pdf/L500-liquid ring vacuum pumps and compressors.pdf

pdf/L500-liquid ring vacuum pumps and compressors.pdf

pdf/L500-liquid ring vacuum pumps and compressors.pdf

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

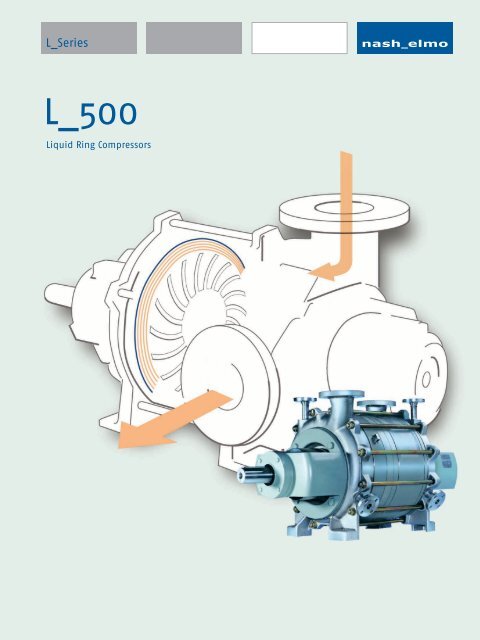

L_Series<br />

L_500<br />

Liquid Ring Compressors

L_500 Compression of process gases<br />

In 2002 The Nash Enginee<strong>ring</strong> Company in the USA <strong>and</strong> elmo<br />

<strong>vacuum</strong> technology GmbH, a Siemens subsidiary in Germany,<br />

united to form nash_elmo Industries.<br />

The L_500 <strong>liquid</strong> <strong>ring</strong> <strong>compressors</strong> were created specifically for the<br />

chemical <strong>and</strong> petrochemical processing industries. They combine<br />

the highest st<strong>and</strong>ard of reliability with a new level of ingenuity.<br />

nash_elmo utilizes advanced design technologies to achieve<br />

optimum capability.<br />

The multidisciplinary design process relied on input from R&D,<br />

manufactu<strong>ring</strong>, marketing <strong>and</strong> most importantly our customers –<br />

the chemical process engineers. The result: a revolutionary line<br />

of <strong>compressors</strong> tough enough to be br<strong>and</strong>ed nash_elmo.<br />

L_500 <strong>compressors</strong> at final inspection<br />

Advantages at a glance:<br />

■ Wide range of gases h<strong>and</strong>led<br />

■ One-stage or two-stage compression<br />

up to 2,600 scfm (4,400 m 3 /h)<br />

■ Pressure capability up to 175 psig (12 bar g)<br />

■ Low temperature compression<br />

■ High reliability<br />

■ Long life cycle<br />

■ High operational safety<br />

■ Robust, low maintenance<br />

Main applications:<br />

■ Chlorine compression<br />

■ Hydrogen compression<br />

■ Vinyl chloride<br />

■ Pulp <strong>and</strong> paper bleaching<br />

process with ozone<br />

■ Recovery of hydrocarbons<br />

e.g. flaregas or gasoline vapors<br />

■ Acetylene compression<br />

… <strong>and</strong> many others<br />

2 nash_elmo Industries L_500

nash_elmo compressor capability chart<br />

Discharge pressure psig<br />

atm 40 80 120 160 175<br />

100,000<br />

m 3 /h<br />

scfm<br />

Suction capacity<br />

28,800<br />

additional models<br />

17,000<br />

9,000<br />

10,000<br />

2,600<br />

2,000<br />

1,500<br />

L_500 models<br />

1,000<br />

1,000<br />

500<br />

160<br />

atm 2 4 6 8 10 12 14<br />

Discharge pressure<br />

bar g<br />

The right design<br />

nash_elmo designs <strong>and</strong> manufactures <strong>liquid</strong> <strong>ring</strong> <strong>compressors</strong> cove<strong>ring</strong> a<br />

wide range of capacities up to 17,000 scfm (28,800 m 3 /h) <strong>and</strong> pressures<br />

up to 175 psig (12 bar g). Our <strong>liquid</strong> <strong>ring</strong> design enables low temperature<br />

gas compression, ideal for h<strong>and</strong>ling many process gases, including<br />

explosive mixtures.<br />

The right materials<br />

Material choices include cast iron, ductile iron, steel <strong>and</strong> stainless steel,<br />

with other materials available on special request, ensu<strong>ring</strong> the right<br />

metallurgy to h<strong>and</strong>le most highly aggressive <strong>and</strong> corrosive vapors, as well.<br />

Single, double, <strong>and</strong> gas lubricated shaft seals are also available.<br />

