Optical Dissolved-Oxygen - Measurement Specialties, Inc.

Optical Dissolved-Oxygen - Measurement Specialties, Inc.

Optical Dissolved-Oxygen - Measurement Specialties, Inc.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Eureka 2 <strong>Optical</strong> <strong>Dissolved</strong>-<strong>Oxygen</strong> Sensor (HDO)<br />

Range: 0 to 20 mg/l<br />

0 to 200% saturation<br />

Linearity: ±0.2 mg/l and ±2% saturation<br />

Resolution: 0.01 mg/l and 0.1% saturation<br />

Units: mg/l (ppm), % saturation<br />

Calibration: one (air-saturated water) or<br />

two (air-saturated water and zero) points<br />

Maintenance: occasional cleaning; replace sensor<br />

tip approximately two - three years<br />

Sensor Life: 5+ years<br />

Sensor Type: optical sensor, lifetime method<br />

Pressure Limit: 200 meters of water<br />

Note: The specifications above apply to Eureka’s lifetime-based sensor; the range for<br />

the intensity-based sensor (see picture below) is 0 – 50 mg/l.<br />

What is dissolved oxygen?<br />

Liquid water is loose matrix of water molecules. If water without oxygen comes into contact with a source of oxygen, such<br />

as the atmosphere, then oxygen will slowly move into the gaps in the water-molecule matrix. That oxygen is called<br />

dissolved oxygen (DO); it’s the same thing as dissolving table salt in water. <strong>Oxygen</strong> dissolved in water comes from the<br />

atmosphere and/or photosynthetic organisms (algae) in the water.<br />

Why would I want to measure dissolved oxygen in my lake, river, wetland, estuary, or aquifer?<br />

Like humans, fish and other aquatic animals must breathe oxygen to live, and they are adapted to breathe oxygen<br />

dissolved in the water instead of oxygen in the atmosphere. Game fish, such as trout, require high DO levels; rough fish,<br />

such as carp, can exist at lower DO levels. Fish kills are often caused by low DO levels, which are often triggered,<br />

ironically, by decomposition of the algae that had been adding oxygen to the water before death.<br />

DO also influences basic water chemistry. Highly oxygenated waters favor the oxidized form of chemicals; poorly<br />

oxygenated waters favor the reduced form of chemicals. For instance, oxygenated waters favor sulfur in the form of<br />

sulfate, SO4, while deoxygenated waters favor sulfur in the form of hydrogen sulfide (H2S). Sulfate is a benign<br />

substance, but hydrogen sulfide is a poison.<br />

Near-zero DO levels are often found in sediment accumulated at the bottom of a water body. This chemically reducing<br />

realm helps lock nutrients and metals into the sediment.<br />

And, changes in long-term DO trends can signal the need for more detailed chemical study of the water and its<br />

contamination sources.<br />

Eureka 2 HDO Sensor www.meas-spec.com September 2012<br />

2113 Wells Branch, Suite 4400, Austin TX 78728 512-302-4333 WQ.sales@meas-spec.com

Eureka 2 <strong>Optical</strong> <strong>Dissolved</strong>-<strong>Oxygen</strong> Sensor (HDO)<br />

How is DO measured?<br />

There are two types of sensors commonly used to measure DO. The traditional Clark Cell consists of two electrodes<br />

surrounded by a water-based electrolyte solution and covered with an oxygen-permeable membrane. As oxygen crosses<br />

the membrane to dissolve in the electrolyte, it is consumed in a chemical reaction which generates a small electrical<br />

current between the two electrodes. That current is directly proportional to the amount of oxygen in the water sample.<br />

This method is further described in Standard Methods 4500-O G.<br />

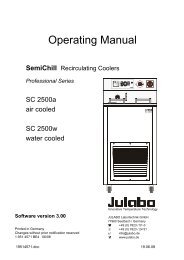

Eureka’s Clark Cell DO Sensor<br />

A weakness of the Clark Cell is that it consumes oxygen from the water surrounding the sensor; this means that the water<br />

must be replaced either by natural flow or the use of a circulator to prevent the readings from drifting downward. The<br />

