IRSE News 176 Mar 12 with Watermark.pdf

IRSE News 176 Mar 12 with Watermark.pdf IRSE News 176 Mar 12 with Watermark.pdf

IRSE NEWS ISSUE 176 MARCH 2012

- Page 2 and 3: TEN 01/10 Annuncio 190x130 mm.qxd:0

- Page 4 and 5: MARCH TECHNICAL PAPER From Safety t

- Page 6 and 7: MARCH TECHNICAL PAPER no checks on

- Page 8 and 9: MARCH TECHNICAL PAPER The function

- Page 10 and 11: MARCH TECHNICAL PAPER In other word

- Page 12 and 13: WEN ZHOU 8:12 pm Train D301 arrives

- Page 14 and 15: IRSE CONVENTION - PART 2 Some indiv

- Page 16 and 17: IRSE CONVENTION - PART 2 equipment

- Page 18 and 19: IRSE CONVENTION - PART 2 hillsides

- Page 20 and 21: IRSE CONVENTION - PART 2 Frank open

- Page 22 and 23: LU TECHNICAL SOCIETY London Undergr

- Page 24 and 25: YORK SECTION Report by Andrew P Smi

- Page 26 and 27: ANNOUNCEMENTS SIMS signals the go a

- Page 28: MEMBERSHIP MATTERS ELECTIONS We ext

<strong>IRSE</strong> NEWS<br />

ISSUE <strong>176</strong> MARCH 20<strong>12</strong>

TEN 01/10 Annuncio 190x130 mm.qxd:01/10 Tenconi Annuncio 190x130 mm 8.6.2010 15:20 Pagina 1<br />

Manufacture of Insulated Rail Joints<br />

in Hardomid for Railways and of<br />

special hollow sleepers<br />

TENCONI plastic division is the only manufacturer of the high quality insulated<br />

rail joints also called "BENKLER" joints. The pieces are produced also in small<br />

batches, according to customers' specifications and needs.<br />

TENCONI steel construction department has a reputation of excellence also for the<br />

manufacture of special steel hollow sleepers, low friction slide chairs, insulated base<br />

plates and many other railway products.<br />

TENCONI SA<br />

Mechanical workshop<br />

CH-6780 Airolo<br />

For more information contact:<br />

Sales manager: Fabrizio Lucchini<br />

Tel.: +41 91 873 30 00<br />

Mobile: +41 79 435 59 84<br />

E-Mail: lucchinifabrizio@ tenconi.ch<br />

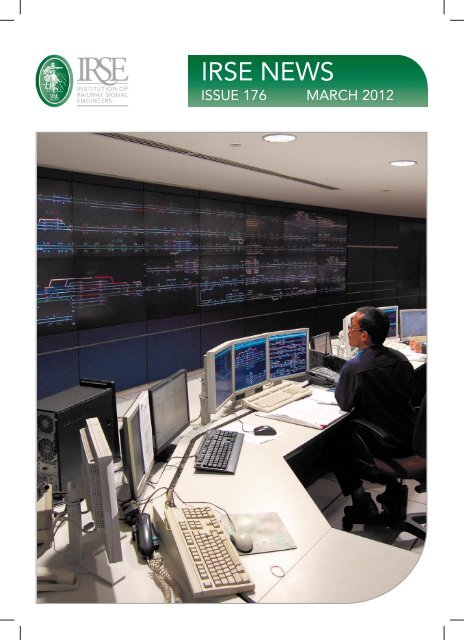

Front Cover:<br />

The Traffic Control Centre for Keretapi Tanah Melayu Behad (KTMB) located at Kuala Lumpur Sentral, taken on Friday 14 October<br />

2011 during Convention Visit . The area of control includes Rawang - Ipoh Double Track (RIDT), Klang Valley Double Track (KVDT)<br />

and Sentul Batu Caves double track sector.<br />

Photo: Ian James Allison

NEWS VIEW <strong>176</strong><br />

Border Challenge<br />

<strong>IRSE</strong> NEWS is published monthly by the Institution of<br />

Railway Signal Engineers (<strong>IRSE</strong>). The <strong>IRSE</strong> is not as a<br />

body responsible for the opinions expressed in<br />

<strong>IRSE</strong> NEWS.<br />

© Copyright 20<strong>12</strong>, <strong>IRSE</strong>. All rights reserved.<br />

