Direct Torque Control with Space Vector Modulation (DTC-SVM) of ...

Direct Torque Control with Space Vector Modulation (DTC-SVM) of ...

Direct Torque Control with Space Vector Modulation (DTC-SVM) of ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

POLITECHNIKA<br />

WARSZAWSKA<br />

WARSAW UNIVERSITY OF TECHNOLOGY<br />

Faculty <strong>of</strong> Electrical Engineering<br />

ROZPRAWA DOKTORSKA<br />

Ph.D. Thesis<br />

Dariusz Świerczyński, M. Sc.<br />

<strong>Direct</strong> <strong>Torque</strong> <strong>Control</strong> <strong>with</strong><br />

<strong>Space</strong> <strong>Vector</strong> <strong>Modulation</strong> (<strong>DTC</strong>-<strong>SVM</strong>) <strong>of</strong> Inverter-Fed<br />

Permanent Magnet Synchronous Motor Drive<br />

WARSZAWA<br />

2005

WARSAW UNIVERSITY OF TECHNOLOGY<br />

Faculty <strong>of</strong> Electrical Engineering<br />

Institute <strong>of</strong> <strong>Control</strong> and Industrial Electronics<br />

Ph.D. Thesis<br />

M. Sc. Dariusz Świerczyński<br />

<strong>Direct</strong> <strong>Torque</strong> <strong>Control</strong> <strong>with</strong> <strong>Space</strong> <strong>Vector</strong><br />

<strong>Modulation</strong> (<strong>DTC</strong>-<strong>SVM</strong>) <strong>of</strong> Inverter-Fed<br />

Permanent Magnet Synchronous Motor Drive<br />

Thesis supervisor<br />

Pr<strong>of</strong>. Dr Sc. Marian P. Kaźmierkowski<br />

Warsaw, Poland - 2005

Contents<br />

Table <strong>of</strong> Contents<br />

Chapter 1 1<br />

INTRODUCTION<br />

Chapter 2 8<br />

MODELING AND CONTROL MODES OF PM SYNCHRONOUS DRIVES<br />

2.1 Mathematical model <strong>of</strong> PM synchronous motor 8<br />

2.1.1 Voltage and flux-current equations 9<br />

2.1.2 Instantaneous power and electromagnetic torque 17<br />

2.1.3 Mechanical motion equation 22<br />

2.2 Static characteristic under different control modes 25<br />

2.3 Summary 33<br />

Chapter 3 34<br />

VOLTAGE SOURCE PWM INVERTER FOR PMSM SUPPLY<br />

3.1 Introduction 34<br />

3.2 Voltage source inverter (VSI) 35<br />

3.3 <strong>Space</strong> vector based pulse width modulation (PWM) methods 46<br />

3.4 Summary 52<br />

Chapter 4 53<br />

CONTROL METHODS OF PM SYNCHRONOUS MOTOR<br />

4.1 Introduction 53<br />

4.2 Field oriented control (FOC) 54<br />

4.3 <strong>Direct</strong> torque control (<strong>DTC</strong>) 57<br />

4.4 Summary 64<br />

Chapter 5 65<br />

DIRECT TORQUE CONTROL WITH SPACE VECTOR MODULATION<br />

(<strong>DTC</strong>-<strong>SVM</strong>)<br />

5.1 Introduction 65<br />

5.2 Cascade structure <strong>of</strong> <strong>DTC</strong>–<strong>SVM</strong> scheme 66<br />

5.2.1 Digital flux control loop 68<br />

5.2.2 Digital torque control loop 82<br />

5.3 Parallel structure <strong>of</strong> <strong>DTC</strong>–<strong>SVM</strong> scheme 91<br />

5.3.1 Digital flux control loop 92<br />

5.3.2 Digital torque control loop 102<br />

5.4 Speed control loop for <strong>DTC</strong>–<strong>SVM</strong> structure control 113<br />

5.5 Summary 122<br />

Chapter 6 121<br />

DIRECT TORQUE CONTROL WITH SPACE VECTOR MODULATION (<strong>DTC</strong>-<br />

<strong>SVM</strong>) OF PMSM DRIVE WITHOUT MOTION SENSOR<br />

6.1 Introduction 121<br />

6.2 Initial rotor position estimation method 123<br />

6.3 Stator flux estimation methods 127<br />

6.3.1 Overview 127<br />

6.3.2 Current model based flux estimator 127<br />

6.3.3 Voltage model based flux estimator <strong>with</strong> ideal integrator 128

Contents<br />

6.3.4 Voltage model based flux estimator <strong>with</strong> low pas filter 129<br />

6.3.5 Improved voltage model based flux estimator 130<br />

6.4 Electromagnetic torque estimation 132<br />

6.5 Rotor speed estimation methods 132<br />

6.5.1 Overview 132<br />

6.5.2 Back electromotive force (BEMF) technique 133<br />

6.5.3 Stator flux based technique 133<br />

6.6 Summary 136<br />

Chapter 7 137<br />

DSP IMPLEMENTATION OF <strong>DTC</strong>-<strong>SVM</strong> CONTROL<br />

7.1 Description <strong>of</strong> the laboratory test-stand 137<br />

7.2 Steady state behaviour 140<br />

7.3 Dynamic behaviour 143<br />

7.3.1 Flux and torque control loop 143<br />

7.3.2 Speed control loop 151<br />

Chapter 8 161<br />

SUMMARY AND CLOSING CONCLUSIONS<br />

Appendices 163<br />

Picture <strong>of</strong> rotor and stator <strong>of</strong> PMSM machine<br />

Basic transformation<br />

Model <strong>of</strong> PM synchronous motor- SABER<br />

Parameters <strong>of</strong> PMSM machine<br />

Parameters <strong>of</strong> voltage source inverter<br />

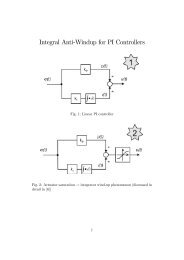

PI speed controller<br />

PWM technique - overmodulation<br />

List <strong>of</strong> Symbols 170<br />

References 172

Introduction<br />

Chapter 1 INTRODUCTION<br />

Recently, an increased interest in application <strong>of</strong> permanent magnet synchronous motors<br />

(PMSM) in speed controlled drives has been observed. This is stimulated mainly by:<br />

• development <strong>of</strong> modern high switching frequency semiconductor power devices (as<br />

for example IGBT modules <strong>of</strong> 5-th generation),<br />

• new rare earth magnetic materials as samarium-cobalt (Sm-Co) or neodymium-ironboron<br />

(Nd-Fe-B),<br />

• specialized digital signal processor (DSP) for AC drive applications <strong>with</strong> integrated<br />

PWM function, A/D converters as well as processing <strong>of</strong> encoder signals (e.g<br />

ADMC401, TMS320FL24XX, TMS320FL28XX).<br />

Synchronous motors <strong>with</strong> an electrically excited rotor winding have a conventional threephase<br />

stator winding (called armature) and an electrically excited field winding on the rotor,<br />

which carries a DC current. The armature winding is similar to the stator <strong>of</strong> induction motor.<br />

The electrically excited field winding can be replaced by permanent magnet (PM) [1]. The use<br />

<strong>of</strong> permanent magnets has many advantages including the elimination <strong>of</strong> brushes, slip rings,<br />

and rotor copper losses in the field winding. It leads to higher efficiency. Additionally since<br />

the copper and iron losses are concentrated in the stator, cooling <strong>of</strong> machines through the<br />

stator is more effective. The lack <strong>of</strong> field winding and higher efficiency results in reduction <strong>of</strong><br />

the machine frame size and higher power/weight ratio.<br />

Figure. 1.1. General classification <strong>of</strong> AC synchronous motors.<br />

1

Introduction<br />

Generally, the permanent magnet AC machines can be classified into two types (Fig.1.1):<br />

trapezoidal type called “brushless DC machine” (BLDCM) and sinusoidal type called<br />

permanent magnet synchronous machine (PMSM). The BLDC machines operate <strong>with</strong><br />

trapezoidal back electromagnetic force (EMF) and require rectangular stator phase current.<br />

The PMSM’s generate sinusoidal EMF and operate <strong>with</strong> sinusoidal stator phase current.<br />

The PMSM can be further divided into two main groups in respect how the magnet bars have<br />

mounted in the rotor [6,7]. In the first group magnets are mounted in the rotor (Fig. 1.2 c-d)<br />

and this type is called interior permanent magnet synchronous motors (IPMSM). The second<br />

group is represented by surface permanent magnet synchronous motors (SPMSM). In the<br />

SPMSM magnet bars are mounted on the rotor surface (Fig. 1.2 a-b).<br />

q<br />

q<br />

SPMSM<br />

S N<br />

S N d<br />

a )<br />

b)<br />

S<br />

N<br />

S<br />

N<br />

d<br />

q<br />

q<br />

IPMSM<br />

S<br />

N<br />

c )<br />

d)<br />

S<br />

N<br />

d<br />

d<br />

Fig. 1.2. The cross section <strong>of</strong> the PMSM rotor shaft and the magnet bars placements:<br />

a),b),c) axial field direction, d) radial field direction.<br />

The magnets can be placed in many ways on the rotor (Fig. 1.2). In radial field fashion the<br />

magnet bars are along the radius <strong>of</strong> the machine and this arrangement provides the highest air<br />

gap flux density, but it has the drawback <strong>of</strong> lower structural integrity and mechanical<br />

robustness. Machines <strong>with</strong> this arrangement <strong>of</strong> magnets are not preferred for high-speed<br />

applications (higher than 3000 rpm). In axial field manner the magnets are placed parallel to<br />

the rotor shaft. This arrangement <strong>of</strong> magnets is much more robust mechanically as compared<br />

