize a mutual transfer that resulted in<br />

my assignment to the USCGC Northwind as it made its way to the Arctic<br />

Region to resupply ships and radar stations. Known as the Grand<br />

Old Lady of the North, the Northwind had a top speed of 13 knots<br />

and measured 269 feet. For a Yeoman 2nd Class from the Piedmont<br />

of North Carolina, this was truly an adventure, as I bid farewell to the<br />

brown bears of my home state and hello to polar bears in the Arctic.<br />

Many of the Coasties from that era still remember that the Order of the<br />

Blue Nose was an honor, although at times a little bit uncomfortable.<br />

Time has moved on and our mission requirements have increased.<br />

Unfortunately, our asset capabilities haven’t kept pace. As recent analysis<br />

by ABS Consulting has shown, the capacity gap leaves four areas of<br />

responsibility vulnerable to mission degradation: defense readiness, ice<br />

operations, marine environmental protection, and ports, waterways,<br />

and coastal security. We need to rethink our asset capabilities going<br />

forward.<br />

Currently we have one icebreaker in service, and that is only a<br />

medium icebreaker. The USCGC Healy carries the statutory mission’s<br />

workload that should be assigned to a minimum of three heavy and<br />

three medium icebreakers. While Healy’s expected service life reaches<br />

to 2030, the Coast Guard’s two heavy icebreakers, which were commissioned<br />

in 1976 and 1977, remain out of active service. Polar Sea is in<br />

an inactive status with no plans to reactive her. Polar Star is currently<br />

being reactivated for service later next year with an expected service<br />

life of seven to 10 years.<br />

Coast Guard’s icebreakers play an important role in supporting<br />

and protecting United States interests in the Polar regions. Let’s look<br />

at the six national objectives established by National Security Presidential<br />

Directive 66 and Homeland Security Directive 25:<br />

1. Meet national security and homeland security needs relevant to<br />

the Arctic region.<br />

2. Protect the Arctic environment and conserve its biological<br />

resources.<br />

3. Ensure that natural resource management and economic<br />

development in the region are environmentally sustainable.<br />

4. Strengthen institutions for cooperation among the eight Arctic<br />

nations (the United States, Canada, Denmark, Finland, Iceland,<br />

Norway, the Russian Federation and Sweden).<br />

5. Involve the Arctic’s indigenous communities in decisions that<br />

affect them.<br />

6. Enhance scientific monitoring and research into local, regional<br />

and global environmental issues.<br />

Given the national objectives stated above, you begin to imagine<br />

the magnitude of the task at hand and the incredibly vast area the<br />

Coast Guard has to monitor. Six percent of the planet’s surface is covered<br />

by the Arctic Circle, which is comprised of an ice sheet four times<br />

the size of Texas. Some 15.5 million square miles are covered by the<br />

Arctic Ocean, which hosts a population of approximately 1.5 million<br />

inhabitants. Maintaining a strategic presence over this vast expanse of<br />

land is far beyond our current capability.<br />

Two areas of U.S. interest, political and economic, will also help<br />

amplify future responsibility. Oil and gas exploration, oil and gas<br />

recovery, and the addition of potential shipping lanes will expand<br />

Coast Guard obligations, as will the incident risk made more possible<br />

by international claims on territorial seas. The five nations that claim<br />

these rights are the United States, Canada, Denmark, Norway and the<br />

Russian Federation. In addition, Iceland, Sweden and Norway also<br />

assert rights to territories above the Arctic Circle.<br />

In examining theoretical mixes of Coast Guard assets, including<br />

icebreakers, helicopters and forward operating locations, it was determined<br />

that a build-out of the icebreaker fleet, along with improved<br />

communications, medium range aircraft and advanced aviation locations<br />

in Alaska could be a suitable foundation for future operations<br />

in the Arctic. Further risk analysis shows that these theoretical force<br />

packages, based on fleet increases, could be used to counter future<br />

Arctic incidents and would greatly magnify the effectiveness of current<br />

assets operating in the Bering Sea.<br />

In plain language, we need to make a real effort to increase the<br />

number of icebreakers in service before the situation deteriorates<br />

further. In the dwindling days of our mission in Afghanistan, it would<br />

be a prudent use of those savings to invest $3 billion over the next<br />

two appropriation cycles to guarantee our mission compliance. Doing<br />

more with less is a source of pride for all Coasties. Due to lack of attention<br />

