Chapter 22 Materials Selection and Design Considerations

Chapter 22 Materials Selection and Design Considerations

Chapter 22 Materials Selection and Design Considerations

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

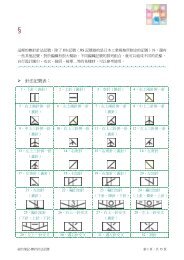

Strength (MPa)<br />

10,000<br />

1000<br />

100<br />

10<br />

1<br />

300 MPa<br />

P = 10<br />

Balsa<br />

(MPa) 2/3 m 3 /Mg<br />

Cork<br />

<strong>22</strong>.2 Strength <strong>Considerations</strong>—Torsionally Stressed Shaft • W91<br />

strength-per-mass basis; materials whose positions lie above a particular line will<br />

have higher performance indices, while those lying below will exhibit poorer performances.<br />

For example, a material on the line will yield the same strength<br />

with one-third the mass as another material that lies along the line.<br />

The selection process now involves choosing one of these lines, a “selection<br />

line” that includes some subset of these materials; for the sake of argument let us<br />

pick P � 10 (MPa) which is represented in Figure <strong>22</strong>.3. <strong>Materials</strong> lying<br />

2�3<br />

P � 30<br />

P � 10<br />

3 m /Mg,<br />

Balsa<br />

Parallel<br />

to Grain<br />

Ash<br />

Oak<br />

Pine<br />

Fir<br />

Polymer<br />

foams<br />

Engineering<br />

composites<br />

Wood<br />

Products<br />

Ash<br />

Woods Oak<br />

Pine<br />

Fir<br />

Perpendicular<br />

to Grain<br />

LDPE<br />

Soft<br />

Butyl<br />

PP<br />

PS<br />

Glasses<br />

CFRP<br />

GFRP<br />

UNIPLY<br />

KFRP<br />

CFRPBe<br />

GFRP<br />

Laminates<br />

KFRP<br />

Nylons<br />

PMMA<br />

MEL<br />

PVC<br />

Epoxies<br />

Polyesters<br />

HDPE<br />

PTFE<br />

PU<br />

Silicone<br />

Engineering<br />

ceramics<br />

Pottery<br />

Mg<br />

Alloys<br />

Elastomers<br />

B<br />

Si<br />

SiC<br />

Cement<br />

Concrete<br />

Engineering<br />

polymers<br />

Diamond<br />

Si3N4 Sialons<br />

Al2O3 ZrO2<br />

Cermets<br />

MgO<br />

Ge<br />

Ti<br />

Alloys<br />

Al Alloys<br />

Stone,<br />

Rock<br />

Engineering<br />

alloys<br />

Porous<br />

ceramics<br />

Steels<br />

Cast<br />

Irons<br />

Zn<br />

Alloys<br />

Lead<br />

Alloys<br />

Ni Alloys<br />

Cu Alloys<br />

Engineering<br />

alloys<br />

W Alloys<br />

Mo Alloys<br />

0.1<br />

0.1 0.3 1 3 10 30<br />

Density (Mg /m 3 )<br />

Figure <strong>22</strong>.3 Strength-versus-density materials selection chart. Those materials lying within<br />

the shaded region are acceptable c<strong>and</strong>idates for a solid cylindrical shaft that has a massstrength<br />

performance index in excess of 10 (MPa) <strong>and</strong> a strength of at least<br />

300 MPa (43,500 psi). (Adapted from M. F. Ashby, <strong>Materials</strong> <strong>Selection</strong> in Mechanical<br />

<strong>Design</strong>. Copyright © 1992. Reprinted by permission of Butterworth-Heinemann Ltd.)<br />

2�3 3<br />

m /Mg,