2

Introduction<br />

to surface-mounted machine. It makes possible to use IPMSM for higher-speed applications<br />

(contrary to SPMSM’s).<br />

Regardless <strong>of</strong> the fashion <strong>of</strong> mounting the PM, the basic principle <strong>of</strong> motor control is the same<br />

and the differences are only in particularities. An important consequence <strong>of</strong> the method <strong>of</strong><br />

mounting the rotor magnets is the difference in direct and quadrature axes inductance values.<br />

The direct axis reluctance is greater than the quadrature axis reluctance, because the effective<br />

air gap <strong>of</strong> the direct axis is multiple times that <strong>of</strong> the actual air gap seen by the quadrature<br />

axis. As consequence <strong>of</strong> such an unequal reluctance, the quadrature inductance is higher than<br />

direct inductance L q<br />

> L d<br />

. It produces reluctance torque in addition to the mutual torque.<br />

Reluctance torque is produced due to the magnet saliency in the quadrature and the direct axis<br />

magnetic paths. Mutual torque is produced due to the interaction <strong>of</strong> the magnet field and the<br />

stator current. In case where the magnets bars are mounted on the rotor surface the quadrature<br />

inductance is equal direct inductance L q<br />

= L d<br />

, because <strong>of</strong> the same flux paths in d and q axis.<br />

As result the reluctance torque disappears.<br />

Among the main advantage <strong>of</strong> PM machines are [12]:<br />

• high air gap flux density,<br />

• higher power/weight ratio,<br />

• large torque/inertia ratio,<br />

• small torque ripples,<br />

• high speed operation,<br />

• high torque capability (quick acceleration and deceleration),<br />

• high efficiency and high cosφ (low expense for the power supply),<br />

• compact design.<br />

Thanks to this advantages the PMSM’s are usually used in high performance servo drives, in<br />

special applications as computer peripheral equipment, robotics, ect. However, recently the<br />

PMSM are also used as adjustable–speed drives in variety <strong>of</strong> application such as fans, pumps,<br />

compressors, blowers. Another area is automotive application as an alternative drive in hybrid<br />

mode <strong>with</strong> classical engine. The power <strong>of</strong> <strong>of</strong>fered synchronous motors is in the range several<br />

kW to MW.<br />

3

Introduction<br />

The main requirements for high performance PWM inverter-fed PMSM drive can be<br />

formulated as follows:<br />

• operation <strong>with</strong> and <strong>with</strong>out mechanical motion sensor,<br />

• fast flux and torque response,<br />

• available maximum output torque in wide range <strong>of</strong> speed operation region,<br />

• constant switching frequency,<br />

• uni-polar voltage PWM,<br />

• low flux and torque ripples,<br />

• robustness to parameters variation,<br />

• four quadrant operation.<br />

To meet the above requirements, different control methods can be used [3,4,10].<br />

Variable<br />

Frequency<br />

<strong>Control</strong><br />

Scalar based<br />

controllers<br />

<strong>Vector</strong> based<br />

controllers<br />

V/Hz=const<br />

<strong>with</strong> stabilization<br />

loop<br />

Field<br />

Oriented<br />

(FOC)<br />

<strong>Direct</strong> <strong>Torque</strong><br />

<strong>Control</strong><br />

(<strong>DTC</strong>)<br />

PM (rotor)<br />

Flux Oriented<br />

(RFOC)<br />

Stator Flux<br />

Oriented<br />

(SFOC)<br />

<strong>Direct</strong> <strong>Torque</strong><br />

<strong>Control</strong> <strong>with</strong> <strong>Space</strong><br />

<strong>Vector</strong> <strong>Modulation</strong><br />

(<strong>DTC</strong>-<strong>SVM</strong>)<br />

Circular flux<br />

trajectory<br />

(Takahashi)<br />

Figure 1.3 Classification <strong>of</strong> PMSM control methods.<br />

The general classification <strong>of</strong> the variable frequency control for PMSM is presented in Fig. 1.3.<br />

The PMSM control methods can be divided into scalar and vector control. According to [3],<br />

in scalar control, which based on a relation valid for steady states, only the magnitude and<br />

frequency (angular speed) <strong>of</strong> voltage, currents, and flux linkage space vectors are controlled.<br />

Thus, the control system does not act on space vector position during transient. Therefore, this<br />

control is dedicated for application, where high dynamics is not demanded. Contrary, in<br />

4

Introduction<br />

vector control, which is based on relation valid for dynamics states, not just magnitude and<br />

frequency (angular speed), but also instantaneous position <strong>of</strong> voltage, current and flux space<br />

vectors are controlled. Thus, the control system adjust the position <strong>of</strong> the space vectors and<br />

guarantee their correct orientation for both steady states and transients.<br />

The scalar constant V/Hz control for PMSM <strong>with</strong>out damper winding (squire cage) is not<br />

simple as for induction motor. It requires additional stabilization control loop, which can be<br />

provide by feedback from: rotor velocity perturbation, active power or DC-link current<br />

perturbation [9].<br />

The most popular vector control method developed in 70s, known as field oriented control<br />

(FOC) [31] gives the permanent magnet synchronous motor high performance. In this method<br />

the motor equation are transformed in a coordinate system that rotates in synchronism <strong>with</strong><br />

permanent magnet flux. It allows separately and indirectly control flux and torque quantities<br />

by using current control loop <strong>with</strong> PI controllers like in well known DC machine control [3].<br />

In search <strong>of</strong> a simpler and more robust high performance control system in 80s new vector<br />

control called direct torque control (<strong>DTC</strong>) was developed [50]. It was innovative studies at<br />

this time and completely different approach which depart from the idea <strong>of</strong> coordinate<br />

transformation and the analogy <strong>with</strong> DC motor control. It allows direct control flux and torque<br />

quantities <strong>with</strong>out inner current control loops. Using bang-bang hysteresis controllers for flux<br />

and torque control loops made this control concept very fast and not complicated. However,<br />

the main disadvantage <strong>of</strong> <strong>DTC</strong> is fast sampling time required and variable switching<br />

frequency, because <strong>of</strong> hysteresis based control loops. In order to eliminate above<br />

disadvantages and kept basic control rules <strong>of</strong> classical <strong>DTC</strong>, at the beginning <strong>of</strong> 90’s a new<br />

developed control technique called direct torque control <strong>with</strong> space vector modulator (<strong>DTC</strong>-<br />

<strong>SVM</strong>) has been introduced [54,55]. However, from the formal consideration this method can<br />

also be viewed as stator flux oriented control (SFOC). This control employed instead <strong>of</strong><br />

hysteresis controller as for classical <strong>DTC</strong>, the PI controllers and space vector modulator<br />

(<strong>SVM</strong>). It allows to achieve fixed switching frequency, what considerably reduce switching<br />

losses as well as torque and current ripples. Also requirement <strong>of</strong> very fast sampling time is<br />

eliminated [113,115,117]. Therefore, this new method is subject <strong>of</strong> this thesis. In spite <strong>of</strong><br />

many control strategies there is no one which may be considered as standard solution.<br />

5

Introduction<br />

Therefore, the following thesis can be formulated:<br />

“In the view <strong>of</strong> commercial manufacturing process the most convenient control scheme<br />

for voltage source inverter-fed permanent magnet synchronous motor (PMSM) drives is<br />

direct torque control <strong>with</strong> space vector modulator (<strong>DTC</strong>-<strong>SVM</strong>)”.<br />

To prove the above thesis, the author used methodology based on an analyze and simulation<br />

as well as experimental verification on the laboratory setup <strong>with</strong> 3kW PMSM motor.<br />

Moreover, the presented control algorithm <strong>DTC</strong>-<strong>SVM</strong> has been introduced and used in serial<br />

commercial product <strong>of</strong> Polish manufacture TWERD, Toruń.<br />

In the author’s opinion the following results <strong>of</strong> the thesis are his original achievements:<br />

• development <strong>of</strong> a simulation algorithm in SABER package for the investigation<br />

<strong>of</strong> PWM inverter-fed PMSM control,<br />

• elaboration and experimental verification <strong>of</strong> digital flux and torque controller<br />

design based on the Z-transform approach for series (cascade) and parallel<br />

structure <strong>of</strong> <strong>DTC</strong>-<strong>SVM</strong> schemes,<br />

• implementation and verification <strong>of</strong> series (cascade) and parallel <strong>DTC</strong>-<strong>SVM</strong><br />

schemes on experimental laboratory setup <strong>with</strong> 3kW PM synchronous motor<br />

drive controlled by floating point DS1103 board.<br />

• bringing into production and testing <strong>of</strong> developed <strong>DTC</strong>-<strong>SVM</strong> algorithm in Polish<br />

industry.<br />

The thesis consists <strong>of</strong> eight chapters. Chapter 1 is an introduction. In Chapter 2 mathematical<br />

model <strong>of</strong> PM synchronous motor and his basic control modes are presented. Chapter 3 is<br />

devoted to voltage source inverter, his nonlinear characteristics and different PWM<br />

techniques. Chapter 4 gives brief review <strong>of</strong> PM synchronous motor control method such as<br />

FOC and classical <strong>DTC</strong>. In Chapter 5 two kind <strong>of</strong> <strong>DTC</strong>-<strong>SVM</strong> control schemes are presented.<br />

Also, the analysis and synthesis <strong>of</strong> digital flux, torque and speed controllers based on Z<br />

transform approach are given. Chapter 6 is devoted to initial rotor detection methods, stator<br />

flux vector and rotor speed estimation algorithms. In Chapter 7 experimental results are<br />