to this problem, however, our mission has evolved into doing<br />

something with nothing. Semper paratus indeed, but we need to be<br />

fully funded, too. O<br />

For more information, contact Editor-In-Chief<br />

Jeff McKaughan jeffm@kmimediagroup.com or<br />

search our online archives for related stories at www.cgf-kmi.com.<br />

www.CGF-kmi.com CGF 5.1 | 5

An oil spill can be disastrous, but the response can be the measure<br />

of the event.<br />

By Peter Buxbaum<br />

CGF Correspondent<br />

It might be hard to believe, but some good actually<br />

emerged from the 2010 Deepwater Horizon oil spill and<br />

disaster in the Gulf of Mexico. Because of the magnitude<br />

of the incident, British Petroleum, the owner of the well,<br />

was motivated to call upon companies to provide ideas for<br />

containing and cleaning up the spill. As a result, future oil<br />

cleanup crews will have new options on how to respond to<br />

a spill.<br />

6 | CGF 5.1<br />

www.CGF-kmi.com

The explosion that tore through BP’s drilling rig on April 20,<br />

2010, began a human, economic and environmental disaster. An<br />

oil discharge continued for 84 days, resulting in the largest oil<br />

spill in U.S. waters, an estimated 206 million gallons. Eleven crew<br />

members died on that day and others were seriously injured. BP<br />

recently agreed to plead guilty to manslaughter in the deaths of<br />

the 11 and to pay $4 billion in penalties.<br />

BP also funded the response activities, led by the U.S. Coast<br />

Guard and supported by other federal agencies as well as state and<br />

local governments, and paid out claims to injured parties estimated<br />

to eventually total close to $22 billion. As recently as January<br />

2013, over 900 response personnel were still on duty and 339<br />

miles of shoreline remained subject to evaluation and/or cleanup.<br />

When a major oil spill occurs, teams provided by local, state<br />

and federal agencies act to contain and clean up the spill, and to<br />

minimize damage to health and the environment. This National<br />

Response System is activated when the National Response Center<br />

receives notification of an oil spill. The National Response Center<br />

(NRC), a multi-department entity hosted at Coast Guard headquarters<br />

in Washington, D.C., gets the first word when an oil spill<br />

occurs.<br />

The Deepwater Horizon incident represents the largest and<br />

most disastrous oil spill in U.S. history. Not every oil spill is as<br />

tragic or impactful, but they occur with regularity. According to<br />

figures supplied by the National Response Center, 32,551 oil and<br />

chemical spills were reported in 2012. That annual figure has<br />

remained fairly steady in the last 12 years. Since 2000, the number<br />

of spills reported in any given year has varied between 31,886 in<br />

2009 and 36,855 in 2006.<br />

If any good can be said to have flowed from Deepwater Horizon,<br />

it is that new technologies for containing and cleaning up oil<br />

spills have come to light, thanks to the call by BP to companies<br />

that could help in the cleanup efforts. Of some 140,000 ideas submitted<br />

to BP, 15 went through an evaluation process and an even<br />

smaller number were actually deployed to the Gulf during the<br />

disaster. Two of the companies BP called on to help in the cleanup<br />

were C.I.Agent Solutions, a company based in Louisville, Ky., and<br />

UltraTech International Inc., headquartered in San Jose, Calif.<br />

“Before the Gulf oil disaster, everyone had been using the<br />

same technology for 20 years,” said Mark Shaw, co-president of<br />

UltraTech. “BP provided an opportunity for new technologies to<br />

be explored.”<br />

C.I.Agent was stationed on Dauphin Island, Ala., beginning on<br />

April 26, less than a week after the explosion. Together with the<br />

Alabama National Guard, C.I.Agent personnel built a six-mile oilwater<br />

separator, a barrier created to allow the use of the company’s<br />

blend of polymers that solidifies hydrocarbons into a recyclable<br />

rubber-like mass.<br />

“We ended up not using any polymer,” said Dan Parker,<br />

C.I.Agent Solutions’ founder and president, “because the oil never<br />

reached Dauphin Island. We built the barrier to separate the oil<br />

from the water if the oil sheen made its way to the beach.”<br />

The National Response System was set up in 1968 pursuant to<br />

the National Oil and Hazardous Substances Pollution Contingency<br />

Plan (National Contingency Plan, or NCP, for short) to provide<br />

planning and organization to efforts to deal with large oil spills.<br />

The NRC was set up later, becoming operational in August 1974,<br />

for the reporting and coordination of response to pollution by oil<br />

and hazardous substances.<br />

The National Response System, a network of individuals and<br />

teams from local, state and federal agencies, combine their expertise<br />

and resources to ensure that oil spill control and cleanup activities<br />

are timely, efficient and minimize threats to human health<br />

and the environment. The system includes on-scene coordinators<br />

(OSCs), a national response team and regional response teams.<br />

OSCs are federal officials responsible for directing response<br />

actions and coordinating all other efforts at the scene of a discharge<br />

or spill. They also work in partnership with other federal, state,<br />

local and private response agencies. OSCs come from the Coast<br />

Guard, the U.S. Environmental Protection Agency (EPA), the U.S.<br />

Department of Energy or the U.S. Department of Defense, depending<br />

on the location and nature of the spill.<br />

The Coast Guard and EPA have the greatest responsibility for<br />

