AP Systems AP P.1-17(21-7) - Kalzip

AP Systems AP P.1-17(21-7) - Kalzip

AP Systems AP P.1-17(21-7) - Kalzip

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

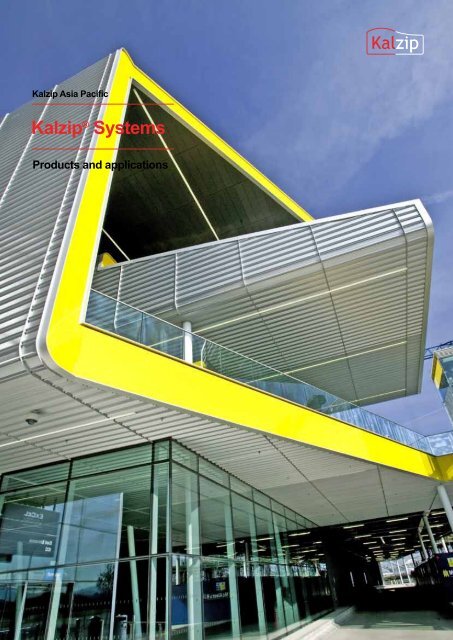

<strong>Kalzip</strong> Asia Pacific<br />

<strong>Kalzip</strong> ® <strong>Systems</strong><br />

Products and applications

<strong>Kalzip</strong> ®<br />

innovative<br />

performance<br />

and proven<br />

system solutions<br />

for creative<br />

architectural<br />

design.

<strong>Kalzip</strong> ® <strong>Systems</strong><br />

Contents<br />

Introduction 4<br />

<strong>Kalzip</strong> ® Standing seam roof systems 6<br />

<strong>Kalzip</strong> ® Solar Power Solutions AluPlusSolar and SolarClad 18<br />

<strong>Kalzip</strong> ® Facade Solutions Innovative building envelope technology 22<br />

<strong>Kalzip</strong> ® Bespoke Solutions Aesthetics and proven performance 32<br />

<strong>Kalzip</strong> ® Acoustic <strong>Systems</strong> Solutions for auditory applications 34<br />

<strong>Kalzip</strong> Nature Roof ® Green roof system 38<br />

Components and accessories 40<br />

Materials and finishes 52<br />

Facing page:<br />

Guangzhou Asian Games Town Gymnasium, China<br />

System design guidelines 56<br />

and performance characteristics

<strong>Kalzip</strong> ® <strong>Systems</strong><br />

Project: Taipei Arena, Taiwan<br />

Architect: Lo Hsing Hua Architect & Associates

<strong>Kalzip</strong> ® <strong>Systems</strong><br />

Innovation is<br />

our strength<br />

Our research and<br />

development work is based<br />

on one aim: to provide you the<br />

customer with the very best<br />

solutions everytime.<br />

<strong>Kalzip</strong> ® will transform your ideas and dreams into<br />

reality – without making any compromises in quality and<br />

with a true passion for detail.<br />

<strong>Kalzip</strong> ® is the source of inspiration for planners and<br />

architects throughout the world. And there are very good<br />

reasons for this: <strong>Kalzip</strong> ® offers perfect system solutions,<br />

limitless design potential, state-of-the-art production technology,<br />

ultimate product quality, innovative material combinations and<br />

harmonious integration of shapes,<br />

colours and surfaces.<br />

<strong>Kalzip</strong> ® aluminium standing seam profiles are able to<br />

meet even the most demanding construction and design<br />

requirements, enabling you to create roofs and facades which<br />

successfully combine outstanding functionality<br />

with stunning aesthetics. The design potential is virtually<br />

limitless – from the discreet to the elaborate; combining<br />

sophisticated elegance with contemporary design.<br />

Intelligent additional features such as <strong>Kalzip</strong> ® Solar<strong>Systems</strong> or<br />

the <strong>Kalzip</strong> NatureRoof ® provide the perfect finishing touches to<br />

the unique <strong>Kalzip</strong> ® range. Spectacular aesthetics are skillfully<br />

integrated into contemporary architectural design. And, as if this<br />

were not enough, <strong>Kalzip</strong> ® also offers significant economic and<br />

ecological advantages.<br />

For more than 40 years we have remained at the very forefront<br />

of architectural design, constantly pushing the boundaries of<br />

creative potential. We are extremely proud of this achievement.<br />

The experience we have gained over many years, together<br />

with our highly-specialised technical expertise, guarantees the<br />

ultimate in quality and reliability – right down to the very last<br />

detail. <strong>Kalzip</strong> ® is a highly sophisticated, light weight building<br />

