Chapter 22 Materials Selection and Design Considerations

Chapter 22 Materials Selection and Design Considerations

Chapter 22 Materials Selection and Design Considerations

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

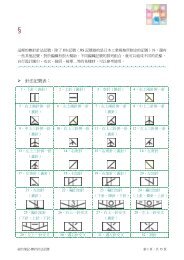

W90 • <strong>Chapter</strong> <strong>22</strong> / <strong>Materials</strong> <strong>Selection</strong> <strong>and</strong> <strong>Design</strong> <strong>Considerations</strong><br />

Strength (MPa)<br />

10,000<br />

1000<br />

100<br />

10<br />

1<br />

P = 100<br />

P = 30<br />

P = 10<br />

Cork<br />

P = 3<br />

Balsa<br />

Balsa<br />

Parallel<br />

to Grain<br />

Polymer<br />

foams<br />

Engineering<br />

composites<br />

Ash<br />

Oak<br />

Pine<br />

Fir<br />

Ash<br />

Woods Oak<br />

Pine<br />

Fir<br />

Perpendicular<br />

to Grain<br />

Wood<br />

Products<br />

LDPE<br />

Soft<br />

Butyl<br />

PP<br />

PS<br />

Engineering<br />

ceramics<br />

Nylons<br />

PMMA<br />

Glasses<br />

MEL<br />

PVC<br />

Epoxies<br />

Polyesters<br />

HDPE<br />

PTFE<br />

PU<br />

Silicone<br />

CFRP<br />

GFRP<br />

UNIPLY<br />

KFRP<br />

CFRPBe<br />

GFRP<br />

Laminates<br />

KFRP<br />

Elastomers<br />

0.1<br />

0.1 0.3 1 3 10 30<br />

B<br />

Si<br />

Mg<br />

Alloys<br />

Density (Mg /m 3 )<br />

Engineering<br />

polymers<br />

Porous<br />

ceramics<br />

Figure <strong>22</strong>.2 Strength-versus-density materials selection chart. <strong>Design</strong> guidelines for<br />

performance indices of 3, 10, 30, <strong>and</strong> 100 (MPa) 2�3 m 3 /Mg have been constructed, all having<br />

3<br />

a slope of 2. (Adapted from M. F. Ashby, <strong>Materials</strong> <strong>Selection</strong> in Mechanical <strong>Design</strong>.<br />

Copyright © 1992. Reprinted by permission of Butterworth-Heinemann Ltd.)<br />

Now, taking the logarithm of both sides of Equation <strong>22</strong>.9 <strong>and</strong> rearranging yields<br />

log t f � 3<br />

2 log r � 3<br />

2 log P<br />

Diamond<br />

Si3N4 Sialons<br />

Al2O3 ZrO2<br />

Cermets<br />

MgO<br />

Ge<br />

Engineering<br />

alloys<br />

(<strong>22</strong>.10)<br />

This expression tells us that a plot of log �f versus log will yield a family of straight<br />

<strong>and</strong> parallel lines all having a slope of each line in the family corresponds to a<br />

different performance index, P. These lines are termed design guidelines, <strong>and</strong> four<br />

have been included in Figure <strong>22</strong>.2 for P values of 3, 10, 30, <strong>and</strong> 100 (MPa)<br />

All materials that lie on one of these lines will perform equally well in terms of<br />

2�3<br />

r<br />

3<br />

2;<br />

3 m /Mg.<br />

SiC<br />

Pottery Ti<br />

Alloys<br />

Cement<br />

Concrete<br />

Al Alloys<br />

Stone,<br />

Rock<br />

Engineering<br />

alloys<br />

Steels<br />

Cast<br />

Irons<br />

Zn<br />

Alloys<br />

Lead<br />

Alloys<br />

Ni Alloys<br />

Cu Alloys<br />

W Alloys<br />

Mo Alloys