responding to oil spill emergencies. “When a spill occurs in coastal<br />

waters, the local Coast Guard port commander is the OSC,” said<br />

Syed Qadir, the director of the National Response Center. “When a<br />

spill occurs in an inland area, such as a spill from a pipeline or rail<br />

tank car, a regional EPA official is assigned as the OSC. The OSC<br />

is responsible for assessment, monitoring, response assistance and<br />

reporting.”<br />

When a spill occurs, the organization responsible for the<br />

release or spill is required by law to notify the NRC if the amount<br />

of a hazardous substance release or oil spill exceeds the established<br />

reporting trigger. “Once a report is made, the NRC immediately<br />

notifies an OSC,” said Qadir. “The OSC determines the status of the<br />

response by state and local government responders and the company<br />

responsible for the release or spill. The OSC also monitors the<br />

situation to determine whether, or how much, federal involvement<br />

is necessary.”<br />

The NRC itself is composed of representatives from 16 federal<br />

agencies. Although located at Coast Guard headquarters, the NRC<br />

is not a Coast Guard unit but is considered to be an independent<br />

federal government entity. “The costs and operations of the center<br />

are supported by these several federal agencies,” said Qadir. Qadir<br />

himself happens to be a Coast Guard employee.<br />

“The NRC is strictly a communications and operations center,”<br />

said Qadir. “The response is taken care of by the on-scene coordinator.<br />

We facilitate and coordinate communications with the national<br />

response team. The NRC briefs the White House, the Department<br />

of Homeland Security and the Secretary of Transportation regarding<br />

significant transportation emergencies reported to the center.<br />

We also provide information to the Coast Guard’s Office of Marine<br />

Safety, Security, and Environmental Protection for a variety of<br />

reports, studies or Congressional inquiries.”<br />

Both UltraTech International and C.I.Agent Solutions have<br />

developed materials that can isolate oil spills and separate oil from<br />

water so that the oil can be removed and cleaned up. In addition,<br />

UltraTech cultivates and markets specialized microbes which can<br />

actually metabolize hydrocarbons.<br />

“We created an oil fencing product that acts like a fence around<br />

a construction site,” said Shaw. “During Deepwater, BP deployed<br />

this fencing in the water close to the water line so that, as the surf<br />

rose and fell, the oil could be captured in the fabric and removed<br />

so that it would not reach the beach.” BP bought 30 miles of<br />

UltraTech’s oil boom product and placed it along the shore lines of<br />

Mississippi and Louisiana.<br />

The booms, made from UltraTech’s Ultra-X-Tex fabric, differs<br />

from its predecessors in that it absorbs both oil and water but then<br />

www.CGF-kmi.com CGF 5.1 | 7

expels the water as it is replaced by oil. “Older fabrics are made<br />

with polypropylene absorbents that repel water and then absorb<br />

oil,” said Shaw. “The problem with these is that the water gets in<br />

the way of the oil. The water can’t pass through the fabric and it<br />

gets blown out of the way. Our patented fabric absorbs both oil<br />

and water but then selectively retains the oil and lets the water<br />

molecules go through.”<br />

Ultra-X-Tex, which has been in use for 10 years for storm water<br />

management, was deployed for the first time in connection with<br />

an oil spill during the Gulf disaster. The fabric has the capacity to<br />

absorb two-thirds of a gallon per square yard. “Once they are saturated<br />

they can be removed and replaced,” said Shaw. “An industrial<br />

wringer can remove 80 percent of the oil out of fabric and it can be<br />

reused, or it can be incinerated.”<br />

C.I.Agent’s solidifiers are polymers listed on the EPA NCP<br />

product schedule and have been approved for work on oil spills in<br />

open waters. “There are certain conditions attached to this,” said<br />

Parker. “The spill has to be contained, meaning a boom had to be<br />

put out first, it has to be recovered, and it can’t be put on animals.”<br />

C.I.Agent has a partner company in Australia that invented<br />

a cannon-like device to disperse the polymers through a water<br />

stream. Coast Guards in the Scandinavian and Baltic regions have<br />

used this system to contain oil spills there. The water cannon was<br />

also used in connection with the Gulf cleanup.<br />

C.I.Agent solidifying polymers works on a full spectrum of<br />

hydrocarbons, from gasoline to crude oil.<br />

The polymers solidify and detoxify hydrocarbons upon contact<br />

for spill control. Hydrocarbons solidified become non-hazardous<br />

and float on the water. “Solidified hydrocarbons can be reused in<br />

various industrial applications, for example in asphalt, or burned<br />

as fuel,” said Parker.<br />

Once the spill matter has been solidified, responders can use<br />

skimmers to clean it up. “We are getting recovery of over 90 percent<br />

of the material with this process,” said Parker.<br />

Oil spills need to be contained or fenced in before the polymers<br />

are applied. This job can be accomplished with the C.I.Agent<br />

Barrier Boom. The boom allows the unimpeded flow of water but<br />

becomes an impervious barrier in the event of an oil release. The<br />

barrier boom is constructed from non-woven geo-textiles filled<br />

with C.I.Agent granules and backed with Agent-X, a non-woven<br />

geo-textile material with C.I.Agent embedded within the fabric.<br />

In addition to the oil-water separator, the company deployed<br />

three new products during the Gulf oil spill cleanup and containment<br />

