Your Kimberly-Clark guide to the new European Standard EN 13795

Your Kimberly-Clark guide to the new European Standard EN 13795

Your Kimberly-Clark guide to the new European Standard EN 13795

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

What will <strong>the</strong> impact be of <strong>EN</strong> <strong>13795</strong> on healthcare facilities that acquire singleuse<br />

or multiple-use gowns and drapes from external suppliers?<br />

As always, <strong>the</strong> healthcare facility should verify that <strong>the</strong> device is CE marked (i.e.<br />

meets <strong>the</strong> requirements of <strong>the</strong> Medical Device Directive). Should <strong>the</strong> manufacturer<br />

claim compliance <strong>to</strong> <strong>EN</strong> <strong>13795</strong>, <strong>the</strong> cus<strong>to</strong>mer can request <strong>the</strong> test data.<br />

Are hospitals obliged <strong>to</strong> purchase devices that comply with <strong>the</strong> standard?<br />

No, as standards are in itself voluntary, manufacturers have <strong>the</strong> choice <strong>to</strong> determine<br />

<strong>the</strong>ir own conformity assessment route. However, in <strong>the</strong> case of <strong>13795</strong>, it is expected<br />

that most manufacturers will claim compliance <strong>to</strong> <strong>the</strong> standard, as <strong>the</strong>re will be no<br />

alternative standards in Europe in <strong>the</strong> near future. Cus<strong>to</strong>mers are always advised <strong>to</strong><br />

request documentation on performance from all manufacturers independently from<br />

<strong>the</strong>m claiming compliance <strong>to</strong> <strong>EN</strong> <strong>13795</strong> or not.<br />

What liability does a hospital have when choosing drapes and gowns?<br />

If hospitals utilise products that are not in compliance with applicable <strong>European</strong> or<br />

International standards, <strong>the</strong>y would need <strong>to</strong> substantiate <strong>the</strong>ir decision, and <strong>the</strong><br />

burden of proof is upon <strong>the</strong> hospital in <strong>the</strong> event of an inspection, a medical complaint<br />

or any o<strong>the</strong>r issues. Therefore, in terms of product liability hospitals would want <strong>to</strong> use<br />

products/devices that comply with International or <strong>European</strong> standards.<br />

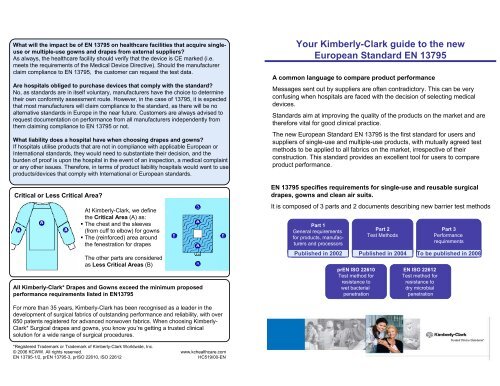

Critical or Less Critical Area?<br />

At <strong>Kimberly</strong>-<strong>Clark</strong>, we define<br />

<strong>the</strong> Critical Area (A) as:<br />

• The chest and <strong>the</strong> sleeves<br />

(from cuff <strong>to</strong> elbow) for gowns<br />

• The (reinforced) area around<br />

<strong>the</strong> fenestration for drapes<br />

The o<strong>the</strong>r parts are considered<br />

as Less Critical Areas (B)<br />

All <strong>Kimberly</strong>-<strong>Clark</strong>* Drapes and Gowns exceed <strong>the</strong> minimum proposed<br />

performance requirements listed in <strong>EN</strong><strong>13795</strong><br />

<strong>Your</strong> <strong>Kimberly</strong>-<strong>Clark</strong> <strong>guide</strong> <strong>to</strong> <strong>the</strong> <strong>new</strong><br />

<strong>European</strong> <strong>Standard</strong> <strong>EN</strong> <strong>13795</strong><br />

A common language <strong>to</strong> compare product performance<br />

Messages sent out by suppliers are often contradic<strong>to</strong>ry. This can be very<br />

confusing when hospitals are faced with <strong>the</strong> decision of selecting medical<br />

devices.<br />

<strong>Standard</strong>s aim at improving <strong>the</strong> quality of <strong>the</strong> products on <strong>the</strong> market and are<br />

