The Current Situation and Challenge of Biomass Gasification ...

The Current Situation and Challenge of Biomass Gasification ...

The Current Situation and Challenge of Biomass Gasification ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

11/12/2012<br />

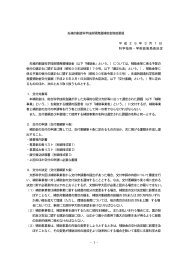

<strong>The</strong> <strong>Current</strong> <strong>Situation</strong> <strong>and</strong> <strong>Challenge</strong> <strong>of</strong><br />

<strong>Biomass</strong> <strong>Gasification</strong> System<br />

with Rotary Kiln<br />

K. Sasauchi<br />

Environmental & <strong>Biomass</strong><br />

Engineering Dept. R&D Center<br />

Chugai Ro Co., Ltd.<br />

1

<strong>The</strong> kind <strong>of</strong> forms <strong>of</strong><br />

renewable energy<br />

Method<br />

Wind Power<br />

Hydro Power<br />

PV<br />

Geothermal power<br />

Energy form<br />

Electric<br />

Electric<br />

Electric<br />

Electric<br />

<strong>Biomass</strong> Electric・Heat・Liqu<br />

fuel ・Chemicals<br />

<strong>Biomass</strong> can be changed<br />

not only electric but also many kind <strong>of</strong> forms<br />

2

Contents<br />

We provide:<br />

Background in Japan<br />

Motivation <strong>of</strong> development<br />

<strong>Current</strong> situation <strong>of</strong> <strong>Biomass</strong> gasifire in Japan<br />

Our developing Rotary Kiln type gasifier<br />

Applied for rubble <strong>of</strong> earthquake disaster<br />

Conclusion<br />

3

Background<br />

<strong>Biomass</strong> resources are widely dispersed,<br />

so it costs a lot to collect a large amount <strong>of</strong> biomass<br />

Small-scale gasification system is desirable for on-site use.<br />

Downdraft gasifiers<br />

are <strong>of</strong>ten used for small-scale in Europe.<br />

It is compact<br />

<strong>and</strong> product gas contains little amount <strong>of</strong> tar.<br />

But it needs uniform size <strong>of</strong> biomass for successful operation<br />

<strong>and</strong> cannot treat unutiized biomass (bark, bamboo, grass).<br />

4

Wood chip<br />

for DownDraft Gasifire<br />

Scraps from Lumber<br />

Regular size with dry<br />

Paper company is using for pulp in Japan<br />

EUR80 / ton<br />

5

Motivation<br />

In Japan, there is currently a strong dem<strong>and</strong><br />

for fuel flexible gasifiers, that are able to convert biomass<br />

difficult to treat (bark, bamboo, grass etc.).<br />

bark bamboo grass<br />

We started the development <strong>of</strong> Rotary Kiln gasifier<br />

supported by NEDO project in 2003<br />

6

<strong>Current</strong> situation <strong>of</strong> biomass gasification<br />