The right protection<br />

nash_elmo L_500 <strong>compressors</strong> are built to ISO 9001:2000 st<strong>and</strong>ards. Most<br />

are also ATEX certified in accordance with guideline 94/9/EG, category 1 <strong>and</strong> 2.<br />

nash_elmo Industries L_500 3

L_500 Performance at a glance<br />

Features<br />

Benefits<br />

Rugged design<br />

High reliability<br />

Low temperature compression Ability to h<strong>and</strong>le explosive <strong>and</strong><br />

flammable gases<br />

Liquid <strong>ring</strong><br />

Low maintenance/vibration<br />

Many material options Ability to h<strong>and</strong>le corrosive gases<br />

Wide variety of seal options Meets process <strong>and</strong> safety needs<br />

ATEX certified<br />

High safety st<strong>and</strong>ards<br />

100% performance tested Troublefree startup <strong>and</strong> operation<br />

Backed by 2 year warranty Peace of mind<br />

<strong>and</strong> over 100 years of <strong>vacuum</strong><br />

<strong>and</strong> compressed gas experience<br />

We design <strong>and</strong> develop solutions engineered<br />

to your individual needs. Contact us for further details.<br />

4 nash_elmo Industries L_500

Technical specifications: L_500 (models 2BK)<br />

D<br />

C<br />

A<br />

B<br />

Model A B C D Suction <strong>and</strong><br />

discharge flange<br />

connections<br />

2BK1 162 1270 380 510 250 DN80 mm<br />

50 15 20 10 3-IN. FLG inches<br />

2BK1 222 1520 510 760 380 DN100 mm<br />

60 20 30 15 4-IN. FLG. inches<br />

2BK1 282 1650 640 890 380 DN125 mm<br />

65 25 35 15 5-IN. FLG. inches<br />

2BK1 332 2160 760 1020 510 DN150 mm<br />

85 30 40 20 6-IN. FLG. inches<br />

■<br />

■<br />

■<br />

Inlet gas path<br />

Discharge gas path<br />

Operating <strong>liquid</strong><br />

Model Suction capacity V Discharge pressure Power P<br />

m 3 /h scfm bar g psig kW hp<br />

2BK1 162 300 – 900 175 – 530 4 60 50 – 100 65 – 135<br />

2BK1 222 800 – 1600 470 – 940 5 75 50 – 200 65 – 270<br />

2BK1 282 1250 – 2700 735 – 1590 4 60 80 – 250 105 – 335<br />

2BK1 332 2500 – 4000 1470 – 2355 4 60 120 – 350 160 – 470<br />

nash_elmo Industries L_500 6

Technical specifications: L_500 (models 2BG)<br />

C<br />

D<br />

A<br />

B<br />

Model A B C D Suction <strong>and</strong><br />

discharge flange<br />

connections<br />

2BG1 150 1265 380 635 250 DN80 mm<br />

50 15 25 10 3-IN. FLG. inches<br />

2BG1 151 1400 380 635 250 DN80 mm<br />

55 15 25 10 3-IN. FLG inches<br />

2BG1 231 1900 760 890 380 DN125 mm<br />

75 30 35 15 5-IN. FLG. inches<br />

2BG3 189 1270 760 635 250 DN80 mm<br />

50 30 25 10 3-IN. FLG. inches<br />

■<br />

■<br />

■<br />

■<br />

Inlet gas path<br />

Inter stage path<br />

Discharge gas path<br />

Operating <strong>liquid</strong><br />

Model Suction capacity V Discharge pressure Power P<br />

m 3 /h scfm bar g psig kW hp<br />

2BG1 150 200 – 400 120 – 235 10 145 50 – 150 65 – 200<br />

2BG1 151 400 – 800 235 – 470 12 175 75 – 250 100 – 335<br />

2BG1 231 900 – 1800 530 – 1060 9 130 300 – 500 400 – 670<br />

2BG3 189 450 – 750 265 – 440 15 220 50 – 250 65 – 335<br />

nash_elmo Industries L_500 7

Technical specifications:<br />

L_500 (models HP)<br />

Models HP4 thru HP8<br />

C<br />

D<br />

Model HP9<br />

A<br />

A<br />

B<br />

B<br />

C<br />

D<br />

Model A B C D Suction <strong>and</strong><br />

discharge flange<br />

connections<br />

HP4 685 340 250 150 DN50 mm<br />

27 13 10 6 2-IN. FLG. inches<br />

HP6 1090 635 510 280 DN100 mm<br />

43 25 20 11 4-IN. FLG. inches<br />

HP7 1270 760 640 355 DN150 mm<br />

50 30 25 14 6-IN. FLG. inches<br />

HP8 1520 940 890 430 DN200 mm<br />

60 37 35 17 8-IN. FLG. inches<br />

HP9 1520 1400 1015 510 DN250 mm<br />

60 55 40 20 10-IN. FLG. inches<br />

Model Suction capacity V Discharge pressure Power P<br />

m 3 /h scfm bar g psig kW hp<br />

HP4 255 – 350 150 – 205 5.5 80 40 – 75 55 – 100<br />

HP6 750 – 900 440 – 530 5.5 80 90 – 160 120 – 215<br />

HP7 950 – 1700 560 – 1000 5.5 80 180 – 300 240 – 400<br />

HP8 1850 – 2900 1090 – 1705 5.5 80 225 – 450 300 – 605<br />

HP9 2800 – 4250 1650 – 2500 7.6 110 600 – 1000 805 – 1340<br />

nash_elmo Industries L_500 5

Functional principle of an L_500 compressor<br />