efforts. C.I.Agent CLAM (continuous low-level aquatic monitoring)<br />

is a submersible extraction sampler to sequester pesticides,<br />

herbicides and other trace organic materials from the water.<br />

C.I.Agent Hydrocarbon Detection Strips determine the presence<br />

of hydrocarbons in water. When the strip is introduced into a<br />

potential hydrocarbon situation, the light blue strip turns a darker<br />

blue if hydrocarbons are present. The color intensity and size of<br />

the darker blue areas are indications of the quantity of hydrocarbons<br />

contained in the sample. The third new product used was the<br />

water cannon.<br />

UltraTech presented another technology to BP that the latter<br />

chose not to test but that Shaw claims can supercharge future<br />

oil cleanup efforts. “There was some discussion during the Gulf<br />

oil spill saying that 50 percent of the oil may have been eaten by<br />

naturally occurring microbes in the ocean,” he said.<br />

UltraTech has a product called UltraMicrobe which is made<br />

out of archaea, one of the oldest organisms. “It is the first microbe<br />

bioremediation agent on the NCP list,” said Shaw. “Research at<br />

Louisiana State University to test the effectiveness of various<br />

agents showed that the microbe destroyed 99.6 percent of the<br />

hydrocarbons and that the microbe was far better than anything<br />

out there.”<br />

UltraMicrobe is specifically cultivated for bioremediation in sea<br />

water, crude oil and ammonia. “That is what they grow up on,” said<br />

Shaw. “They are trained like Spartan warriors to destroy hydrocarbons.<br />

After they digest the toxic material, it comes out as carbon,<br />

hydrogen and a fatty acid, all benign, non-hazardous materials.”<br />

Given the frequency of oil spills, companies like UltraTech<br />

and C.I.Agent will have plenty of practice and proofs of concept<br />

in case another catastrophic spill like the Deepwater Horizons<br />

occurs. Government agencies and private companies also conduct<br />

exercises on a regular basis in which these newer technologies are<br />

put to the test.<br />

“BP is still stimulating a lot of activity in this area,” said<br />

Parker. “They are challenging us and working with us to come up<br />

with newer and better technologies.” O<br />

For more information, contact Editor-In-Chief<br />

Jeff McKaughan jeffm@kmimediagroup.com or<br />

search our online archives for related stories at www.cgf-kmi.com.<br />

8 | CGF 5.1<br />

www.CGF-kmi.com

Cleaner, Better<br />

Engines<br />

Fuel Efficiency<br />

maintenance cost<br />

cylinder use<br />

More power is not always the answer,<br />

but more efficient power can be.<br />

By Henry Canaday<br />

CGF Correspondent<br />

Engines for all Coast Guard vessels are heavily affected by the<br />

ongoing advances in emission rules, both in the U.S. and worldwide.<br />

These rules tend to tighten most and earliest for larger<br />

engines but will eventually affect engines of all sizes.<br />

Engine designers must meet emission rules, but should seek to<br />

do much more. Fuel efficiency, reliability, low maintenance cost,<br />

size and weight are also important considerations for customers<br />

and thus engine makers.<br />

The first requirement of good design is to achieve emission<br />

goals without giving up too much in fuel efficiency or other objectives.<br />

Often, a new design may actually gain along other dimensions<br />

while it reaches tougher environmental goals.<br />

Much engine design is still in flux. Some future emission<br />

requirements are known and design is well along in development.<br />

Other requirements, especially for smaller engines, are still not<br />

certain, and some design decisions must still be made. Engine<br />

makers are thus at different points on the design curve, depending<br />

partly on what kinds of engines they manufacture.<br />

Most engine makers tend to be very proud of their products.<br />

“We do it better than the next guy,” said Karl Sandstrom, project<br />

leader for BRP’s Outboard Engines Division. “Evinrude E-TEC<br />

is the cleanest, most efficient and powerful technology available<br />

today.”<br />

While many competitive engines are four-stroke, E-TEC outboards<br />

features a direct-injection, two-stroke design that provides<br />

a smaller and lighter package. “A lightweight engine is important<br />

to the way a boat handles while navigating through varying sea<br />

conditions, cruising, running full speed or even coming on or off<br />

plane,” Sandstrom said.<br />

Offering a direct-injected, two-stroke design also means E-TEC<br />

engines are very powerful at low-end torque because there is one<br />

power stroke for every revolution, rather than one for every other<br />

revolution as in four-stroke engines. “In fact, E-TEC outboards<br />

produce so much low-end torque that you typically can plane a<br />

larger twin-engine boat with only one engine, without having to<br />

change the propeller,” Sandstrom said. “That kind of power can be<br />

important to the Coast Guard when having to operate in heavy seas<br />

or when rescuing or towing other vessels.”<br />

E-TEC outboards also feature an advanced two-stage form of<br />

direct fuel injection (DFI) that includes both stratified and homogeneous<br />

combustion. In the stratified mode, an onboard computer<br />

instructs the spark plug to ignite the fuel charge immediately as it<br />

enters the combustion chamber. This uses only a small portion of<br />

the cylinder, effectively allowing the engine to operate like a much<br />

smaller engine.<br />

Not available on any four-stroke outboard, stratified combustion<br />

is featured on all E-TEC engines at slower operating speeds,<br />

providing superior fuel efficiency and greater range. “Superior efficiency<br />