<strong>the</strong>refore vital for good clinical practice.<br />

The <strong>new</strong> <strong>European</strong> <strong>Standard</strong> <strong>EN</strong> <strong>13795</strong> is <strong>the</strong> first standard for users and<br />

suppliers of single-use and multiple-use products, with mutually agreed test<br />

methods <strong>to</strong> be applied <strong>to</strong> all fabrics on <strong>the</strong> market, irrespective of <strong>the</strong>ir<br />

construction. This standard provides an excellent <strong>to</strong>ol for users <strong>to</strong> compare<br />

product performance.<br />

<strong>EN</strong> <strong>13795</strong> specifies requirements for single-use and reusable surgical<br />

drapes, gowns and clean air suits.<br />

It is composed of 3 parts and 2 documents describing <strong>new</strong> barrier test methods<br />

Part 1<br />

General requirements<br />

for products, manufacturers<br />

and processors<br />

Part 2<br />

Test Methods<br />

Part 3<br />

Performance<br />

requirements<br />

Published in 2002 Published in 2004 To be published in 2006<br />

pr<strong>EN</strong> ISO 22610<br />

Test method for<br />

resistance <strong>to</strong><br />

wet bacterial<br />

penetration<br />

<strong>EN</strong> ISO 22612<br />

Test method for<br />

resistance <strong>to</strong><br />

dry microbial<br />

penetration<br />

For more than 35 years, <strong>Kimberly</strong>-<strong>Clark</strong> has been recognised as a leader in <strong>the</strong><br />

development of surgical fabrics of outstanding performance and reliability, with over<br />

650 patents registered for advanced nonwoven fabrics. When choosing <strong>Kimberly</strong>-<br />

<strong>Clark</strong>* Surgical drapes and gowns, you know you’re getting a trusted clinical<br />

solution for a wide range of surgical procedures.<br />

*Registered Trademark or Trademark of <strong>Kimberly</strong>-<strong>Clark</strong> Worldwide, Inc.<br />

© 2006 KCWW. All rights reserved. www.kchealthcare.com<br />

<strong>EN</strong> <strong>13795</strong>-1/2, pr<strong>EN</strong> <strong>13795</strong>-3, prISO 22610, ISO 22612<br />

HC519/00-<strong>EN</strong>

BARRIER<br />

LINTING<br />

Resistance <strong>to</strong> Dry Microbial Penetration (<strong>EN</strong> ISO 22612)<br />

Objective: determine <strong>the</strong> ability of <strong>the</strong> dry<br />

fabric <strong>to</strong> resist penetration of particles<br />

carrying micro-organisms.<br />

Method: <strong>the</strong> test fabric is placed in a<br />

container with talc powder contaminated<br />

with Bacillus subtilis. Any talc that<br />

penetrates <strong>the</strong> fabric is captured on a<br />

sedimentation plate underneath and<br />

incubated.<br />

Measure: number of colonies formed<br />

after incubation, expressed as log 10.<br />

Test Performance Requirements<br />

(Log 10 (CFU))<br />

Gown<br />

Drape<br />

<strong>Standard</strong><br />

Perf.<br />

C<br />

-<br />

-<br />

LC<br />

≤2<br />

≤2<br />

C<br />

-<br />

-<br />

High<br />

Perf.<br />

LC<br />

≤2<br />

≤2<br />

Cleanliness - Particulate Matter & Linting (ISO 9073-10)<br />

Cleanliness – Particulate Matter<br />

Objective: estimate linting of <strong>the</strong> fabric in<br />

a dry state, prior <strong>to</strong> twisting and<br />

compressing.<br />

Method: fabric is placed in a chamber<br />

and number particles are calculated<br />

Measure: number of particles from 3µm<br />

<strong>to</strong> 25µm, as an index for Particulate<br />

Matter (IPM) expressed as log 10.<br />

Test Performance Requirements<br />

(IPM)<br />

Gown<br />

Drape<br />

<strong>Standard</strong><br />

Perf.<br />

C LC<br />

≤3,5 ≤3,5<br />

≤3,5<br />

≤3,5<br />

C<br />

≤3,5<br />

≤3,5<br />

High<br />

Perf.<br />

LC<br />

≤3,5<br />

≤3,5<br />

Resistance <strong>to</strong> Wet Microbial Penetration (pr<strong>EN</strong> ISO 22610)<br />

