University of Pune - K. K. Wagh Education Society

University of Pune - K. K. Wagh Education Society

University of Pune - K. K. Wagh Education Society

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Subject<br />

Code<br />

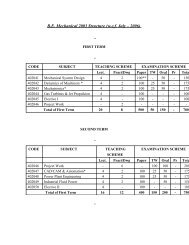

<strong>University</strong> <strong>of</strong> <strong>Pune</strong><br />

Structure <strong>of</strong><br />

BE (PRODUCTION ENGINEERING) 2003 Course<br />

Semester- I<br />

Subject<br />

Teaching<br />

Scheme<br />

(Hrs)<br />

Lecture<br />

Pr<br />

/D<br />

w<br />

Examination Scheme<br />

Th Tw Or Pr Total<br />

411081 Production 4 2 100 50 - - 150<br />

Management<br />

411082 Machine Tool 4 2 100 50 50 - 200<br />

Design<br />

411083 Manufacturing 4 2 100 - 50 - 150<br />

Automation<br />

and Control<br />

411084 Operations 4 2 100 50 - - 150<br />

Research<br />

411085 Elective I 4 - 100 - - - 100<br />

411086 Project<br />

Work**<br />

- 2 - - - - -<br />

Total 20 10 500 150 100 750<br />

** It is mandatory to submit preliminary project report for the grant <strong>of</strong> the term I<br />

Semester II<br />

Subject<br />

Code<br />

Subject<br />

Teaching<br />

Scheme (Hrs)<br />

Examination Scheme<br />

Lecture Pr/Dw Th Tw Or Pr Total<br />

411086 Project Work - 6 - 100 100 - 200<br />

411087 Material and<br />

Financial<br />

Management<br />

4 2 100 25 - - 125

411088 Process Planning 4 4 100 - 50 - 150<br />

and<br />

Tool Selection<br />

411089 CAD/CAM/CIM 4 2 100 25 50 - 175<br />

411090 Elective II 4 - 100 - - - 100<br />

Total 16 14 400 150 200 750<br />

Th: Theory Pr: Practical Dw: Drawing Tw: Term Work Or: Oral<br />

Note: Practical/Oral based on Term Work<br />

Elective I<br />

1) Reliability Engineering<br />

2) Powder Metallurgy<br />

3) Plant Engineering. and Maintenance<br />

4) Material Handling and Engineering<br />

Design<br />

Elective II<br />

1) Robotics<br />

2) Ergonomics and Human Factors in<br />

Engg.<br />

3) Advanced Material Processing<br />

4) Advanced Production Technology<br />

Detail B. E. Prod Syllabus<br />

Teaching Scheme<br />

Lectures: 4 hrs/week<br />

Practical: 2 hrs/week<br />

411081: PRODUCTION MANAGEMENT<br />

Examination Scheme<br />

Theory: 100 Marks<br />

Duration: 3 hours<br />

Term Work: 50 Marks<br />

Objectives<br />

• To learn and understand Concepts and functions <strong>of</strong> Production Management<br />

• To learn and use s<strong>of</strong>tware packages for decision making<br />

Prerequisites<br />

• Industrial Engineering and Management<br />

• Production Planning and Control<br />

Unit I<br />

Scope <strong>of</strong> Production Management (4)<br />

The evolution <strong>of</strong> Production management / Operations Management. Different<br />

production eras - Mass production, flexible and mass customization and customization.<br />

Relationship <strong>of</strong> Production / Operations Management with materials, maintenance,

quality control, design engineering, production engineering, material and sales. Scope,<br />

Definition and its relationship with other management functions such as marketing,<br />

finance and personal management. Production organizations for single product, multi<br />

product, single location, multi location.<br />

Product Design (4)<br />

Product life cycle, Relationship between product design and product cost. Functional,<br />

Economic, manufacturing and marketing aspects in product design, Concept <strong>of</strong><br />

Concurrent engineering.<br />

Unit II<br />

Location (2)<br />

Facility-location: Objectives, site selection, floor rating, center <strong>of</strong> gravity method.<br />

Layout (3)<br />

Layout types, quantitative models for facility layout, locations, layout planning for<br />

distribution centers.<br />

Material handling (3)<br />

Material handling: Its relation with layout, Objectives, principles and types <strong>of</strong> material<br />

handling. Material handling analysis. Unit load concept.<br />

Unit III<br />

Manpower Planning and Capacity Planning<br />

(4)<br />

Manpower forecasting, manpower inventory, capacity and level strategies, aggregate<br />

capacity planning, determining optimal operating levels and timing <strong>of</strong> capacity<br />

increments.<br />

Productivity Engineering (4)<br />

Productivity: factor productivity, total productivity, labour Productivity, measurement <strong>of</strong><br />

productivity, improvement techniques <strong>of</strong> productivity. Development and implementation<br />

<strong>of</strong> Productivity improvement programme.<br />

Unit IV<br />

World Class Manufacturing<br />

(8)<br />

Concept <strong>of</strong> World Class Manufacturing, Emergence <strong>of</strong> information age, Manufacturing<br />

challenges <strong>of</strong> the information age, elements <strong>of</strong> business turbulent environment. Problems<br />

in the manufacturing sector. Evolution and principles <strong>of</strong> WCM. Contribution <strong>of</strong> Hall,<br />

Schoenberger, Gunn, Maskel, World class practices in the industry, WCM-Indian<br />

Scenario.

Unit V<br />

Industrial maintenance (8)<br />

Organization, administration <strong>of</strong> maintenance function, types <strong>of</strong> maintenance, principles,<br />

operating policies, scope <strong>of</strong> maintenance management, Work authorization, work<br />

scheduling<br />

maintenance budget and costs, Total productive maintenance.<br />

Unit VI<br />

Advanced topics in production Management<br />

(8)<br />

Energy conservation and Energy audit, Eco development considerations, Green<br />

production, Lean and Agile manufacturing, Problems <strong>of</strong> technology choice and<br />

technology transfer, environmental pollution and control strategies, computerized<br />

production management systems.<br />

Term Work:<br />

1. Facility location models (any 3).<br />

2. Study <strong>of</strong> Plant layouts: Manufacturing/Service unit using SLP<br />

3. Computerized facility layout Planning – CORELAP, CRAFT, ADLEP,<br />

4. Aggregate planning using MS Excel<br />

5. Energy audit and Study <strong>of</strong> energy conservation practices for a specific industry<br />

6. One Internet based assignment on any one <strong>of</strong> topics above<br />

Text Books:<br />

1. J. L. Riggs, “Production Systems”, John Wiley and Sons.<br />

2. Mayer, “Production Management”, Tata McGraw Hill Publications<br />

3. M. Telsang, “Industrial Engineering and Production Management”, S. Chand<br />

Publication<br />

Reference Books:<br />

1. H. B. Maynard and others, “Modem manufacturing”, IVth edition - McGraw Hill<br />

Publications, ISBN 0-07-041084-4.<br />

2. H. B. Maynard and others, “Industrial Engineering Handbook”, IVth edition -<br />

McGraw Hill Publications, ISBN 0-07-041084-4.<br />

3. L. R. Higgnis, R. K. Mobley, Smith Ricky, “Maintenance Engineering<br />

Handbook”, McGraw Hill Publications, ISBN 0-07-028819-4.<br />

4. Kanter Jerome, “Management Information System”, Prentice Hall, ISBN 0-<br />

87692-358-9.

5. H. Noori and R. Radford, “Production and Operation Management”, Total Quality<br />

and<br />

Responsiveness international Edition - 1995 - McGraw Hill Inc.<br />

6. B.S. Sahay, K B C. Saxena, Ashish Kumar, “World Class Manufacturing-A<br />

Strategic perspective”,McMillan India Ltd.<br />

7. F. L. Francis, J. A. White, L. F. McGinnis, “Facilities Layout and Location”,<br />

Prentice Hall <strong>of</strong> India Pvt. Ltd., ISBN 81-203-1460-3.<br />

8. T. E. Vollmann, W. L. Bery, “Manufacturing Planning and control Systems”,<br />

Galgotia Publication New Delhi, ISBN 81-7515-084-X.<br />

9. Richard Muther, “Systematic Layout Planning”<br />

Teaching Scheme<br />

Lectures: 4 hrs/week<br />

Practical: 2 hrs/week<br />

Objectives<br />

411082: MACHINE TOOL DESIGN<br />

• To learn and understand Machine Tool Design<br />

• To learn and compute design aspects for machine tools<br />

Prerequisites<br />

• Design <strong>of</strong> Machine Elements<br />

• Kinematics and Design <strong>of</strong> Manufacturing Machines<br />

Examination Scheme<br />

Theory: 100 Marks<br />

Duration: 3 hours<br />

Term Work: 50 Marks<br />

Oral: 50 Marks<br />

Unit I<br />

Drives (4)<br />

Design considerations for drives based on continuous and intermittent requirement<br />

<strong>of</strong> power, Types and selection <strong>of</strong> motor for the drive, Regulation and range <strong>of</strong> speed<br />

based on preferred number series, geometric progression. Design <strong>of</strong> speed gear box<br />

for spindle drive and feed gear box.<br />

Stepless drives<br />

(4)<br />

Design considerations <strong>of</strong> Stepless drives, electromechanical system <strong>of</strong> regulation,<br />

friction, and ball variators, PIV drive, Epicyclic drive, principle <strong>of</strong> self locking,<br />