6

Introduction<br />

presented and studied. Chapter 8 includes the finally conclusions. Description <strong>of</strong> the SABER<br />

based control algorithm, basic coordinate transformations and parameters <strong>of</strong> used PM<br />

synchronous machine as well as inverter are given in Appendices.<br />

7

Modeling and control modes <strong>of</strong> PM synchronous motor drives<br />

Chapter 2<br />

MODELING AND CONTROL MODES OF PM SYNCHRONOUS DRIVES<br />

2.1 Mathematical model <strong>of</strong> PM synchronous motor<br />

Development <strong>of</strong> the machine model through the understanding <strong>of</strong> physics <strong>of</strong> the<br />

machine is the key requirement for any type <strong>of</strong> electrical machine control. Since in this<br />

project a Surface type Permanent Magnet Synchronous Motor (SPMSM) is used for the<br />

investigation [9,13,14,15,16]. The development <strong>of</strong> those models is under bellow<br />

assumptions as [3]:<br />

• three-phase motor is symmetrical,<br />

• only a fundamental harmonic <strong>of</strong> the magneto motive force (MMF) is taking in to<br />

account,<br />

• the spatially distributed stator and rotor winding are replaced by a concentrated<br />

coil,<br />

• an anisotropy effects, magnetic saturation, iron loses and eddy currents are not<br />

taking into considerations,<br />

• the coil resistances and reactances are taking to be constant,<br />

• in many cases, especially when is considered steady state, the currents and<br />

voltages are assumed to be sinusoidal,<br />

• thermal effect for permanent magnets is omitted.<br />

The synchronous motor model will be presented in space vector notation. <strong>Space</strong> vector<br />

form <strong>of</strong> the machine equations has many advantages such as compact notation, easy<br />

algebraic manipulation, and very simple graphical interpretation. Specially, this notation<br />

is very useful when analyzing the vector control based technique <strong>of</strong> the AC machines.<br />

The space vector representation <strong>of</strong> AC machine equations has been discussed in detail<br />

in number <strong>of</strong> text books ([3,4,12]).<br />

The instantaneous value <strong>of</strong> a three-phase system KA, KB,<br />

K<br />

C<br />

(such as currents, voltages<br />

and flux linkages) can be replaced by one resultant vector called the space vector,<br />

2<br />

K = ⎡ 1 ⋅ K + a⋅ K + a K<br />

3 ⎣<br />

2<br />

A B C<br />

⎤<br />

⎦<br />

(2.1)<br />

8

Modeling and control modes <strong>of</strong> PM synchronous motor drives<br />

2π<br />

2π<br />

4π<br />

j 1 3<br />

where:1,<br />

3 2<br />

− j j 1 3<br />

a= e =− + j , a = e<br />

3<br />

= e<br />

3<br />

=− − j - complex vectors, 2/3 –<br />

2 2<br />

2 2<br />

normalization factor (guarantee that for balanced sinusoidal waveforms the magnitude<br />

<strong>of</strong> the space vector is equal to the amplitude <strong>of</strong> that phase waveforms).<br />

The elements <strong>of</strong> this space vector satisfy the condition:<br />

KA + KB + KC<br />

= 0<br />

(2.2)<br />

and it means that we have three-phase system <strong>with</strong>out neutral wire.<br />

2.1.1 Voltage and current equations<br />

For idealized motor (Fig. 2.1), the following equations <strong>of</strong> the instantaneous stator phase<br />

voltages can be written [3]:<br />

B<br />

b<br />

Z sB<br />

I sB<br />

a<br />

U sB<br />

S<br />

N<br />

N<br />

S<br />

U sA<br />

γ m<br />

Z sA<br />

A<br />

I sA<br />

I sC<br />

Z sC<br />

U sC<br />

N<br />

S<br />

C<br />

c<br />

Figure 2.1. Layout and symbols for three-phase PMSM electric motor windings.<br />

dΨ<br />

dt<br />

sA<br />

sA<br />

=<br />

sA sA<br />

+ (2.3a)<br />

U I R<br />

U I R<br />

dΨ<br />

dt<br />

sB<br />

sB<br />

=<br />

sB sB<br />

+ (2.3b)<br />

U I R<br />

dΨ<br />

dt<br />

sC<br />

sC<br />

=<br />

sC sC<br />

+ (2.3c)<br />

9

Modeling and control modes <strong>of</strong> PM synchronous motor drives<br />

where<br />

U ,<br />

sA, U<br />

sB<br />

U<br />

sC<br />

are the instantaneous stator voltage values, I<br />

sA<br />

I<br />

sB<br />

, I<br />

sC<br />

, are<br />

instantaneous values <strong>of</strong> the current,<br />

R = R = R = R is the resistance <strong>of</strong> the stator<br />

s<br />

sA<br />

sB<br />

sC<br />

windings, and ΨsA,<br />

Ψ<br />

sB<br />

and Ψ<br />

sC<br />

are magnetic flux linkages stator windings A, B and<br />

C , respectively.<br />

Using the space vector theory to voltage equations we can written in vector form<br />

where:<br />

U<br />

d Ψ<br />

dt<br />

sABC<br />

sABC<br />

= Rs<br />

I<br />

sABC<br />

+ (2.4)<br />

2 2<br />

U<br />

sABC<br />

= (1 UsA + aUsB + a UsC<br />

) ,<br />

2 2<br />

2 2<br />

I<br />

sABC<br />

= (1 IsA + aIsB + a IsC<br />

) ,<br />

sABC (1<br />

sA<br />

a<br />

sB<br />

a<br />

sC )<br />

3<br />

3<br />

3<br />

stator voltage, current and flux space vectors, respectively.<br />

Ψ = Ψ + Ψ + Ψ are the<br />

The stator winding flux consist <strong>of</strong> rotor flux and stator flux linkages:<br />

where,<br />

Ψ<br />

sABC<br />

=Ψ<br />

ABC ( s) +Ψ<br />

ABC( r)<br />

(2.5)<br />

⎡ LsA MsAB MsAC⎤⎡IsA⎤<br />

⎢<br />

M L M<br />

⎥⎢<br />

I<br />

⎥<br />

Ψ<br />

ABC( s)<br />

= ⎢ sBA sB sBC ⎥⎢ sB ⎥<br />

⎢⎣ M<br />

sCA<br />

MsCB L ⎥⎢<br />

sC ⎦⎣I<br />

⎥<br />

sC ⎦<br />

(2.6)<br />

⎡<br />

⎤<br />

⎢ cosθ<br />

⎥<br />

r<br />

⎢<br />

⎥<br />

2π<br />

Ψ<br />

ABC ( r)<br />

=Ψ ⎢<br />

PM<br />

cos( θr<br />

− ) ⎥<br />

⎢ 3 ⎥<br />

⎢<br />

2π<br />

⎥<br />

cos( θr<br />

+ )<br />

⎢⎣<br />

3 ⎥⎦<br />

(2.7)<br />

and, θr<br />

is electrical rotor position. Mechanical rotor position is defined as:<br />

θ = p γ<br />

(2.8)<br />

r b m<br />

where: pb<br />

- number <strong>of</strong> pole pairs, γ<br />

m<br />

- mechanical position.<br />

In equation (2.6) LsA<br />

is the self-inductance <strong>of</strong> phase A winding, M<br />

sAB<br />

and M<br />

sAC<br />

are the<br />

mutual inductances between A and B phase, A and C phase, respectively. For self and<br />

mutual inductances <strong>of</strong> B and C phase the same notations used. In (2.7),<br />

Ψ<br />

PM<br />

is the<br />

10

Modeling and control modes <strong>of</strong> PM synchronous motor drives<br />

amplitude <strong>of</strong> the flux linkages established by the permanent magnet on the rotor. The<br />

inductances are described below.<br />

Due to the rotor saliency in IPMSM the air gap is not uniform and, therefore, the self<br />

and mutual inductances <strong>of</strong> stator windings are a function <strong>of</strong> the rotor position.<br />

The derivation <strong>of</strong> these rotor position dependent inductances is available in details in<br />

[5]. The results are summarized here as follows:<br />

The stator winding self-inductances are<br />

L = L + L − L cos 2θ<br />

(2.9a)<br />

sA ls A B r<br />

2π<br />

4π<br />

LsB = Lls + LA −LB cos2( θr − ) = Lls + LA −LB cos(2 θr<br />

− )<br />

3 3<br />

(2.9b)<br />

2π<br />

4π<br />

LsC = Lls + LA − LB cos 2( θr + ) = Lls + LA − LB cos(2 θr<br />

+ )<br />

3 3<br />

(2.9c)<br />

where, Lls<br />

is stator-winding leakage inductance and LA,<br />

LB<br />

are given by<br />

L<br />

A<br />

⎛ms<br />

⎞<br />

= ⎜<br />

2 ⎟<br />

⎝ ⎠<br />

2<br />

πµ rlε<br />

0 1<br />

(2.10a)<br />

L<br />

B<br />

1 ⎛ms<br />

⎞<br />

=<br />

2 ⎜<br />

2 ⎟<br />

⎝ ⎠<br />

2<br />

πµ rlε<br />

0 2<br />

(2.10b)<br />

where,<br />

m<br />

s<br />

is number <strong>of</strong> turns <strong>of</strong> each phase winding, r is radius, which is from center<br />

