Chapter 22 Materials Selection and Design Considerations

Chapter 22 Materials Selection and Design Considerations

Chapter 22 Materials Selection and Design Considerations

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>22</strong>.15 Introduction • W119<br />

<strong>and</strong> also with regard to other factors to include material degradability, flexibility,<br />

grip, puncture resistance, etc.<br />

<strong>Materials</strong> for Integrated Circuit Packages<br />

<strong>22</strong>.15 INTRODUCTION<br />

The microelectronic circuitry, including the integrated circuits that are used in our<br />

modern computers, calculators, <strong>and</strong> other electronic devices, was briefly discussed<br />

in Section 18.15. The heart of the integrated circuit (abbreviated IC) is the chip, a<br />

small rectangular substrate of high-purity <strong>and</strong> single-crystal silicon (or more recently<br />

gallium arsenide) onto which literally millions of circuit elements are imprinted.<br />

Circuit elements (i.e., transistors, resistors, diodes, etc.) are created by selectively<br />

adding controlled concentrations of specific impurities to extremely minute <strong>and</strong><br />

localized regions near the surface of the semiconducting material using involved<br />

photolithographic techniques. The chips are small in size, with the largest on the<br />

1<br />

4<br />

order of 6 mm ( in.) on each side <strong>and</strong> approximately 0.4 mm (0.015 in.) thick.<br />

Photographs of a typical chip are shown in Figure 18.27.<br />

Furthermore, chips are very fragile inasmuch as silicon is a relatively brittle material<br />

<strong>and</strong> gallium arsenide is even more brittle. It is also necessary to fabricate conducting<br />

circuit paths over the surface of the chip to facilitate the passage of current<br />

from device to device; on silicon ICs the metal conductor used is aluminum or an aluminum–silicon<br />

alloy (99 wt% Al, 1 wt% Si) that is metallized onto the chip surface to<br />

form a very thin film. The chip design also calls for these circuit paths to terminate at<br />

contact pads on the chip periphery, at which points electrical connections may be made<br />

with the macroscopic world. It should be obvious that a functioning microelectronic<br />

chip is a very sophisticated electronic entity, that materials requirements are very stringent,<br />

<strong>and</strong> that elegant processing techniques are involved in its fabrication.<br />

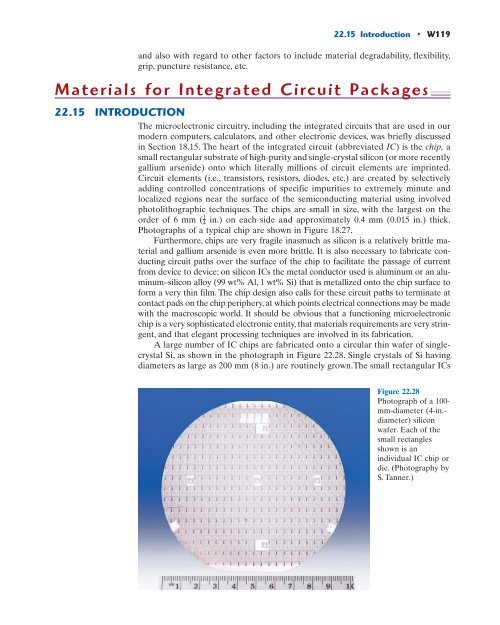

A large number of IC chips are fabricated onto a circular thin wafer of singlecrystal<br />

Si, as shown in the photograph in Figure <strong>22</strong>.28. Single crystals of Si having<br />

diameters as large as 200 mm (8 in.) are routinely grown.The small rectangular ICs<br />

Figure <strong>22</strong>.28<br />

Photograph of a 100mm-diameter(4-in.diameter)<br />

silicon<br />

wafer. Each of the<br />

small rectangles<br />

shown is an<br />

individual IC chip or<br />

die. (Photography by<br />

S. Tanner.)