at lower throttle settings is important because based on the<br />

ICOMIA [International Council of Marine Industry Associations]<br />

duty cycle, the industry standard used by the U.S. EPA [Environmental<br />

Protection Agency], an average boater operates their engine<br />

at idle speed about 40 percent of the time,” Sandstrom noted.<br />

In addition to unsurpassed fuel economy, stratified combustion<br />

has the additional benefits of lower emissions and fewer fumes,<br />

which can be particularly important when operating at slow speeds<br />

or in a following sea. At idle speeds, an E-TEC emits up to 80 times<br />

less carbon monoxide than a typical competitor’s four-stroke outboard.<br />

“It’s very efficient. The stratified mode makes the combustion<br />

process and running quality very controlled and very clean,”<br />

Sandstrom explained.<br />

If operators have a 300-horsepower engine, they do not need<br />

300 horsepower at idle. But when more power is needed, the E-TEC<br />

computer shifts to homogenous combustion, so fuel passes by an<br />

unlit spark plug, fills up the entire chamber and is then ignited by<br />

the plug. In the homogeneous mode, the engine is free to develop<br />

its full power potential.<br />

“All outboard engines are much better than they were 20 or<br />

even 10 years ago,” Sandstrom acknowledged. But E-TEC twostroke<br />

engines also yield very low maintenance costs. There is no<br />

break-in period. “You do not have to bring it in for a 10- or 20-hour<br />

check, and there is no annual service to change the oil, adjust or<br />

change belts or adjust the valves like our competitors’ engines.”<br />

E-TEC engines only require dealer-scheduled maintenance once<br />

every three years or 300 hours, instead of the annual service that<br />

most boaters have come to expect. And an E-TEC’s maintenance<br />

requirements are minimal, such as changing spark plugs, gear<br />

lube, water pump impeller and greasing fittings.<br />

Furthermore, the typical four-stroke engine needs a lengthy<br />

period for winterization, best done by a dealer, said Sandstrom.<br />

www.CGF-kmi.com CGF 5.1 | 9

“Our winterization is very simple, costs almost nothing and can be<br />

done by the user in a matter of minutes.”<br />

The alternators on E-TEC engines also produce substantial electric<br />

power. Smaller E-TEC engines generate 25 net amps, and the larger<br />

engines produce a full 50 net amps of battery charging power. “At<br />

1,000 RPM, our larger-horsepower engines deliver 30 net amps, and go<br />

on to produce a full 50 net amps at as little as 2,000 RPM,” Sandstrom<br />

said. “Many competitive offerings peak out at 25 or 30 amps.”<br />

Developing an abundance of amperage at idle speeds means that<br />

in virtually any situation, operators have positive amperage to the<br />

battery to compensate for the drain of onboard electronics so they are<br />

not running the batteries down. “That is important when you operate<br />

at low speeds with lots of electronic equipment like the Coast Guard<br />

does,” Sandstrom said.<br />

E-TEC technology generates this electrical power using a maintenance-free,<br />

under-the-flywheel magneto system instead of a beltdriven<br />

alternator, which means no adjustments and no chance of a belt<br />

breaking and needing to be replaced, reducing maintenance worries<br />

and costs.<br />

Maintenance costs are further reduced by solid protection against<br />

saltwater corrosion. E-TEC uses aluminum that has some of the lowest<br />

copper content in the industry and uses electro-deposition painting<br />

“to get it into every nook and cranny of aluminum parts,” Sandstrom<br />

said. Extensive use of stainless steel with fasteners and major components<br />

helps ensure long engine life, even in the harshest saltwater<br />

conditions.<br />

All E-TEC engines are built with the same technology, and<br />

Sandstrom said the entire line has more parts commonality than<br />

competitive engine lines. “Diagnostics are the same; if you can<br />

work on one, you can work on them all.” And all the engines are<br />

built in Wisconsin.<br />

New EPA regulations in January 2013 tightened emission<br />

requirements in some respect. Beyond 2013, “nothing definitive<br />

has been approved,” for the engine sizes BRP makes, Sandstrom<br />

said. BRP speculates that the EPA may move toward emission levels<br />

similar to those now applied to automobiles, and this would<br />

require a catalytic converter. “We estimate additional legislation<br />

may be implemented somewhere around 2018, and required levels<br />

may go to 5 grams per kilowatt hour from the current 16 per<br />

kWh,” Sandstrom said. “That would require a catalytic converter<br />

for both two- and four-stroke engines.” Sandstrom added that<br />

“when and if that level of emissions is required, Evinrude E-TEC<br />

technology will be ready and will continue to lead the industry in<br />

cleaner-running outboard technology.”<br />

In addition to the full line of Evinrude E-TEC outboards,<br />

BRP also offers a special line of multi-fuel engines built and<br />

engineered to U.S. military specifications. “Our MFE engines<br />

are true, multi-fuel engines. They can run on gasoline, JP5,<br />

JP8, kerosene and even diesel—in a combat emergency,” said<br />

Justin Antolini, BRP’s government sales manager. “These highly<br />

advanced and vertatile engines are available in traditional propeller<br />

and jet pump versions, have been deployed in mulitple<br />

10 | CGF 5.1<br />

www.CGF-kmi.com

theatres across the globe and offer our military personnel the<br />

flexibility of changing from conventional gasoline to heavy fuels<br />

at any given time.”<br />

Cummins engine design has been driven chiefly by emission<br />