system, which is extremely flexible and can be precisely<br />

adapted to suit the static requirements of a building. Even large<br />

spans can be accommodated without a problem. <strong>Kalzip</strong> ® can<br />

be easily combined with other construction materials to create<br />

stunning and inspirational buildings.<br />

05

<strong>Kalzip</strong> ® <strong>Systems</strong><br />

<strong>Kalzip</strong> ® – the sophisticated,<br />

lightweight building system<br />

Highly flexible and can be adapted to suit the<br />

precise static requirements of the building.<br />

Unlimited application potential<br />

• Suitable for ventilated and nonventilated<br />

roof designs and all shapes<br />

and pitches of roof from 1.5°. Suitable for<br />

all substructures and supporting<br />

structures.<br />

• Can be flexibly adjusted to suit the<br />

layout, geometry and dimensions of any<br />

building.<br />

• Extremely strong and lightweight.<br />

Therefore ideal for large spans and for<br />

renovating old roofs.<br />

• Continuous lengths of 100 m and more,<br />

when production takes place on-site.<br />

Superior thermal and acoustic insulation<br />

• Fulfills strict thermal insulation<br />

requirements. By choosing the<br />

appropriate thickness of insulating<br />

material, the roof structure can be<br />

adapted to suit the precise requirements<br />

of the building.<br />

• Highly efficient thermal insulation can be<br />

achieved by means of constructive<br />

measures.<br />

• A series of acoustic tests and<br />

appreciation of the demanding<br />

requirements for noise control within<br />

buildings helps to create optimum<br />

internal conditions.<br />

A high level of safety throughout the<br />

entire service life<br />

• A non-penetrative patented clip attaches<br />

the sheets to the substructure. These<br />

clips are locked into the seam to ensure<br />

smooth thermal cycling of the external<br />

sheet over the clip head whilst facilitating<br />

outstanding spanning capacity under<br />

high wind loading.<br />

• The mechanical zipping of the seams<br />

produces a load bearing, permanent<br />

connection.<br />

• Pressure and suction loads are safely<br />

absorbed.<br />

• The weather tight seam permits any<br />

residual moisture in the insulating layer<br />

to evaporate through the seam allowing<br />

the roof to breathe naturally.<br />

• Sophisticated detailed solutions for roof<br />

penetrations, joints and gable ends.<br />

• Non-flammable. Resistant to flying<br />

sparks and radiant heat.<br />

• <strong>Kalzip</strong> ® can be used as a lightning<br />

conductor in conformity with<br />

requirements of EN62305-3 in<br />

conjunction with DIN V VDE V0185- 600.<br />

Durability and economy<br />

• Corrosion-resistant, weather-resistant<br />

aluminium alloy base material.<br />

• Non-sensitive to UV rays, resistant to<br />

microorganisms, resistant to ageing.<br />

• Installation is particularly quick and<br />

largely independent of weather. Cost<br />

savings through pre-fabricated<br />

components.<br />

Valuable ecological and<br />

sustainable properties<br />

• The raw material that contains<br />

aluminium - bauxite - is the third most<br />

commonly occurring element in the<br />

earth’s crust with at least 300 years of<br />

current reserves left at the present rates<br />

of usage – a figure that is improved<br />

by the increasing amount of aluminium<br />

that is being recycled.<br />

• Over 60% of all aluminium is produced<br />

using hydroelectric power, which is<br />

clean, CO 2<br />

free and renewable.<br />

• Aluminium is a closed loop process;<br />

once produced - it can be recycled<br />

infinitely with no loss of performance.<br />

• <strong>Kalzip</strong> is a fully demountable system<br />

which, at the end of the buildings<br />

life, can be unzipped and reused or<br />

recycled without limitation.<br />

• Up to 95% of the energy required to<br />

manufacture the original aluminium<br />

material is saved through recycling.<br />

• A study by Delft University, supported<br />

by the European Aluminium Association<br />

through the Aluminium for Future<br />

Generations programme, found that<br />

the general collection rates of aluminium<br />

from individual buildings was between<br />

93 and 98 percent – almost total<br />

recovery.<br />

• An insulated <strong>Kalzip</strong> roof structure<br />

contributes significantly to emissions<br />

reduction.<br />

Right:<br />

Lien Khuang,Vietnam<br />

06

<strong>Kalzip</strong> ® <strong>Systems</strong><br />

Available shapes<br />

Widths of <strong>Kalzip</strong> ® profiled sheets<br />

<strong>Kalzip</strong> ® dimensions<br />

333<br />

straight<br />

<strong>Kalzip</strong> ® 50/333<br />

50<br />

429<br />

<strong>Kalzip</strong> ® 50/429<br />

50<br />

convex<br />

curved<br />

<strong>Kalzip</strong> ® 65/305<br />

305<br />

65<br />

333<br />

<strong>Kalzip</strong> ® 65/333<br />

65<br />

tapered-convex<br />

curved<br />

400<br />

<strong>Kalzip</strong> ® 65/400<br />

65<br />

500<br />

tapered<br />

<strong>Kalzip</strong> ® 65/500<br />

65<br />

333<br />

<strong>Kalzip</strong> ® AF 65/333*<br />

65<br />

tapered-concave<br />

curved<br />

434<br />

<strong>Kalzip</strong> ® AF 65/434*<br />

65<br />

concave<br />

curved<br />

* only when used with rigid thermal insulation or timber lining<br />

07

<strong>Kalzip</strong> ® <strong>Systems</strong><br />

BMW central building Leipzig<br />

Winner of the German Architecture<br />

Award 2005<br />

Architect: Zaha Hadid<br />

with Patrik Schumacher<br />

Perfection in roll-forming technology<br />

Flexibility and freedom of design<br />

The unique formability of <strong>Kalzip</strong> ® aluminium profiled sheets enables design and functionality<br />

to be combined with technical perfection. The range of shapes available – convex, concave,<br />

elliptically or hyperbolically curved – opens up a whole variety of fascinating options for<br />

creating stunning architectural designs.<br />

Perfection in production<br />

The high-precision <strong>Kalzip</strong> components<br />

can be produced using the very latest<br />

equipment both in the factory and also<br />

on mobile roll formers to create a variety<br />

of complex shapes and geometric<br />

options. Numerous patents and utility<br />

models are clear evidence of the unique<br />

features and technological preeminence<br />

of this system. Even unconventional<br />

roof shapes are subject to no restriction.<br />

In addition to aluminium, it is also<br />

possible to process other materials<br />

such as stainless steel, copper and<br />

AluPlusZinc. The large number of mobile<br />

roll formers which are in operation<br />

throughout the world, guarantees an<br />

economical and sophisticated complete<br />

solution with minimum logistical costs<br />

and without having to compromise on<br />

creative architectural design. The unique<br />

advantages of on-site production are<br />

clearly evident when continuous sheet<br />

lengths in excess of 150 metres are used<br />

to cover large spans.<br />

Above:<br />

Cite Shopping Mall, Germany<br />

Above:<br />

Basketball Sports Hall, Croatia<br />

08

<strong>Kalzip</strong> ® <strong>Systems</strong><br />

Available shapes<br />

<strong>Kalzip</strong> XT Profiles<br />

The advent of a new architectural era<br />

Malleable, pliable, foldable and flexible,<br />

<strong>Kalzip</strong> XT profiled sheets make it possible<br />

to transform computer-generated designs<br />

and structural principles into reality. These<br />

evolutionary animations, visualized in 3D<br />

objects, enable new architectural shapes<br />

and forms to be created.<br />

Revolutionary in its field this computer<br />

controlled patented roll forming<br />

technology allows three dimensional<br />

contouring to be combined with a<br />

standing seam system to achieve<br />

technical perfection in the creation<br />

of free flowing shapes. The ability to<br />

achieve extremely tight radii guarantees<br />

unusual shapes of buildings, including:<br />

ellipses, cones, semi-spheres, prisms,<br />

pyramids, as well as classic geometrical<br />

shapes –both horizontal and vertical.<br />

Left top:<br />

Emmen Hospital, The Netherlands<br />

elliptically<br />

curved<br />

hyperbolically<br />

curved<br />

XT Freeform<br />

XT Freeform<br />

Left bottom:<br />

Vigo University, Spain<br />

XT Freeform<br />

09

<strong>Kalzip</strong> ® <strong>Systems</strong><br />

Form and functionality<br />

<strong>Kalzip</strong> standing seam roof systems are available<br />

in a multitude of configurations to cater to the most<br />

challenging architectural design or most exacting<br />

performance requirements.<br />

<strong>Kalzip</strong> liner roof system<br />

<strong>Kalzip</strong> liner roof systems are predominantly<br />

used for new build construction, although<br />

they can be used for refurbishment<br />

especially where the existing roofing system<br />

has been completely removed.<br />

The <strong>Kalzip</strong> liner roof system is ideal where<br />

speed of installation on a project is of utmost<br />

importance. A non-fragile walkable <strong>Kalzip</strong><br />

liner sheet can be quickly installed to provide<br />

a weather cover to allow other trades to work<br />

below. The remainder of the roofing<br />

components can then be installed without<br />

affecting the critical path of the construction<br />

programme.<br />

The <strong>Kalzip</strong> liner roof system has the outer<br />

<strong>Kalzip</strong> standing seam roof sheet and the<br />

internal <strong>Kalzip</strong> liner trapezoidal profiled liner<br />

sheet laid in the same direction across roof<br />

purlins acting as the primary support. Typical<br />

purlin centres would be approximately 1.0 to<br />

2.0m. This type of roof construction can also<br />

be known as a purlin roof construction.<br />

The <strong>Kalzip</strong> standing seam roof sheets are<br />

supported directly off the roof purlins via the<br />

support clips/halters (aluminium clips or E<br />

clips) so therefore act independently of the<br />

<strong>Kalzip</strong> liner sheet. When lightweight quilt<br />

type insulation (compressed by<br />

approximately 15% to 20%) is used, the<br />

external loads (wind suction, snow, access,<br />

etc.) are transmitted direct to the support<br />

purlins and not the liner sheet.<br />

The profile and thickness of the <strong>Kalzip</strong><br />

standing seam roof sheet will be<br />

determined by the external loads and<br />

the purlin centres.<br />

The profile of the <strong>Kalzip</strong> liner sheets will be<br />

determined by its dimensional compatibility<br />

with the <strong>Kalzip</strong> standing seam roof sheet<br />

and its thickness will be determined by the<br />

internal wind pressure, the purlin centres,<br />

dead weight of the construction<br />

components, its walkability requirement<br />

and its non-fragility rating.<br />

Left to right:<br />

Supreme Court, Singapore<br />

Mumbai Terminal T1B, India<br />

10

<strong>Kalzip</strong> ® <strong>Systems</strong><br />

Liner roof system<br />

<strong>Kalzip</strong> standing seam sheet<br />

Rockwool insulation<br />

Aluminium ST clip with thermal barrier pad<br />

Vapour control layer<br />

Trapezoidal liner sheet<br />

Purlin<br />

Structural cassette roof system<br />

<strong>Kalzip</strong> standing seam sheet<br />

Rockwool insulation<br />

Aluminium ST Clip with thermal barrier pad<br />

Vapour control layer<br />

Rockwool insulation<br />

Top hat<br />

Structural cassette<br />

Structural deck roof system<br />

<strong>Kalzip</strong> standing seam sheet<br />

Rockwool insulation<br />

Aluminium ST clip with thermal barrier pad<br />

Vapour control layer<br />

Structural deck<br />

11

<strong>Kalzip</strong> ® <strong>Systems</strong><br />

Project: Spencer Street Station, Australia<br />

Architect: Grimshaw Jackson Joint Venture

<strong>Kalzip</strong> ® <strong>Systems</strong><br />

Outstanding and proven performance<br />

An impressive list of project references stand<br />

testament to <strong>Kalzip</strong>’s ability to perform in a wide<br />

array of applications and conditions<br />

With over 80 million square metres of<br />

<strong>Kalzip</strong> roofing and façade systems installed<br />

across the last 40 years, <strong>Kalzip</strong>’s superior<br />

performance in the most trying conditions<br />

have met and often exceeded specifiers’<br />

needs for durability, versatility, design<br />

flexibility and corrosion-resistance.<br />

Transport facilities<br />

Passenger transport facilities, whether air,<br />

rail, road or sea, requires easy accessibility,<br />

the capacity to handle high human traffic<br />

and a welcoming environment.<br />

Terminals are designed to insulate<br />

passengers from the noise and pollution<br />

associated with busy transport facilities and<br />

it entails that the construction materials used<br />

will be exposed to the harsh external<br />

environment. <strong>Kalzip</strong>’s proven durability and<br />

versatility would fulfill the key requirements<br />

of any transport terminal, including: high<br />

wind loading capabilities, superior acoustic<br />

reduction/absorption and low radar<br />

signature.<br />

International transport hubs are icons of<br />

national identity and the gateway for visitors<br />

from the world over. <strong>Kalzip</strong> Building <strong>Systems</strong><br />