Unit II<br />

Design <strong>of</strong> Machine Tool Structures (8)

Analysis <strong>of</strong> forces on machine tool structure, static and dynamic stiffness.<br />

Design <strong>of</strong> beds, columns, housings, bases and tables.<br />

Unit III<br />

Design <strong>of</strong> Guideways and Power Screws (8)<br />

Functions and types <strong>of</strong> guideways, design criteria and calculation for slideways,<br />

design <strong>of</strong> hydrodynamic, hydrostatic and aerostatic slideways, Stick-Slip motion in<br />

slideways. Design <strong>of</strong> power screws: Distribution <strong>of</strong> load and rigidity analysis.<br />

Unit IV<br />

Design <strong>of</strong> Spindles and Spindle Supports (8)<br />

Design <strong>of</strong> spindle and spindle support using deflection and rigidity analysis, analysis<br />

<strong>of</strong> anti-friction bearings, preloading <strong>of</strong> antifriction bearing.<br />

Unit V<br />

Dynamics <strong>of</strong> machine tools (8)<br />

Dynamic characteristic <strong>of</strong> the cutting process, Stability analysis, vibrations <strong>of</strong> machine<br />

tools.<br />

Control Systems: Mechanical and Electrical, Adaptive Control System, relays, push<br />

button control, electrical brakes, drum control.<br />

Unit VI<br />

Advances in Machine Tool Design (8)<br />

Design considerations for SPM, NC/CNC, and micro machining, Retr<strong>of</strong>itting,<br />

Recent trends in machine tools, Design Layout <strong>of</strong> machine tool using matrices.<br />

Term work:<br />

Term work shall consist <strong>of</strong> record <strong>of</strong> assignments on following topics. Oral shall be based<br />

on term work.<br />

1. Design and working drawing <strong>of</strong> speed gear box<br />

2. Design and working drawing <strong>of</strong> feed gear box<br />

3. Study <strong>of</strong> stepless drives<br />

4. Design <strong>of</strong> bed or column.<br />

5. Design for spindle or power screw.<br />

6. Design for guideways and slideways.<br />

7. Internet assignment based on any one <strong>of</strong> the topics above.

Text Books:<br />

1. N. K. Mehta, “Machine Tool Design”, Tata McGraw Hill, ISBN 0-07-451775-9.<br />

2. A. Bhattacharya and S. G. Sen., “Principles <strong>of</strong> Machine Tool”, New central book<br />

agency Calcutta, ISBN 81-7381-1555.<br />

3. D. K Pal, S. K. Basu, “Design <strong>of</strong> Machine Tool”, 4th Edition. Oxford IBH 2005,<br />

ISBN 81-204-0968.<br />

Reference Books:<br />

1. N. S. Acherkan, “Machine Tool”, Vol. I, II, III and IV, MIR publications.<br />

2. F. Koenigsberger, “Design Principles <strong>of</strong> Metal Cutting Machine Tools”, The<br />

Macmillan Company New York 1964.<br />

Teaching Scheme<br />

411083: MANUFACTURING AUTOMATION AND CONTROL<br />

Lectures: 4 hrs/week<br />

Practical: 2 hrs/week<br />

Objectives<br />

Examination Scheme<br />

Theory: 100 Marks<br />

Duration: 3 hours<br />

Oral: 50 Marks<br />

• To learn and understand Hard and S<strong>of</strong>t Automation<br />

• To learn and perform experiments with hydraulic and pneumatic circuits<br />

Prerequisites<br />

• Machine Tools and Advance Manufacturing Systems<br />

Unit I<br />

Basics <strong>of</strong> Automation and Industrial Hydraulics (8)<br />

Basic concepts <strong>of</strong> automated system, Advanced automated functions, levels <strong>of</strong><br />

automation, Principles <strong>of</strong> hydraulics, hydraulic fluids, filtration technology, hydraulic<br />

pumps, hydraulic valves, and hydraulic actuators.<br />

Unit II<br />

Design <strong>of</strong> Hydraulic Circuits<br />

(8)<br />

Basic hydraulic circuits such as regenerative circuits, sequencing circuit, meter in and<br />

meter out circuit, standards in circuit diagram representation, power pack design layout,

design <strong>of</strong> pumps, reservoir, accumulators and intensifiers, selection <strong>of</strong> standard<br />

components, hydraulic servo mechanism, proportional valves.<br />

Unit III<br />

Pneumatic Systems (6)<br />

Operational principles and application, air compressors, pneumatic cylinders and air<br />

motors, pneumatic valves, Design <strong>of</strong> pneumatic circuits, hydro-pneumatic, control in<br />

pneumatic system.<br />

Unit IV<br />

Programmable Automation (10)<br />

Microprocessor, microprocessor instrumentation system for process control, logic gate<br />

and control, programmable logic control, computer process controls.<br />

Unit V<br />

Control System (7)<br />

Electric control: - features and design principles <strong>of</strong> electrical circuits in drives, PLC, data<br />

conversion (ADC/DAC), interfacing circuits, actuating signals, relays, contactors, types<br />

<strong>of</strong> control systems, linear feedback control system, optimal control system.<br />

Unit VI<br />

Factory Automation (9)<br />

Transfer systems-Continuous, intermittent, Indexing mechanisms, vibratory bowl<br />

feeders, non-vibratory feeders, hopper feeders, rotary disc feeder, centrifugal, revolving<br />

feeder, assembly systems, automated assembly, design for automated assembly,<br />

synchronous and non synchronous material transfer, industrial robots, Automated Guided<br />

Vehicles and FMS, automated warehouse.<br />

Term Work:<br />

The term work shall consist <strong>of</strong> record <strong>of</strong> any eight assignments on following topics.<br />

1. Study <strong>of</strong> control valves, actuators, accumulators and pumps.<br />

2. Study <strong>of</strong> hydraulic circuits: - hydraulic press, machine tools, automobile systems,<br />

etc<br />

3. Performance analysis <strong>of</strong> positive displacement pumps.<br />

4. Comparative studies on hydraulic circuit design for suitable industrial<br />

applications.<br />

5. Study <strong>of</strong> pneumatic circuits.<br />

6. Study <strong>of</strong> automation in material handling system.<br />

7. Use <strong>of</strong> microprocessors: applications in manufacturing engineering.

8. Study and experiments in programmable logic controllers: ladder logic<br />

programming<br />

9. Study <strong>of</strong> displacement, level and pressure controls<br />

10.Measurement and design circuits for speed and temperature measurement.<br />

Oral shall be based on the above Term work. ,<br />

Text Books:<br />

1. B. C Kuo, “Automatic control systems”, Prentice Hall India Pvt. Ltd., ISBN 0-<br />

87692-480-1.<br />

2. Peter Rohner, “Industrial hydraulic control”<br />

3. Mikell P Groover, “Automation, Production System and Computer Integrated<br />

Manufacturing”, Prentice Hall Publications, ISBN 81-203-0618-X.<br />

4. S. R. Mujumdar, “Pneumatic system”, Tata McGraw Hill 2002 Edition.<br />

5. Gopal, “Control systems Engineering”, Willey Eastern Ltd., ISBN 0-85226-605-<br />

7.<br />

Reference Books:<br />

1. E. O Doebelin., “Measurement System, Application and Design”, Tata McGraw<br />

Hill Publications Ltd., New Delhi, ISBN 0-07—17338-9.<br />

2. W Bolton., “Mechatronics Electronic Control Systems in Mechanical and<br />

Electrical<br />

Engineering”, Pearson <strong>Education</strong> (Singapore) Pvt Ltd., ISBN 81-7808-339-6.<br />

3. C S Rangan, G R Sharma, V S Mani, “Instrumentation - Devices and Systems”,<br />

Tata<br />

McGraw Hill Publications Ltd., New Delhi, ISBN 0-07-463350-3.<br />

4. B H Histand, D G Alciatore, “Introduction to Mechatronics and Measurement<br />

Systems”, ISBN 0-07-052910-8.<br />

5. C D Johnson, “Process Control Instrumentation Technology”, Prentice Hall <strong>of</strong><br />

India Pvt. Ltd., New Delhi, ISBN 81-203-0987-1.<br />

6. HMT Mechatronics, HMT, ISBN 0-07-462147-5..<br />

7. Vickers manual on hydraulics<br />

8. G. Boothroyd , C. Poli, L. Murch, “Automatic Assembly”, Marcel Dekker Inc.<br />

1982.<br />

9. Ramesh Gaonkar, “Microprocessor”, Penram International Pub. Pvt. Ltd., ISBN<br />

81-900-828-7-6.<br />

10. Werner Deport and Kurt Stool, "Mechanization by pneumatic control", Vol. I and<br />

II<br />

411084: OPERATIONS RESEARCH

Teaching Scheme<br />

Lectures: 4 hrs/week<br />

Practical: 2 hrs/week<br />

Objectives<br />

Examination Scheme<br />

Theory: 100 Marks<br />

Duration: 3 hours<br />

• To learn and understand Quantitative Techniques<br />

• To learn and use s<strong>of</strong>tware packages for quantitative techniques<br />

Prerequisites<br />

Term Work: 50 Marks<br />

• Production Planning and Control<br />

• Data Base and Information Technology for Production Engineers<br />

Unit I<br />

Linear programming<br />

(8)<br />

Definition <strong>of</strong> Operations Research: objectives, formulation <strong>of</strong> problem, graphical method,<br />

simplex methods for maximization and minimization problems, degeneracy in L.P.,<br />

duality in L. P.; Sensitivity analysis,<br />

Unit II<br />

Transportation and assignment problem (8)<br />

Structure, industrial and business application Transportation problems- use <strong>of</strong> various<br />

methods for solving transportation problem, degeneracy and its solution, transhipment<br />

problem. Assignment problem- solutions <strong>of</strong> various types <strong>of</strong> problems, travelling<br />

salesman Problem.<br />

Unit III<br />

Introduction to Integer, Dynamic and Non-linear programming<br />

(6)<br />

Simulation (3)<br />

Introduction, application, Monte Carlo simulation <strong>of</strong> queuing system, inventory system,<br />

capital budgeting, new product planning etc.<br />

Unit IV<br />

Introduction to Geometric and Goal Programming.<br />

(3)<br />

Replacement models (4)<br />

Replacement <strong>of</strong> capital equipments that deteriorates with time,<br />

time value <strong>of</strong> money (a) remains same (b) changes with constant rates during period.