<strong>of</strong> machine to the inside circumference <strong>of</strong> the stator, and l is the axial length <strong>of</strong> the air<br />

gap <strong>of</strong> the machine, µ<br />

0<br />

is permeability <strong>of</strong> the air, ε<br />

1<br />

and ε<br />

2<br />

are defined as s:<br />

1 1 1<br />

ε<br />

1<br />

= ( + )<br />

(2.11a)<br />

2 g g<br />

min<br />

max<br />

1 1 1<br />

ε<br />

2<br />

= ( − )<br />

(2.11b)<br />

2 g g<br />

min<br />

max<br />

where,<br />

gmin<br />

is minimum air gap length and<br />

max<br />

g<br />

is maximum air gap length.<br />

The mutual inductances between stator phase are:<br />

1 π 1 2π<br />

MsAB = MsBA =− LA −LB cos 2( θr − ) =− LA −LB cos(2 θr<br />

− ) (2.12a)<br />

2 3 2 3<br />

11

Modeling and control modes <strong>of</strong> PM synchronous motor drives<br />

1 π 1 2π<br />

MsAC = MsCA =− LA − LB cos 2( θr + ) =− LA − LB cos(2 θr<br />

+ ) (2.12b)<br />

2 3 2 3<br />

1 1<br />

MsBC = MsCB =− LA − LB cos 2( θr + π) =− LA − LB cos(2θr<br />

+ 2 π)<br />

2 2<br />

1<br />

=− LA −LBcos 2θ<br />

r<br />

2<br />

(2.12c)<br />

Using the space vector theory, the flux linkage<br />

Ψ<br />

sABC<br />

space vector can be written as:<br />

3 3<br />

∗ j2θr<br />

jθr<br />

Ψ<br />

sABC<br />

= ( Lls + LA)<br />

IsABC − LB IsABC<br />

e +Ψ<br />

PM<br />

e<br />

(2.13)<br />

2 2<br />

where,<br />

2 2<br />

(1<br />

sA sB sC )<br />

IsABC<br />

= I + aI + a I ,<br />

3<br />

space vector and conjugate stator current space vector.<br />

2 2 (1<br />

sA sB sC )<br />

I ∗ sABC<br />

= I + a I + aI are the stator current<br />

3<br />

Taking into account that:<br />

Ld = Lls + Lmd<br />

(2.14a)<br />

Lq = Lls + Lmq<br />

(2.14b)<br />

3 3<br />

where, Lmd = ( LA + LB<br />

) , Lmq = ( LA − LB<br />

) are d and q magnetizing inductances and<br />

2<br />

2<br />

are defined as [5].<br />

Finally, equations (2.13) comes as:<br />

where, L<br />

d<br />

, L<br />

q<br />

are d and q inductances.<br />

Ld + Lq Lq −Ld ∗ j2θr<br />

jθ<br />

r<br />

Ψ<br />

sABC<br />

= ( ) I<br />

sABC<br />

− ( ) IsABC<br />

e +Ψ<br />

PM<br />

e<br />

(2.15)<br />

2 2<br />

<strong>Space</strong> vector form <strong>of</strong> machine equations (2.4, 2.15) becomes more compact, but the<br />

rotor position dependent parameters still exist in that form <strong>of</strong> expressions for the stator<br />

flux linkage space vector. Therefore, the space vector model is still not simple to use for<br />

the analysis. A simplification can be made if the space vector model is referred to a<br />

suitably selected rotating frame.<br />

12

Modeling and control modes <strong>of</strong> PM synchronous motor drives<br />

Figure 2.2 shows axes <strong>of</strong> reference for the three-stator phase ABC. , , It also shows a<br />

rotating set <strong>of</strong> x,<br />

y axes, where the angleθ K<br />

is position <strong>of</strong> x -axis in respect to the stator<br />

A phase axis. Variables along the AB , and C axes can be referred to the x − and<br />

y − axes by the expression:<br />

⎡K<br />

A ⎤<br />

⎡K<br />

x ⎤ 2 ⎡ cosθK cos( θK − 2 π / 3) cos( θK<br />

+ 2 π / 3) ⎤⎢<br />

K<br />

⎥<br />

⎢ B<br />

K<br />

⎥ =<br />

y 3<br />

⎢<br />

sinθK sin( θK 2 π / 3) sin( θK<br />

2 π / 3)<br />

⎥⎢ ⎥<br />

⎣ ⎦ ⎣− − − − + ⎦<br />

⎢⎣K<br />

⎥<br />

C ⎦<br />

(2.16)<br />

y<br />

K B<br />

K ABC<br />

K y<br />

K x<br />

Ω K<br />

x<br />

θ K<br />

K A<br />

K C<br />

Figure 2.2. Stator fixed three phase axes (A,B,C) and general rotating reference frame ( x,<br />

y ).<br />

Finally, the space vector in general rotating frame can be written as:<br />

j K<br />

K = K (cosΘ + jsin Θ ) = K e θ<br />

(2.17)<br />

ABCs K K<br />

K K<br />

In this case the voltage equation (2.4) using (2.17) can written as:<br />

jθK jθ d<br />

K jθK<br />

U<br />

sKe Rs IsKe (<br />

sKe<br />

)<br />

dt<br />

= + Ψ (2.18)<br />

Using chain rule, equation. (2.17) and divided by term<br />

j K<br />

e θ<br />

can be written as:<br />

d Ψ<br />

U<br />

sK<br />

R I j<br />

dt<br />

= + + Ω Ψ (2.19)<br />

sK<br />

s sK K sK<br />

where<br />

U<br />

sK<br />

rotating frame.<br />

, I sK , Ψ sK is the stator voltage, current and flux space vector in general<br />

Making similar arrangement like for the voltage equation the flux linkage vector in<br />

general reference frame can be expressed as:<br />

13

Modeling and control modes <strong>of</strong> PM synchronous motor drives<br />

Ld + Lq Lq −Ld j2( θr θK) j( θr θK)<br />

Ψ<br />

sK<br />

= ( ) IsK − ( ) I ∗ sK<br />

e − +Ψ<br />

PM<br />

e<br />

− (2.20)<br />

2 2<br />

Stator fixed system ( α,<br />

β )<br />

Taking the angular speed <strong>of</strong> the reference frame to be Ω<br />

K<br />

= 0 and θ<br />

K<br />

= 0 , the set <strong>of</strong><br />

synchronous machine vector equations (2.19) and (2.20) my be written as:<br />

U<br />

d Ψ<br />

sαβ<br />

sαβ<br />

= Rs<br />

Isαβ<br />

+ (2.21)<br />

dt<br />

Ld + Lq Lq −Ld ∗ j2θr<br />

jθ<br />

r<br />

Ψ<br />

sαβ = ( ) I<br />

sαβ − ( ) Isαβ<br />

e +Ψ<br />

PM<br />

e<br />

(2.22)<br />

2 2<br />

Substituting to above equations the following expressions for complex vectors<br />

U U jU<br />

= s sα<br />

+ , αβ sβ<br />

s sα<br />

sβ<br />

I αβ = I + jI , Ψ αβ =Ψ<br />

sα<br />

+ jΨ sβ<br />

and splitting into real and<br />

s<br />

imaginary parts one can obtain the scalar form <strong>of</strong> the machine equations in stationary<br />

α,<br />

β reference frame:<br />

U<br />

U<br />

dΨ<br />

dt<br />

sα<br />

sα<br />

= RsIsα<br />

+ (2.23a)<br />

dΨ<br />

sβ<br />

sβ<br />

= RsIsβ<br />

+ (2.23b)<br />

dt<br />

Ld + Lq Lq −Ld Lq −Ld<br />

( cos2 θ ) Is<br />

( )sin2θ Is<br />

cosθ<br />

2 2 2<br />

Ψ = − − +Ψ (2.24a)<br />

sα r α r β PM r<br />

Lq − Ld Ld + Lq Lq −Ld<br />

Ψ<br />

sβ =− ( )sin 2 θrIsα + [( ) + ( )cos2 θr] Isβ<br />

+Ψ<br />

PM<br />

sinθ<br />

(2.24b)<br />

r<br />

2 2 2<br />

Note, that in the flux-current equations (2.24a and b) still we can observe that value <strong>of</strong><br />

inductances depends on rotor position θ<br />

r<br />

.<br />

Stator flux fixed system ( x,<br />

y )<br />

In order to take advantage <strong>of</strong> the set <strong>of</strong> equations (2.19) and (2.20) in rotating coordinate<br />

system, one assumes that the coordinate system rotates <strong>with</strong> the stator flux linkage<br />

angular speed Ω<br />

K<br />

=Ω<br />

Ψ<br />

and θK<br />

= θ Ψ<br />

. As a<br />

sx s<br />

Ψ =Ψ , δ = −( θ − θ )<br />

Ψ<br />

r<br />

Ψ<br />

d Ψ<br />

U R I j<br />

dt<br />

sxy<br />

sxy<br />

=<br />

s sxy<br />

+ + ΩΨsΨ (2.25)<br />

sxy<br />

Ld + Lq Lq −Ld ∗ − j2δΨ<br />

− jδΨ<br />

Ψ<br />

sxy<br />

= ( ) Isxy − ( ) Isxy<br />

e +Ψ<br />

PM<br />

e<br />

(2.26)<br />

2 2<br />

14

Modeling and control modes <strong>of</strong> PM synchronous motor drives<br />

Substituting to above equations the following expressions for complex vectors<br />