regulations, initially voluntary but increasingly mandatory<br />

since the U.S. signed International Maritime Organization (IMO)<br />

Annex 6 and the EPA started its Tier 2 rules in 2004, explained<br />

Marine Product Planning Manager Eddie Brown. “Today we are<br />

going from Tier 2 to Tier 3 and we are in the process of upgrading<br />

to meet these requirements,” Brown said.<br />

When redesigning engines to meet new emission rules, Cummins<br />

also looks at other ways to add value for customers or to<br />

respond to any issues raised. And emission rules can pose some<br />

tough design problems. “One challenge in meeting emission<br />

rules is to keep fuel efficiency up. You also want the engine to be<br />

durable, reliable and affordable to service,” Brown noted.<br />

Coast Guard cutters typically have propulsion requirements<br />

that are outside Cummins’ current power range. However the<br />

company can provide auxiliary power packages to generate<br />

emergency or ship power, as it does for the Sentinel-Class fast<br />

response cutter with 5.9-liter engines.<br />

For the future, Chief Engineer-Commercial Marine Mike<br />

Aufdermauer is looking at how to meet EPA Tier 4 rules, which<br />

have been issued for the engine sizes Cummins makes. He said<br />

Cummins will meet tougher limits on particulates “in cylinder”—that<br />

is, with changes in fuel injection and piston geometry,<br />

rather than with particulate traps or filters. To meet the limit<br />

of 2 grams of nitrogen oxide set for larger engines, Cummins<br />

will need selective catalytic reduction (SCR). This limit applies<br />

to engines of more than 600 kW capacity and goes into effect at<br />

different dates, from 2014 to 2017, for different-sized engines.<br />

For engines above 2,000 kW, Tier 4 starts in 2014.<br />

Aufdermauer said Cummins is studying how to meet Tier 4<br />

even as it develops Tier-3 engines. “We have proven our technology<br />

can meet Tier 3 and then we will introduce SCR for Tier 4.”<br />

A modified common-rail system for direct-fuel injection will be<br />

optimized for both emissions and fuel efficiency. “We are looking<br />

to gain back some fuel efficiency. That is why we chose SCR<br />

technology, to gain back some fuel efficiency.”<br />

Aufdermauer estimates that this approach will reduce the<br />

overall cost of ownership by 5 percent, including both fuel consumption<br />

and urea in diesel exhaust fluids.<br />

Emission rules affect everything engines designer do now. “In<br />

the past, you could put a product on the market for years with no<br />

change,” the Cummins engineer said. “Now you have to change<br />

for emissions and look at durability, reliability and efficiency and<br />

take those into account.”<br />

Apart from meeting new emission requirements, Cummins<br />

is also working on expanding its power range. The company now<br />

makes engines from 6.7 to 60 liters, or 150 to 2,700 horsepower.<br />

In 2017 it will introduce a V16 at 95 liters and is also planning<br />

on a V12 at 79 liters and a V20 at 120 liters.<br />

“Tognum is currently the leading provider of high speed diesel<br />

engine-based propulsion systems to the U.S. Coast Guard,”<br />

said Bernard Bentgen, government and naval sales director,<br />

Tognum America Inc. “MTU engines power the recently-commissioned<br />

Sentinel-class cutter USCGC Bernard C. Webber and the<br />

national security cutter USCGC Stratton, and several additional<br />

new cutters in each of those classes.”<br />

Tognum’s MTU engines are designed and built with leadingedge<br />

technology, such as electronically controlled common rail<br />

fuel injection and sequential turbocharging. This technology<br />

reduces emissions while improving performance and fuel efficiency.<br />

The MTU brand is more than 100 years old and has a long<br />

legacy of excellence in marine propulsion systems.<br />

Engine designers have long sought the perfect mix of power<br />

and efficiency. “MTU engines have featured common-rail fuel<br />

injection systems since 1996,” said Bentgen. “This innovative<br />

technology has resulted in diesel engines that are more efficient,<br />

cleaner and more powerful.”<br />

Tognum America has an extensive network of independent distributors<br />

and service providers that provide service and support for<br />

all MTU customers. “In addition, the MTU training center in Canton,<br />

Mich., provides detailed service and maintenance training on<br />

all MTU marine engines for Coast Guard personnel,” said Bentgen.<br />

The Coast Guard purchases a broad range of Mercury Marine<br />

outboard motors, from 25 horsepower all the way to 300 horsepower,<br />

for a variety of operational craft, explained Jeff Krueger,<br />

director of sales, service & marketing for racing, commercial and<br />

government. The 300-horsepower model is used mostly for homeland<br />

security boats and interceptors; 150-horsepower engines propel<br />

surface boats, and 25-horsepower engines propel flat-bottom<br />

boats.<br />

Krueger said Mercury outboards are available in low-emission,<br />

two-stroke models as well as four-stroke electronic fuel injection<br />

and four-stroke supercharged models. “We also offer a specialty<br />

two-stroke DFI outboard that is capable of running on multiple<br />

fuels such as kerosene, commercial Jet A and military JP fuels.”<br />

Krueger said Mercury will continue to engineer outboard and<br />

stern-drive products to meet and exceed current and future emission<br />

regulations, both domestic and international. “There are a<br />

series of steps in putting new emission requirements in place. We<br />

intend to stay well ahead of the curve.” The Mercury exec believes<br />

his line of engines is distinguished by its performance, advanced<br />