plant for electrical generation in Japan<br />

300kW Downdraft (2010) TSK<br />

180kW Rotary Kiln (2013) ChugaiRo<br />

2000kW Updraft (2008) JFEE<br />

175kW Downdraft (2006) KHI<br />

Foreign License<br />

3000kW (2014) JBEC<br />

180kW Rotary Kiln (2006) ChugaiRo<br />

35kWDowndraft (2010) Yanmer<br />

250kW EB (2011) MAFF<br />

330kW Rotary Koln (2012) ChugaiRo<br />

2000kW Updraft (2007) JFEE<br />

150kW CFB (2007) KHI<br />

130kW Downdraft (2005) TSK<br />

175kW Downdraft (2009) KHI<br />

7

Fixed bed type Direct Gasifiers<br />

Updraft Type Gasifier<br />

Downdraft Type Gasifier<br />

<strong>Biomass</strong><br />

<strong>Biomass</strong><br />

<strong>The</strong>rmal decomposition<br />

gas +tar<br />

Air<br />

Reduced zone<br />

Combustion<br />

Zone<br />

Air<br />

Air<br />

Combustion<br />

Zone<br />

Reduced zone<br />

Air<br />

<strong>The</strong>rmal decomposition<br />

gas +tar<br />

Carbide<br />

Carbide<br />

8

Demonstration Plant <strong>of</strong> Stirling<br />

Engine<br />

Aichi Energy Park<br />

Owner:Chubu Electric Power Co.<br />

Constructor:ChugaiRo<br />

OutPut Power:30kW Eff:25%<br />

Fuel :Wood chip<br />

Type <strong>of</strong> Furnace:Direct fired<br />

Circulation Combustion<br />

Heat Exchanger<br />

Stirling Engine from DTU<br />

Overview <strong>of</strong> Plant<br />

9

間 接 式 木 質 バイオマスガス 発 生 の 原 理<br />

System <strong>of</strong> Indirect woody biomass gasification<br />

木 質 バイオマス<br />

Woody biomass<br />

Test 試 験 tube 管<br />

Combustible 可 燃 性 ガス Gas<br />

External アルコールランプ Heat Source<br />

10

Gasifier with externally heating kiln<br />

<strong>Biomass</strong><br />

<strong>The</strong>rmal decomposition<br />

gas +tar<br />

Hot Air<br />

Char/Ash<br />

Burning<br />

char<br />

Ash<br />

11

●External heating type multi-chamber<br />

rotary kiln<br />

12

Woody Chip<br />

Indirect gasification<br />

System <strong>of</strong> <strong>Gasification</strong><br />

Hot Gas<br />

Product gas<br />

Oxygen<br />

Reforming Gas<br />

Steam<br />

<strong>The</strong>rmal<br />

decomposition<br />

Shift<br />

reaction<br />

Combustible<br />

Gas<br />

Reformer<br />

Combustible<br />

Gas<br />

+<br />

Gasifier:External heating kiln<br />

Residuals(Char +Ash)<br />

Tar<br />

Removing tar by high<br />

temperature (1100℃)<br />

860℃<br />

200℃ <strong>The</strong>rmal decomposition<br />

Shift reaction<br />

約 1.5h<br />

13

Great East Japan Earthquake<br />

In Minamisanriku Town Miyagi<br />

612 people were dead<br />

226 people are missing<br />

3316 houses were destroyed<br />

<strong>The</strong> generated amount <strong>of</strong> rubble in<br />

this disaster is 1.8 million tons<br />

Town hall Feb.2012 Foundation <strong>of</strong> the house 14

<strong>Gasification</strong> <strong>and</strong> Co-generation Plant<br />

in Minamisannriku Miyagi Pref. Japan<br />

Input <strong>of</strong> <strong>Biomass</strong>:<br />

830 kg/h(50% moisture content)<br />

20 t/day<br />

Generation Capacity: 330kW efficiency 18%<br />

Hot water production:<br />

1980MJ/h[550kW]efficiency 30%<br />

Operation Started: Sep. 2012<br />

15

Waste<br />

Gasifire<br />

Waste<br />

incinerator<br />

Temporary<br />

storage <strong>of</strong><br />

waste<br />

Overview <strong>of</strong> disaster waste treatment<br />

plant in Minamisanriku<br />

16

Metal in the rubble<br />

<strong>Biomass</strong> selected from the rubble<br />

17

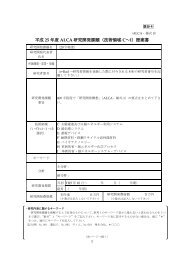

Property <strong>of</strong> chips for materials<br />

Unit<br />

Measurement<br />

Values from<br />

technical<br />

analysis<br />

Values from<br />

elemental<br />

analysis<br />

Moisture<br />

content<br />

wet% 64<br />

Volatile matter dry% 83.5<br />

Fixed carbon dry% 13.2<br />

Ash dry% 0.3<br />

C dry% 46<br />

H dry% 6.1<br />

N dry% 0.2<br />

O dry% 46<br />

T-S dry% 0.22<br />

T-Cl dry% 0.39<br />

Na<br />

K<br />

mg/kgdry<br />

mg/kgdry<br />

360<br />

1500<br />

Higher calorific value J/g 19200<br />

18

Schematic Flow Diagram<br />

Vent<br />

Gas Reformer<br />

Flare Stuck<br />

Vent<br />

Storage<br />

140m3<br />

Dryer<br />

Oxygen<br />

Filter<br />

Gas Holder<br />

Gasifier<br />

Gas Cooler<br />

Receiving Hopper<br />

Char<br />

Water<br />

Tank<br />

Metal or<br />

Others<br />

Hot Gas F’ce<br />

Drain<br />

Heat Exchanger<br />

Gas Engine Generator<br />

19

Differential in the composition <strong>of</strong> the produced gas<br />

<strong>Gasification</strong> at 850℃ <strong>Gasification</strong> at 700℃<br />