U U jU<br />

sxy<br />

=<br />

sx<br />

+<br />

sy, Isxy<br />

Isx jIsy<br />

= + , Ψ =Ψ<br />

s<br />

and splitting into real and imaginary parts<br />

sxy<br />

one can obtain the scalar form <strong>of</strong> the machine equations in stationary x,<br />

y reference<br />

frame:<br />

U<br />

dΨ<br />

dt<br />

s<br />

sx<br />

= Rs Isx<br />

+ (2.27a)<br />

U = R I +ΩΨ<br />

Ψ (2.27b)<br />

sy s sy s<br />

s<br />

1 1<br />

Ψ<br />

s<br />

= [( Ld + Lq) −( Lq − Ld)cos 2 δΨ ] Isx<br />

+ ( Lq − Ld)sin 2δΨIsy<br />

+Ψ<br />

PM<br />

cosδΨ<br />

2 2<br />

(2.28a)<br />

1 1<br />

0 = ( Lq − Ld)sin2 δΨIsx<br />

+ [( Ld + Lq) + ( Lq −Ld)cos2 δΨ] Isy<br />

−Ψ<br />

PM<br />

sinδΨ<br />

2 2<br />

(2.28b)<br />

The current-flux equations can be expressed also in simplest form as:<br />

2 2<br />

s<br />

( Ld cos δΨ Lqsin δΨ) Isx<br />

( Lq Ld)sinδΨcosnδΨIsy<br />

PM<br />

cosδΨ<br />

Ψ = + + − +Ψ (2.29a)<br />

2 2<br />

q d<br />

δΨ δΨ sx d<br />

δΨ q<br />

δΨ sy PM<br />

δΨ<br />

0 ( L L )sin cos I ( L sin L cos ) I sin<br />

= − + + −Ψ (2.29b)<br />

Rotor flux fixed system ( dq) ,<br />

In order to take advantage <strong>of</strong> the set <strong>of</strong> equations (2.19) and (2.20) in rotating coordinate<br />

system, one assumes that the coordinate system rotates <strong>with</strong> the rotor flux angular speed<br />

Ω<br />

K<br />

= pbΩ m<br />

and θK = pbγm = θr<br />

d Ψ<br />

U<br />

sdq<br />

R I jp<br />

dt<br />

sdq<br />

s sdq<br />

b m<br />

= + + Ω Ψ (2.30)<br />

sdq<br />

Ld + Lq Lq −Ld<br />

∗<br />

Ψ<br />

sdq<br />

= ( ) Isdq − ( ) Isdq<br />

+Ψ<br />

PM<br />

(2.31)<br />

2 2<br />

Substituting the following expressions for complex vectors U = Usd + jUsq,<br />

I I jI<br />

sdq<br />

=<br />

sd<br />

+<br />

sq, sdq sd<br />

j<br />

sq<br />

Ψ =Ψ + Ψ to (2.30) and (2.31), and splitting for real and<br />

imaginary parts the scalar form <strong>of</strong> the machine equations in rotational fixed reference<br />

frame can be obtained:<br />

dΨ<br />

sd<br />

Usd = Rs Isd + − pbΩmΨ sq<br />

(2.32a)<br />

dt<br />

sdq<br />

15

Modeling and control modes <strong>of</strong> PM synchronous motor drives<br />

dΨsq<br />

Usq = Rs Isq + + pbΩmΨ sd<br />

(2.32b)<br />

dt<br />

where,<br />

Ψ<br />

sd<br />

= LI<br />

d sd<br />

+Ψ (2.33a)<br />

PM<br />

Ψ<br />

sq<br />

= LqI<br />

(2.33b)<br />

sq<br />

It should be noted that when transforming the flux linkage vector<br />

Ψ s<br />

to the dq ,<br />

reference frame the rotor position θ r<br />

dependent terms disappear it can be seen from<br />

equation (2.31). This is the main advantage <strong>of</strong> rotor-oriented representation.<br />

Substituting the relationship <strong>of</strong> (2.33a-b) into (2.32a-b), and also considering<br />

dΨ PM = 0 , the most common scalar form <strong>of</strong> the machine voltage equations in the rotor<br />

dt<br />

reference frame can be obtained as:<br />

dIsd<br />

Usd = RsIsd + Ld − pbΩ mLqIsq<br />

(2.34a)<br />

dt<br />

dIsq<br />

Usq = Rs Isq + Lq + pbΩmΨ PM<br />

+ pbΩ mLd Isd<br />

(2.34b)<br />

dt<br />

Based on the above voltage-current equations it is possible to draw the equivalent<br />

electrical circuit separately for d and q axes (Fig. 2.3).<br />

R s<br />

p Ω<br />

L I<br />

b m q sq<br />

R s<br />

p Ω<br />

L I<br />

b m d sd<br />

U<br />

sd<br />

I sd<br />

L d<br />

U<br />

sq<br />

I sq<br />

p Ω Ψ<br />

b m PM<br />

L q<br />

Figure 2.3. Equivalent circuit model <strong>of</strong> PMSM in the rotor reference frame. (a) Rotor d-axis<br />

equivalent circuit, (b) Rotor q-axis equivalent circuit.<br />

16

Modeling and control modes <strong>of</strong> PM synchronous motor drives<br />

2.1.2 Instantaneous power and electromagnetic torque<br />

The three-phase star-connection system <strong>with</strong>out neutral wire is shown in Fig. 2.4. This<br />

is classical configuration for AC motor windings connections.<br />

A<br />

I sA<br />

U sAC<br />

U sAB<br />

B<br />

U sA<br />

Z sC<br />

Z sA<br />

U sAB<br />

Z sB<br />

C<br />

U sBC<br />

I sC<br />

U sC U sB<br />

I sB<br />

Figure 2.4. Three-phase star connection system <strong>with</strong>out neutral wire.<br />

For this configuration the expression for instantaneous active power supplied to load<br />

can be expressed as:<br />

P= UsAIsA+ UsBIsB+ UsCIsC<br />

(2.35)<br />

Introducing space vector definition, after some arrangement and taking into account the<br />

relation: I + I + I = 0, the equation (2.35) can be written as:<br />

sA sB sC<br />

3 ∗<br />

P= Re[ U<br />

sABC<br />

IsABC<br />

]<br />

(2.36)<br />

2<br />

For dq , frame, the equation (2.35) for the active power can be expressed as:<br />

3<br />

P= ( UsdIsd + UsqIsq<br />

)<br />

(2.37)<br />

2<br />

Substituting voltage equation (2.4) into (2.36), and adopting Ω<br />

K<br />

= pbΩmone obtains<br />

3 ∗ d Ψ<br />

[Re(<br />

sABC ∗ ∗<br />

P= RsIsABC IsABC + IsABC − jpbΩmΨ sABCIsABC<br />

)] (2.38)<br />

2<br />

dt<br />

Note that<br />

sABC<br />

sABC<br />

2<br />

s<br />

I I ∗ = I and:<br />

3 2 d Ψ<br />

[ Re(<br />

sABC ∗<br />

∗<br />

P= Rs Is + IsABC ) + Re( −jpbΩmΨ sABC<br />

IsABC<br />

)] (2.39)<br />

2<br />

dt<br />

d ΨsABC<br />

Hence, neglecting the losses in stator resistance R<br />

s<br />

and assuming that = 0 , the<br />

dt<br />

electromagnetic power is expressed:<br />

17

Modeling and control modes <strong>of</strong> PM synchronous motor drives<br />

3<br />

∗<br />

Pe = pbΩmIm( Ψ<br />

sABC<br />

IsABC<br />

)<br />

(2.40)<br />

2<br />

In dq , frame the active power can be written:<br />

3<br />

Pe = pbΩm( ΨsdIsq −Ψ<br />

sqIsd)<br />

(2.41)<br />

2<br />

For the presented system (Fig. 2.4) the expression for instantaneous reactive power<br />

supplied to the three-phase load system <strong>with</strong>out neutral wire can be calculated as:<br />

1<br />

Q= ( IsAUsBC + IsBUsCA + IsCUsAB<br />

)<br />

(2.42)<br />

3<br />

Introducing the space vector definition into equation (2.42), after some arrangement,<br />

and taking into account the relation: I + I + I = 0, one obtains:<br />

sA sB sC<br />

3 ∗<br />

Q= Im[ U<br />

sABC<br />

IsABC<br />

]<br />

(2.43)<br />

2<br />

In dq , frame the reactive power is expressed as:<br />

3<br />

Q= ( UsqIsd − UsdIsq<br />

)<br />

(2.44)<br />

2<br />

Substituting voltage equation (2.4) into (2.43), adopting Ω<br />

K<br />

= pbΩ m<br />

and made similar<br />

arrangements like for active power calculation, the final expression for reactive power<br />

is:<br />

3<br />

∗<br />

Q= pbΩmRe( Ψ<br />

sABC<br />

I<br />

sABC<br />

)<br />

(2.45)<br />

2<br />

In dq , frame the expression (2.45) for the reactive power becomes:<br />

3<br />

Q= pbΩm ( Ψ<br />

sd<br />

Isd +Ψ<br />

sqIsq<br />

)<br />

(2.46)<br />

2<br />

The important quantity <strong>of</strong> the drive is the power factor cosφ , which can be calculated<br />

as:<br />

Q<br />

cosφ = (2.47)<br />

S<br />

where S is module <strong>of</strong> apparent power vector S = P+ jQ:<br />

2 2<br />

S = P + Q<br />

(2.48)<br />

18

Modeling and control modes <strong>of</strong> PM synchronous motor drives<br />

The instantaneous electromagnetic torque developed by an electric motor can be defined<br />

as:<br />

P<br />

e<br />

M<br />

e<br />

= (2.49)<br />

Ω<br />

m<br />

where, P<br />

e<br />

is the electromagnetic power and<br />

Ωm<br />

is the mechanical angular rotor speed.<br />

Finally, taking into account equation (2.49) the expression for electromagnetic torque<br />