Equipment renewal policy, group and individual replacement.<br />

Unit V<br />

Queuing theory (3)<br />

Operating characteristics, Poisson single and multi channel queuing system M/M/1: /<br />

FCFS.<br />

Games Theory<br />

(4)<br />

Introduction, two -person zero sum game, minimax and maximin principle, saddle point,<br />

methods for solving game problems with mixed strategies, Graphical and iterative<br />

methods.<br />

Unit VI<br />

Network modeling (3)<br />

Fundamentals <strong>of</strong> CPM. and PERT networks.<br />

CPM (3)<br />

Construction <strong>of</strong> networks, critical paths, forward and backward pass, floats and<br />

their significance, crashing for optimum and minimum duration and the cost, resource<br />

allocation and leveling<br />

PERT (3)<br />

Time estimates, construction <strong>of</strong> networks, probability <strong>of</strong> completing projects by given<br />

date.<br />

Term Work<br />

One exercise on each unit. At least one Computer s<strong>of</strong>tware package such as Lindo/Lingo,<br />

MATLAB, MS-Excel and Tora should be used.<br />

Oral shall be based on the term work.<br />

Text Books:<br />

1. S. D. Sharma, “Operations Research”, Kedarnath Ramnath and company<br />

Publications.<br />

2. P. K. Gupta, D. S. Hira, “Operations Research”, S Chand and Co. Ltd., ISBN 81-<br />

219-0281-9.<br />

3. H. A Taha., “Operations Research”, An introduction Prentice Hall Pvt. Ltd., ISBN<br />

81-203-1222-8.<br />

Reference Books:

1. F. S. Hillier, G. J Lieberman, “Introduction to Operations Research”, Tata<br />

McGraw-Hill, ISBN 0-07-047387-0.<br />

2. H. M. Wagner, “Principles <strong>of</strong> Operations Research”, Prentice-Hall India, ISBN<br />

81-203-0162-5.<br />

3. A. Ravindran, “Operations Research”, Tata McGraw-Hill.<br />

4. S. K. Basu, D. K. Pal, H. Bagchi, “Operations Research for Engineers”, Oxford<br />

and IBH Publishing Co. Pvt. Ltd., ISBN 81-204-1251-6.<br />

5. R. Panneerselvam, “Operations Research”, Prentice Hall <strong>of</strong> India Ltd., ISBN 81-<br />

203-<br />

1923-0.

Teaching Scheme<br />

Lectures: 4 hrs/week<br />

411085: RELIABILITY ENGINEERING<br />

ELECTIVE I<br />

Objectives<br />

• To learn and understand Reliability Engineering<br />

Prerequisites<br />

• Metrology and Quality Control<br />

Examination Scheme<br />

Theory: 100 Marks<br />

Duration: 3 hours<br />

Unit I<br />

Introduction to Reliability (8)<br />

Importance <strong>of</strong> reliability, performance cost and reliability, quality and safety, system<br />

configuration with examples, stochastic processes, bathtub concept, MTBF, MTTR,<br />

hazard rate, failure rate, probability and sampling, cumulative probability distribution<br />

function, data and distributions.<br />

Unit II<br />

System safety analysis (8)<br />

Fault tree and event tree concept, construction and analysis, failure modes effects and<br />

criticality analysis, systems approach, techno-physio constraints, typical failure analysis,<br />

risk priority number and its allocation.<br />

Unit III<br />

Reliability in design and Life Cycle costing<br />

(8)<br />

Survival rate, bath-tub curve analysis <strong>of</strong> characteristics <strong>of</strong> failure regimes, design<br />

synthesis, reliability effort function, safety margin, allocation <strong>of</strong> reliabilities by AGREE,<br />

ARINC, proportional distribution <strong>of</strong> unreliability, heuristic method, mean and median<br />

methods.<br />

Unit IV<br />

System reliability and redundancy<br />

(8)

Active and Passive Redundancy, redundancy allocation and limitations, Evaluation <strong>of</strong><br />

overall system reliability, Conditional probability, Matrix methods, set theory analysis <strong>of</strong><br />

system reliability.<br />

Unit V<br />

Loads, capacity, maintainability and availability<br />

(8)<br />

Reliability and safety factors, Repetitive loading, Preventive maintenance, Testing and<br />

repair, reliability centered maintenance, system availability and maintainability.<br />

Unit VI<br />

Reliability testing and Failure Interactions<br />

(8)<br />

Reliability growth models, grouped. and ungrouped data, censored data, accelerated life<br />

testing, Markov analysis .<strong>of</strong> two independent components, reliability with standby<br />

system, multicomponent systems, DTMC and CTMS models.<br />

Text Books:<br />

1. E. E. Lewis, “Introduction to Reliability Engineering”, John Wiley and Sons.<br />

2. L. S. Srinath, “Reliability Engineering”, Affiliated East-West Press Pvt. Ltd.,<br />

ISBN 81-85336-39-3.<br />

3. S. S. Rao, “Reliability Engineering”.<br />

References Books:<br />

1. S. K. Basu, B. Bhadury, “Terotechnology-Reliability Engineering and<br />

maintenance”, Asian books Pvt. Ltd (2003), ISBN 81-86299-40-6.<br />

2. Sheldon M. Ross, “Stochastic Processes”, John Wiley and Sons.<br />

Teaching Scheme<br />

Lectures: 4 hrs/week<br />

411085: POWDER METALLURGY<br />

ELECTIVE I<br />

Examination Scheme<br />

Theory: 100 Marks<br />

Duration: 3 hours<br />

Objectives<br />

• To learn and understand Powder Metallurgy and Applications<br />

Prerequisites<br />

• Engineering Metallurgy-I

• Material Science and Composite Materials<br />

Unit I<br />

Powder Metallurgy (8)<br />

Historical development, Introduction, Basic principles, techniques, classification,<br />

applications, merits and demerits. Production <strong>of</strong> metal powders: reduction, atomization,<br />

and electrolysis etc. Characteristics <strong>of</strong> powders and properties, production methodology<br />

and quality control. Preparation <strong>of</strong> powder: grading, sizing, blending, handling and<br />

storage. Testing <strong>of</strong> powders. Particle size distribution, surface conditions, purity, flow<br />

properties, porosity, true and apparent density, Green compact strength.<br />

Unit II<br />

Compaction (8)<br />

fundamentals <strong>of</strong> compaction, presses used, selection <strong>of</strong> presses, Automation and<br />

Handling <strong>of</strong> powder, tool clearances, Die design principles, wear reclamation, Die and<br />

punch materials selection and heat treatment, surface treatment properties, compact<br />

density variations, effect <strong>of</strong> blending powders, lubricants and lubrication in process.<br />

Unit III<br />

Sintering (8)<br />

principle, time temperature effects, theories <strong>of</strong> sintering mechanism. Sintering methods,<br />

sintering furnaces-characteristics and selection. Dimensional and property changes after<br />

sintering, sintering atmosphere and its impact on process performance. Hot compaction,<br />

hot and cold pressing, spot sintering operations, impregnation.<br />

Unit IV<br />

Special P.M. processes (8)<br />

Hot isostatic pressing, merits, demerits and typical applications. Powder Metal products<br />

with polymer blends, expendable and retaining roll compaction. P.M. forging, Spray,<br />

deposition and surface structure development.<br />

Unit V<br />

Powder Metallurgy Applications (8)<br />

As structural parts, gears, levers, ratchets, etc. lamp filament and filament support,<br />

refractory metal components, electrical contact material, Cemented Carbide tools and<br />

wear parts, brakes and clutch lining material, porous bearings and filters, catalytic<br />

components etc.