have the resource to work as an effective<br />

and supportive partner on major projects<br />

from conception right through<br />

to completion.<br />

Sporting facilities<br />

Whether dedicated to one sport like the<br />

Qizhong International Tennis Centre in<br />

Shanghai or a multi-purpose stadium like the<br />

Taipei Arena in Taiwan, sports facilities have<br />

much in common architecturally.<br />

Easy accessibility, ample and safe<br />

seating capacity, adequate facilities for<br />

support staff and optimized views of the<br />

action are hallmarks of a well-designed<br />

sporting facility.<br />

Convention and exhibition facilities<br />

Convention and exhibition centres are often<br />

amongst the most extensive installations of<br />

<strong>Kalzip</strong> in the world. From the 200,000 square<br />

metres Munich Exhibition Centre in Germany<br />

to the AsiaWorld Expo spanning 90,000<br />

square metres in Hong Kong, <strong>Kalzip</strong> is a truly<br />

cost-effective solution for such large projects.<br />

The system offers high performance with<br />

minimal maintenance requirements and high<br />

residual value (at the end of the building’s life<br />

span) – a critical consideration when such<br />

large areas are specified.<br />

<strong>Kalzip</strong> has the flexibility and capability to<br />

meet the complex and stringent<br />

requirements of the modern sports facility,<br />

not withstanding the high loadings<br />

associated with the “open roof”<br />

configurations of many stadiums<br />

worldwide.<br />

Left to right:<br />

AsiaWorld Expo, Hong Kong<br />

Republic Polytechnic Sports Complex,<br />

Singapore<br />

13

<strong>Kalzip</strong> ® <strong>Systems</strong><br />

<strong>Kalzip</strong> ®<br />

Structural<br />

Deck system<br />

14

<strong>Kalzip</strong> ® <strong>Systems</strong><br />

<strong>Kalzip</strong> structural decking provides an<br />

economical solution for long span<br />

installations and eliminate the need for<br />

purlins. For enhanced acoustic adsorption,<br />

decking sheets can be perforated and can<br />

support mass, such as increased insulation<br />

or board, which may be introduced for more<br />

rigorous acoustic specifications.<br />

Decking sheets can be supplied in<br />

galvanised or polyester-coated in any RAL<br />

colour. For buildings with extreme<br />

temperature variations, a very effective<br />

anti-condensation coating can also be<br />

applied. With a choice of steel or<br />

aluminium, a selection of profiles, gauges<br />

and sheet lengths – this range of products<br />

has been developed to extend the<br />

versatility of <strong>Kalzip</strong>, making it suitable for a<br />

wide range of applications.<br />

As a general rule, steel is cost effective and<br />

provides the optimum in loading and<br />

spanning capability; whereas aluminium<br />

offers exceptional durability in buildings with<br />

high humidity levels such as swimming pools<br />

and wet industrial process plants, e.g. paper<br />

mills.<br />

Where structural decking are installed there<br />

is a reduced requirement for secondary<br />

steelwork – the sheets span between main<br />

steel rafters with the <strong>Kalzip</strong> outer sheet<br />

being fixed either directly to the decking or<br />

onto top hat sub-purlins riveted to the<br />

decking.<br />

<strong>Kalzip</strong> structural decking sheets are<br />

manufactured from high grade steel to BS<br />

EN 10346 or from aluminium alloy.<br />

Standard finishes for decking sheets,<br />

available on a short lead time are:<br />

• Hot-dip galvanized, natural finish, ideal<br />

for situations where the deck is not<br />

visible or where visual appearance is<br />

not critical.<br />

• White polyester coated on hot-dip<br />

galvanized substrate. This finish is<br />

highly durable, resists scratching and<br />

has good formability, suitable for<br />

exterior soffits.<br />

Alternative coatings such as PVDF or<br />

double-side polyurethane are available to<br />

suit particular specifications<br />

Left to right:<br />

Jurong West Sports Complex, Singapore<br />

<strong>Kalzip</strong> structural decking sheets are<br />

available perforated to provide sound<br />

absorption performance. Alternative<br />

perforation patterns and sizes are available<br />

to suit specific requirements.<br />

Perforated decking will improve the acoustic<br />

conditions within a building by helping to<br />

optimise reverberation times. Furthermore,<br />

the decking sheets can contribute to noise<br />

reduction and noise containment within the<br />

building by the inclusion of mass above the<br />

decking sheet such as cement board or<br />

calcium silicate and the inclusion of air<br />

spaces within the system. If the application<br />

requires, the system can be configured for<br />

both acoustic absorption and noise<br />

reduction. To obtain the correct specification<br />

for precise acoustic requirements, please<br />

contact our technical department.<br />

Product advantages<br />

• Capable of spanning up to 8m<br />

between trusses<br />

• Eliminates the need for purlins<br />

• Reduced construction time<br />

• Can be used as stress skin<br />

design to reduce the requirement<br />

for bracing<br />

• Perforated options provide good<br />

acoustic absorption<br />

15

<strong>Kalzip</strong> ® <strong>Systems</strong><br />

<strong>Kalzip</strong> ®<br />

Structural<br />

Cassette<br />

system<br />

16

<strong>Kalzip</strong> ® <strong>Systems</strong><br />

Suitable for both roof and wall applications,<br />

<strong>Kalzip</strong> structural cassette are available in<br />

both aluminium and steel and are available<br />

as a tested and proven alternative lining<br />

element for the <strong>Kalzip</strong> standing seam<br />

system. With good strength and stability,<br />

cassette are suitable for long span<br />

applications and there is also a reduced<br />

requirement for structural steelwork.<br />

Once in position the interior face of<br />

the cassette provides a clean and pleasing<br />

appearance with no visible fixings.<br />

For increased spanability a special<br />

section can be inserted into the side lap of<br />

the cassette.<br />

Structural cassette materials and<br />

finishes<br />

<strong>Kalzip</strong> structural cassette are manufactured<br />

from high grade steel to BS EN 10346 or<br />

from aluminium alloy.<br />

Perforated versions are available where<br />

acoustic absorption is required. The sheets<br />

also have the strength to support the<br />

introduction of additional mass such as<br />

cement board or calcium silicate where<br />

there is a requirement for good sound<br />

reduction. For further details, please refer to<br />

the acoustic section on page 34, or contact<br />

out technical department.<br />

Standard finishes for cassette, available on<br />

a short lead time are:<br />

• Hot-dip galvanized, natural finish. Ideal<br />

for situations where the cassette is not<br />

visible or where visual appearance is<br />

not critical.<br />

• White polyester coated on hot-dip<br />

galvanized substrate. This finish is<br />

highly durable, resists scratching and<br />

has good formability, suitable for<br />

exterior soffits.<br />

A wide range of special colours can be<br />

supplied subject to order quantity and<br />

extended delivery. Alternative coatings such<br />

as PVDF or double-side polyurethane are<br />

available to suit particular specifications, e.g.<br />

swimming pools and wet industrial processes.<br />

Left to right:<br />

Wieland Factory, Singapore<br />

<strong>Kalzip</strong> structural cassette are available<br />

perforated to provide sound absorption<br />

performance.<br />

Alternative perforation patterns and sizes<br />

are available to suit specific requirements.<br />

Perforated cassette will improve the<br />

acoustic conditions within a building by<br />

helping to optimise reverberation times.<br />

Furthermore, the cassette can contribute to<br />

noise reduction and noise containment<br />

within the building by the inclusion of mass<br />