Clark Cell has performed will in the field for decades, but is slowly being replaced by optical DO sensors. The latter have<br />

little calibration drift in the field, are not flow-sensitive (no circulator needed), and do not require the occasional membrane<br />

changes that annoy Clark Cell users.<br />

Clark<br />

Cell’s<br />

circulator<br />

Clark Cell<br />

DO sensor<br />

The second type of DO sensor is the optical DO sensor, in which a blue light is directed to an oxygen-active compound<br />

that has been stabilized in an oxygen-permeable polymer. The blue light causes the oxygen-active compound to<br />

fluoresce – i.e. it absorbs energy in the form of blue light and then emits energy as red light. The fluorescence is<br />

quenched by oxygen – that is, the emission of red light is reduced if oxygen molecules are present to interfere with the<br />

oxygen-active compound. The more oxygen present, the smaller the amount of red light produced.<br />

When the polymer sensing surface is exposed to water, oxygen diffuses into the sensing surface according to the amount<br />

(“partial pressure”) of oxygen in the water. Thus, the amount of red light received by the sensor is directly relatable to the<br />

amount of oxygen in the water. The red light signal is calibrated to the proper DO units.<br />

Despite its considerably higher cost, the optical sensor is often favored over the Clark Cell because the optical sensors<br />

have little calibration drift in the field, are not flow-sensitive (no circulator needed), and do not require the occasional<br />

membrane changes that annoy Clark sensor users.<br />

Eureka 2 HDO Sensor www.meas-spec.com September 2012<br />

2113 Wells Branch, Suite 4400, Austin TX 78728 512-302-4333 WQ.sales@meas-spec.com

Eureka 2 <strong>Optical</strong> <strong>Dissolved</strong>-<strong>Oxygen</strong> Sensor (HDO)<br />

The amount of oxygen dissolved in, for instance, a lake or river, depends on several variables. The higher the barometric<br />

pressure, the more oxygen can dissolve in water. And the higher the water temperature, the less oxygen can dissolve in<br />

water.<br />

Eureka’s Intensity-Based<br />

<strong>Optical</strong> DO Sensor<br />

If the water has absorbed as much oxygen as it can for a particular combination of temperature and barometric pressure,<br />

the water is said to be saturated with oxygen. If, on average, no oxygen is moving into the water or out of the water, the<br />

oxygen in the water is said to be in equilibrium with the oxygen in the atmosphere.<br />

<strong>Dissolved</strong> oxygen (DO) is commonly reported in two units. DO concentration is the weight of oxygen dissolved in water,<br />

and is reported in mg/l or ppm. DO percent saturation is the ratio of oxygen actually in the water to the maximum amount<br />

of oxygen that can dissolve in a water sample under the same conditions, and is reported in % saturation.<br />

Clark Cells were traditionally calibrated in water-saturated air, but calibration in air-saturated water is growing in favor.<br />

The latter is done by shaking a half-liter of water in a one-liter container for one minute, and then waiting one minute for<br />

the bubbles to rise to the surface and disappear. The Clark Cell is immersed in that water and given time to stabilize.<br />

With knowledge of the water temperature and the barometric pressure, the instrument can figure out the DO level in the<br />

water because it knows that the water is saturated with oxygen. The instrument sets the Clark Cell reading accordingly.<br />

The Clark Cell can also be calibrated in water with a DO determined by, for instance, a Winkler titration.<br />

<strong>Optical</strong> DO sensors can also be calibrated in air-saturated water, with the same process. Some optical DO sensor<br />

manufacturers recommend that the user also calibrate at zero DO, and some say that zero calibrations are rarely<br />

necessary.<br />

What should I know about DO measurement in the field?<br />

Flow - Clark Cells are sensitive to water flow, but optical sensors are not. Low water flow results in depleted DO near the<br />

active surface of a Clark Cell; this produces falsely low sensor readings. Traditionally, a sample flow rate of one ft/sec is<br />

required for proper Clark Cell operation. Eureka’s sample circulator provides adequate flow for accurate DO<br />

measurement, and also somewhat reduces biological fouling and insures the measurement is being taken on a<br />

representative sample.<br />

Temperature - Both Clark Cell and optical DO sensors are intrinsically sensitive to changes in temperature, but the<br />

correction for this sensitivity is done automatically by the instrument. The behavior of oxygen in water is also intrinsically<br />

sensitive to changes in temperature. The saturation level of oxygen in water increases with decreasing temperature. If<br />

you have oxygen-saturated water at 25°C and slowly raise the temperature of the water to 30°C, oxygen will leave the<br />

water because hot water won’t hold as much dissolved oxygen as cold water. This phenomenon doesn’t matter to DO<br />

concentration (mg/l) measurements. But it matters to DO saturation (% sat) measurements because % sat relies on<br />

knowledge of a water’s DO saturation point. Fortunately, Eureka instruments automatically compensate for this effect.<br />