H 2 : 48%<br />

H 2 : 28%<br />

CO: 26%<br />

CO: 30%<br />

CO: 2 17%<br />

CO: 2 25%<br />

CH 4 : 8%<br />

CH 4 : 13%<br />

LCV 2,615 kcal/m3NLCV 3,233 kcal/m3N<br />

40℃ or less<br />

40℃ or less<br />

Relative humidity Relative 80%<br />

humidity 80%<br />

or less<br />

or less<br />

20

Result <strong>of</strong> <strong>Gasification</strong> Test<br />

Water<br />

20%<br />

Water<br />

20%<br />

Gas<br />

99%<br />

Solid 860℃<br />

(Continuous)<br />

80%<br />

Gas<br />

85%<br />

Solid 700℃<br />

(Continuous)<br />

80%<br />

Residual<br />

1%<br />

Residual<br />

15%<br />

Material<br />

(Wood Chip)<br />

Producer<br />

Material<br />

(Wood Chip)<br />

Producer<br />

21

Result <strong>of</strong> <strong>Gasification</strong> Test<br />

Outlet <strong>of</strong><br />

gasifier<br />

Outlet <strong>of</strong><br />

Refromer<br />

Gas volume wet m 3 N/h 348 269<br />

dry m 3 N/h 116 130<br />

Gas temperature o<br />

C 650 474<br />

Moisture content vol% 66.7 51.7<br />

Gas components CO 2<br />

vol% 20 31<br />

Calorific value (lower) MJ/m 3<br />

CO vol% 31 25<br />

H 2<br />

vol% 30 36<br />

CH 4<br />

vol% 13.6 7.4<br />

C 2<br />

H 4<br />

vol% 3.1 0.2<br />

C 2<br />

H 6<br />

vol% 0.3

Change <strong>of</strong> Calorific <strong>and</strong> volume<br />

Calorific value <strong>of</strong> the<br />

gas (MJ/m<br />

3 N)<br />

12<br />

250<br />

10<br />

200<br />

8<br />

150<br />

6<br />

4<br />

100<br />

2<br />

50<br />

0<br />

0<br />

0 30 60 90 120 1500 30 60 90 120 150<br />

Time (minutes)<br />

Time (minutes)<br />

Gas volume (m<br />

3 /h)<br />

Change in the calorific value <strong>of</strong><br />

gas with time<br />

Change in the gas<br />

volume with time<br />

23

<strong>The</strong>rmal reforming <strong>of</strong> tar<br />

Measured at the exit <strong>of</strong> reforming unit<br />

Time 10:09 10:31 11:02 11:4<br />

Reforming temp.(℃) 715 867 1200< 1079<br />

Oxygen (m3N/h) 7 8.77 9.02 14<br />

Tar in alcohol solvent<br />

24

Middle Gas Engine for<br />

generator<br />

Type<br />

Cylinder<br />

Displacement<br />

Power<br />

MAN<br />

V12<br />

19L<br />

Compression ratio 11<br />

350kW at Natural Gas 180kW at<br />

Pyrolysis Gas<br />

25

Small Gas Engine for<br />

generator<br />

Type<br />

2GR-FE(Toyota)<br />

Cylinder V6<br />

Displacement 3.456L<br />

Power<br />

30kW at Pyrolysis Gas<br />

Compression ratio 10.8<br />

HARRIER(TOYOTA)<br />

We try to use car engine for power generation<br />

26

Connect to diesel<br />

generator<br />

180kW<br />

<strong>Gasification</strong> Plant<br />

30kW×5<br />

500kW Diesel<br />

To other plant<br />

27

Conclusion<br />

1. Rotary kiln gasifire system is effective for<br />

gasification <strong>of</strong> biomass <strong>of</strong> irregular size<br />

2. Tar can be removed completely by thermal<br />

reforming<br />

3. <strong>Biomass</strong> power generation is not able to<br />

follow the electrical load variation, but it may<br />

be based by the generator connected to the<br />

emergency power system, even in no grid<br />

such as disaster area<br />

4. A motor vehicle engine can be used for<br />

biomass power generation<br />

28