above the cassette such as particle board<br />

or plaster board and the inclusion of air<br />

spaces within the system. If the application<br />

requires, the system can be configured for<br />

both acoustic absorption and noise<br />

reduction. To obtain the correct<br />

specification for precise acoustic<br />

requirements, please contact our technical<br />

department.<br />

Product advantages<br />

• Capable of spanning up to 6m<br />

between trusses<br />

• Eliminates the need for purlins<br />

• Concealed fixing<br />

• Provides smooth internal finish<br />

eliminating the need for a seperate<br />

ceiling<br />

<strong>17</strong>

<strong>Kalzip</strong> ® <strong>Systems</strong><br />

<strong>Kalzip</strong> ®<br />

Solar Power<br />

Solutions<br />

AluPlusSolar<br />

and SolarClad<br />

18

<strong>Kalzip</strong> ® <strong>Systems</strong><br />

Sustainable architectural aesthetics<br />

A roof-integrated source of renewable energy<br />

The solar laminates are flexible and<br />

extremely durable. Depending on the<br />

particular roof design, they are permanently<br />

bonded to straight, convex or concave<br />

<strong>Kalzip</strong> ® aluminium profiled sheets. The<br />

flexibility of <strong>Kalzip</strong> ® AluPlusSolar can<br />

accommodate barrel vault or mono-pitch<br />

roofs, as well as individual roof designs.<br />

The combination of thin-film solar<br />

cells with the characteristics of <strong>Kalzip</strong> ®<br />

profiled sheets guarantees the architects<br />

and planners of photovoltaic systems<br />

a truly integrated solar solution,<br />

which optimises both roof design and<br />

energy generation.<br />

<strong>Kalzip</strong> ® AluPlusSolar is available as a fully<br />

integrated system, including inverter and<br />

accessories, on the AF 65/537/1.0 mm<br />

profiled sheet with an RAL 9006 coating<br />

(other colours available on request).<br />

The solar film, available in two lengths,<br />

is laminated in the factory and then<br />

permanently bonded to the outer surface of<br />

the <strong>Kalzip</strong> ® profiled sheets. This film<br />

will subsequently generate the power in<br />

the photovoltaic system. <strong>Kalzip</strong> ® profiled<br />

sheets which have already been installed<br />

cannot be retrofitted with laminated solar<br />

film. However, existing <strong>Kalzip</strong> ® roofs can be<br />

retrofitted with <strong>Kalzip</strong> ® SolarClad.<br />

In addition to a roof-integrated, regenerative<br />

method of energy production, <strong>Kalzip</strong> ® solar<br />

systems also offer the opportunity of<br />

generating energy in the facade. We can<br />

send you detailed information on request.<br />

The silicon solar cells use triple-junction<br />

technology to generate more energy in<br />

diffuse light conditions than crystalline solar<br />

cells of the same rated power and are<br />

therefore ideal for use.<br />

The durability of the <strong>Kalzip</strong> ® profiled<br />

sheets and the guaranteed efficiency of the<br />

solar modules now make it possible to<br />

create contemporary, modern buildings<br />

which combine maximum freedom of<br />

architectural design with the integration<br />

of ecological concepts.<br />

Product advantages<br />

• Attractive, roof-integrated<br />

photovoltaics without additional<br />

fixing elements<br />

• Optimum utilization of solar energy<br />

even in weaker light conditions<br />

through triple-junction technology<br />

• Greater shade tolerance than<br />

crystalline modules through narrowmeshed<br />

bypass circuit<br />

• Economical – supplied with a 20-<br />

year performance guarantee<br />

• Self-cleaning surface – therefore<br />

low-maintenance<br />

• Suitable for use as an insulated or<br />

non-insulated roof<br />

• Ideal for the most challenging<br />

architectural design<br />

• Available as a complete system<br />

inclusive of inverter and accessories<br />

• Advice and planning support<br />

provided by <strong>Kalzip</strong>, also project<br />

management support on request<br />

Left to right:<br />

Auguste Bozon Ochestra training room, France<br />

Mastershausen Town Hall, Germany<br />

Versatile photovoltaic solutions<br />

Flexibility in sustainable development<br />

The ideal retrofitting solution for all<br />

metal roofs <strong>Kalzip</strong> ® SolarClad is a<br />

photovoltaic cladding which has been<br />

optimised for use in building envelopes. Its<br />

flexibility and versatility enables the solar<br />

modules to be fixed onto all standing seam<br />

systems made from a variety of materials. It<br />

can be retrofitted to existing installations or<br />

used in new builds.<br />

The system consists of extremely<br />

robust thin-film modules made from<br />

amorphous silicon (a-Si), bonded onto<br />

aluminium carrier plates, which can be<br />

installed on any metal roof system in a<br />

non-penetrative manner.<br />

These extremely lightweight module<br />

units are suitable for all roof shapes and<br />

guarantee maximum freedom of design for<br />

planners and architects.<br />

<strong>Kalzip</strong> ® SolarClad is supplied as a<br />

complete system, including inverters,<br />

for different standing seam designs. The<br />

solar film, available in two different lengths,<br />

is laminated onto <strong>Kalzip</strong> ® carrier plates<br />

in the factory to ensure high quality and fast<br />

installation. The solar laminates generate<br />

power from the Sun as soon as they are<br />

connected.<br />

19

<strong>Kalzip</strong> ® <strong>Systems</strong><br />

Triple-junction technology<br />

The solar cells used in amorphous silicon thin-film laminates consist<br />

of three silicon layers applied one after the other. The different<br />

layers are optimized so that each layer can optimally convert a<br />

different range of the light spectrum to electrical energy. This<br />

enables greater efficiency in diffuse light conditions, which<br />

constitute the predominant form of daylight in central and northern<br />

Europe. The specific yields of a <strong>Kalzip</strong> ® AluPlusSolar or <strong>Kalzip</strong> ®<br />

SolarClad system are thus, depending on local conditions, 10-20%<br />

higher than yields from a regular crystalline system in identical<br />

conditions.<br />

Relative Intensity<br />

1,0<br />

0,8<br />

0,6<br />

0,4<br />

0,2<br />

0<br />

300 400 500 600 700 800 900<br />

Wavelength in µm<br />

Tight bypass circuitry<br />

When partially or temporarily shaded, amorphous thin-film<br />

laminates have at their disposal a bypass circuit so that the system<br />

power is not significantly reduced or affected. This is in contrast to<br />

a similarly shaded crystalline system which, in the event of partial<br />

shading, would deactivate much larger areas.<br />

Temperature performance<br />

The temperature coefficient describes the output reductions<br />

exhibited by solar cells when exposed to heat. For regular<br />

monocrystalline or polycrystalline modules, this coefficient is around<br />

-0.5%/K. For the PV laminates used in <strong>Kalzip</strong> ® Solar Power<br />

<strong>Systems</strong>, it is only -0.2%/K.<br />

Amorphous module<br />

(e.g. <strong>Kalzip</strong> ® AluPlusSolar)<br />

Crystalline module<br />

Output [%]<br />

105<br />

100<br />

95<br />

90<br />

85<br />

80<br />

75<br />

70<br />

65<br />

60 25 30 35 40 45 50 55 60 65 70 75 80<br />

Cell temperature [°C]<br />

Environmentally friendly<br />

The low energy demands during the manufacture and the<br />

high yields result in an energy payback time of approximately 3<br />

years. This is a fraction of the required energy payback times<br />

for crystalline modules.<br />

Cumulative energy consumption and energy payback time of<br />

frameless PV modules<br />

Areas of use<br />

<strong>Kalzip</strong> ® AluPlusSolar is suitable for all roof designs with a<br />

pitch of up to 60°. In case of a combined roof and facade via a<br />

curved or continuous eaves detail, advice should be obtained from<br />

your local office.<br />

<strong>Kalzip</strong> ® AluPlusSolar is available with a choice of two different<br />