Unit VI<br />

Powder Metallurgy Components characteristics (8)<br />

Economics, Quality, Manufacturing Competitiveness due to conservation <strong>of</strong> energy,<br />

Materials, Operations, Durability, rigidity, near net – shape, surface finish and<br />

machining.<br />

Heat treatment <strong>of</strong> Powder Metallurgy parts, advantages and limitations, typical<br />

applications.<br />

Quality control and quality assurance. Newer materials, production <strong>of</strong> nano-composites.<br />

Text Books:<br />

1. A.K Sinha, “A textbook <strong>of</strong> power Metallurgy”, D.P. Tai.<br />

2. Schartz Kopf, “Powder Metallurgy”, McmilJar Company.<br />

3. W.D Jone, “Fundametal principals <strong>of</strong> power Metallurgy”, Edword Arnold (UK)<br />

Reference Books:<br />

1. J. S Hirschhorn, “Introduction to powder Metallurgy”, America P .M. Institute<br />

New York<br />

2. H. H. Hausner, M. kumar Lal, “Handbook <strong>of</strong> Powder Metallurgy”, Chemical<br />

Publishing Company, New York, ISBN 0-8206-0301-5.<br />

3. Goetzel C. G., “Treatise on power Metallurgy “, Vol I to IV Inter Science<br />

publisher Company, New York.<br />

4. A.R. Poster (Editor), “Handbook <strong>of</strong> Metal powder Van Norstar Rembold<br />

Company”, New York.<br />

5. “A practical Guide to Metal Powder”, Hogans India Ltd.<br />

6. Yarten, Argly, “Power Metallurgy”, Machinery Publishing U.K.<br />

7. Hari Singh Nalwa (Editor), “Handbook <strong>of</strong> Nano-structured Materials and<br />

Nanotechnology”Vol 1-5, Springer Verlang<br />

Teaching Scheme<br />

Lectures: 4 hrs/week<br />

411085: PLANT ENGINEEREING AND MAINTAINANCE<br />

ELECTIVE I<br />

Objectives<br />

• To learn and understand Plant Engineering function<br />

Prerequisites<br />

Examination Scheme<br />

Theory: 100 Marks<br />

Duration: 3 hours

Unit I<br />

Introduction (4)<br />

Scope and importance <strong>of</strong> plant engineering. function – estimation <strong>of</strong> capacity for services<br />

like manpower, water resource, power, choice <strong>of</strong> factors involving environment,<br />

pollution control, sewage and waste disposal. Importance <strong>of</strong> location,<br />

Location (4)<br />

Economics, social, climatological, legal, political and industrial factors affecting site<br />

selection. Establishing various kind <strong>of</strong> weighing coefficients <strong>of</strong> these factors in relation to<br />

the nature <strong>of</strong> plant.<br />

Unit II<br />

Plant Layout<br />

(4)<br />

Types <strong>of</strong> production and their influence on layout, layout planning for various types <strong>of</strong><br />

production- functional layout, cellular layout, PQ analysis, PQRST analysis, Space<br />

requirement analysis and space diagram, REL chart, Material flow analysis; layout<br />

analysis for operation and maintenance <strong>of</strong> auxiliary services; Systematic layout planning<br />

(SLP), Computer aided planning for layout design- types <strong>of</strong> layout problems, use <strong>of</strong><br />

computers in planning and solving layout problems.<br />

Plant Safety<br />

(4)<br />

Planning for safety against mechanical, chemical hazards, pollution, sewage and waste<br />

disposal, prevention practices against accident, fire, pollution, noise- safety codes<br />

introduction, introduction to industrial safety Acts.<br />

Unit III<br />

Material handling (4)<br />

Analysis and design <strong>of</strong> material flow; principles <strong>of</strong> material handling analysis systemunit<br />

load concept, system approach – flow process charts; development <strong>of</strong> new systems/<br />

quantitative analysis <strong>of</strong> material flow. Line balancing technique with optimal material<br />

flow configuration, layout material handling and transportation and maintenance function<br />

on productivity improvement.<br />

Auxiliary Services Planning<br />

(4)

Planning and maintenance <strong>of</strong> auxiliary services like security service, Transportation<br />

service, water supply, recycling <strong>of</strong> disposal, effluent water treatment, Sewage water<br />

treatment, scrap disposal or recycling.<br />

Unit IV<br />

Maintenance Organization and Management<br />

(4)<br />

Responsibilities and functions - operating policies-work allocation and schedulingdistribution<br />

<strong>of</strong> work load –centralized Vs decentralized; organizational structures <strong>of</strong><br />

maintenance department- maintenance- history cards for equipments-maintenance<br />

manual records- utilities generation.<br />

Types <strong>of</strong> Maintenance<br />

(4)<br />

Concept <strong>of</strong> life cycle, maintenance- Breakdown, Corrective, Predictive, Elimination<br />

(Design out) maintenance and Maintenance indication. Condition based maintenance<br />

Unit V<br />

Monitoring <strong>of</strong> Maintenance System<br />

(4)<br />

History records, Signature Analysis, Sound monitoring, Maintenability -Productivity and<br />

reliability, Optimization <strong>of</strong> total maintenance. Lubrication and Lubricants- analysis <strong>of</strong><br />

effects <strong>of</strong> lubricants: Corrosion and wear their causes and prevention. Spectrometric Oil<br />

Analysis Procedure (SOAP)<br />

Spare Parts Management (4)<br />

Financial aspects <strong>of</strong> spares- survey on spares practices-management <strong>of</strong> issues <strong>of</strong> spareslead<br />

time analysis-requirement planning- selective control <strong>of</strong> stock levels- spare parts<br />

cost reduction-reliability and quality <strong>of</strong> spares-obsolescence and standardization. Logistic<br />

management spare parts inventory.<br />

Unit VI<br />

Reliability (4)<br />

Reliability Concepts- reliability-MTBF, MTTR, MTTF-reliability improvement: Fault<br />

tree analysis and other techniques.<br />

Maintainability (4)

Preventive maintenance principle-availability-optimum preventive maintenance, Analysis<br />

<strong>of</strong> equipments-quantification <strong>of</strong> system effectiveness, Reliability Centered Maintenance<br />

(RCM), Total Productive Maintenance (TPM), Merits, Demerits, House Keeping.<br />

Computerized Maintenance Management System, Failure Mode and Effect Analysis<br />

(FMEA).<br />

Text Books:<br />

1. H.P Garg.,”Industrial Maintenance”, S. Chand and co. New Delhi<br />

2. Dr. S.K Basu., “Terotechnology :Reliability Engg. and Maintenance Mgt.”, Asian<br />

Book (P) Ltd. (2003), ISBN 81-86299-40-8.<br />

Reference Books:<br />

1. H. B. Maynard and Others, “Industrial Engineering Handbook” Ivth edition,<br />

McGraw Hill Publications, ISBN 0-07-041084-4.<br />

2. L.S. Shrinath, “Reliability Engineering”, Affiliated East-West press (P) Ltd, New<br />

Delhi, ISBN 81-85336-39-3.<br />

3. R.C. Roslar, “Handbook <strong>of</strong> Plant Engg.”, McGraw Hill.<br />

4. Higgins “Handbook <strong>of</strong> Plant Engg.” McGraw Hill.<br />

411085: MATERIAL HANDLING TECHNOLOGY AND EQUIPMENT DESIGN<br />

Teaching Scheme<br />

Lectures: 4 hrs/week<br />

Examination Scheme<br />

Theory: 100 Marks<br />

Duration: 3 hours<br />

Objectives<br />

• To learn and understand Material Handling concepts and Principles<br />

• To learn design <strong>of</strong> Material Handling Equipment<br />

Prerequisites<br />

• Design <strong>of</strong> Machine Elements<br />

Unit I

Introduction to Material Handling<br />

(8)<br />

Objectives <strong>of</strong> Material Handling, Basic storage methods and equipment. Factors<br />

governing selection <strong>of</strong> Material Handling systems, Systems Approach to Material<br />

Handling, Systematic Handling Analysis, Data Collection Analysis and<br />

Development <strong>of</strong> New System. Unit load concept.<br />

Unit II<br />

Classification and Principles <strong>of</strong> Material Handling<br />

(8)<br />

I) Classification <strong>of</strong> various Material Handling Equipments and Accessories<br />

a) Unrestricted b) Area Restricted c) Line Restricted d) Position Restricted<br />

e) Auxiliary Restricted<br />

II) Principles <strong>of</strong> Material Handling.<br />

Unit III<br />

Conventional Material Handling Equipments<br />

(8)<br />

Design Consideration for Material Handling Equipments e.g. Belt, Chain, Roller<br />

Conveyor, Factors involved in Equipment Selection.<br />

a) Manually Operated: Pallet Truck, Fork Lifts, Pillar and Overhead Cranes,<br />

b) Liquid and Gas Handling, Pneumatic Conveying.<br />

Unit IV<br />

Automated Material Handling<br />

(8)<br />

Automation in Material Handling Equipment, Consideration for automating the material<br />

handling equipment, Drives for Equipment e.g. Hydraulic, Pneumatic, Electrical.<br />

Design considerations <strong>of</strong> Bulk Material Handling and Unit Load Handling. Advantages<br />

and Disadvantages <strong>of</strong> Automated Material Handling. Financial Justification for<br />

Implementing and automating Material Handling, Robot assisted Material Handling,<br />

Actuators.<br />

Unit V<br />

Advanced Material Handling Equipment for Computer Integrated<br />

Manufacturing (8)

a) Automated Guided Vehicles (AGV), Principle <strong>of</strong> its Working, Types <strong>of</strong> AGV’s, its<br />