No part of this publication may be reproduced,<br />

stored in a retrieval system, or transmitted in any<br />

form or by any means <strong>with</strong>out the permission in<br />

writing of the publisher. Copying of articles is not<br />

permitted except for personal and internal use.<br />

Multiple copying of the content of this publication<br />

<strong>with</strong>out permission is always illegal.<br />

Editor<br />

Ian J Allison<br />

31 Bainbridge Road, Loughborough, LE11 2LE, UK<br />

Tel: +44 (0) 7794 879286<br />

e-mail: irsenews@btinternet.com<br />

Deputy Editor<br />

Tony Rowbotham<br />

36 Burston Drive, Park Street, St Albans, AL2 2HP, UK<br />

e-mail: irsenews@aol.com<br />

Assistant Editors<br />

(Africa) Harry Ostrofsky<br />

e-mail: thehzos@icon.co.za<br />

(Australasia) Tony Howker<br />

e-mail: ahowker@bigpond.com<br />

(N. America) David Thurston<br />

e-mail: david.thurston@parsons.com<br />

(Asia) Buddhadev Dutta Chowdhury<br />

e-mail: bduttac@gmail.com<br />

(Europe) Wim Coenraad<br />

e-mail: wimcoenraad@me.com<br />

(Younger Nigel Handley e-mail:<br />

Members) nigel.handley@signallingsolutions.com<br />

Contributions<br />

Articles of a newsworthy or technical nature are always<br />

welcome for <strong>IRSE</strong> NEWS. Members should forward<br />

their contributions to one of the Editors listed above.<br />

Advertising<br />

For advertising rates and deadlines call<br />

Claire Barber at Ten Alps Media<br />

Tel: +44 (0)20 7878 2319<br />

Fax: +44 (0)20 7379 7118<br />

e-mail: Claire.Barber@tenalps.com<br />

Advertisements are accepted on the basis that the<br />

advertiser and agency (if any) warrant that the contents<br />

are true and correct in all respects.<br />

Web Site<br />

For up to date information about the Institution or its<br />

activities, or to download a membership application<br />

form, log on to the <strong>IRSE</strong> Web Site: www.irse.org<br />

London Office<br />

<strong>IRSE</strong>, 4 th Floor, 1 Birdcage Walk, Westminster,<br />

London, SW1H 9JJ, United Kingdom<br />

Enquiries<br />

MEMBERSHIP OR OF A GENERAL NATURE<br />

Tel: +44 (0)20 7808 1180<br />

Fax: +44 (0)20 7808 1196<br />

e-mail: hq@irse.org<br />

PROFESSIONAL DEVELOPMENT<br />

Tel: +44 (0)20 7808 1186<br />

e-mail: training@irse.org<br />

LICENSING<br />

Tel: +44 (0)20 7808 1190<br />

e-mail: licensing@irse.org<br />

Back in July 2008, through this same medium of <strong>News</strong> View (edition 136),<br />

I expressed an aspiration for the Borders Rail Link in Scotland to be signalled<br />

in a manner suitable to its needs and (to use a popular Scottish term) out<strong>with</strong><br />

the constraints of the standards prescribed by the UK’s national infrastructure<br />

owner.<br />

Given the original thrust for the route to be constructed by a third party<br />

<strong>with</strong> the ability to provide an enlightened solution embracing fresh thinking,<br />

innovation and commensurate technology for this blank canvas was highly<br />

plausible. This would have given us S&T engineers a unique challenge in an<br />

otherwise monotone future. It could have revealed our skills and given our<br />

profession a fillip, raising our profile and gaining us new respect.<br />

Sadly, the procurement competition to finance, design, build and maintain<br />

this line foundered, <strong>with</strong> the result that it is now to be built by Network Rail.<br />

Refresh your memory of the words contained in <strong>News</strong> View 136 and join<br />

me in lamenting what will probably now turn out to be a lost opportunity<br />

unless Network Rail has the courage to recognise the potential. So I call on<br />

Network Rail’s S&T engineers to stand up and show how they would relish<br />

this chance they have been given to confound the critics, including myself, by<br />

delivering a solution that does not just “paint by numbers” but which really<br />

looks at the fundamentals in order to match rolling stock, service pattern,<br />

availability and efficiency to this “green field” railway.<br />

J.D. Francis<br />

IN THIS ISSUE<br />

©<br />

NOT FOR RE-PRINTING<br />

Page<br />

From Safety to Security – How Secure is ERTMS? (London <strong>Mar</strong>ch Paper) 2<br />