technology and reliability. “These are the key factors that keep<br />

Mercury Marine ahead of the competition.”<br />

“From a technological standpoint, Caterpillar, along with<br />

its peers in the industry, is constantly working to meet the latest<br />

level of emissions standards imposed both domestically and<br />

worldwide,” said Darrell Kuhne, manager, Global Governmental<br />

Marine, of Caterpillar Defense & Federal Products. “Currently, we<br />

are addressing the Tier 3 and Tier 4 standards.”<br />

Depending on what needs to be done to meet these requirements,<br />

Caterpillar will modify each platform accordingly. “This<br />

may involve anything from little or no modification up to the<br />

addition of accessories to achieve the desired level of emissions,”<br />

Kuhne said. Both requirements and modifications will vary<br />

depending on size of engine.<br />

Kuhne said Caterpillar invests hundreds of millions of dollars<br />

annually in research and development to enhance its engines and<br />

improve cost of ownership. It also looks at global trends and tries<br />

to position its product in line with these. O<br />

For more information, contact Editor-In-Chief<br />

Jeff McKaughan jeffm@kmimediagroup.com or<br />

search our online archives for related stories at www.cgf-kmi.com.<br />

www.CGF-kmi.com CGF 5.1 | 11

On Thin Ice<br />

Changing Arctic sea ice patterns,traffic create<br />

greater need for icebreakers.<br />

By John M. Doyle<br />

CGF Correspondent<br />

The sea ice in the Arctic has been melting in the summer at a<br />

faster rate than ever before, opening up new sea lanes for cargo,<br />

cruise and warships crossing the top of the world.<br />

But with increased traffic comes the increased risk of an<br />

accident or emergency and an increased need for icebreakers to<br />

smash their way through the walls of ice that still form in the<br />

waters of the High North.<br />

Russia, Canada and other countries that border the Arctic<br />

have, or are building, new icebreakers, while China, which desperately<br />

wants to find shorter, Arctic sea routes to Western markets,<br />

has one icebreaker and is building another.<br />

But the United States has had only one medium icebreaker for<br />

the last two years. That is about to change. The 399-foot heavy<br />

icebreaker, Coast Guard Heavy Icebreaker Polar Star, is rejoining<br />

the Coast Guard fleet this year after $56 million in repairs and<br />

upgrades at Vigor Shipyards in Seattle.<br />

“Commercial, shipping and industrial activity<br />

is increasing in Arctic waters each year,” said<br />

Vigor Industrial Chief Executive Officer Frank Foti,<br />

explaining that the Portland, Ore.-based parent of<br />

Vigor Shipyards expects increased activity in the<br />

Arctic to drive demand for a range of shipbuilding<br />

and repair services—including icebreakers.<br />

According to Coast Guard documents, the<br />

United States has a vital national interest in<br />

maintaining robust polar icebreaking capability<br />

to ensure “year-round Coast Guard presence in<br />

these important waters.” In submitting its budget<br />

request for fiscal year 2013, the Coast Guard noted “the criticality<br />

of the Arctic as a strategic national priority, given the increasing<br />

presence and interest by other nations, the preponderance of<br />

natural resources … and increasing maritime commercial and<br />

recreational activity.”<br />

Frank Foti<br />

With that growth, Foti said, “the need for additional U.S. icebreakers<br />

will only grow. Better icebreaking capacity is critical to keeping all<br />

those people safe and maintaining the nation’s ability to respond to<br />

emergencies.” He added: “That capacity can only come from expanding<br />

the American icebreaker fleet.”<br />

The Polar Star (WAGB-10), which can break through ice up to 6<br />

feet thick at a speed of three knots, will be joining the USCGC Healy, a<br />

medium, or polar, icebreaker that made headlines last year creating a<br />

path through Arctic waters for a Russian fuel tanker bringing heating<br />

oil and gasoline to icebound Nome, Alaska. At 420 feet long and displacing<br />

16,000 tons, the Healy is considered only a medium icebreaker<br />

because it can only crack ice 4.5 feet thick at 3 knots. The Polar Star’s<br />

sister ship, the Polar Sea (WAGB-11), which needs extensive engine<br />

repair or replacement as well as upgrades, remains in Vigor Shipyards,<br />

with its fate still undetermined. Both of the heavy icebreakers were<br />

built by Lockheed Shipbuilding of Seattle in the late<br />

1970s and both are well past their original service lifespan<br />

of 30 years. Lockheed left the shipbuilding business<br />

in the 1980s.<br />

The Coast Guard plans to keep the refurbished Polar<br />

Star in service until 2020, but notes that the need for<br />

heavy icebreaking capability will continue for the foreseeable<br />

future. The service, a unit of the Department of<br />

Homeland Security, is now in the preliminary phase of a<br />

new, heavy polar icebreaker acquisition project.<br />

“We would like to have two heavy endurance ones<br />

and one medium endurance [icebreaker] in the fleet,”<br />

<strong>Adm</strong>iral <strong>Robert</strong> J. <strong>Papp</strong> <strong>Jr</strong>., the Coast Guard commandant,<br />

said last month at the Surface Navy Association’s 25th annual<br />

symposium in Arlington, Va.<br />

For years now, <strong>Papp</strong> has been making the case for at least one<br />

additional heavy icebreaker and government reports and studies—<br />

including a 2010 analysis by the Coast Guard—have recommended<br />

12 | CGF 5.1<br />

www.CGF-kmi.com

expanding the icebreaker fleet for national security, safety, scientific and<br />