Control, its capabilities<br />

b) Automatic Storage and Retrieval System (ASRS) Interfacing <strong>of</strong> Advanced Material<br />

Handling Equipment with Manufacturing Equipment. Use <strong>of</strong> Advance Technology for<br />

Material Handling Equipment like Vision System, Adaptive Control System, etc.<br />

Unit VI (8)<br />

Computer Applications in material handling, Packaging, Automatic identification<br />

systems, RFID, Safety aspects considerations in design and operation <strong>of</strong> material<br />

handling equipments, Environmental and Human factors considerations.<br />

Text Books:<br />

1. Allegri Theodore, “Material Handling Principles and practice” (CBS Publisher<br />

Delhi)<br />

2. Mikell P Groover, “Automation, Production System and Computer Integrated<br />

Manufacturing”, Prentice Hall Publications, ISBN 0-87692-618-9.<br />

Reference Books:<br />

1. D. E. Mulcahy, “Material Handling Handbook”, McGraw-Hill<br />

2. Kulwiec Raymond (editor), “Materials Handling Hand Book”, John Wiley (2 nd<br />

Edition)<br />

3. R. G. T Lindkvist., “HandBook <strong>of</strong> Material Handling”, John Wiley and Sons, INC<br />

New York, ISBN 0-85312-574-0.<br />

411086: PROJECT WORK<br />

Teaching Scheme<br />

Examination Scheme<br />

Practicals: 2 hrs/week (I Semester) Term Work: 100 Marks<br />

Practicals: 4hrs/week (II Semester) Oral: 100 Marks<br />

Objectives<br />

• To undertake small project in group related to application <strong>of</strong> principles studied<br />

during the course<br />

Prerequisites<br />

The student shall take up suitable project, the scope <strong>of</strong> the project shall be such as to<br />

complete it with the time schedule, The term work shall consist <strong>of</strong>,<br />

1. Fabrication <strong>of</strong> models, machines, prototypes based on new ideas, robots and machine<br />

based on hitech systems and automation, experimental set-up, fabrication <strong>of</strong> testing

equipment, renovation <strong>of</strong> machines, etc. Above work shall be taken up individually or in<br />

groups. The group shall not be more than 4 students,<br />

OR<br />

Extensive analysis <strong>of</strong> some problems done with the help <strong>of</strong> a computer individually or in<br />

a group not exceeding two students.<br />

2. A detailed report on the work done shall include project specification, design<br />

procedure, drawings, process sheets, assembly procedure and test results etc.<br />

Project may be <strong>of</strong> the following types:<br />

1. Manufacturing / Fabrication <strong>of</strong> a prototype machine' including selection, concept,<br />

design, material, manufacturing the components, assembly <strong>of</strong> components, testing and<br />

performance evaluation.<br />

2. Improvement <strong>of</strong> existing machine / equipment / process.<br />

3. Design and fabrication <strong>of</strong> Jigs and Fixtures, dies, tools, special purpose equipment,<br />

inspection gauges, measuring instruments for machine tools.<br />

4. Computer aided design, analysis <strong>of</strong> components such as stress analysis.<br />

5. Problems related to Productivity improvements.<br />

6. Problems related to value engineering.<br />

7. Problems relating to material handling system.<br />

8. Energy Audit <strong>of</strong> organization, Industrial evaluation <strong>of</strong> machine devices.<br />

9. Design <strong>of</strong> a test rig for performance evaluation <strong>of</strong> machine devices.<br />

10. Product design and development.<br />

11. Analysis, evaluation and experimental verification <strong>of</strong> any engineering problem<br />

encountered.<br />

12. Quality systems and management. Total Quality Management.<br />

13. Quality improvements, In-process Inspection, Online gauging.<br />

14. Low cost automation, Computer Aided Automation in Manufacturing.<br />

15. Time and Motion study, Job evaluation.<br />

16. Ergonomics and safety aspects under industrial environment<br />

17. Management Information System.<br />

18. Market Analysis in conjunction with Production Planning and Control.<br />

OR<br />

Computer based design / analysis or modeling / simulation <strong>of</strong> product(s), mechanism(s)<br />

or system (s) and its validation or comparison with available benchmarks / results. When<br />

a group <strong>of</strong> students is doing a project, names <strong>of</strong> all the students shall be included on every<br />

certified report copy. Two copies <strong>of</strong> Project Report shall be submitted to the college. The<br />

students shall present their Project before the examiners. The oral examination, shall be<br />

based on the term work submitted and jointly conducted by an internal and an; external

examiner from industry, at the end <strong>of</strong> second semester. Format <strong>of</strong> the project report<br />

should be as follows:<br />

1. Paper: The Project report should be types. printed on white paper <strong>of</strong> A-4 size.<br />

2. Typing: The typing shall be with single spacing and on one side <strong>of</strong> the paper.<br />

3. Binding: The Industrial Inplant Report should be submitted with front and back cover<br />

in black hand bound, with golden embossing.<br />

4. Margins: Left - 1.25", Right - 1". Top and Bottom 1 "<br />

5. Sequence <strong>of</strong> Pages:<br />

1. Title page<br />

2. Certificate form Institute<br />

3. Completion Certificate form Industry, if sponsored.<br />

4. Acknowledgement<br />

5. Abstract<br />

6. Index<br />

7. Nomenclature and Symbols<br />

8. Actual Content<br />

9. Conclusion<br />

10. References.<br />

6. Front cover: The front cover shall have the following details in block capitals<br />

i. Title at the top.<br />

ii. Name <strong>of</strong> the candidate in the centre, and<br />

iii. Name <strong>of</strong> the Institute, Name <strong>of</strong> Industry, if sponsored and the year <strong>of</strong> submission on<br />

separate lines, at the bottom.<br />

7. Blank sheets: No blank sheets be left any where in the report. 8. Project Completion<br />

Certificate:<br />

The approval sheet follow the title sheet and shall be as shown with proper spacing.<br />

CERTIFICATE<br />

This is to certify that Mr. /Ms ……………………………………………<br />

……<br />

Has carried out a Project entitled,<br />

(Name)<br />

…………………………………………during the course <strong>of</strong> his<br />

(Name <strong>of</strong> Project)<br />

training at………………………………………………..in<br />

(Name <strong>of</strong> Industry)<br />

partial fulfillment <strong>of</strong> the requirement <strong>of</strong> the B.E. Production Course <strong>of</strong><br />

<strong>University</strong> <strong>of</strong> <strong>Pune</strong><br />

at ……………………………during the academic Year ………………

(Name <strong>of</strong> Industry)<br />

Date:<br />

Place:<br />

(Guide)<br />

(Examiner)<br />

(Head <strong>of</strong> Department)

Teaching Scheme<br />

Lectures: 4 hrs/week<br />

Practicals: 2 hrs/week<br />

411087: MATERIALS AND FINANCIAL MANAGEMENT<br />

Objectives<br />

• To learn and understand Materials Management Functions<br />

• To learn and understand Financial Management Functions<br />

Prerequisites<br />

Unit I<br />

• Industrial Engineering and Management<br />

• Production Planning and Control<br />

Examination Scheme<br />

Theory: 100 Marks<br />

Duration: 3 hours<br />

Term Work: 25 Marks<br />

Materials Management (2)<br />

Introduction to Material Management functions, objectives, tools and techniques<br />

Value analysis<br />

(3)<br />

Value engineering, concepts, advantages, applications, problem recognition, role <strong>of</strong><br />

creativity, analysis <strong>of</strong> functions, use, esteem and exchange values elimination <strong>of</strong><br />

unnecessary costs, value engineering techniques.<br />

Inventory control (3)<br />

Probabilistic models, Cost, Safety stocks, service levels, inventory control <strong>of</strong> finished<br />

goods, single order inventory policies Inventory models under risk and under uncertainty.<br />

Unit II<br />

Supply Chain Management (4)<br />

Design considerations, the role <strong>of</strong> safety inventory, planning and managing inventories,<br />

order processing, Determining appropriate level <strong>of</strong> safety and economic considerations.<br />

Logistics Management<br />

(3)<br />

Evolution <strong>of</strong> logistics, Objective and its functions, financial control <strong>of</strong> logistic<br />

performance.<br />

Waste Management (2)<br />

Importance <strong>of</strong> waste management and techniques.