Barometric pressure (BP) - If you have oxygen-saturated water at one standard atmosphere (760 mmHg) and slowly<br />

lower the BP to 740 mmHg, oxygen will leave the water because there’s just not enough air pressure to force the oxygen<br />

to stay dissolved. When you calibrate DO, you must tell the instrument the local barometric pressure so that it can<br />

calculate the proper relationship between concentration and saturation. But suppose the barometric pressure changes<br />

after calibration. The concentration readings will be correct, but the saturation readings will not be correct – you must tell<br />

the instrument the new BP so that it can make the proper calculations.<br />

Eureka 2 HDO Sensor www.meas-spec.com September 2012<br />

2113 Wells Branch, Suite 4400, Austin TX 78728 512-302-4333 WQ.sales@meas-spec.com

Eureka 2 <strong>Optical</strong> <strong>Dissolved</strong>-<strong>Oxygen</strong> Sensor (HDO)<br />

This brings up the Austin-to-Denver example. If you calibrate DO in Austin and then take the instrument to Denver, the<br />

concentration will be correct because a mg/l of oxygen is the same in both cities. However, the lower barometric pressure<br />

in Denver means that saturated water there has less oxygen than does saturated water in Austin. So the instrument will<br />

continue to calculate percent saturation based on the saturation level in Austin, not Denver. The percent saturation<br />

reading will be wrong until you tell the instrument the barometric pressure of Denver. Then the instrument would lower its<br />

expectations of oxygen pressure at saturation and provide the correct data.<br />

Salinity - The saturation level of oxygen in water decreases with increasing salinity. If you have oxygen-saturated water at<br />

a salinity of 5 (on the PSS) and slowly raise the salinity of the water to 30, oxygen will leave the water because salty water<br />

can’t hold as much dissolved oxygen as can pure water because salt ions are clogging up the spaces in the watermolecule<br />

matrix normally available for oxygen molecules. This phenomenon doesn’t matter to DO concentration (mg/l)<br />

measurements. But it matters to DO saturation (% sat) measurements because % sat relies on knowledge of a water’s<br />

DO saturation point, and that saturation point falls as salinity rises. Fortunately, Eureka instruments with conductivity<br />

sensors calculate salinity, and compensate the DO readings accordingly.<br />

The length of time that DO sensors operate well in the field is influenced by the drift characteristics of the sensor, and by<br />

sensor fouling. <strong>Optical</strong> sensors are said to have much lower drift than Clark Cells, but there is little empirical evidence in<br />

field deployments to quantify any difference in deployment times.<br />

Fouling - Clark Cells are sensitive to passive foulants, i.e. material in the water that neither consumes nor produces<br />

oxygen. When, for instance, silt accumulates on the Clark Cell membrane, the rate at which oxygen passes through the<br />

membrane is reduced. Not knowing any better, the instrument reports an errantly low DO reading. <strong>Optical</strong> DO sensors,<br />

however, are not so sensitive to passive foulants because they do not consume oxygen and so do not rely so much on<br />

unimpeded oxygen movement.<br />

However, optical DO sensors are more sensitive to active foulants, i.e. material in the water that produces and/or<br />

consumes oxygen. When, for instance, photosynthetic algae accumulate on the optical sensor, the sensor tends to report<br />

the DO associated with the algae colony, not the DO of the bulk water sample. This causes the DO reading to be errantly<br />

high during the sunlight hours when the algae produces oxygen, and errantly low during the night hours when the algae<br />

consumes oxygen.<br />

Response time - When lowering a Manta 2 from the air into low-DO waters, the Clark Cell especially takes time to reach a<br />

stable reading, particularly in cold waters. In most situations, the DO reading will be within specifications within 2 minutes,<br />

though more accurate readings can be achieved by waiting at least 5 minutes. In monitoring mode, this is less of an<br />

issue, since the sensors reach equilibration with the sample, and natural DO levels are unlikely to go through large, rapid<br />

step changes.<br />

Maintenance - <strong>Optical</strong> dissolved-oxygen sensor maintenance is nothing more than occasionally cleaning the sensing<br />

surface (the red material; about a centimeter diameter) with a soft cloth and soapy water.<br />

