- Page 1 and 2: POLITECHNIKA WARSZAWSKA WARSAW UNIV

- Page 3: Contents Table of Contents Chapter

- Page 7 and 8: Introduction to surface-mounted mac

- Page 9 and 10: Introduction vector control, which

- Page 11 and 12: Introduction presented and studied.

- Page 13 and 14: Modeling and control modes of PM sy

- Page 15 and 16: Modeling and control modes of PM sy

- Page 17 and 18: Modeling and control modes of PM sy

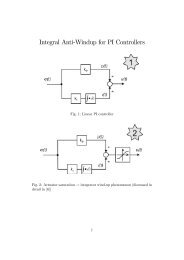

- Page 19 and 20: Modeling and control modes of PM sy

- Page 21 and 22: Modeling and control modes of PM sy

- Page 23 and 24: Modeling and control modes of PM sy

- Page 25 and 26: Modeling and control modes of PM sy

- Page 27 and 28: Modeling and control modes of PM sy

- Page 29 and 30: Modeling and control modes of PM sy

- Page 31 and 32: Modeling and control modes of PM sy

- Page 33 and 34: Modeling and control modes of PM sy

- Page 35 and 36: Modeling and control modes of PM sy

- Page 37 and 38: Modeling and control modes of PM sy

- Page 39 and 40: Voltage source PWM inverter for PMS

- Page 41 and 42: Voltage source PWM inverter for PMS

- Page 43 and 44: Voltage source PWM inverter for PMS

- Page 45 and 46: Voltage source PWM inverter for PMS

- Page 47 and 48: Voltage source PWM inverter for PMS

- Page 49 and 50: Voltage source PWM inverter for PMS

- Page 51 and 52: Voltage source PWM inverter for PMS

- Page 53 and 54: Voltage source PWM inverter for PMS

- Page 55 and 56:

Voltage source PWM inverter for PMS

- Page 57 and 58:

Control methods of PM Synchronous m

- Page 59 and 60:

Control methods of PM Synchronous m

- Page 61 and 62:

Control methods of PM Synchronous m

- Page 63 and 64:

Control methods of PM Synchronous m

- Page 65 and 66:

Control methods of PM Synchronous m

- Page 67 and 68:

Control methods of PM Synchronous m

- Page 69 and 70:

Direct Torque Control with Space Ve

- Page 71 and 72:

Direct Torque Control with Space Ve

- Page 73 and 74:

Direct Torque Control with Space Ve

- Page 75 and 76:

Direct Torque Control with Space Ve

- Page 77 and 78:

Direct Torque Control with Space Ve

- Page 79 and 80:

Direct Torque Control with Space Ve

- Page 81 and 82:

Direct Torque Control with Space Ve

- Page 83 and 84:

Direct Torque Control with Space Ve

- Page 85 and 86:

Direct Torque Control with Space Ve

- Page 87 and 88:

Direct Torque Control with Space Ve

- Page 89 and 90:

Direct Torque Control with Space Ve

- Page 91 and 92:

Direct Torque Control with Space Ve

- Page 93 and 94:

Direct Torque Control with Space Ve

- Page 95 and 96:

Direct Torque Control with Space Ve

- Page 97 and 98:

Direct Torque Control with Space Ve

- Page 99 and 100:

Direct Torque Control with Space Ve

- Page 101 and 102:

Direct Torque Control with Space Ve

- Page 103 and 104:

Direct Torque Control with Space Ve

- Page 105 and 106:

Direct Torque Control with Space Ve

- Page 107 and 108:

Direct Torque Control with Space Ve

- Page 109 and 110:

Direct Torque Control with Space Ve

- Page 111 and 112:

Direct Torque Control with Space Ve

- Page 113 and 114:

Direct Torque Control with Space Ve

- Page 115 and 116:

Direct Torque Control with Space Ve

- Page 117 and 118:

Direct Torque Control with Space Ve

- Page 119 and 120:

Direct Torque Control with Space Ve

- Page 121 and 122:

Direct Torque Control with Space Ve

- Page 123 and 124:

Direct Torque Control with Space Ve

- Page 125 and 126:

Sensorless Speed Direct Torque Cont

- Page 127 and 128:

Sensorless Speed Direct Torque Cont

- Page 129 and 130:

Sensorless Speed Direct Torque Cont

- Page 131 and 132:

Sensorless Speed Direct Torque Cont

- Page 133 and 134:

Sensorless Speed Direct Torque Cont

- Page 135 and 136:

Sensorless Speed Direct Torque Cont

- Page 137 and 138:

Sensorless Speed Direct Torque Cont

- Page 139 and 140:

Sensorless Speed Direct Torque Cont

- Page 141 and 142:

DSP implementation of DTC-SVM contr

- Page 143 and 144:

DSP implementation of DTC-SVM contr

- Page 145 and 146:

DSP implementation of DTC-SVM contr

- Page 147 and 148:

DSP implementation of DTC-SVM contr

- Page 149 and 150:

DSP implementation of DTC-SVM contr

- Page 151 and 152:

DSP implementation of DTC-SVM contr

- Page 153 and 154:

DSP implementation of DTC-SVM contr

- Page 155 and 156:

DSP implementation of DTC-SVM contr

- Page 157 and 158:

DSP implementation of DTC-SVM contr

- Page 159 and 160:

DSP implementation of DTC-SVM contr

- Page 161 and 162:

DSP implementation of DTC-SVM contr

- Page 163 and 164:

DSP implementation of DTC-SVM contr

- Page 165 and 166:

Summary and closing conclusion Chap

- Page 167 and 168:

Appendices APPENDICES A1 Rotor and

- Page 169 and 170:

Appendices ⎡ ⎤ ⎢ 1 0 ⎥ ⎡K

- Page 171 and 172:

Appendices i(t1->t0)+=it1 it1: it1=

- Page 173 and 174:

Appendices A7 PWM technique - six s

- Page 175 and 176:

List of symbol List of symbols Symb

- Page 177 and 178:

References Books and PhD-Thesis 1.

- Page 179 and 180:

References 39. J.-I. Itoh, N. Nomur

- Page 181 and 182:

References 74. N. Ertugrul, P. Acar

- Page 183 and 184:

References 108. D. Świerczyński,

![[TCP] Opis układu - Instytut Sterowania i Elektroniki Przemysłowej ...](https://img.yumpu.com/23535443/1/184x260/tcp-opis-ukladu-instytut-sterowania-i-elektroniki-przemyslowej-.jpg?quality=85)