photovoltaic thin-film solar modules PVL-68 and PVL-136, each<br />

with different performance characteristics. Roof and facade<br />

surfaces can therefore be used to their optimum potential.<br />

0 2 4 6 8 10 12 14<br />

CEE [GJ/m] and EPT [a]<br />

Ranges from different studies for calculation of:<br />

Cumulative expenditure of energy (CEE) in gigajoules per m<br />

Energy payback time (EPT) in years<br />

(Data source: Möller, Jochen. 1998.<br />

Integrierte Betrachtung der Umweltauswirkungen<br />

von Photovoltaik -Technologien.)<br />

20

<strong>Kalzip</strong> ® <strong>Systems</strong><br />

Technical Data<br />

Surface required per kWp<br />

(installation parallel to standing seams) [m 2 ]<br />

Module length [m]<br />

Rated power [W]<br />

Operating voltage V MPP [V]<br />

Operating current I MPP [A]<br />

Open-circuit voltage V OC [V]<br />

PVL-68<br />

> 18.50<br />

2.85<br />

68.00<br />

16.50<br />

4.13<br />

23.10<br />

PVL-136<br />

> 18.50<br />

5.50<br />

136.00<br />

33.00<br />

4.13<br />

46.20<br />

Planning guidance<br />

• In addition to SolarClad, the <strong>Kalzip</strong><br />

AluPlusSolar roof integrated<br />

photovoltaic system is also suitable for<br />

new <strong>Kalzip</strong> roofs<br />

• Recommended roof pitch min. of<br />

3°(5%)<br />

Open-circuit voltage V OC at<br />

-10 °C and 1250 W/m 2 [V]<br />

Short-circuit current I SC [A]<br />

Short-circuit current I SC bei 75 °C<br />

and 1250 W/m 2 [A]<br />

Series fuse rating/blocking<br />

26.30<br />

5.10<br />

6.70<br />

52.70<br />

5.10<br />

6.70<br />

• <strong>Kalzip</strong> profiled sheets cannot be<br />

laminated once installed with<br />

thin-film solar modules, for retrofitting<br />

we recommend the use of <strong>Kalzip</strong><br />

SolarClad<br />

diode rating [A]<br />

Maximum system voltage DC [V]<br />

8.00<br />

1000.00<br />

8.00<br />

1000.00<br />

• Minimum radius in the area of the<br />

profiled sheets fitted with modules<br />

Pleae note: The values specified ± 5 % represent stabilised values. During the first 8-10 weeks of operation,<br />

power output may be higher by 15 %, operating voltage may be higher by 11% and operating current may be<br />

higher by 4 %.<br />

Design suitability and approval in accordance<br />

with IEC 61646<br />

TÜV Rheinland, Cologne, Germany<br />

Possible methods of installation<br />

<strong>Kalzip</strong> SolarClad parallel to<br />

standing seams<br />

<strong>Kalzip</strong> SolarClad perpendicular to<br />

standing seams<br />

<strong>Kalzip</strong> SolarClad elevated from roof<br />

Day Nursery for the Companies Sodeb'O, France<br />

Arnold Lodge Phase 2, United Kingdom<br />

Sports hall Frechen, Germany<br />

Schiller School Bretten, Germany<br />

<strong>21</strong>

<strong>Kalzip</strong> ® <strong>Systems</strong><br />

<strong>Kalzip</strong> ®<br />

Facade Solutions<br />

Innovative<br />

building envelope<br />

technology<br />

22

<strong>Kalzip</strong> ® <strong>Systems</strong><br />

Unique building envelopes<br />

Complementing contemporary architectural design<br />

with stunning aesthetics<br />

Designers and architects throughout<br />

the world use <strong>Kalzip</strong> ® roof and facade<br />

systems to create stunning buildings. The<br />

combination of traditional materials such as<br />

glass and wood with <strong>Kalzip</strong> ® aluminium<br />

profiles is already an established approach<br />

to leading-edge architectural design.<br />

Product advantages<br />

• Durability<br />

• Lightweight<br />

• High bearing capacity<br />

• Saltwater-resistant aluminium alloy<br />

In this respect, a facade becomes so<br />

much more than a building envelope –<br />

it highlights the unique individuality and<br />

character of a building. <strong>Kalzip</strong> ® facade<br />

systems provide architects with the ideal<br />

scope for creating contemporary and<br />

individual designs.<br />

The wide range of shapes, surface finishes<br />

and colours available provides virtually<br />

unlimited opportunities for enhancing<br />

architectural design – functionality is<br />

complemented by stunning aesthetics.<br />

The flexibility of <strong>Kalzip</strong> ® facade systems<br />

creates exciting potential for pushing the<br />

boundaries of contemporary architectural<br />

design even further. Individual and<br />

future-oriented solutions highlight the unique<br />

nature of a building.<br />

23

Louisiana Superdome, USA<br />

<strong>Kalzip</strong> FC rainscreen system<br />

Ingenious, attractive,<br />

innovative and economical<br />

<strong>Kalzip</strong> FC rainscreen is a non-penetrative<br />

facade system that incorporates a<br />

fast-to-install lightweight flat rainscreen<br />

panel, suitable for both new build and<br />

refurbishment projects.<br />

The main feature of the system is its<br />

flexibility which allows the installation of the<br />

profiles to be carried out in two directions,<br />

either from the top down or from the bottom<br />

up.<br />

This choice of panel mounting direction is a<br />

unique benefit which enables not only easier<br />

and faster installation compared to<br />

conventional panel systems but also allows<br />

scaffolding or subsequent construction work<br />

to be coordinated independently from the<br />

installation process.<br />

The system's innovative design and technical<br />

capabilities also allow individual sheets to be<br />

removed and installed without compromising<br />

the adjoining panels or the overall integrity of<br />

the facade system.<br />

Product advantages<br />

• Contemporary, visually stunning<br />

aesthetics<br />

• Several different standard profile<br />

widths<br />

• Simple and fast installation<br />

techniques<br />

• Optimised panel geometry<br />

• Variable acoustic and thermal<br />

insulation options<br />

• A wide range of colour and surface<br />

finishes<br />

• High structural performance<br />

• Creation of fixed point<br />

Profile options and dimensions<br />

Materials and finishes:<br />

FC rainscreen panels are available in stucco<br />

embossed aluminium EN AW 6025<br />

(AIMg2.5SiMnCu) and painted aluminium EN<br />

AW 3004 (AIMn1Mg1) or EN AW 3005<br />

(AIMn1Mg0.5) The profiles are available as<br />

standard in a range of RAL / PVDF colours.<br />

Other surface finishes are available on<br />

request including stucco-embossed,<br />

AluPlusPatina, micro-ribbed, perforated and<br />

with integrated recessed seams.<br />

Protective foil:<br />

All material is provided with protective film.<br />

Please contact us for further information.<br />

24

Technical information<br />

Installation and fixing<br />

The <strong>Kalzip</strong> FC rainscreen system has been<br />

designed for horizontal installation and for<br />

use with all common substructures.<br />

The panels are fixed into either proprietary<br />

individual clips or continuous modular rails<br />

which feature integrated plastic inlays that<br />

lock the panels securely into place. The<br />

individual mono-click brackets can also be<br />

used for creating special details.<br />

The modular click rail is typically supplied in<br />

three to four metre lengths. This is not only<br />

for practical handling reasons but also<br />

where a break in the facade<br />

sub-construction is required to allow<br />

expansion between floors. A specially<br />

designed setting out tool is available to<br />

ensure the correct spacing and alignment<br />

between adjacent rails. The same tool can<br />

be adjusted to accommodate all standard<br />

profile cover widths.<br />

The system components have been<br />

optimised to enable the system to be<br />

adjusted and aligned solely via the<br />

substructure. Fully integrated corner panels<br />

add a subtle yet harmonious detail to the<br />

building geometry and enhance the overall<br />

aesthetics of the facade.<br />

Installation from the bottom upwards<br />

Installation from the top downwards<br />

Individual rainscreen panel demounting<br />

A particular advantage of this rainscreen system is that, in case of damage to the facade panels, individual panels can be exchanged<br />

without having to dismount entire facade areas. Please contact us for further information.<br />

