Chapter 22 Materials Selection and Design Considerations

Chapter 22 Materials Selection and Design Considerations

Chapter 22 Materials Selection and Design Considerations

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

W118 • <strong>Chapter</strong> <strong>22</strong> / <strong>Materials</strong> <strong>Selection</strong> <strong>and</strong> <strong>Design</strong> <strong>Considerations</strong><br />

Computation of<br />

exposure rate of a<br />

hazardous chemical<br />

that is diffusing<br />

through a chemical<br />

protective glove<br />

material<br />

C A<br />

C B<br />

substitutions for<br />

sion for re: <strong>and</strong> into Equation <strong>22</strong>.28, we obtain the following expres-<br />

r e � DAS A<br />

/<br />

(<strong>22</strong>.29)<br />

Table <strong>22</strong>.5 also includes, for these several glove materials, values of that were<br />

determined using Equation <strong>22</strong>.29.<br />

At this point, a key question is: What is an acceptable <strong>and</strong> safe exposure rate?<br />

Based on airborne exposure limits set by the Occupational Safety <strong>and</strong> Health Administration<br />

(OSHA) of the US, the maximum allowable to methylene chloride<br />

is approximately 1 g/h.<br />

Now let us examine <strong>and</strong> compare computed breakthrough times <strong>and</strong> exposure<br />

rates for the several glove materials, as listed in Table <strong>22</strong>.5. First of all, with regard<br />

to exposure rate, two of the seven materials meet or exceed the st<strong>and</strong>ard set by<br />

OSHA (viz., 1 g/h)—viz. multilayer (Silver Shield TM ) <strong>and</strong> Viton TM re rubber (with re values of 0.43 <strong>and</strong> 0.35 g/h, respectively). Relative to breakthrough time, the multilayer<br />

material has the longer tb (24 h versus about 1 h for the Viton rubber). Furthermore,<br />

the multilayer gloves are considerably less inexpensive (at $US4.19 per<br />

pair compared to $US72.00 for Viton rubber, Table <strong>22</strong>.5).<br />

Therefore, of these two glove materials, other relevant characteristics/properties<br />

being equal, the one of choice for this application is multilayer Silver Shield. It<br />

has a significantly longer breakthrough time <strong>and</strong> is much less costly than the Viton<br />

rubber material, whereas there is very little difference between their exposure rates.<br />

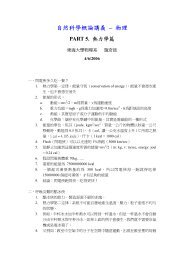

The photograph of Figure <strong>22</strong>.27 shows a pair of Silver Shield gloves.<br />

It should be noted that calculated breakthrough time values presented in Table<br />

<strong>22</strong>.5 assumed the glove material had no previous exposure to methylene chloride.<br />

For a second application, some of the methylene chloride that dissolved in the glove<br />

during the first exposure probably remains; thus, the breakthrough time will be much<br />

shorter than predicted for an unused glove. For this reason, CPC gloves are often<br />

discarded after one usage.<br />

One final comment is in order: one should always consult an industrial hygiene<br />

specialist when selecting chemical protection clothing. These specialists are experts<br />

as to what materials are suitable for exposure to specific toxic chemical substances,<br />

Figure <strong>22</strong>.27 Photograph of Silver Shield<br />

multilayer chemical protective gloves.<br />

(Photograph courtesy of North Safety<br />

Products, Anjou, Quebec, Canada.)<br />

r e