Clark Cell maintenance is little more than refilling its electrolyte and replacing the membrane. There should be no bubbles<br />

in the electrolyte, and the membrane should be taut with no wrinkles or holes.<br />

How does Eureka’s DO measurement compare with the competition?<br />

Most Clark Cells are similar in performance, although Eureka seems to spend more time checking for flow sensitivity and<br />

response time. YSI has a clever adaptation, called the Rapid-Pulse sensor, which largely eliminates the need for a<br />

circulator – however, that sensor is reported to require considerable maintenance, and may present an error of up to -5%<br />

or reading in still waters.<br />

There is considerable discussion about the difference between “lifetime” and “intensity” types of optical Do sensors,<br />

mostly driven by Hach (Hydrolab) because they were the first to market a lifetime sensor. There are some interesting<br />

technical differences between the lifetime and intensity methods, but no one has presented a convincing case that one is<br />

better than the other in field measurements. Eureka is the only manufacturer to offer both the lifetime sensor (we call ours<br />

the “Hamilton”) and the intensity sensor (we call ours the “Insite”). Both appear to work quite well in the field, but the<br />

Insite has the advantage of never needing its membrane cap replaced. All other optical DO sensors – Hydrolab, YSI, In-<br />

Situ, and Eureka’s Hamilton – require that the cap be replaced annually, at a cost of between $200 and $300.<br />

Eureka 2 HDO Sensor www.meas-spec.com September 2012<br />

2113 Wells Branch, Suite 4400, Austin TX 78728 512-302-4333 WQ.sales@meas-spec.com

Eureka 2 <strong>Optical</strong> <strong>Dissolved</strong>-<strong>Oxygen</strong> Sensor (HDO)<br />

Eureka’s Insite sensor will thus save you $1000 over a five-year instrument life. The Insite sensor is pretty much<br />

bulletproof (it was designed for work in waste-water sludge pits), and has a typical lifetime of over seven years. Its single<br />

disadvantage is that it is somewhat larger tha<br />

n other optical DO sensors.<br />

TEXAS OFFICE<br />

NORTH AMERICA<br />

HEADQUARTERS<br />

<strong>Measurement</strong> <strong>Specialties</strong>, <strong>Inc</strong>.<br />

2113 Wells Branch Parkway<br />

Suite 4400<br />

Austin, TX 78728<br />

USA<br />

Tel: 1-512-302-4333<br />

Fax: 1-512-251-6842<br />

Sales: WQ.sales@meas-spec.com<br />

<strong>Measurement</strong> <strong>Specialties</strong>, <strong>Inc</strong>.<br />

1000 Lucas Way<br />

Hampton, VA 23666<br />

USA<br />

Tel: 1-757-766-1500<br />

Fax: 1-757-766-4297<br />

Toll Free: 1-800-745-8008<br />

Sales: WL.sales@meas-spec.com<br />

The information in this sheet has been carefully reviewed and is believed to be accurate; however, no responsibility is assumed for inaccuracies. Furthermore, this<br />

information does not convey to the purchaser of such devices any license under the patent rights to the manufacturer. <strong>Measurement</strong> <strong>Specialties</strong>, <strong>Inc</strong>. reserves the right<br />

to make changes without further notice to any product herein. <strong>Measurement</strong> <strong>Specialties</strong>, <strong>Inc</strong>. makes no warranty, representation or guarantee regarding the suitability of<br />

its product for any particular purpose, nor does <strong>Measurement</strong> <strong>Specialties</strong>, <strong>Inc</strong>. assume any liability arising out of the application or use of any product or circuit and<br />

specifically disclaims any and all liability, including without limitation consequential or incidental damages. Typical parameters can and do vary in different applications.<br />

All operating parameters must be validated for each customer application by customer’s technical experts. <strong>Measurement</strong> <strong>Specialties</strong>, <strong>Inc</strong>. does not convey any license<br />

under its patent rights nor the rights of others.<br />

Eureka 2 HDO Sensor www.meas-spec.com September 2012<br />

2113 Wells Branch, Suite 4400, Austin TX 78728 512-302-4333 WQ.sales@meas-spec.com