can be obtained as:<br />

and in dqframe: ,<br />

3<br />

∗<br />

Me = pbIm( Ψ<br />

sABC<br />

IsABC<br />

) , (2.50)<br />

2<br />

3<br />

M<br />

e<br />

= pb ( Ψsd Isq −Ψ<br />

sqIsd<br />

)<br />

(2.51)<br />

2<br />

Substituting Ψ , Ψ from (2.33a-b), the torque expression <strong>of</strong> equations (2.47)<br />

becomes:<br />

sd<br />

sq<br />

3<br />

M<br />

e<br />

= pb ( ΨPM Isq −( Lq − Ld ) Isd Isq<br />

)<br />

(2.52)<br />

2<br />

It can be seen from (2.52), that developed torque consist <strong>of</strong> two parts, one produced by<br />

the permanent magnet flux called synchronous torque ( M<br />

reluctance torque ( M<br />

er<br />

es<br />

) and the second called<br />

), which is produced by the difference <strong>of</strong> the inductance in rotor<br />

d- and q-axes. Expressions for those two torque components are:<br />

3<br />

M<br />

es<br />

= pbΨ PM<br />

Isq<br />

(2.53a)<br />

2<br />

3<br />

M<br />

er<br />

=− pb ( Lq − Ld ) Isd Isq<br />

(2.53b)<br />

2<br />

It should be mentioned that for SPMSM ( L d<br />

= L ) the reluctance torque does not exist<br />

q<br />

due to the same inductance paths in rotor d- and q-axes.<br />

The torque expression (2.52) can also be written in polar form using the current vector<br />

amplitude<br />

vector (Fig. 2.5.).<br />

I<br />

s<br />

and the torque angle δ I<br />

, i.e. angle between rotor d-axis and current<br />

19

Modeling and control modes <strong>of</strong> PM synchronous motor drives<br />

q−<br />

axis<br />

I sq<br />

I s<br />

Ω s<br />

δ I<br />

d<br />

− axis<br />

I sd<br />

Ψ PM<br />

Figure 2.5. Stator current vector in rotor reference frame.<br />

For two current components using trigonometrical rules we can write:<br />

I = I cosδ<br />

(2.54a)<br />

sd<br />

s<br />

I<br />

I = I sinδ<br />

(2.54b)<br />

sq<br />

s<br />

I<br />

Substituting I , I into equation (2.52), the torque expression can be obtain as:<br />

sd<br />

sq<br />

M 3 1<br />

2<br />

e = b[ PM sin I ( q d) sin2 I]<br />

2 p Ψ I s δ −<br />

2<br />

L − L I s δ<br />

(2.55)<br />

<br />

M<br />

es<br />

For given current amplitude the synchronous and reluctances torque varies according to<br />

the sine <strong>of</strong> torque angle δ<br />

I<br />

. The variation <strong>of</strong><br />

M<br />

er<br />

M<br />

es<br />

and M<br />

er<br />

and resultant torque M<br />

e<br />

<strong>with</strong><br />

torque angle are illustrated in Fig. 2.6. The IPMSM parameters used for this calculation<br />

are given in the Appendices.<br />

e [ ] M Nm<br />

M [ ] er<br />

Nm M<br />

es<br />

[ Nm ]<br />

[deg] δ I<br />

Figure 2.6. Variation <strong>of</strong> synchronous torque M es<br />

, reluctance torque M<br />

er<br />

and resultant<br />

torque M as a function <strong>of</strong> torque angle (for rated current amplitude).<br />

e<br />

20

Modeling and control modes <strong>of</strong> PM synchronous motor drives<br />

Referring to Fig. 2.7, stator flux components in rotor reference frame can be written as:<br />

where:<br />

Ψ = Ψ cos = LI +Ψ (2.56a)<br />

sd s<br />

δ Ψ d sd PM<br />

Ψ = Ψ sin = LI<br />

(2.56b)<br />

sq s<br />

δ Ψ q sq<br />

Ψ<br />

s<br />

is stator flux linkage amplitude, Ψ<br />

PM<br />

is rotor permanent magnet and δ Ψ<br />

is<br />

torque angle (angle between stator flux linkage vector and rotor permanent magnets flux<br />

vector).<br />

q−<br />

axis<br />

I sq<br />

Ψ sd<br />

Ψ PM<br />

I s<br />

Ω s<br />

Ψ s<br />

Ψ<br />

sq<br />

= LqI<br />

sq<br />

LI<br />

d<br />

sd<br />

δ Ψ<br />

I sd<br />

d<br />

− axis<br />

Ψ<br />

sd<br />

= LI<br />

d sd<br />

+ΨPM<br />

Figure 2.7. Rotor permanent magnet flux vector and stator flux linkage vector in rotor reference<br />

frame.<br />

From (2.56a) and (2.56b) the I<br />

sd<br />

and Isq<br />

can be obtained as:<br />

I<br />

I<br />

sd<br />

sd<br />

Ψs<br />

cosδ Ψ<br />

−ΨPM<br />

= (2.57a)<br />

L<br />

d<br />

Ψs<br />

sinδ = Ψ<br />

(2.57b)<br />

L<br />

q<br />

Substituting current components (2.57a), (2.57b) into equation (2.51), one can obtain<br />

another useful torque expressions:<br />

M<br />

e<br />

3 Ψ sin<br />

2 s<br />

ΨPM<br />

δΨ Ψs<br />

( Lq<br />

−Ld)sin2δ<br />

Ψ<br />

= pb[ −<br />

]<br />

2 Ld 2LdL<br />

<br />

q<br />

<br />

Mes<br />

M<br />

er<br />

(2.58)<br />

where:<br />

Ψ<br />

s<br />

stator flux linkage amplitude, and Ψ<br />

PM<br />

rotor flux, δ Ψ<br />

is torque angle, M<br />

es<br />

-<br />

synchronous torque,<br />

M<br />

er<br />

- reluctance torque.<br />

21

Modeling and control modes <strong>of</strong> PM synchronous motor drives<br />

For the PM synchronous motor the amplitude <strong>of</strong> stator flux<br />

Ψ<br />

s<br />

is established by<br />

permanent magnet. Operation <strong>with</strong> stator flux amplitude belong the nominal value <strong>of</strong><br />

rotor flux amplitude<br />

Ψ<br />

PM<br />

increases the amplitude <strong>of</strong> stator phase current. Please note<br />

that maximum amplitude <strong>of</strong> the stator current vector is calculated as:<br />

higher value may damage the PM (complete demagnetization).<br />

I<br />

s<br />

Ψ<br />

≤<br />

L<br />

PM<br />

d<br />

, and<br />

From the Fig. 2.8 it can be observed that rated torque is achieved for torque angle<br />

0< < 25 <br />

electrical degree.<br />

δ Ψ<br />

e[ ] M Nm<br />

M<br />

er<br />

[ Nm ]<br />

M<br />

es<br />

[ Nm ]<br />

δ Ψ<br />

[deg]<br />

Figure 2.8. Variation <strong>of</strong> synchronous torque M es<br />

, reluctance torque M<br />

er<br />

and resultant<br />

torque M as a function <strong>of</strong> torque angle (for constant stator flux equal value <strong>of</strong> PM).<br />

e<br />

2.1.3 Mechanical motion equation<br />

The equation <strong>of</strong> rotor motion dynamics describes the mechanical equilibrium <strong>of</strong> a drive<br />

system. Taking the moment <strong>of</strong> inertia to be constant ( J = const.<br />

) and neglecting friction<br />

and elastic torque we can write:<br />

where,<br />

M<br />

e<br />

= Ml + Md<br />

(2.59)<br />

Ml<br />

is the external torque on the motor shaft, and<br />

M<br />

dΩ<br />

dt<br />

where: J is total moment <strong>of</strong> inertia,<br />

M<br />

d<br />

the dynamic torque<br />

m<br />

d<br />

= J<br />

(2.60)<br />

Ω<br />

m<br />

angular speed <strong>of</strong> the rotor.<br />

22

Modeling and control modes <strong>of</strong> PM synchronous motor drives<br />

In general, for a drive system,<br />

J = J + J<br />

(2.61)<br />

m<br />

where: J<br />

m<br />

- motor inertia, J<br />

l<br />

load moments <strong>of</strong> inertia.<br />

l<br />

From equation (2.55) and (2.56) one can write:<br />

and, <strong>with</strong> (2.50),<br />

dΩ m 1 = ( M<br />

e − M<br />

l )<br />

(2.62)<br />

dt J<br />

dΩ m 1 3<br />

∗<br />

= ( pb<br />

Im( Ψ<br />

s<br />

Is<br />

) − Ml<br />

)<br />

(2.63)<br />

dt J 2<br />

Finally, the full mathematical model <strong>of</strong> PM synchronous machine which is used in<br />

simulation studies [Appendices] is described in dq , reference frame as:<br />

dΨ<br />

sd<br />

Usd = Rs Isd + − pbΩmΨ sq<br />

(2.64a)<br />

dt<br />

dΨ<br />

sq<br />

Usq = Rs Isq + + pbΩmΨ sd<br />

(2.64b)<br />

dt<br />

Ψ<br />

sd<br />

= LsdIsd +Ψ<br />

PM<br />

(2.65a)<br />

Ψ<br />

sq<br />

= LsqIsq<br />

(2.65b)<br />

dΩ m 1 = ( M<br />

e − M<br />

l )<br />

(2.66)<br />

dt J<br />

3 ∗ 3<br />

M<br />

e<br />

= pbIm( Ψ<br />

s<br />

Is) = pb( ΨsdIsq −Ψ<br />

sqIsd)<br />

(2.67)<br />

2 2<br />

Based on above equations we can create the block scheme <strong>of</strong> the PMSM machine (Fig.<br />