Unit III<br />

Import and Import Substitution (4)<br />

Factors affecting National and International markets, Import procedure and documents<br />

(Bill <strong>of</strong> lading, letter <strong>of</strong> credit etc.), current EXIM policies, import Substitution, E-<br />

procurement.<br />

Warehouse Management (3)<br />

Nature and importance <strong>of</strong> warehousing, warehousing operations and Facility<br />

development.<br />

Unit IV<br />

Financial Management (3)<br />

Financial Function, Scope, goals and tools. Sources <strong>of</strong> finance.<br />

Ratio Analysis<br />

(3)<br />

Classification, Ratio Analysis and its limitations.<br />

Working Capital Management (2)<br />

Concept and design <strong>of</strong> Working Capital, types <strong>of</strong> working capital, sources <strong>of</strong> working<br />

capital, Time value <strong>of</strong> money, definition <strong>of</strong> cost and capital.<br />

Unit V<br />

Costing (2)<br />

Methods <strong>of</strong> costing and elements <strong>of</strong> cost.<br />

Material Cost (2)<br />

Different methods <strong>of</strong> pricing <strong>of</strong> issue <strong>of</strong> materials.<br />

Labour Cost (2)<br />

Different methods, wages and incentive plans. Principles <strong>of</strong> good remunerating system,<br />

labour turnover.<br />

Depreciation (2)<br />

Concept, importance and different methods <strong>of</strong> depreciation<br />

Unit VI<br />

Overheads (2)<br />

Classification, collection <strong>of</strong> overheads, Primary and Secondary apportionment <strong>of</strong><br />

overheads, absorption <strong>of</strong> overheads- Machine hour and labour hour rate. Under and over<br />

absorption <strong>of</strong> overheads.<br />

Standard costing (2)<br />

Concept, development and use <strong>of</strong> standard costing, variance analysis.

Marginal Costing (2)<br />

Use <strong>of</strong> Marginal Costing in decision-making.<br />

Capital Budgeting (2)<br />

Control <strong>of</strong> Capital Expenditure, Evaluation Process-Payback approach, IRR, present<br />

value method.<br />

Term Work:<br />

The term work shall consist <strong>of</strong> record <strong>of</strong> assignments on following topics.<br />

1. A case study <strong>of</strong> value analysis.<br />

2. Assignment on inventory control and Supply Chain Management.<br />

3. Study and consolidation <strong>of</strong> import documents.<br />

4. Case study on financial statements and its analysis<br />

5. Collection and consolidation <strong>of</strong> labour and material costing data from anyone<br />

production company for a specific period.<br />

6. Assignments on overheads and depreciation.<br />

Text Books:<br />

1. Dobler and Lee, “Purchasing and Material Management”, Tata McGraw Hill,<br />

ISBN 0-07-462082-7<br />

2. Henry M. Steiner, “Engineering Economics Principles”, McGraw Hill<br />

Publication.<br />

3. N. K. Prasad, “Principles and Practice <strong>of</strong> Cost Accounting”, Book Syndicate Pvt.<br />

Ltd., Calcutta 700009.<br />

4. L. C. Jhamb, “Inventory Management”, Everest Publications, ISBN 81-86314-54-<br />

7<br />

5. S. Chopra, Peter Meindl, “Supply Chain Management: Strategy: Planning and<br />

Operation”, Sunil– 2 nd Ed, Pearsoh <strong>Education</strong>.<br />

Reference Books:<br />

1. K. S. Menon, “Purchasing and Inventory Control”, Wheeler Publication, ISBN<br />

81-85814-10-4<br />

2. L. D. Miles, “Techniques <strong>of</strong> Value Analysis and Engineering”, McGraw Hill<br />

Book Company.<br />

3. C. B. Gupta, “Fundamentals <strong>of</strong> Business”, Sultan Chand and Co.,<br />

4. P. A. Samualson, “Economics”, McGraw Hill International.<br />

5. Colin Drury, “Management and Cost Accounting”, English Language Book<br />

<strong>Society</strong>, Chapman and Hall London.<br />

6. Simchi-Levi, Kaminsky, “Designing and Managing the Supply Chain, Concepts<br />

Strategies and Case studies”, 2 nd edition, Tata McGraw Hill, ISBN 0-07-058666-7

7. James R. Stock and Diouglas M. Lambert, “Strategic Logistics Management”<br />

IVth edition, McGraw Hill International Edition.<br />

8. D. J. Bowersox, D. J.Closs, “Logistical Managemant”, McGraw Hill Book<br />

Company, ISBN 0-07<br />

Teaching Scheme<br />

Lectures: 4 hrs/week<br />

Practicals: 4 hrs/week<br />

411088: PROCESS PLANNING AND TOOL SELECTION<br />

Objectives<br />

• To learn and understand Process Planning function<br />

• To design Process sheet and estimate time requirement<br />

Examination Scheme<br />

Theory: 100 Marks<br />

Duration: 3 hours<br />

Oral: 50 Marks<br />

Prerequisites<br />

• Metal Cutting and Tool design<br />

• Manufacturing Processes-II<br />

• Machine Tool Design<br />

Unit I<br />

Product Engineering (4)<br />

Concept <strong>of</strong> a product – Its elements, units, subassemblies and assemblies, scope <strong>of</strong><br />

product engineering function, Flow charts <strong>of</strong> assemblies, Product analysis and planning:<br />

Design for Manufacturing and assembly (DFMA). Product selection and criteria <strong>of</strong><br />

Product acceptability based on market research.<br />

Process Engineering (4)<br />

Organizational activities, functional activities, relation with other departments,<br />

classification <strong>of</strong> processes, manufacturing operations, operational elements - machining,<br />

handling, setting, inspection and approach for selecting and planning a process:<br />

determining machining sequences - criteria, classification <strong>of</strong> operations and<br />

manufacturing sequence, criteria for analysis for selection <strong>of</strong> best process.<br />

Unit II<br />

Analysis <strong>of</strong> Part Print<br />

(4)<br />

Method <strong>of</strong> reading and interpreting Part dimensions, part specification, identification <strong>of</strong><br />

nature <strong>of</strong> work to be performed, identification <strong>of</strong> functional surfaces, grouping <strong>of</strong> related

surfaces to be machined, size and shape needing, special handling, identification <strong>of</strong> basic<br />

process for processing, sequences <strong>of</strong> operation from part print. Study <strong>of</strong> function <strong>of</strong> parts<br />

in assembly and operations needed<br />

Dimensional Analysis<br />

(4)<br />

Types <strong>of</strong> dimensions, concept <strong>of</strong> baseline dimension, basic geometrical surfaces, concept<br />

<strong>of</strong> straightness, squareness, roundness, and concentricity. Surface Quality and surface<br />

integrity, surface finish affecting product properties and product cost. Baselines, datum<br />

surfaces selection, dimensional chain and linkage analysis, fixing in process dimensions<br />

Unit III<br />

Tolerance analysis (4)<br />

Producing accuracies and attainable accuracies - process capability relation with<br />

statistical accuracies, prime accuracies, Size and form, grades <strong>of</strong> tolerances, tolerance<br />

grade calculations, Tolerance Stacks, Tolerance analysis for Assembly, purpose, use, and<br />

layout <strong>of</strong> Tolerance charts development and balancing the Tolerance Chart, individual<br />

size maintenance and automatic size maintenance<br />

Work piece control (4)<br />

Causes <strong>of</strong> Work piece variation, shape <strong>of</strong> part affecting processing, Variables influencing<br />

Work piece control, Mechanical, Geometric and Dimensional Control, Equilibrium<br />

Theories. Concept <strong>of</strong> Location - fundamental <strong>of</strong> Locating datum features, errors in<br />

locating and clamping, establishing process areas, guide lines for identifying holding<br />

areas, supporting areas and critical areas.<br />

Unit IV<br />

Selection <strong>of</strong> proper Equipment (4)<br />

Process capability <strong>of</strong> Equipments, prime accuracies and producible accuracies <strong>of</strong><br />

Equipments, Factors influencing make or buy decisions, relation between Process<br />

selection and Machine selection, basic factors in machine selection in terms <strong>of</strong> cost and<br />

design factors, Determining machining conditions and computing manufacturing times.<br />

Selection <strong>of</strong> Tooling (4)<br />

Factors affecting selection <strong>of</strong> Tooling, commercial tooling, special tooling, selection <strong>of</strong><br />

Tools: jigs, fixtures, gauges, form tool in relation to process selected .Use <strong>of</strong> multitooling<br />

set up, tooling economics as applied to Process Engineering.<br />

Stock preparations and blank selection with material estimates.

UNIT V<br />

Selecting and planning the process (4)<br />

Study <strong>of</strong> Basic Processes Operations, Principal Processes and Auxiliary Processes.<br />

Identification <strong>of</strong> major, critical, qualifying, re-qualifying and supporting operations.<br />

Selection <strong>of</strong> single or combined operation, identification <strong>of</strong> finishing operations,<br />

establishing <strong>of</strong> manufacturing sequence through classifying operation - critical analysis in<br />

determining best operation sequence by selecting best process sequence.<br />

Computer aided process planning (4)<br />

CAPP -variant approach and generative approach. CAD database, work center database,<br />

Automatic time standard system (ATS), sequencing operations and grouping, selection<br />

<strong>of</strong> datum surfaces and holding devices, including inspection stages into computer<br />

program, structured process planning s<strong>of</strong>tware system, Computerized report generation,<br />

Introduction to expert system for process planning.<br />

Unit VI<br />

Process Sheet design (8)<br />

Study <strong>of</strong> the parts to be processed, Logical design <strong>of</strong> a process plan, stock preparations,<br />

blank selection with material estimates, Selection <strong>of</strong> datum features, identification <strong>of</strong><br />

machining surfaces, incorporation <strong>of</strong> dimensions including tolerance analysis, selection<br />

<strong>of</strong> machining methods with time estimates and time standard for each operation, Process<br />