Dr Robert Stroud and Professor Robin Bloomfield<br />

Wen Zhou: What went wrong? 9<br />

George Nikandros<br />

Industry <strong>News</strong> 11<br />

<strong>IRSE</strong> International Convention 2011: Part 2 <strong>12</strong><br />

Tuesday 11 October 2011 Trevor Foulkes <strong>12</strong><br />

Wednesday <strong>12</strong> October 2011 Ian Bridges 13<br />

The Guest Perspective Lyn Burkhardt 15<br />

The Future Beckons Nine Younger Members 17<br />

<strong>IRSE</strong> Matters 19<br />

<strong>IRSE</strong> Professional Examination: Results 2011 19<br />

London Underground’s Technical Society 20<br />

York Section January Meeting 22<br />

Midland & North Western Section January Meeting 23<br />

Feedback 22<br />

Announcements 24<br />

SIMS Apprenticeships 24<br />

M&NW Section Ninth Annual Luncheon & Technical Visit 24<br />

<strong>IRSE</strong> Wing Award for Safety: Call for Nominations 20<strong>12</strong> 25<br />

<strong>IRSE</strong> Merit Awards: Call for Nominations 20<strong>12</strong> 25<br />

Younger Members Technical Papers Competition: Call for Papers 25<br />

Membership Matters 26<br />

<strong>IRSE</strong> NEWS | ISSUE <strong>176</strong> | MARCH 20<strong>12</strong><br />

1

MARCH TECHNICAL PAPER<br />

From Safety to Security – How Secure is ERTMS?<br />

by Dr Robert Stroud and Professor Robin Bloomfield<br />

Both authors are <strong>with</strong> Adelard LLP. Robin Bloomfield is a Professor in the Centre for Software Reliability at City University, London<br />

Paper to be read in London on 8 <strong>Mar</strong>ch 20<strong>12</strong><br />

INTRODUCTION<br />

The European Railway Traffic Management System (ERTMS) is a<br />

major industrial project that aims at replacing the many different<br />

national train control and command systems in Europe. The<br />

deployment of ERTMS will support the creation of a seamless<br />

European railway system and increase the competitiveness of<br />

European railways.<br />

ERTMS consists of two major components:<br />

ETCS, the European Train Control System, is a train control<br />

and Automatic Train Protection system (ATP) to replace the<br />

existing national systems;<br />

GSM-R is a radio system for providing voice and data<br />

communication between the track and the train, using GSM<br />

technology over frequencies reserved for railway use.<br />

Network Rail is preparing to introduce ETCS and GSM-R as part<br />

of the upgrade of the signalling and communications systems<br />

running on the rail infrastructure in Great Britain. Within the rail<br />

industry safety has always been paramount, but security has not<br />

always been considered. However this upgrade has the<br />

potential to increase the risk of an electronic attack on the rail<br />

infrastructure, as it brings more systems under centralised<br />

control.<br />

This paper reports on the results of a security audit of ERTMS<br />

that was commissioned by the Centre for the Protection of<br />

National Infrastructure (CPNI) on behalf of key railway<br />

stakeholders. We first discuss the ERTMS/ETCS specifications<br />

from a security perspective and then contrast our results <strong>with</strong> the<br />

safety requirements for ERTMS, highlighting areas where<br />

different assumptions about the threat model lead to different<br />

concerns.<br />

OVERVIEW OF ERTMS<br />

The ERTMS/ETCS System Requirements Specification (SRS)<br />

(Ref. 1) provides a technical specification of the overall system.<br />

Figure 1, which is taken from the SRS, provides a simplified<br />

view of the ERTMS/ETCS reference architecture. The trackside<br />

sub-system consists of balises (track-mounted devices that<br />

communicate <strong>with</strong> passing trains), the radio communication<br />

system (GSM-R), and Radio Block Centres (RBCs). The RBCs<br />

issue movement authorities to trains on the basis of information<br />

received from external trackside systems and information<br />

exchanged <strong>with</strong> the on-board systems.<br />

The on-board system receives movement authorities from an<br />

RBC via radio messages, and calculates a speed profile for the<br />

track ahead based on the braking characteristics of the train and<br />

the safe speed limits for the track conditions. Although the<br />

driver remains in control of the train, the system will supervise<br />

the maximum speed of the train, and ensure that the brakes are<br />

applied automatically if the train exceeds the safe speed limit for<br />

a particular section of track, or is in danger of not being able to<br />

2<br />

NOT FOR RE-PRINTING<br />

©<br />

<strong>IRSE</strong> NEWS | ISSUE <strong>176</strong> | MARCH 20<strong>12</strong><br />