25

<strong>Kalzip</strong> ® <strong>Systems</strong><br />

<strong>Kalzip</strong> ® TF facade systems<br />

Combining a unique facade design with<br />

optimum functionality<br />

The sleek profiling of this facade system<br />

enhances the sophisticated interplay of<br />

light and shade across all elevations, at the<br />

same time creating a distinct and unique<br />

overall appearance with a real sense of<br />

clarity. The <strong>Kalzip</strong> ® TF facade system not<br />

only enhances the individual character of<br />

the building but also offers optimum<br />

functional benefits such as outstanding<br />

thermal insulation characteristics. This is a<br />

system which is both aesthetically<br />

appealing and highly practical.<br />

The <strong>Kalzip</strong> ® TF facade system is so much<br />

more than a building envelope – it provides<br />

planners and architects with a wealth of<br />

scope to create stunning buildings with a<br />

highly individual character. This is a<br />

perfectly systemised solution which is<br />

available in a range of colours and<br />

combines sophisticated, appealing<br />

aesthetics with optimum practicality.<br />

Special system components are available<br />

which have been developed specifically for<br />

the <strong>Kalzip</strong> ® TF facade system. These<br />

components provide perfect interfaces with<br />

other building elements and systems. They<br />

also add the ultimate finishing touches to<br />

the optics of the building, creating a<br />

perfectly integrated overall appearance<br />

which is distinctive and sophisticated.<br />

Assembly and installation<br />

The <strong>Kalzip</strong> ® TF facade system is suitable<br />

for horizontal or slightly pitched building<br />

elevations. Fixing takes place within the<br />

narrow lower brace between the ribs –<br />

either inside each rib or in line with the<br />

longitudinal joints.<br />

Attachment<br />

Fastener with JT3-FR-6-5.5xL E10 internal<br />

Torx drive, or irius ® drive system<br />

SX-L12-A10-5.5xL.<br />

Product advantages<br />

• Unique, aesthetic design with a<br />

distinct “long view” visual appeal<br />

• Lightweight and therefore<br />

economical in terms of both cost and<br />

materials<br />

• Wide range of acoustic and thermal<br />

insulation options<br />

• Harmonised system components<br />

and interfaces<br />

• Available in a wide range of colours<br />

Technical data<br />

TF800R<br />

<strong>Kalzip</strong> ®<br />

TF800R<br />

Material:<br />

EN AW-3004 or EN AW-6025<br />

Dimensions:<br />

Thickness<br />

Constructional width<br />

Profile length<br />

Profile height<br />

Load bearing capacity:<br />

Surface finishes:<br />

0.9mm, 1.0 mm and 1.2 mm<br />

800 mm<br />

max. 6000 mm<br />

37 mm<br />

Load bearing capacity values in accordance with BS EN<br />

1999-1-4:2007<br />

Polyester and PVDF<br />

66.7 200 66.7 200<br />

800<br />

Colours:<br />

RAL standard colours in accordance with the <strong>Kalzip</strong> ® colour<br />

chart, special colours available on request.<br />

200<br />

Sub-structure:<br />

Vertical girders or spacer elements<br />

37<br />

26

<strong>Kalzip</strong> ® <strong>Systems</strong><br />

<strong>Kalzip</strong> Structural cassette facade system<br />

Economical facade solution offering a combination<br />

of durability and performance<br />

<strong>Kalzip</strong> facade cassette systems<br />

comprises a variable system of supporting<br />

coffers in different designs, dimensions and<br />

lengths. It enables a simple and<br />

economical construction with very<br />

good insulation values.<br />

Perforated facade cassettes offer<br />

high sound absorption values in technically<br />

important frequency ranges and are<br />

used very successfully to ensure<br />

economical compliance with noise<br />

protection stipulations.<br />

The <strong>Kalzip</strong> facade cassette system<br />

can span up to 6m between supports,<br />

eliminating the need for purlins. This<br />

smooth finish of the cassette provides a<br />

durable and maintenance free facade,<br />

without the need for additional sealant.<br />

The fixings for the cassette system can<br />

be concealed with the flanges of the tray to<br />

further enhance the aesthetics of<br />

the system.<br />

Product advantages<br />

• Capable of spanning up to 6m<br />

without supports<br />

• Provides a smooth, maintenancefree<br />

facade<br />

• Concealed fixing system<br />

• Can be supplied in coated steel or<br />

aluminium<br />

• Acoustic and thermal performance<br />

can be customised to suit specific<br />

requirements<br />

<strong>Kalzip</strong> structural cassette facade system-Typical build up<br />

<strong>Kalzip</strong> standing seam on <strong>Kalzip</strong> structural<br />

cassette with top hat<br />

<strong>Kalzip</strong> TF on <strong>Kalzip</strong> structural cassette<br />

without top hat<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

<strong>Kalzip</strong> 65/400<br />

Vapour barrier<br />

Insulation<br />

Structural cassette<br />

Top hat to cassette<br />

E-clip or ST clip with thermal barrier<br />

1<br />

2<br />

3<br />

4<br />

TF800R (Applicable for W18/76 & TR35/200)<br />

Vapour barrier<br />

Insulation<br />

Structural cassette<br />

* The above are just typical build-up. All the profiles can be lay vertically, horizontally or diagonally.<br />

27

<strong>Kalzip</strong> ® <strong>Systems</strong><br />

<strong>Kalzip</strong> trapezoidal and corrugated profiles<br />

A variety of profiles - a diversity of designs for roofs<br />

and facades<br />

Metal and glass building envelopes<br />

characterise contemporary architectural<br />

design for all kinds of buildings. Metal<br />

building envelopes have not only<br />

become a striking feature in the design<br />

of functional industrial and commercial<br />

properties, but also in public and private<br />

residential developments.<br />

<strong>Kalzip</strong> ® trapezoidal and corrugated<br />

profiles offer tremendous scope for design.<br />

The variety of different profiles available –<br />

ranging from different trapezoidal sections<br />

to classic corrugated designs - provides<br />

planners and designers with a wealth of<br />

scope to create fascinating, unique<br />

designs.<br />

Whichever <strong>Kalzip</strong> ® profiles you decide<br />

to use, this facade system creates stunning<br />

buildings with a highly individual and<br />

unique character. The highest quality of<br />

manufacture and the functional reliability of<br />

all components create a solution which is<br />

not only strong and durable but also<br />

aesthetically pleasing.<br />

All elements – the facade and roof<br />

sheets, the corresponding connecting<br />

flanges, the end plates of the substructure,<br />

the transition sheets and the pilaster<br />

strips – are designed and manufactured for<br />

complete compatibility and fulfill the most<br />

demanding requirements stipulated by<br />

architects and planners.<br />

In addition to the diverse selection of<br />

profiles available, there is also a wide range<br />

of <strong>Kalzip</strong> ® colour and surface finish options<br />

which provides maximum freedom of<br />

design and maximum peace of mind.<br />

Only high-quality PVDF or polyester-based<br />

paints are used for coating <strong>Kalzip</strong> ®<br />

trapezoidal and corrugated profiles as<br />

this ensures our products meet the high<br />

performance requirements of modern<br />

building methods.<br />

Product advantages<br />

• Lightweight<br />

• High strength<br />

• Excellent acoustic and thermal<br />

insulation properties<br />

• Easy installation<br />

• Long life expectancy<br />

• Economical solution<br />

• Ideal for refurbishment project;<br />

suitable for all types of existing<br />

cladding and sub-structures<br />

Left to right:<br />

Seagate Building, Singapore<br />

Tradeport Logistics Centre, Hong Kong<br />

28

<strong>Kalzip</strong> <strong>Kalzip</strong> ® <strong>Systems</strong><br />

® Intelligent fixing systems<br />

The system has been developed with<br />

careful attention to every single component<br />

– aesthetics, efficiency, performance and<br />

safety are of critical importance in every<br />

case. For instance, a special drill fastener<br />

has been developed to either blend<br />

harmoniously into coloured facades or,<br />

alternatively, to provide stylish accentuating<br />

colour contrasts. What’s more, the new drill<br />

fastener offers many functional benefits.<br />

Developed by SFS exclusively for use on<br />

the <strong>Kalzip</strong> ® system, the drill<br />

fastener joins two thin metal sheets load<br />

bearing and securely. In comparison to the<br />

riveting process, the drill fastener saves a<br />

considerable amount of time during<br />

installation work.<br />

Fixing systems<br />

Substructure<br />

Maximum Sheet Length<br />

Fixing Method<br />

Fastener<br />

Aluminium<br />

Steel<br />

16m (horizontal 6m)<br />

in bottom flange<br />

Stainless steel self-tapping fasteners, disc with seal.<br />

Dimensions<br />

<strong>Kalzip</strong> ® W 18/76<br />

(recommended)<br />

Thickness:<br />

1.0 mm<br />

1.2 mm<br />

18<br />

76,2<br />

Constructional width<br />

13 x 76.2 = 991<br />

Side A<br />

Side B<br />

13<br />

<strong>Kalzip</strong> ® TR 35/200<br />

Thickness:<br />

0.9 mm<br />

1.0 mm<br />

1.2 mm<br />

35<br />

200<br />

Constructional width 1000<br />

35 Side A<br />

90 110<br />

Side B<br />

Load bearing capacity:<br />

Surface finishes:<br />

Colours:<br />

Load bearing values: in accordance with BS EN 1999-1-4:2007 (see calculation tables)<br />