Picture sheet including process symbols, processing dimensions. Process plan sheet<br />

design for complete manufacturing part<br />

Term Work:<br />

1. One case study <strong>of</strong> process documentation as per International Standards (ISO,<br />

QS, TS etc) using cutting tool manufacturers’ catalogues.<br />

2. Part print analysis <strong>of</strong> one industrial component drawing.<br />

3. Process Sheet design <strong>of</strong> one component on GPM for batch production.<br />

4. Process Sheet design <strong>of</strong> one component on CNC for batch production.<br />

5. Process Sheet design <strong>of</strong> one component for mass production.<br />

6. Time estimation for assembly using flow-charting techniques.<br />

7. Industrial visit to study process designing and its report.<br />

Oral shall be based on the above Term work.<br />

Text Books:

1. D. F. Eary, G. E Johnson, “Process Engineering for Manufacturing”, Prentice Hall<br />

<strong>of</strong> India Pvt. Ltd.<br />

2. P.W. Wang, J.K Li, “Computer-Aided Process Planning”, Elsevier, Amsterdam.<br />

3. Nanua Singh, “Systems Approach to Computer Integrated Design and<br />

Manufacturing”<br />

Reference Books:<br />

1. H.W. Wage, “Manufacturing Engineering”, McGraw Hill.<br />

2. “Manufacturers catalogues for cutting tools and inspection equipments”<br />

3. P. Radhakrishanan, S. Subramanyan , V. Raju , “CAD/CAM/CIM”, New Age<br />

International (P) Limited.<br />

4. K. Hitomi , “Manufacturing System Engineering”, Taylor and Francis 1996, ISBN<br />

0-7484-0324-8.<br />

5. Groover, Mikell P., “Fundamentals <strong>of</strong> Modern Manufacturing- Materials,<br />

Processes, and Systems”, Second Edition, Wiley, 2002.<br />

6. K. L. Narayana, P. Kannaiah, K. Venkata Reddy, “Production Drawing”, New age<br />

International Publishers, ISBN 81-224-0953-9.

Teaching Scheme<br />

Lectures: 4 hrs/week<br />

Practicals: 2 hrs/Week<br />

411089: CAD/CAM/CIM<br />

Examination Scheme<br />

Theory: 100 Marks<br />

Duration: 3 hours<br />

Term Work: 25 Marks<br />

Oral: 50 Marks<br />

Objectives<br />

• To learn and understand Computer Aided Design and Manufacturing<br />

• Learn to use CAD/CAM s<strong>of</strong>tware packages<br />

Prerequisites<br />

• Machine Tools and Advance Manufacturing Systems<br />

• Manufacturing Automation and Control<br />

• Computer Graphics<br />

Unit I<br />

Computer Aided Design (8)<br />

Fundamentals <strong>of</strong> CAD: CAD system definition and historical perspective design process,<br />

application <strong>of</strong> computer for design and manufacturing database design, workstation,<br />

graphics terminals, input and output devices. computer graphics s<strong>of</strong>tware and database,<br />

s<strong>of</strong>tware configuration <strong>of</strong> a graphic system, functions <strong>of</strong> graphic package, constructing<br />

the geometry, data base structure and content, wire frame, surface and solid modeling <strong>of</strong>,<br />

hidden entity removal, real time picture, animation, CAD hierarchy.<br />

Unit II<br />

Computer Aided Manufacturing (CAM) (4)<br />

Devices <strong>of</strong> NC system, data processing unit, linear and circular interpolations Control<br />

loops, positioning control loops, continuous loops, incremental and absolute system,<br />

computer control concepts, CNC and DNC system.<br />

Advanced Topics in FMS (4)<br />

Components <strong>of</strong> FMS, FMS planning, automated work piece –handling, layout, cost<br />

feasibility typical application and emerging areas: Automated factory, remote control,<br />

analytical models <strong>of</strong> FMS: CANQ, deterministic models, petrinets.<br />

Unit III

Computer Integrated Manufacturing (CIM)<br />

(8)<br />

Computer application in manufacturing automation and Robotics, Robot programming,<br />

computer aided inspection and quality control. Computer integrated production<br />

management system, inventory, material requirement planning, manufacturing resource<br />

planning, enterprise resource planning<br />

Unit IV<br />

Rapid Prototyping and Rapid Tooling<br />

(8)<br />

Methods <strong>of</strong> rapid prototyping: steriolithography, Laminated Object Manufacturing<br />

(LOM), Fused Deposition Modeling (FDM), selective laser sintering, solid ground<br />

curing, 3D Printing system, Application <strong>of</strong> rapid tooling methods to press tool<br />

manufacture.<br />

Unit V<br />

Group Technology (4)<br />

Part families, part classification and coding, Cell formation techniques, production flow<br />

analysis; machine cell Design, cellular Manufacturing systems.<br />

Computer Applications In Engineering Analysis (4)<br />

Finite Element analysis, concept, mesh generation, elements. Examples <strong>of</strong> static, thermal<br />

and vibration analysis, graphical analysis.<br />

Unit VI<br />

CIM Models (4)<br />

Introduction, ESPRIT – CIM OSA Model, The NIST – AMRF Hierarchical Model, The<br />

Siemens Model <strong>of</strong> CIM, The CIM model <strong>of</strong> Digital Equipment Corporation, IBM concept<br />

<strong>of</strong> CIM, Present Scenario, Rapid Product Development and Manufacture, Extended<br />

Enterprises.<br />

Concurrent Engineering (4)<br />

Sequential engineering versus Concurrent engineering, Mathematical model for<br />

understanding between design and manufacturing, concurrent engineering techniques,<br />

Characterization <strong>of</strong> the CE environment.<br />

Term Work:<br />

The term work shall consist six assignments on following topics

1. Construction <strong>of</strong> parametric solid model <strong>of</strong> any machine elements using s<strong>of</strong>tware<br />

package.<br />

2. Programming on CNC machine.<br />

3. Programming on Robot application.<br />

4. Flexible Manufacturing System.<br />

5. Manufacturing resource planning.<br />

6. Simulation <strong>of</strong> a simple mechanical system.<br />

Text Books:<br />

1. T. K. Kundra, P. N Rao, N. K. Tiwari, “Numerical control and Computer aided<br />

manufacturing”, Tata McGraw Hill 1992, ISBN 0-07-451740-6.<br />

2. Ibraim Zeid, “Mastering CAD/CAM” – Tata McGraw Hill Publishing Co. 2000,<br />

ISBN 0-07-072857-7.<br />

3. Nanua Singh, “System Approach to Computer Integrated Design and<br />

Manufacturing”, John Wiley (1996), ISBN 0-471-58517-3.<br />

4. P.Radhakrishanan, S. Subramanium, V. Raju, “CAD /CAM / CIM”, New Age<br />

International Pvt. Ltd. New Delhi, ISBN 81-224-1248-3.<br />

Reference Books:<br />

1. Mikel P.Groover, Emory W. Zimmers, “Computer aided design and<br />

manufacturing”, Prentice Hall India Ltd. 2000, ISBN 81-203-0402-0.<br />

2. Paul C. Bave, “CAD principles and applications”.<br />

3. Mikell P. Groover, “Automation, Production systems and Computer Integrated<br />

Manufacturing”, Prentice Hall <strong>of</strong> India Pvt. Ltd. 1999, ISBN 81-203-0618-X.<br />

4. D. F. Rogers, “Procedural elements for computer graphics”, TMH Book Co. New<br />

Delhi 2004, ISBN 0-07-047371-4.<br />

5. Harrrington Steven ‘ Computer graphics- a programming approach’, McGraw<br />

Hills Inc. 2003, ISBN 0-07-100472-6.<br />

6. T R Chandrupatla, A D Belegundu, “Introduction to finite elements in<br />

engineering”, Prentice Hall <strong>of</strong> India 2003, ISBN 81-203-2106-5.<br />

7. L J Segerund, “Applied finite elements analyses”, John Wiley and Sons.<br />

8. K J Bathe, “Finite element procedures”, Prentice Hall <strong>of</strong> India 2001, ISBN 81-<br />

203-1075-6.<br />

9. V Ramamurti, “Computer aided mechanical design and analysis”, Tata McGraw<br />

Hill Pub. Co. New Delhi 1987, ISBN 0-07-463352-X.<br />

Teaching Scheme<br />

411090: ROBOTICS - ELECTIVE-II<br />

Examination Scheme

Lectures: 4 hrs/week<br />

Objectives<br />

• To study and understand Robots<br />

• To learn Robot applications in Manufacturing<br />

Prerequisites<br />

• Manufacturing Automation and Control<br />

Theory: 100 Marks<br />

Duration: 3 hours<br />

Unit I<br />

Basic concept in Robotics (4)<br />

Automation and robotics, robot anatomy, basic structure <strong>of</strong> robots, resolution, accuracy<br />

and repeatability.<br />

Classification and structure <strong>of</strong> robotics system (4)<br />

Point to point and continuous path system control loops <strong>of</strong> robotics system, manipulators,<br />

wrist motions and grippers.<br />

Unit II<br />

Drives and control system (4)<br />

Hydraulic system, DC servo motors, basic control system, concept and models, control<br />

system analysis, robot activation feed back components, positional and velocity sensor,<br />

actuators, power transmission system, robot joint control design.<br />

Robot arm kinematics and dynamics<br />

(4)<br />

The direct kinematics problem, the inversion kinematics solution, Lagrangian –Euler<br />

formation, generalized D’Almbert equations <strong>of</strong> motion. Denavit Hartenberg convention<br />

and its application.<br />

Unit III<br />

Sensor and Grippers in Robotics (4)<br />

Tactile sensors, proximity and range sensors, force and torque sensors in robotics, design<br />

consideration for gripper, mechanical gripper, vaccum gripper and magnetic grippers.<br />