Figure 1: The reference architecture of ERTMS/ETCS<br />

stop before the end of its movement authority. Balises are used<br />

to provide the train <strong>with</strong> location references, so that it can<br />

correct for any errors in its odometry, and keep the RBC<br />

informed about its current position.<br />

As the train progresses along its allocated route, it keeps the<br />

RBC informed about its current position, and as track becomes<br />

available, the RBC extends the train’s movement authority so<br />

that the train is able to maintain an optimal speed for the traffic<br />

conditions ahead.<br />

THREATS AND HAZARDS<br />

A safety analysis usually starts by identifying the core hazard and<br />

then examining potential failure modes that could cause that<br />

hazard, but a security analysis considers a rather different set of<br />

potential threats and undesirable consequences.<br />

Traditionally, computer security deals <strong>with</strong> threats to<br />

confidentiality, integrity, and availability, but here we are<br />

concerned <strong>with</strong> train movements rather than information, so our<br />

primary concern is integrity, then availability, and finally<br />

confidentiality. Loss of integrity could result in accidents or<br />

collisions, whereas loss of availability would bring the railway<br />

system to a halt. Loss of confidentiality is less of an immediate<br />

threat, but might result in the leak of sensitive operational<br />

information. Reliability is also important, since an unreliable train<br />

service will result in a loss of public confidence in the railway<br />

operators.

Thus, the hazards or potential failures to be avoided are the<br />

following:<br />

a collision involving multiple trains;<br />

an accident such as derailment involving a single train;<br />

widespread disruption of train service over a large area;<br />

disruption to individual trains, or trains <strong>with</strong>in a local area;<br />

creation of a situation that leads to panic and potential loss of<br />

life (e.g., an emergency stop and uncontrolled evacuation on to<br />

the track);<br />

creation of a situation that leads to passenger discomfort and<br />

dissatisfaction, (e.g., stopping a train indefinitely in a tunnel);<br />

loss of public confidence in the railway system due to<br />

intermittent low-level problems affecting the reliability of the<br />

service;<br />

leak of sensitive information (e.g., movements of hazardous<br />

cargoes or VIPs).<br />

Note that these hazards are concerned <strong>with</strong> system-wide failures<br />

whereas the safety analysis only deals <strong>with</strong> the failure of a single<br />

train. Similarly, a safety analysis is only concerned <strong>with</strong> accidents<br />

resulting from a hazard; reliability and availability are treated<br />

separately, and confidentiality is not usually an issue. However<br />

faults that could result in an accident need to be considered in both<br />

a safety and security analysis, regardless of the underlying cause of<br />

the fault (accidental, deliberate or malicious).<br />

A security analysis also needs to consider the capabilities of the<br />

attacker. It is usual to make a distinction between an insider and an<br />

outsider. An insider is someone <strong>with</strong> legitimate access to a system<br />

who abuses their position and privileges, either willingly or under<br />

duress; whereas an outsider is someone outside the system <strong>with</strong><br />

limited access, who seeks to break into the system out of curiosity,<br />

malice, or for personal gain. Historically, railway systems have<br />

relied on highly specialised, proprietary technology, and there has<br />

been a relatively small community <strong>with</strong> the necessary knowledge to<br />

exploit vulnerabilities. However the widespread adoption of open<br />

standards like ERTMS, that are designed to promote<br />

interoperability and the commoditisation of technology, could<br />

result in both the necessary knowledge and the necessary tools<br />

becoming more readily available to potential attackers who are<br />

sufficiently motivated to gain the necessary skills.<br />

ERTMS FROM A SECURITY PERSPECTIVE<br />

NOT FOR RE-PRINTING<br />

Our approach to the security analysis has been to consider the<br />

context in which ERTMS operates, and its relationship <strong>with</strong> other<br />

systems. ERTMS is implemented using a number of trackside and<br />

on-board sub-systems, and the ERTMS/ETCS specifications<br />

describe the interfaces by which these various sub-systems interact,<br />

and how the ETCS application responds to messages via these<br />

interfaces and ensures that trains move safely <strong>with</strong>out exceeding<br />

their movement authority.<br />

It is important to note that the ERTMS/ETCS specifications only<br />

deal <strong>with</strong> the interoperability requirements of a European Railway<br />