2.9), where the input signals are the voltage components in dq , reference frame<br />

U , U and the output signal is the mechanical speed <strong>of</strong> the rotor Ω<br />

m<br />

. As the external<br />

sd<br />

sq<br />

load torque<br />

M<br />

l<br />

is disturbance.<br />

23

Modeling and control modes <strong>of</strong> PM synchronous motor drives<br />

M l<br />

U sd<br />

+<br />

−<br />

pbΩmΨsd<br />

∫<br />

Ψ sd<br />

Ψ PM<br />

−<br />

1<br />

L d<br />

I sd<br />

Ψ<br />

sq<br />

I<br />

sd<br />

p b<br />

R s<br />

−<br />

3<br />

p<br />

2 b<br />

M e<br />

−<br />

1<br />

J<br />

∫<br />

Ω m<br />

R s<br />

U sq<br />

−<br />

−<br />

∫<br />

Ψ sq<br />

1<br />

L q<br />

I sq<br />

Ψ<br />

sd<br />

I<br />

sq<br />

pbΩmΨsq<br />

p b<br />

Figure 2.9. Block scheme <strong>of</strong> PM synchronous machine in rotating dq , frame.<br />

Based on equations (2.64-2.67) we can also draw the vector diagram <strong>of</strong> PM<br />

synchronous motor (Fig. 2.10). From this vector representation it can see the positions<br />

<strong>of</strong> the vectors (currents, voltages and fluxes). Especially, power angle φ (angle between<br />

voltage and current vectors) and torque angle defined in two manners: as an angle<br />

between current and rotor flux vectors -δ I<br />

, or as angle between stator flux and rotor<br />

flux vectors -δ Ψ<br />

.<br />

q−axis<br />

β<br />

U s<br />

RI<br />

s<br />

s<br />

I s<br />

Ψ sq<br />

I sq<br />

LI<br />

d sd<br />

ΩΨ<br />

s<br />

s<br />

φ<br />

Ψ s<br />

LqI<br />

sq<br />

I sd<br />

δ I<br />

δ Ψ<br />

θ r<br />

Ψ sd<br />

θ Ψs<br />

Ψ PM<br />

d −axis<br />

rotor<br />

α ( A)<br />

stator<br />

Figure 2.10. <strong>Vector</strong> diagram <strong>of</strong> PM synchronous motor in rotor reference frame dq. ,<br />

24

Modeling and control modes <strong>of</strong> PM synchronous motor drives<br />

2.2 Static characteristic under different control modes<br />

In this section, basic steady state properties <strong>of</strong> the PMSM under different control mode<br />

strategies will be study [6,9]. The key control strategies for the PMSM can be listed as<br />

follows:<br />

• Constant torque angle control (CTAC).<br />

• Maximum torque per ampere control (MTPAC)<br />

• Unity power factor control (UPFC)<br />

• Constant stator flux control (CSFC)<br />

Constant torque angle (CTA) control<br />

This control strategy for PMSM keeps the torque angle δ<br />

I<br />

(angle between stator current<br />

vector and rotor permanent magnet flux) at constant value 90 .<br />

q−<br />

axis<br />

Isq<br />

= I<br />

s<br />

δ = 90<br />

I<br />

<br />

d<br />

− axis<br />

Figure 2.11. Current vector and permanent magnet flux vector for constant torque angle<br />

operation (CTAC)<br />

Hence, this control can be achieved by controlling the d-axis current components to<br />

zero leaving the current vector on the rotor q-axis (see Fig. 2.11). Therefore, this<br />

strategy is also referred to as I<br />

sd<br />

= 0 control. The amplitude <strong>of</strong> rotor flux vector is<br />

constant and also the torque angle is constant. So, the torque depends only on the value<br />

<strong>of</strong> stator current amplitude. Therefore, this control strategy is not recommended for<br />

IPMSM <strong>with</strong> high saliency ratio. However, for SPMSM, this strategy is commonly<br />

used.<br />

Ψ PM<br />

The torque equation in this mode <strong>of</strong> operation becomes:<br />

3 3<br />

M<br />

e<br />

= pbΨ PMIsq = pbΨ PM<br />

Is<br />

(2.68)<br />

2 2<br />

25

Modeling and control modes <strong>of</strong> PM synchronous motor drives<br />

The steady state voltage components based on the equations (2.34a) and (2.34b) are:<br />

Usd =−pbΩ mLq Iqs =−pbΩ mLq Is<br />

(2.69a)<br />

U = R I + p Ω Ψ = R I + p Ω Ψ (2.69b)<br />

sq s qs b m PM s s b m PM<br />

The amplitude <strong>of</strong> stator voltage vector can be calculated as:<br />

s<br />

2 2<br />

sd sq<br />

U = U + U<br />

(2.70)<br />

The stator flux vector amplitude can be calculated from equations (2.65a-b) as:<br />

s<br />

2 2<br />

sd sq<br />

Ψ = Ψ +Ψ (2.71)<br />

The active and reactive power and also the power factor can be obtained from equations<br />

(2.41),(2.46), (2.47).<br />

Maximum torque per ampere (MTPA) control<br />

The main idea <strong>of</strong> this control is develop the torque using minimum value <strong>of</strong> stator<br />

current amplitude. In this case the I sd<br />

components is not equal zero, and may cancel the<br />

reluctance torque produced by high saliency ratio. Therefore, this control strategy is<br />

recommended for IPMSM.<br />

q−<br />

axis<br />

I s<br />

I sq<br />

δ >= 90<br />

I<br />

<br />

d<br />

− axis<br />

I sd<br />

Figure 2.12. Current vector I s and permanent magnet flux vector Ψ<br />

PM<br />

for maximum torque<br />

per ampere operation (MTPAC).<br />

In order to obtain the maximum torque per ampere we should solve the derivative <strong>of</strong><br />

torque equations (2.55) in respect to torque angle. Solving for torque angle α and taking<br />

into account that only negative sign should be considered for the solution, we can<br />

calculate torque angle as:<br />

Ψ PM<br />

−1 −1 1 1 2<br />

δ<br />

I<br />

= cos [ − + ( ) ]<br />

4( L −L ) I 2 4( L −L ) I<br />

d q s<br />

d q<br />

s<br />

(2.72)<br />

26

Modeling and control modes <strong>of</strong> PM synchronous motor drives<br />

From Fig. 2.8, it can be seen that<br />

M is maximum when torque angle is 90 < < 180<br />

e<br />

The relevant torque equation in this mode <strong>of</strong> operation becomes from (2.55).<br />

<br />

δ <br />

I<br />

.<br />

The steady state voltage equations can be written using the current vector amplitude<br />

I<br />

s<br />

and the torque angle δ<br />

I<br />

as:<br />

U = R I cosδ<br />

+ p Ω L I sinδ<br />

(2.73a)<br />

sd s s I b m q s I<br />

U = R I sinδ<br />

− p Ω L I cosδ<br />

+ p Ω Ψ (2.73b)<br />

sq s s I b m d s I b m PM<br />

The amplitude <strong>of</strong> stator voltage vector can be calculated from equation (2.70) and<br />

amplitude <strong>of</strong> stator flux vector from (2.71). The active and reactive power and also the<br />

power factor can be obtained from equations (2.41),(2.46), (2.47).<br />

Unity power factor (UPF) control<br />

Under this control strategy there is no phase different between the current vector and the<br />

voltage vector. Hence, power factor angle φ (see Fig. 2.13) becomes zero. Since only<br />

active power is supplied to the machine under unity power factor operation, the VA<br />

rating requirement <strong>of</strong> the inverter can be reduced.<br />

q − axis<br />

U s<br />

φ = 0<br />

I s<br />

δ I<br />

d − axis<br />

Figure 2.13. Current vector and permanent magnet flux vector under unity power factor<br />

operation (UPFC).<br />

Ψ PM<br />

In this case when φ = 0 we have the relationship:<br />

U<br />

U<br />

sq<br />

sd<br />

Isq<br />

= = tanδ<br />

I<br />

(2.74)<br />

I<br />

sq<br />

Substituting the voltage equations (2.69a-b) into (2.71) and made some simplifying, we<br />

can obtain:<br />

I L −L −Ψ + L I = (2.75)<br />

2<br />

s<br />

(<br />

d q)cos δI PM<br />

cosδI q s<br />

0<br />

27

Modeling and control modes <strong>of</strong> PM synchronous motor drives<br />

Solving for the torque angle δ<br />

I<br />

:<br />

2 2<br />

PM PM<br />

4 Is<br />

( Ld Lq)<br />

Lq<br />

Ψ − Ψ − −<br />

−1<br />

δ<br />

I<br />

= cos [ ]<br />

2( L − L ) I<br />

d q s<br />

(2.76)<br />

only positive sign should be take into consideration.<br />

After obtaining δ I<br />

the amplitude <strong>of</strong> stator voltage vector can be calculated from<br />

equation (2.70) and amplitude <strong>of</strong> stator flux vector from (2.71). The active and reactive<br />

power and also the power factor can be obtained from equations (2.41),(2.46), (2.47).<br />

Constant stator flux (CSF) control<br />

As it can be see from the torque expression (2.58) for a given stator flux amplitude<br />

the electromagnetic torque<br />

amplitude<br />

M<br />

e<br />

is a function <strong>of</strong> torque angle δ Ψ<br />

. The stator flux linkage<br />

Ψ<br />

s<br />

is kept constant <strong>of</strong> the permanent magnet flux amplitude Ψ<br />

PM<br />

.<br />

I s<br />

q − axis<br />

Ψs<br />

Ψ<br />

s<br />

δ I<br />

δ Ψ<br />

d − axis<br />

Figure 2.14. Flux vector and permanent magnet flux vector under constant stator flux operation<br />