Single-stage<br />

The rotor 1 is positioned in the center of the elliptical casing 2. Centrifugal force causes<br />

the seal <strong>liquid</strong> to form a <strong>ring</strong> against the inner surface of the casing 3. The <strong>liquid</strong> is<br />

moving away from the center of the rotor in the inlet area, drawing the gas into the<br />

rotor chambers 4. As these chambers rotate, the <strong>liquid</strong> is pushed back into the chambers,<br />

compressing the gas before exiting at the discharge port 5. The internal forces are<br />

balanced due to the double-acting design, thereby reducing stress on the shaft, bea<strong>ring</strong>s<br />

<strong>and</strong> mechanical seals for longer pump life.<br />

Discharge<br />

2BK models<br />

Inlet<br />

HP models<br />

1 Rotor<br />

2 Casing<br />

3 Liquid <strong>ring</strong><br />

4 Intake port<br />

Inlet<br />

Discharge<br />

5 Discharge port<br />

The brown arrows show the balanced<br />

forces in the compressor.<br />

Two-stage<br />

The rotors 1 are positioned eccentrically in two cylindrical casings 2. Centrifugal force<br />

causes the seal <strong>liquid</strong> to form a <strong>ring</strong> 4 against the inner surface of the casing. The <strong>liquid</strong><br />

is moving away from the center of the rotor in the inlet area, drawing the gas into the<br />

rotor chambers 3. As these chambers rotate, the <strong>liquid</strong> is pushed back into the chambers,<br />

compressing the gas before exiting the first stage 5. The second stage functions in the<br />

same manner, but is rotated 180°, thereby balancing the internal forces. This reduces<br />

stress on the shaft, mechanical seals <strong>and</strong> bea<strong>ring</strong>s, thus extending pump life.<br />

2nd stage 2BG models 1st stage<br />

1 Rotor<br />

2 Casing<br />

3 Intake port<br />

4 Liquid <strong>ring</strong><br />

5 Discharge port<br />

8 nash_elmo Industries L_500

Commitment, reliability <strong>and</strong> worldwide support<br />

For 100 years, we have been assisting our customers in making the right <strong>vacuum</strong><br />

pump or compressor choice. As your enginee<strong>ring</strong> partners, we will provide you with<br />

a nash_elmo performance analysis which includes a review of your particular process<br />

requirements, <strong>and</strong> provides you with alternative means for meeting your process<br />

needs. We will supply enginee<strong>ring</strong> data <strong>and</strong> application information, along with<br />

short- <strong>and</strong> long-term cost comparisons.<br />

Beginning today <strong>and</strong> throughout the life of every nash_elmo system, our engineers<br />

are ready to support you to meet your <strong>vacuum</strong> <strong>and</strong> compressor process tasks.<br />

Factory tested<br />

Before any nash_elmo compressor is shipped out of our factory, it is performance tested<br />

to meet the highest st<strong>and</strong>ards. We st<strong>and</strong> behind our products: every nash_elmo L_500<br />

pump comes with a TWO-YEAR WARRANTY. Our new test bay gives us the capability to<br />

simulate nearly all real operating conditions for <strong>liquid</strong> <strong>ring</strong> <strong>compressors</strong>.<br />

A global service network with local support<br />

nash_elmo maintains service centers strategically located throughout the United States,<br />

Europe <strong>and</strong> Asia. Each center is staffed by specialists with considerable application<br />

know-how. They have original factory replacement parts in stock <strong>and</strong> are equipped<br />

with the tools, fixtures <strong>and</strong> special machinery necessary for pump <strong>and</strong> compressor<br />

repair. The nash_elmo commitment to service extends to its regional distribution centers<br />

<strong>and</strong> retailers. Stocked with inventories of factory parts <strong>and</strong> purchased components,<br />

our distribution centers can deliver <strong>pumps</strong> <strong>and</strong> parts anywhere, any time. We are also<br />

able to service <strong>vacuum</strong> <strong>pumps</strong> <strong>and</strong> <strong>compressors</strong> of other makes <strong>and</strong> models.<br />