Traffic Management System, and therefore do not cover the<br />

interfaces that are used by each national railway to control and<br />

manage its own infrastructure. This limits the scope of any security<br />

or safety analysis to interactions between the various components<br />

of the ERTMS/ETCS architecture<br />

©<br />

Messages are transmitted between the ERTMS/ETCS subsystems<br />

over various channels, so a security analysis needs to<br />

consider whether these channels can be trusted to deliver the<br />

messages reliably or whether an attacker can interfere <strong>with</strong> the<br />

delivery channels in some way. Safety measures that guard<br />

against random errors caused by environmental noise are not<br />

robust against deliberate attempts to corrupt the channel,<br />

because errors are then no longer random. A security analysis<br />

also needs to consider what might happen if a particular<br />

component of the system were compromised in some way.<br />

For example, ERTMS is designed to prevent the driver from<br />

exceeding the safe speed limit by accident, but is it possible<br />

for the driver to bypass ERTMS in some way and remove this<br />

protection, and how does the system deal <strong>with</strong> this possibility?<br />

A security analysis therefore needs to consider:<br />

whether there are safeguards built into the system that<br />

protect against messages being corrupted in transmission<br />

by the input channel;<br />

whether these safeguards protect against all possible<br />

threats to the input channel (e.g., deliberate attacks on the<br />

channel, as opposed to random failures of the channel);<br />

whether the source of the input is trustworthy, or whether<br />

it is possible for the input source to have been<br />

compromised;<br />

whether there is adequate protection at the application<br />

level to guard against malicious messages generated by an<br />

attacker who controls the input source.<br />

The on-board system needs to interact <strong>with</strong> the driver, the<br />

train, the balises, and the radio block centres. So the on-board<br />

system either needs to trust these components of the ERTMS<br />

system absolutely, which means that it is vulnerable to abuse if<br />

these components are compromised, or else take appropriate<br />

steps to guard against potential failures and compromises of<br />

these components.<br />

Moreover, the ERTMS/ETCS system needs to ensure that<br />

the channels of communication between these components<br />

are trustworthy, or else an outsider could compromise the<br />

system by disrupting communications and either injecting false<br />

messages or modifying or deleting correct messages.<br />

Communication Channels<br />

We start by examining the communication channels from a<br />

security perspective. The ERTMS/ETCS architecture involves<br />

two kinds of communication: on-board and train/trackside.<br />

On-board Communications<br />

The driver and the train itself are part of the on-board train<br />

system, and therefore the security of the channels between the<br />

driver/train and the ETCS application depends on the physical<br />

security of the train (e.g., the use of a special driver’s key to<br />

operate the driver’s console, and the integrity of the traction<br />

equipment). Although it would be possible for an attacker to<br />

tamper <strong>with</strong> these physical interfaces, this kind of attack falls<br />

outside the scope of an information assurance audit of ERTMS.<br />

Nevertheless, it is worth mentioning that the ERTMS/ETCS<br />

specifications provide no protection for the ETCS/Train<br />

interface and the ETCS/Driver interface. In particular there are<br />

<strong>IRSE</strong> NEWS | ISSUE <strong>176</strong> | MARCH 20<strong>12</strong> 3

MARCH TECHNICAL PAPER<br />

no checks on the integrity or authenticity of the messages<br />

exchanged over these channels, because they are assumed to be<br />

part of a closed system. The driver interacts directly <strong>with</strong> ETCS<br />

via the driver’s control panel, and ETCS interacts directly <strong>with</strong> the<br />

train via an electro-mechanical interface, and there is assumed to<br />

be no possibility of intervention or compromise.<br />

The weakness <strong>with</strong> this approach is the assumption that ETCS<br />

remains a closed system. For various economic and practical<br />

reasons, there is a trend towards integrated control systems<br />

based on commodity components, and towards the use of<br />

shared communication networks between the various on-board<br />

train systems. If ETCS were to be accessible over such a network<br />

<strong>with</strong>out adequate authentication or integrity checking, it would<br />