Stucco-embossed<br />

RAL standard colours in accordance with the <strong>Kalzip</strong>® colour chart, special colours available on request.<br />

29

<strong>Kalzip</strong> ® <strong>Systems</strong><br />

Steba Industria Building, Austria<br />

<strong>Kalzip</strong> ® perforated facade systems<br />

A fascinating interplay of light and shade<br />

<strong>Kalzip</strong> ® perforated facade systems<br />

provide an inspirational and highly creative<br />

extension to the range of <strong>Kalzip</strong> ® aluminium<br />

profiled sheets already available.<br />

Architects continue to conceive new ways<br />

of using light to create new and exciting<br />

effects for enhancing their architectural<br />

designs. However, the most inspirational<br />

design can only be successfully<br />

accomplished with the right materials.<br />

It requires the perfect combination of<br />

appealing aesthetics with the highest<br />

standards of quality and functionality.<br />

<strong>Kalzip</strong> ® perforated facade systems provide<br />

planners and architects with virtually<br />

unlimited design potential – allowing them<br />

to turn their visions into a reality.<br />

A perforated facade solution provides<br />

immense scope for design creativity and<br />

the interplay of light and shade. Creating<br />

aesthetics which change with the light. At<br />

night, the introduction of lighting adds a<br />

totally new dimension. An inspirational<br />

building envelope can totally transform<br />

a building, making it come alive. The range<br />

of different hole diameters available means<br />

that the scope for design is virtually<br />

limitless. <strong>Kalzip</strong> ® perforated facade<br />

systems are a simple, cost-effective and<br />

elegant solution for creating striking and<br />

sophisticated designs.<br />

The strength and quality of <strong>Kalzip</strong> ® is<br />

combined with the design flexibility of a<br />

perforated solution.<br />

Product advantages<br />

• Ideal for solar shading on transparent<br />

facades<br />

• Sophisticated accentuation of facade<br />

surfaces<br />

• Differentiates between public and<br />

semi-public areas<br />

• Ideal for enhancing the appearance<br />

of unsightly facades<br />

• Economic refurbishment of facades<br />

30

<strong>Kalzip</strong> ® <strong>Systems</strong><br />

<strong>Kalzip</strong> ® perforated facade systems offer a wide variety of surface finishes and are available in all standard <strong>Kalzip</strong> ® widths and lengths.<br />

Technical data<br />

Material<br />

EN AW-3004 or EN AW-6025<br />

Thickness (mm) 0.8, 0.9, 1.0, 1.2<br />

Perforation<br />

Ao<br />

Rv 3-5<br />

32%<br />

Rv 5-8<br />

35%<br />

Profile Dimensions<br />

<strong>Kalzip</strong> ® 50/333, 50/429, 65/305, 65/333, 65/400,FC30/400<br />

AF65/333, AF65/434<br />

TF800R, TR35/200,W18/76<br />

<strong>Kalzip</strong> perforated profiles<br />

<strong>Kalzip</strong><br />

<strong>Kalzip</strong> 65/400<br />

<strong>Kalzip</strong> FC30/400<br />

<strong>Kalzip</strong> TF800R<br />

In lower flange<br />

In wide flange<br />

In wide flange<br />

Trapezoidal & corrugated<br />

<strong>Kalzip</strong> TR35/200 <strong>Kalzip</strong> W18/76<br />

In wide flange<br />

Full surface<br />

31

<strong>Kalzip</strong> ® <strong>Systems</strong><br />

<strong>Kalzip</strong> ®<br />

Bespoke<br />

Solutions<br />

Aesthetics<br />

and proven<br />

performance<br />

32

<strong>Kalzip</strong> ® <strong>Systems</strong><br />

<strong>Kalzip</strong> Bespoke Solutions<br />

Guaranteed watertightness for open panel systems<br />

<strong>Kalzip</strong> cladded systems were developed to<br />

satisfy the increasing demand for open joint<br />

systems on complex roof geometry. The<br />

architecture of the roof is becoming<br />

increasingly important, requiring more<br />

sophisticated cladding solutions to be<br />

developed. The <strong>Kalzip</strong> Cladded System<br />

allows the architect complete freedom to<br />

use any panel or louvre system on the roof<br />

without the need to penetrate the<br />

waterproof layer of the roof system.<br />

The <strong>Kalzip</strong> system can be designed and<br />

installed in the normal manner. An<br />

additional cladding system can be installed<br />

on top of the <strong>Kalzip</strong> system by using unique<br />

<strong>Kalzip</strong> seam clips and an extruded<br />

Aluminium framework to mount the panels<br />

on top of the <strong>Kalzip</strong> without having to make<br />

a single penetration through the roof. The<br />

Aluminium framework is designed to allow<br />

final adjustments of the support structure to<br />

guarantee the perfect alignment of the<br />

external clad panels.<br />

The joints between the external panels are<br />

normally left open with a gap of 10 to<br />

15mm between the panels. The rainwater<br />

will drain between these gaps onto the<br />

<strong>Kalzip</strong> system, and then to the gutter and<br />

rainwater disposal system. The system<br />

does not require any silicone joints between<br />

the panels which eliminates the<br />

requirement of maintenance and avoids<br />

any streaking or dirt accumulation between<br />

the panels.<br />

Product advantages<br />

• Attachment of the external panel of<br />

louvre system with no penetrations<br />

through the waterproof layer<br />

• Open joints between the panels or<br />

louvres eliminating maintenance and<br />

reducing cleaning requirements<br />

• Adjustable system allowing perfect<br />

alignment of the external panels or<br />

louvre system<br />

• Minimal maintenance other than<br />

cleaning of the external panels<br />

• Improved acoustics due to the air<br />

gap between the external panels and<br />

the <strong>Kalzip</strong><br />

• Complete flexibility to use any<br />

external panel<br />

• Able to meet any acoustic or thermal<br />

performance requirement<br />

Left to right:<br />

China Central Academy of Fine Arts,<br />

China<br />

Supreme Court,<br />

Singapore<br />

33

<strong>Kalzip</strong> ® <strong>Systems</strong><br />

<strong>Kalzip</strong> ®<br />

Acoustic <strong>Systems</strong><br />

Solutions for<br />

auditory<br />

applications<br />

34

<strong>Kalzip</strong> ® <strong>Systems</strong><br />

Tailored to high acoustic performance<br />

Combining <strong>Kalzip</strong>’s proven durability and versatility<br />

with effective acoustic insulation<br />

<strong>Kalzip</strong> roof constructions can be modified<br />

to accommodate various acoustic<br />

performance requirements, by<br />

incorporating other layers such as high<br />

density insulation, acoustic boards and<br />

flexible membranes to provide increased<br />

sound reduction performance and by<br />

perforating the liner to provide improved<br />

sound absorption performance.<br />

Acoustic performance is an important<br />

consideration in the design of buildings,<br />

especially within the education sector.<br />

Multi-layer forms of construction achieve<br />

better results and the built-up <strong>Kalzip</strong><br />

system allows for many combinations to<br />

address various acoustic requirements<br />

within a building. By using its different<br />

system variations <strong>Kalzip</strong> can assist in<br />

achieving the right sound reduction<br />

and/or absorption levels required for<br />

specific applications.<br />

Over 80 tests have been conducted<br />

on <strong>Kalzip</strong> roof constructions for air-bourne<br />

sound reduction and sound<br />

absorption levels.<br />

Air-bourne sound reduction<br />

A standard insulated <strong>Kalzip</strong> roof<br />

construction will have an approximate<br />

weighted sound reduction (Rw) of 33dB<br />

with an aluminium trapezoidal liner and 36<br />

dB with a steel trapezoidal liner.<br />

The Rw can be increased by varying the<br />

number and the densities of the insulation<br />

layers as well as adding additional mass<br />

into the construction e.g. through the<br />

incorporation of high density <strong>Kalzip</strong><br />

insulation, <strong>Kalzip</strong> acoustic board or <strong>Kalzip</strong><br />

