Chapter 22 Materials Selection and Design Considerations

Chapter 22 Materials Selection and Design Considerations

Chapter 22 Materials Selection and Design Considerations

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

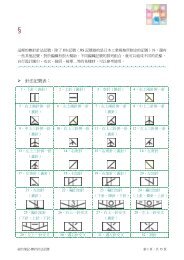

(a) (b)<br />

<strong>22</strong>.19 Package Encapsulation • W125<br />

Figure <strong>22</strong>.32 Scanning electron micrographs of (a) a ball bond ( 475�),<br />

<strong>and</strong> (b) a wedge<br />

bond ( 275�).<br />

(Photographs courtesy of National Semiconductor Corporation.)<br />

Unfortunately, the bending motion of wedge-bonded wires is restricted to a single<br />

direction. Gold wires may also be bonded using wedge microjoints. Figure <strong>22</strong>.32b<br />

is a scanning electron micrograph of a wedge microjoint.<br />

There are other considerations relative to wire bonding that deserve mentioning.<br />

Microjunction alloy combinations that form intermetallic phases should be<br />

avoided because these phases are normally brittle <strong>and</strong> yield microjoints lacking<br />

long-term mechanical stability. For example, Au <strong>and</strong> Al may react at elevated temperatures<br />

to form AuAl 2, termed the “purple plague”; this compound is not only<br />

very brittle (<strong>and</strong> purple), but also highly electrically resistive. Furthermore, mechanical<br />

integrity at each microjoint is important to (1) withst<strong>and</strong> vibrations that<br />

the package may experience, <strong>and</strong> (2) survive thermal stresses that are generated as<br />

the packaging materials change temperature.<br />

<strong>22</strong>.19 PACKAGE ENCAPSULATION<br />

The microelectronic package, as now constituted, must be provided some type of<br />

protection from corrosion, contamination, <strong>and</strong> damage during h<strong>and</strong>ling <strong>and</strong> while<br />

in service. The wire interconnection microjunctions are extremely fragile <strong>and</strong> may<br />

be easily damaged. Especially vulnerable to corrosion are the narrow Al circuit<br />

paths that have been metallized onto the surface of the IC chip; even the slightest<br />

corrosion of these elements will impair the operation of the chip. These Almetallized<br />

layers experience corrosion when atmospheric moisture in which even<br />

minute concentrations of ionic contaminants are dissolved (especially chlorine <strong>and</strong><br />

phosphorus) condenses on the chip surface. Furthermore, the corrosive reactions<br />

are accelerated as a consequence of electric currents that pass through these circuit<br />

paths. In addition, any sodium (as Na � ) that gets on the chip surface will eventually<br />

diffuse into the chip <strong>and</strong> destroy its operation.