Objective: determine a fabric's resistance<br />

<strong>to</strong> penetration of bacteria in a liquid while<br />

being subjected <strong>to</strong> mechanical rubbing.<br />

Method: <strong>the</strong> test fabric is subjected <strong>to</strong><br />

material contaminated with<br />

Staphylococcus aureus suspension. If<br />

penetration occurs, bacteria will collect<br />

on <strong>to</strong> an agar surface and be incubated<br />

Measure: number of colonies formed<br />

after incubation, expressed in Barrier<br />

Index (BI)<br />

Test Performance Requirements<br />

(BI)<br />

Gown<br />

Drape<br />

<strong>Standard</strong><br />

Perf.<br />

C LC<br />

≥2,8 -<br />

≥2,8<br />

-<br />

C<br />

6,0<br />

6,0<br />

High<br />

Perf.<br />

LC<br />

-<br />

-<br />

Linting<br />

Objective: estimate linting of <strong>the</strong> fabric in<br />

a dry state, after twisting and<br />

compressing<br />

Method: <strong>the</strong> same fabric sample is<br />

twisted and compressed<br />

Measure: number of particles from 3µm<br />

<strong>to</strong> 25µm generated after <strong>the</strong> twisting and<br />

compressing, expressed as log 10 of <strong>the</strong><br />

count value<br />

Test Performance Requirements<br />

(Log 10 (lint count))<br />

Gown<br />

Drape<br />

<strong>Standard</strong><br />

Perf.<br />

C LC<br />

≤4,0 ≤4,0<br />

≤4,0<br />

≤4,0<br />

C<br />

≤4,0<br />

≤4,0<br />

High<br />

Perf.<br />

LC<br />

≤4,0<br />

≤4,0<br />

STR<strong>EN</strong>GTH<br />

Resistance <strong>to</strong> Liquid Penetration (<strong>EN</strong> 20811)<br />

Bursting Strength – Dry & Wet (<strong>EN</strong> 13938-1)<br />

Objective: estimate <strong>the</strong> resistance of<br />

fabrics <strong>to</strong> liquid penetration by water<br />

under constantly increasing hydrostatic<br />

pressure.<br />

Method: One side of <strong>the</strong> fabric sample is<br />

subjected <strong>to</strong> purified water pressure<br />

which is increased at a constant rate until<br />

leakage appears on <strong>the</strong> o<strong>the</strong>r side of <strong>the</strong><br />

fabric sample.<br />

Measure: The head height results are<br />

recorded in centimeters of water<br />

pressure on <strong>the</strong> fabric sample.<br />

Test Performance Requirements<br />

(cm H 2 O)<br />

Gown<br />

Drape<br />

<strong>Standard</strong><br />

Perf.<br />

C LC<br />

≥20 ≥10<br />

≥30<br />

≥10<br />

High<br />

Perf.<br />

C<br />

≥100<br />

≥100<br />

LC<br />

≥10<br />

≥10<br />

Objective: determine <strong>the</strong> resistance of a<br />

fabric <strong>to</strong> puncture under dry and wet<br />

conditions.<br />

Method: A fabric sample is clamped over<br />

an expansive diaphragm by means of a<br />

circular ring. Fluid pressure is applied at<br />

a constant rate on <strong>the</strong> o<strong>the</strong>r side of <strong>the</strong><br />

diaphragm causing distension of <strong>the</strong><br />

diaphragm and fabric until <strong>the</strong> fabric<br />

bursts.<br />

Measure: strength at burst, in kPa<br />

Test Performance Requirements<br />

(kPa)<br />

For<br />

Dry &<br />

Wet<br />

Gown<br />

Drape<br />

<strong>Standard</strong><br />

Perf.<br />

C LC<br />

≥40 ≥40*<br />

≥40<br />

≥40*<br />

C<br />

≥40<br />

≥40<br />

High<br />

Perf.<br />

LC<br />

≥40*<br />

≥40*<br />

Cleanliness – Microbial (<strong>EN</strong>-1174-2)<br />

Objective: estimate <strong>the</strong> bioburden or<br />

number of viable micro-organisms on a<br />

product prior <strong>to</strong> sterilization.<br />

Method: Micro-organisms are removed<br />

and transferred <strong>to</strong> plates, slides or agar<br />

medium <strong>to</strong> incubate <strong>the</strong> colonies.<br />

Colonies are counted <strong>to</strong> indicate<br />

microbial cleanliness level of unsterile<br />

product<br />

Measure: number of colonies formed (per<br />

dm²)<br />

CLEANLINESS<br />

Test Performance Requirements<br />

Log 10 (CFU/dm²)<br />

Gown<br />

Drape<br />

<strong>Standard</strong><br />

Perf.<br />

C LC<br />