environmental reasons.<br />

“Although polar ice is diminishing due to climate change,<br />

observers generally expect that this development will not eliminate<br />

the need for U.S. polar icebreakers and, in some respects, might<br />

increase the mission demands for them,” a December 12, 2012 Congressional<br />

Research Service report on Coast Guard polar icebreaker<br />

modernization said.<br />

Fiscal<br />

Year<br />

Cost<br />

Category<br />

FY2013<br />

FY2014<br />

Totals<br />

($000s)<br />

2014 Design $2,000 $1,000 $3,000<br />

2015<br />

Program<br />

Management<br />

System<br />

Engineering &<br />

Integration<br />

Program<br />

Management<br />

$2,000 $2,000<br />

$2,000 $2,000<br />

$1,000 $1,000<br />

Total $6,000 $2,000 $8,000<br />

The Coast Guard is in the process of developing a formal mission<br />

need statement, a concept of operations and an operational requirements<br />

document for a detailed acquisition project plan. At least two<br />

large shipbuilders in addition to Vigor are interested in building the<br />

new heavy icebreaker—depending on what the Coast Guard has in<br />

mind and whether it gets the funding from Congress in these times<br />

of fiscal restraint.<br />

Michael Carroll, vice president for operations at STX US Marine<br />

in Houston, said his company has already had discussions with the<br />

U.S. Coast Guard about the Polar Class 2 (heavy) ice breaker STX<br />

Marine is building for Canada’s Coast Guard. “They’re interested in<br />

our polar class vessel. We’ve done presentations for<br />

them, showing our polar class icebreaker.”<br />

Together with its Finnish partner Aker Arctic<br />

Technologies—now part of STX Europe who have<br />

built or been involved in the design of over 60 percent<br />

of the world’s icebreakers. And Carroll thinks the<br />

market won’t be drying up anytime soon—even with<br />

climate change—“until it’s clear that icebreakers are<br />

not needed.”<br />

At Huntington Ingalls Industries (HII), which<br />

now owns the Avondale Industries shipyard that built<br />

the Healy, there is definite interest in the next heavy<br />

icebreaker.<br />

“The commandant says that’s something they’re going to continue<br />

to make an investment in. It’s a unique ship. We have experience<br />

in building icebreakers,” said Jim French, manager of HII’s<br />

National Security Cutter program, which includes icebreakers.<br />

The Polar Sea and Polar Star were both built back in the 1970s,<br />

French noted, but the Healy was built in 1999, “so it’s much more<br />

advanced in the technology that went into outfitting it.”<br />

He noted that the Healy, even though it was designed as a<br />

medium endurance cutter, could be modified for use as a heavy<br />

icebreaker. “What we would do is simply look at what kinds of<br />

changes you would have to do to the skantlings [the structural<br />

strength of framing and structural supports like girders and I-beams]<br />

and everything in order to reinforce the steel for breaking the heavier<br />

RFI for Polar Icebreaker Replacement<br />

The Coast Guard’s Polar Icebreaker Replacement Project Office<br />

has issued a request for information as a means of market research<br />

for (A) candidate heavy polar icebreaker designs and (B) U.S.<br />

shipyards capable of building a heavy polar icebreaker. This RFI is<br />

issued as a precursor to a potential polar non-nuclear icebreaker<br />

procurement program and to initiate market research in assisting<br />

the USCG in developing an acquisition strategy for new construction<br />

of a potential non-nuclear heavy icebreakers.<br />

At a minimum, a candidate heavy icebreaker design must be<br />

able to perform the missions performed by the USCGC Polar Star. At<br />

a continuous speed of 3 knots, the Polar Star can break ice 6 feet<br />

thick, and by ramming, can break 21 feet pack ice.<br />

Prospective shipyards and ice breaker design must be based<br />

on: Information on candidate designs submitted must be based<br />

on: Proven, currently in-service vessels that are capable of being<br />

built in the U.S.; In-service vessel designs that are capable of<br />

being licensed for building in the U.S.; Variants of in-service vessel<br />

designs capable of being licensed in the U.S.; or For new designs or<br />

new construction, also include details regarding its current status<br />

and expected in-service date.<br />

While the Coast Guard will accept candidate designs from both<br />

domestic and international entities, the vessel must be able to be<br />

licensed to be built in the U.S.<br />

ice and, of course, you’d have to have a heavier propulsion system<br />

to maintain the speed through the heavier ice. In their prime, both<br />

the Polar Sea and Polar Star had more powerful engines than the<br />

Healy.”<br />

But that all depends on what the government decides to do,<br />

he cautioned. “We will follow the developments as<br />

it goes through the Coast Guard and Congress, and<br />

if additional monies are funded, then HII would be<br />

interested in following that development. And if an<br />

RFP [request for proposals] is issued, we would be<br />

interested in evaluating that, bidding on it and construction,”<br />

French said.<br />

In December, President Barack Obama signed into<br />

law the Coast Guard authorization bill that bars the<br />

decommissioning of the Polar Sea unless the Coast<br />

Guard conducts a study showing that scrapping the<br />

Michael Carroll vessel is the most cost-effective option for developing<br />

a larger icebreaker fleet.<br />

“Icebreakers are critical to our national security and America’s<br />

interests in the Arctic,” said Senator Maria Cantwell (D-Wash.),<br />

author of the Polar Sea amendment, adding: “As commerce in the<br />

Arctic continues to increase, our nation’s need for icebreakers will<br />

continue to grow.”<br />

According to Cantwell’s office, refurbishing a large icebreaking<br />

vessel like the Polar Sea can take roughly five years and employ<br />

upwards of 300 workers. Building a new vessel can take eight to 10<br />

years, employing more than 1,000 workers. O<br />

For more information, contact Editor-In-Chief<br />

Jeff McKaughan jeffm@kmimediagroup.com or<br />

search our online archives for related stories at www.cgf-kmi.com.<br />

www.CGF-kmi.com CGF 5.1 | 13

ON THE HORIZON<br />

Support for<br />

Carderock Division<br />

Corrosion Teams<br />

Science Applications International<br />

Corporation (SAIC) has been awarded<br />

a prime contract by the United States<br />

Naval Surface Warfare Center Carderock<br />

Division to provide logistics and program<br />

management services for the Navy corrosion<br />

control assistance teams (CCAT). The<br />

single-award cost-plus-fixed-fee contract<br />

has a one-year base period of performance,<br />

two one-year options and a total contract<br />

value of approximately $23 million, if all<br />

options are exercised.<br />

Under the contract, SAIC will provide<br />

logistics and program management<br />

services including labor, technical assistance,<br />

training and process consumables<br />

for the Navy CCAT. Tasks will also<br />

include issuing government-owned tools<br />

and process consumables and conducting<br />

training.<br />

“We look forward to fulfilling the<br />

Navy’s need for technical expertise and<br />

introducing new technology onboard U.S.<br />

Navy and Coast Guard ships and boats,”<br />

said JT Grumski, SAIC senior vice president<br />

and business unit general manager.<br />

New National Security Cutter Contracted<br />

Huntington Ingalls Industries has been awarded a $487 million, fixed-price-incentive-fee<br />

contract to its Ingalls Shipbuilding division to build the sixth national security cutter, Munro<br />

(WMSL 755).<br />