(CSFC).<br />

The amplitude <strong>of</strong> the stator flux linkage vector is<br />

Ψ PM<br />

2 2 2 2<br />

Ψ<br />

s<br />

= Ψ<br />

sd<br />

+Ψ<br />

sq<br />

= ( LI<br />

q sq<br />

) + ( LI<br />

d sd<br />

+Ψ<br />

PM<br />

)<br />

(2.77)<br />

Equating<br />

Ψ =Ψ (2.78)<br />

s<br />

PM<br />

can be obtain the relationship for rotor frame currents as:<br />

2 2<br />

q sq d sd d PM sd<br />

( LI ) + ( LI ) + 2LΨ I = 0<br />

(2.79)<br />

This condition is true if I<br />

sd<br />

< 0 , because expression<br />

always positive values.<br />

2 2<br />

q sq<br />

LI<br />

d sd<br />

( LI ) + ( ) and L , Ψ are<br />

d<br />

PM<br />

28

Modeling and control modes <strong>of</strong> PM synchronous motor drives<br />

2 2 2 2 2 2<br />

d q s<br />

δI d PM s<br />

δI q s<br />

( L − L ) I cos + 2L Ψ I cos + L I = 0 (2.80)<br />

Solving for the torque angle δ<br />

I<br />

2 2 2 2 2 2<br />

d PM d PM s<br />

(<br />

d q<br />

)<br />

q<br />

−L Ψ ± L Ψ − I L −L L<br />

−1<br />

δ<br />

I<br />

= cos [ ]<br />

( L L ) I<br />

2 2<br />

d<br />

−<br />

q s<br />

(2.81)<br />

For givenδ I<br />

, the amplitude <strong>of</strong> stator voltage vector we can be calculated from equation<br />

(2.70) and amplitude <strong>of</strong> stator flux vector from (2.71). The active and reactive power<br />

and also the power factor can be obtained from equations (2.41),(2.46),(2.47),<br />

respectively for defined speed.<br />

Comparison study<br />

In order to compare the control strategies and to cancel dependence <strong>of</strong> machine power,<br />

per unit values defined as shown in Table 2.1 below have been introduced [3,9].<br />

The value <strong>of</strong> current vector:<br />

I<br />

sN<br />

= Is<br />

Is<br />

I<br />

= 2I<br />

(2.82)<br />

b<br />

srms( rated )<br />

The value <strong>of</strong> voltage vector: U<br />

s<br />

U<br />

s<br />

U<br />

sN<br />

= = (2.83)<br />

Ub ΩΨ<br />

b PM<br />

where: Ω b<br />

= 2 π f and b<br />

fb<br />

is rated frequency<br />

<strong>of</strong> the PM motor.<br />

The value <strong>of</strong> flux vector is: Ψ<br />

s<br />

Ψ<br />

s<br />

Ψ<br />

sN<br />

= =<br />

(2.84)<br />

Ψb<br />

ΨPM<br />

The value <strong>of</strong> torque is:<br />

Me<br />

Me<br />

M<br />

eN<br />

= =<br />

(2.85)<br />

M 3<br />

b pbΨ<br />

PMIb<br />

2<br />

The value <strong>of</strong> apparent power vector<br />

S S<br />

S = N<br />

S<br />

= 3<br />

(2.86)<br />

b UI<br />

b b<br />

2<br />

The value <strong>of</strong> active power<br />

P<br />

PN<br />

= (2.87)<br />

Sb<br />

The value <strong>of</strong> reactive power<br />

Q<br />

QN<br />

= (2.88)<br />

S<br />

b<br />

Table 2.1. Per unit values definition.<br />

In order to compare the steady state performance characteristic <strong>of</strong> the above discussed<br />

control strategies, for each <strong>of</strong> the control strategy some important quantities <strong>of</strong> the<br />

machine have been plotted as a function <strong>of</strong> the torque. The PMSM parameters, which<br />

are used for the calculations are given in Appendices.<br />

29

Modeling and control modes <strong>of</strong> PM synchronous motor drives<br />

The current requirement versus torque is illustrated in Fig. 2.15 for the different control<br />

strategies. It can be seen, that up to 1 pu torque, the requirement for current is lowest for<br />

CSF control. Highest than 1 pu torque the low current needs MTPA control requirement<br />

lowest current for a given torque.<br />

3<br />

I<br />

sN<br />

[ pu]<br />

2.5<br />

2<br />

1.5<br />

UPF<br />

CSF<br />

CTA<br />

MTPA<br />

1<br />

0.5<br />

0<br />

0 0.2 0.4 0.6 0.8 1 1.2 1.4 1.6 1.8 2<br />

M [ ] eN<br />

pu<br />

Figure 2.15. Stator current amplitude under different control strategies versus electromagnetic<br />

torque.<br />

The voltage requirement versus torque for the different control strategies is illustrated in<br />

Fig. 2.16. It can be seen, that CSF requires the highest value <strong>of</strong> stator voltage.<br />

U<br />

sN<br />

[ pu]<br />

2.5<br />

2<br />

1.5<br />

1<br />

CSF<br />

CTA<br />

MTPA<br />

0.5<br />

UPF<br />

0<br />

0 0.2 0.4 0.6 0.8 1 1.2 1.4 1.6 1.8 2<br />

M [ ] eN<br />

pu<br />

Figure 2.16. Stator voltage amplitude versus electromagnetic torque under different control<br />

strategies (at 1 pu rotor speed).<br />

3<br />

PN<br />

2<br />

[ pu]<br />

1<br />

UPF<br />

CSF<br />

CTA<br />

MTPA<br />

0<br />

0 0.2 0.4 0.6 0.8 1 1.2 1.4 1.6 1.8 2<br />

M [ ] eN<br />

pu<br />

Figure 2.17. Active power versus electromagnetic torque under different control strategies.<br />

30

Modeling and control modes <strong>of</strong> PM synchronous motor drives<br />

The active power requirement as a function <strong>of</strong> torque is illustrated in Fig. 2.17 for the<br />

different control strategies. It can be seen, that all control strategies require<br />

approximately the same value <strong>of</strong> active power for a given torque. CSF control needs<br />

less active power in the region up to 1.3 pu torque.<br />

The reactive power requirement as a function <strong>of</strong> torque is illustrated in Fig. 2.18. It can<br />

be seen, that CTA control requires the highest value <strong>of</strong> active power for a given torque<br />

and the CSF control lowest.<br />

4<br />

QN<br />

[ pu]<br />

3<br />

2<br />

CTA<br />

MTPA<br />

1<br />

UPF<br />

CSF<br />

0<br />

0 0.2 0.4 0.6 0.8 1 1.2 1.4 1.6 1.8 2<br />

M [ ] eN<br />

pu<br />

Figure 2.18. Reactive power versus electromagnetic torque under different control strategies.<br />

1.1<br />

1<br />

0.9<br />

UPF<br />

CSF<br />

cosφ<br />

0.8<br />

MTPA<br />

0.7<br />

0.6<br />

CTA<br />

0.5<br />

0 0.2 0.4 0.6 0.8 1 1.2 1.4 1.6 1.8 2<br />

M [ ] eN<br />

pu<br />

Figure 2.19. Power factor as a function <strong>of</strong> electromagnetic torque under different control<br />

strategies.<br />

The power factor as a function <strong>of</strong> torque is illustrated in Fig. 2.19. It can be seen, that as<br />

it could be expected, UPF control requires constant power factor for a given torque.<br />

CSF control is very close to the unity power factor up to 1 pu torque.<br />

The above analysis can be summarized as shown in Table. 2.2.<br />

31

Modeling and control modes <strong>of</strong> PM synchronous motor drives<br />

Table. 2.2. Summary <strong>of</strong> voltage, power, power factor requirements under control modes.<br />

Requirement<br />

<strong>Control</strong><br />

method<br />

Voltage<br />

Current<br />

Power<br />

factor<br />

CTA middle low<br />

low<br />

MTP<br />

A<br />

low<br />

low<br />

middle<br />

UPF low high 1<br />

CSF high lowes up to 1.1<br />

pu torque<br />

Close to 1 up to<br />

1 pu torque<br />

From this comparison study it can be concluded that CSF control appears to be superior<br />

in terms <strong>of</strong> steady state performance characteristics compared to other methods under<br />

discussion.<br />

32

Modeling and control modes <strong>of</strong> PM synchronous motor drives<br />

2.3 Summary<br />

‣ There are different forms to express the PMSM equations, but the rotor<br />

reference frame equations are the most widely used. The simplification in rotor<br />

dq , reference frame equations results from the disappearance <strong>of</strong> position<br />

dependent inductances.<br />

‣ The electromagnetic torque <strong>of</strong> the IPMSM is not only produced by the<br />

permanent magnet flux, but also by the reluctance difference in rotor d- and q-<br />

axes.<br />

‣ Electromagnetic torque as cross vector product <strong>of</strong> the stator flux linkage and<br />

current space vectors or rotor and stator flux linkages is independent <strong>of</strong><br />

coordinate system selected. Therefore, can be expressed in stationary ( α,<br />

β ) or<br />

rotated ( dq) , coordinates.<br />

‣ For further control strategies consideration it is convenient to express the<br />

electromagnetic torque <strong>of</strong> PMSM machine by:<br />

• vector product <strong>of</strong> stator current and rotor flux vectors. The rotor flux<br />

vector in PMSM machine is constant, because <strong>of</strong> the PM. Therefore, to<br />

increase and decrease the torque, the current amplitude and the torque<br />

angle δ<br />

I<br />