A new company, a unified vision<br />

nash_elmo is more than a new company. It is the fusion of global leaders in the<br />

development, design <strong>and</strong> application of <strong>vacuum</strong> <strong>and</strong> compressor system technology.<br />

Our combined resources give us the ability to provide the best solution to any industrial<br />

need virtually anywhere in the world. We are a company with an extensive range of<br />

products <strong>and</strong> services <strong>and</strong> an unmatched reputation for reliability. Because nash_elmo<br />

is a company with the resources to turn the most ambitious vision into reality <strong>and</strong> to<br />

put that vision to work for you.<br />

nash_elmo Industries L_500 9

Other nash_elmo product lines<br />

L_Series:<br />

Liquid Ring Pumps<br />

Robust technology for the highest dem<strong>and</strong>s <strong>and</strong> varied applications<br />

Machines in the L_Series distinguish themselves through low operating<br />

temperatures <strong>and</strong> are suitable for h<strong>and</strong>ling splash water, steam<br />

<strong>and</strong> condensates. They were developed for the toughest applications<br />

<strong>and</strong> can safely <strong>and</strong> reliably extract or compress even explosive gas/<br />

steam mixtures (ATEX-certified). Selection of a suitable operating<br />

<strong>liquid</strong> enables the L_Series <strong>vacuum</strong> <strong>pumps</strong> <strong>and</strong> <strong>compressors</strong> to be<br />

optimally integrated into processes. Thanks to their low operating<br />

costs <strong>and</strong> extensive performance range up to 37,000 m 3 /h<br />

(22,000 cfm), they excel in any application.<br />

G_Series:<br />

V_Series:<br />

D_Series:<br />

Gas Ring Blowers<br />

Vane Pumps<br />

Dry Pumps<br />

nash_elmo Industries<br />

www.nash-elmo.com<br />

info@nash-elmo.com<br />

Corporate Headquarters<br />

Trumbull, CT USA<br />

9 Trefoil Drive<br />

Trumbull, CT 06611-1330<br />

Tel.: +1 800 553 6274<br />

Proven, reliable <strong>and</strong> extremely quiet<br />

Whether <strong>vacuum</strong> <strong>pumps</strong>, <strong>compressors</strong> or systems for conveying air,<br />

gases or air/gas mixtures, the extensive range of products in the<br />

G_Series meets the widest range of requirements. Thanks to their<br />

variable voltage motors, many are usable anywhere in the world<br />

without the need for conversion. In addition to their compact construction,<br />

full UL/CSA certification <strong>and</strong> innovative design, G_Series<br />

<strong>pumps</strong> <strong>and</strong> <strong>compressors</strong> offer a comprehensive power range up to<br />

2,500 m 3 /h (1,470 cfm), maximum power density <strong>and</strong> a wide selection<br />

of accessories, including frequency converters.<br />

Simple design for varied applications<br />

The vane <strong>pumps</strong> in our V_Series are known for their robust design,<br />

easy h<strong>and</strong>ling <strong>and</strong> long service life. Furnished with an extremely<br />

sturdy metal coating as well as installation- <strong>and</strong> service-friendly<br />

plug & play functionality, these high performance machines are<br />

extremely quiet in operation, <strong>and</strong> can meet even the most challenging<br />

industrial dem<strong>and</strong>s while cove<strong>ring</strong> an impressive performance<br />

range up to 4,000m 3 /h (2,350 cfm) <strong>and</strong> 10 bar g (145 psig).<br />

High reliability with low operating costs<br />

The dry-running <strong>vacuum</strong> <strong>pumps</strong> in our D_Series are explosion-proof<br />

<strong>and</strong> were specially developed for production processes involving<br />

sensitive materials. Throughout the entire process, they operate<br />

condensation-free – <strong>and</strong> therefore corrosion-free – because there<br />

are no operating fluids to mix with the process gases. As a result,<br />

discharge gases can simply be collected <strong>and</strong>/or returned to the process.<br />

There are no waste products. In addition, all <strong>pumps</strong> in the D_Series<br />

are highly efficient <strong>and</strong> provide a constant suction capacity over an<br />

extremely wide range of pressures with a performance range up to<br />

to 2,200 m 3 /h (1,300 cfm).<br />

European Headquarters<br />

Nuremberg, Germany<br />

Katzwanger Straße 150<br />

D-90461 Nürnberg<br />

Tel.: +49 911 1454 0<br />

Order-No: VNE:B-PB013-A2-AM<br />

Printed in Germany<br />

Dispo 27801<br />

2238/021 16.0 / 04-2004<br />

© 2004 All rights reserved<br />

HENNIG · Nbg All illustrations are non-binding · All dimensions are approximate. Subject to technical modifications