Vision systems<br />

(4)<br />

Vision equipment, CCD camera image processing, concept <strong>of</strong> low level and high level<br />

vision, image smoothening and thresholding.<br />

Unit IV

Robot Programming (4)<br />

Methods <strong>of</strong> robot programming, lead through programming methods, a robot program for<br />

generating a path in space, motion interpolation WAIT, SIGNAL and DELAY<br />

commands, branching capabilities and limitations <strong>of</strong> lead through methods.<br />

Robot languages (4)<br />

The textual robot language, generation <strong>of</strong> robot programming language, structure,<br />

constants, variable and other data objects motion commands end effectors and sensor<br />

commands, computations and operations, program control and data monitor mode<br />

commands. Introduction to artificial intelligence.<br />

Unit V<br />

Interfacing (8)<br />

Interfacing robot with PC, handshaking, hardware handshaking, RS232C serial interface.<br />

Robot Applications in Manufacturing: Material transfer and machine loading/unloading<br />

processing, assembly and inspection, welding, concept <strong>of</strong> safety in robotics, social factors<br />

in use <strong>of</strong> robots, economics <strong>of</strong> robots<br />

Unit VI<br />

Introduction <strong>of</strong> telechirs (8)<br />

Robot walking, one legged robot, Telechiric machines and its application- handling<br />

radioactive materials, work in space, exploration, mining and under water operations,<br />

Telechiric surgery.<br />

Text Books:<br />

1. S. R. Deb. “Robotics”, Tata McGrawHill Publishing Co. Ltd., ISBN 0-07-460090-<br />

7.<br />

2. Yoren Koren, “ Robotics for Engineers”, McGraw Hill Book Co., ISBN 0-07-<br />

035341-7.<br />

3. M. P. Grover, M. Weiss, R. N. Nagel, N. G. Odrey, “Industrial Robotics<br />

Technology”, ISBN 0-07-100442-4.<br />

4. K. S. Fu, C. G. S. Lee, R. C. Gonzaler, “Robotics Control, Sensing, Vision and<br />

Intelligence”, Tata McGraw Hill, ISBN 0-07-100421-4.<br />

Reference Books:<br />

1. H. Asada John, “Robot analysis and control”.<br />

2. M. W. Thring, “Robots and telechirs”, Ellis Horwood Limited, ISBN 0-85312-<br />

274-1.<br />

3. Hall A. S., “Kinematics and Linkage Dynamics”, Jr. Prentice Hall.

4. J. Hirchhorn,, “Kinematics and Dynamics <strong>of</strong> Machinery”, McGraw Hill Book<br />

Co.<br />

5. Kafler, “Robotics Engineering”, Prentice Hall India Pvt. Ltd., ISBN 81-203-<br />

0842-5.<br />

6. Jankiraman, “Image Processing and Analysis”<br />

411090: ERGONOMICS AND HUMAN FACTORS IN ENGINEERING<br />

Teaching Scheme<br />

Lectures: 4 hrs/week<br />

ELECTIVE-II<br />

Objectives<br />

• To learn and understand Ergonomic aspects in Engineering<br />

• To study the effect <strong>of</strong> Human Factors in Engineering<br />

Prerequisites<br />

• Industrial Engineering and Management<br />

• Production Management<br />

Examination Scheme<br />

Theory: 100 Marks<br />

Duration: 3 hours<br />

Unit I<br />

Introduction (8)<br />

Introduction to ergonomics and human factors engineering; physiological basis <strong>of</strong> human<br />

work, biomechanics; psychology <strong>of</strong> work and work load perception; physical work<br />

environment, basis <strong>of</strong> ergonomic problem identification, work and rest cycle.<br />

Unit II<br />

Anthropometry (8)<br />

Anthropometry - Need, Important Body Dimensions, Data Collection, Statistical<br />

Analysis.<br />

Applied Anthropometry - Work design and Work Space Layout, physical space and<br />

arrangement, design <strong>of</strong> MMH task.<br />

Unit III<br />

Environmental factors in design (4)<br />

Atmospheric conditions: Heat, cold and humidity.<br />

Noise: Measurement <strong>of</strong> sound Noise exposure and hearing loss and reduction <strong>of</strong> noise.<br />

Effects <strong>of</strong> noise, heat, cold on human performance.<br />

Illumination and contrast (4)

Concept <strong>of</strong> visibility, Effects <strong>of</strong> lighting on performance, glare, luminance, luminance<br />

ratio, reflectance, Use <strong>of</strong> Photometers-Recommended illumination levels, The aging eye<br />

-Use <strong>of</strong> in directed (Reflected) lighting - Cost efficiency <strong>of</strong> illumination-Special purpose<br />

lighting for illumination<br />

Unit IV<br />

Design <strong>of</strong> systems (8)<br />

Control: Types, control response ratio, Work place-Seating/Standing- Work process-<br />

Duration <strong>of</strong> rest periods-Hand tool design-Design <strong>of</strong> visual display-design for shift work,<br />

design considerations for knobs, foot and pedals, special control devices.<br />

Unit V<br />

Work Philosophy (8)<br />

Provision <strong>of</strong> energy for muscular work-Full body, localised and static. Physical exertion<br />

Measurement <strong>of</strong> energy expenditure and oxygen consumption, learning curves.<br />

Respiration – Pulse rate and blood pressure during physical work-Physical work capacity<br />

and its evaluation. Human factors applications in system design.<br />

Unit VI<br />

Advanced Time and Motion Study<br />

(8)<br />

Predetermined Motion Time Analysis (PMTS) Method Time Analysis (MTA), work<br />

factor system (WFS), method time measurement (MTM-1, MTM-2, MTM-3), Maynard’s<br />

operation sequence technique (MOST),<br />

Text Books:<br />

1. ILO, “Introduction to work-study”, Universal Publishing Company, ISBN 81-<br />

8502700-4.<br />

2. M.S. Saunders, EJ McCormick, “Human Factors Engineering and Design”,<br />

McGraw Hill.<br />

3. Maynard, Industrial Engineering Handbook.<br />

References Books:<br />

1. Curie R M Faraday, “Work study”, The English Language Book <strong>Society</strong>, ISBN 0-<br />

273-00959-1.<br />

2. M. S. Sanders and Ernest J. McCormick, “Engineering and Design”<br />

3. E Grad, “Fitting Task to the Man”, McGraw Hill.<br />

4. Grandjean E, “Fitting the Task to the man”, Taylor and Francis London.

Teaching Scheme<br />

Lectures: 4 hrs/week<br />

Objectives<br />

411090: ADVANCED MATERIAL PROCESSING<br />

ELECTIVE II<br />

• To learn and understand Advanced Manufacturing Processes<br />

Prerequisites<br />

• Engineering Metallurgy-I<br />

• Manufacturing Processes-II<br />

Examination Scheme<br />

Theory: 100 Marks<br />

Duration: 3 hours<br />

Unit I<br />

Advanced machining processes and tools (8)<br />

Recent developments in tool materials, Special machining processes like dynamic turning<br />

oscillating turning and drilling, hard turning, ultrasonic vibration assisted machining,<br />

modern techniques in grinding operations and grinding wheels, high productivity<br />

machining such as high speed machining.<br />

Unit II<br />

Advances in non-conventional machining processes<br />

(8)<br />

Rotary ultrasonic machining, ultrasonic impact grinding, electrochemical grinding and<br />

honing, electric discharge grinding, wire cut EDM, shaped tube electrolytic machining<br />

(STEM), thermal energy method. Chemical Milling (CM), Photochemical Machining.<br />

Unit III<br />

Advanced Forming processes<br />

(4)<br />

Ring rolling, roll forming, high energy rate forming, flow forming forging <strong>of</strong> stainless<br />

steel and heat resisting alloys Developments in hydro forming. Auto-for-cast processes.<br />

Impact extrusion<br />

Advanced Forging Processes<br />

(4)<br />

Radial forging, orbital forging, isothermal and hot die forging, precision forging, powder<br />

forging, magneto forging.<br />

Unit IV

Advanced Casting Processes<br />

(8)<br />

Injection casting, No-flask. Casting, continuous casting- Reciprocating mould processes,<br />

Asarco process, Brass mould process and direct chill process.<br />

Unit V<br />

Processing <strong>of</strong> Plastic, Ceramics, Glass<br />

(8)<br />

Different methods like casing, moulding, forming, Process equipment, joining, Printing.<br />

Simulation and fault prediction. Processing <strong>of</strong> mushy materials. Ceramic shell process.<br />

Master mould casting.<br />

Unit VI<br />

Surface cleaning and coating<br />

(8)<br />

Different cleaning methods, Metal coating, electro plating, ceramic coating, polymer,<br />

paint coating Nano surface machining, MEMS fabrication, photo electrical polishing,<br />

LIGA technique for fabrication.<br />