acoustic membrane, etc.<br />

In situations with overt external noise near<br />

a railway or airport, for instance there is<br />

high density <strong>Kalzip</strong> acoustic board to help<br />

reduce incoming sounds.<br />

Recent tests carried out incorporating<br />

varying types and levels of mass have<br />

recorded sound reduction rates of between<br />

33dB and 52dB depending on the product<br />

combinations applied.<br />

A valid consideration is <strong>Kalzip</strong> Nature Roof<br />

which adds weight and therefore ‘mass’ to<br />

a <strong>Kalzip</strong> system build up especially when<br />

fully saturated. This solution can be a<br />

natural way of providing dB reduction and a<br />

number of additional benefits.<br />

Sound absorption<br />

Sound absorption is achieved by<br />

perforating the metal liner sheet and<br />

incorporating a ‘soft’ absorbing material<br />

behind it. Different combinations of<br />

perforations and levels of insulation will<br />

give varying results of sound absorption.<br />

Impact noise due to rainfall<br />

In all <strong>Kalzip</strong> roof construction the top layer<br />

of insulation is typically a low density<br />

mineral fibre insulation which is slightly<br />

compressed to the underside of the <strong>Kalzip</strong><br />

outer sheet. The <strong>Kalzip</strong> anti-drumming<br />

membrane is highly effective and inhibits<br />

the build up of resonant vibrations.<br />

National Convention Centre, Hanoi<br />

35

<strong>Kalzip</strong> ® <strong>Systems</strong><br />

Liner roof system<br />

<strong>Kalzip</strong> standing seam sheet<br />

Rockwool insulation<br />

Aluminium ST Clip with thermal barrier pad<br />

Vapour control layer<br />

Cement board<br />

Trapezoidal liner sheet<br />

Purlin<br />

Structural cassette roof system<br />

<strong>Kalzip</strong> standing seam sheet<br />

Rockwool insulation<br />

Aluminium ST Clip with thermal barrier pad<br />

Vapour control layer<br />

Rockwool insulation<br />

Top hat<br />

Structural cassette<br />

Structural deck roof system<br />

<strong>Kalzip</strong> standing seam sheet<br />

Rockwool insulation<br />

Aluminium ST Clip with thermal barrier pad<br />

Vapour control layer<br />

Cement board<br />

Rockwool insulation<br />

Top hat<br />

Structural decking<br />

36

<strong>Kalzip</strong> ® <strong>Systems</strong><br />

Project: Foshan lignan Pearl Stadium, China<br />

Architect:Pan Weijiang, Architectural Design &<br />

Research Institute of Guangdong Province<br />

37

<strong>Kalzip</strong> ® <strong>Systems</strong><br />

<strong>Kalzip</strong><br />

Nature Roof ®<br />

A robust and<br />

sustainable<br />

green roof<br />

system<br />

38

<strong>Kalzip</strong> ® <strong>Systems</strong><br />

The <strong>Kalzip</strong> Nature Roof ® is unique<br />

both in terms of its construction and design<br />

There is nothing to compare with<br />

the fascinating wonders of nature. In<br />

this day and age, the preservation of our<br />

natural environment has become more<br />

important that ever before. <strong>Kalzip</strong> ® offers a<br />

perfectly balanced and complete solution –<br />

it not only enhances the aesthetic appeal of<br />

a building, but also provides important<br />

environmental benefits.<br />

The <strong>Kalzip</strong> Nature Roof ® meets high<br />

environmental, technical and design<br />

requirements. This lightweight roofing<br />

system improves thermal insulation and<br />

is kind on resources – essential features for<br />

intelligent and environmentally-friendly<br />

architecture.<br />

The <strong>Kalzip</strong> Nature Roof ® provides<br />

extensive greening and is<br />

low-maintenance. This roofing system<br />

successfully combines environmental<br />

benefits with stunning architectural design.<br />

The Nature Roof provides almost total plant<br />

cover – a natural carpet of colours which<br />

changes with the seasons.<br />

Low-growing, self-regenerating,<br />

drought-resistant sedum plants transform<br />

dreary roofscapes into an oasis of colour.<br />

Sedums are extremely hardy, they can<br />

withstand smoke and exhaust fumes<br />

and are resistant to both frost and wind.<br />

The additional features of the <strong>Kalzip</strong><br />

Nature Roof ® are certainly impressive:<br />

• Significant reduction in the load placed<br />

on the drainage system and time<br />

delayed release of excess rainwater<br />

into the local and domestic drainage<br />

systems.<br />

• Reduced load placed on the drainage<br />

culverts, storage tanks, sewage plants<br />

and rivers.<br />

• Considerable reduction in waste water<br />

and sewage costs.<br />

• Approximately 50% of the rainwater is<br />

stored.<br />

• Approximately 30% of the rainwater<br />

retained by <strong>Kalzip</strong> Nature Roof ® is<br />

returned to the natural cycle by<br />

evaporation.<br />

Left to Right:<br />

Universal Studio, Singapore<br />

• Improved oxygen levels, improved<br />

microclimate and air humidity in the<br />

area surrounding the building.<br />

• Absorption of dust and pollution<br />

such as CO 2 .<br />

• Thermal and mechanical protection<br />

against the effects of temperature,<br />

weather and radiation.<br />

• Improvement of sound insulation,<br />

internal and external noise is reduced.<br />

• Improved thermal insulation and<br />

room climate throughout the year.<br />

• Temperature peaks are levelled out and<br />

temperature variations caused by<br />

temperature fluctuations are reduced.<br />

• Creates a more attractive and<br />

comfortable place in which to live<br />

and work.<br />

• Reduced temperature-related<br />

deformation processes which affect<br />

components.<br />

• Increases the value of the building.<br />

• Provides an ecological balance in the<br />

face of increasing urbanisation.<br />

Product advantages<br />

• The Nature Roof is constructed<br />

directly onto the <strong>Kalzip</strong> ® profile<br />

panels without the need for<br />

additional sealing work.<br />

• The aluminium surface offers lasting<br />

protection against rooting and<br />

moisture penetration.<br />

• The complete modular package<br />

features a highly economical,<br />

modular design, guaranteeing<br />

quick and easy installation.<br />

• Nature Roof offers the same level<br />

of planning security, ease of handling<br />

and recognised performance<br />

characteristics as you would expect<br />

from the <strong>Kalzip</strong> ® building system.<br />

• Anti-slip devices ensure that even<br />

sloping or curved roofs can be<br />

landscaped.<br />

• The roof still acts as a lightening<br />

conductor.<br />

• All components are environmentally<br />

friendly and can be recycled.<br />

• Uniform planning – even if only<br />

sections of a roof are to be<br />

landscaped.<br />

• <strong>Kalzip</strong> ® can be easily converted into<br />

a Nature Roof, by taking into account<br />

the static requirements.<br />

• When the greenery has been<br />

removed, <strong>Kalzip</strong> ® makes an<br />

excellent, attractive roof covering.<br />

• The <strong>Kalzip</strong> ® aluminium profiles offer a<br />

high level of protection against<br />

mechanical damage of the roof during<br />

installation of the Nature Roof<br />

components.<br />

• <strong>Kalzip</strong> ® is resistant to flying sparks<br />

and radiant heat. These properties<br />

are maintained if the corresponding<br />

installation requirements and local<br />

construction regulations are<br />

followed.<br />

39

<strong>Kalzip</strong> ® <strong>Systems</strong><br />

Project: Jalan Besar Stadium, Singapore<br />

Architect: SAA Partnership

<strong>Kalzip</strong> ® <strong>Systems</strong><br />

Components and<br />

accessories<br />

<strong>Kalzip</strong> components and accessories are specially<br />

designed to meet the exacting requirements of<br />

discerning architects and planners. Perfectly<br />

matched system components and a comprehensive<br />

range of accessories provide the ideal complement<br />

to <strong>Kalzip</strong>'s unlimited design potential.<br />

Visible elements can be adapted to match the<br />

individual hue of the profiles or the surface of the<br />

profiled sheets to produce a synergistic harmony<br />

with the roof and wall cladding surfaces. The<br />

materials are manufactured according to the most<br />

stringent technical standards, with regards to<br />

longevity, ease of handling, installation safety<br />

and recyclability.<br />

<strong>Kalzip</strong> components and accessories feature the<br />

renowned and outstanding quality of <strong>Kalzip</strong><br />

products - performance and reliability right through<br />

to the very last detail. Coupled with compliance with<br />

the current regulations and relating to the thermal<br />

insulation of building envelopes, the required fire<br />

protection class and the relevant industrial norms.<br />

41

<strong>Kalzip</strong> ® <strong>Systems</strong><br />

<strong>Kalzip</strong> Clips<br />

Advanced E Clip<br />