be possible for any system connected to the network to interfere<br />

<strong>with</strong> the correct operation of the ERTMS system, either<br />

accidentally or deliberately. For example, a virus on a<br />

passenger’s laptop computer could try to spread itself via the<br />

train’s communication network, which could result in the train<br />

control system malfunctioning.<br />

Train/Trackside Communications<br />

The other channels of communication are between the train and<br />

the trackside, and these therefore have to cross the air gap,<br />

which is assumed to be untrustworthy. One channel is between<br />

the train and the RBC, which is secured using the Euroradio<br />

protocol. The other channel is between the train and the balises,<br />

where the air gap interface is protected by an elaborate<br />

encoding scheme to guard against accidental loss or corruption,<br />

but is assumed to be tamperproof by its very nature.<br />

Trust relationships<br />

We now explore the trust relationships between the various<br />

components of the ERTMS/ETCS architecture.<br />

ETCS – Driver<br />

The driver is trusted to enter correct data about the train’s<br />

braking requirements, and to operate the ETCS system in a<br />

responsible fashion. In particular, although the driver’s actions<br />

are normally supervised by ETCS, it is possible for the driver to<br />

disable the ETCS system completely, and then drive the train in<br />

an unsupervised fashion <strong>with</strong>out any speed restrictions or<br />

interventions if the train exceeds its movement authority.<br />

However, because there is an operational need for this<br />

functionality to be available (e.g., in an emergency or if the<br />

system breaks down), this vulnerability is unavoidable and drivers<br />

have to be trusted not to abuse their privileges. The only<br />

protection that can be provided is a set of operational<br />

procedures that drivers must follow, but these fall outside the<br />

scope of ERTMS and cannot be enforced or policed by an<br />

automated system.<br />

ETCS – Train<br />

NOT FOR RE-PRINTING<br />

©<br />

The on-board system has detailed knowledge of the train’s<br />

braking characteristics, the track adhesion conditions and the<br />

response time before full braking is enabled, and can therefore<br />

perform an accurate calculation about when to apply the brakes<br />

to bring the train to a halt. The train is trusted to apply the<br />

brakes on demand but the service brake is not required to be<br />

trustworthy; if the train does not respond to the service brake as<br />

expected, the emergency brake will be applied and this is<br />

assumed to be fail-safe. Track-based train detection equipment<br />

linked to the interlocking provides a final safeguard if a train<br />

overruns the end of its movement authority.<br />

To know when to apply the brakes, ETCS needs to keep track<br />

of the train’s current speed and position – this information is<br />

provided by a separate interface from ETCS, to an odometer<br />

device. The odometer is required to supply ETCS <strong>with</strong><br />

reasonably accurate information about the distance travelled,<br />

and ETCS can use this information to calculate an estimate of the<br />

train’s current location and speed. However, ETCS does not<br />

trust the odometer to provide completely precise distance<br />

measurements – instead, the odometer is expected to associate<br />

a confidence interval <strong>with</strong> all its measurements, and re-calibrate<br />

itself using location references received from the balises.<br />

Thus, in principle, ETCS guards against receiving inaccurate<br />

information about the speed and position of the train, but<br />

ultimately depends on an external position reference provided<br />

by the balises and its own internal time reference.<br />

ETCS – RBC<br />

The train interacts <strong>with</strong> the RBCs via a GSM-R radio link, and<br />

implicitly trusts the movement authorities and the data it<br />

receives from the RBCs about the track conditions ahead.<br />

However, the GSM-R network is not considered to be secure,<br />

and the Euroradio protocol (Ref. 2) is used to ensure that<br />

messages from RBCs cannot be forged or modified in<br />

transmission. This ensures that there is a secure channel of<br />

communication between the RBCs and the train.<br />

Euroradio only provides a basic transport service, <strong>with</strong> no<br />

error detection or error recovery. Thus protection against lost,<br />

duplicated, or out-of-order messages has to be provided at the<br />

ERTMS application level. In particular, messages are given a<br />

timestamp, and if no messages are received <strong>with</strong>in a given time<br />

window, the safe connection is released and set up again, <strong>with</strong><br />

the option of applying the service brake or tripping the system.<br />

Although Euroradio protects the train against attacks from<br />

outside the system, it does not protect the train against attacks<br />

from <strong>with</strong>in the system. In particular, if an attacker was able to<br />

compromise an RBC and cause it to issue false instructions, then<br />

a hazardous situation could arise.<br />

Clearly, the RBCs need to be protected against such attacks<br />

– an uncontrolled external interface to an RBC would be a major<br />

vulnerability. However, this falls outside the scope of the<br />

ERTMS/ETCS specifications, which are only concerned <strong>with</strong><br />

interoperability. The specifications only describe the messages<br />

exchanged between the RBCs and the train, and the protocol for<br />

handing on control of trains from one RBC to the next.<br />

The security of the Euroradio protocol depends on the<br />

existence of a secure mechanism for creating and distributing<br />

keys to trains and RBCs but this is not addressed by the<br />

specifications. However, in order to support interoperability<br />

across national borders, it is necessary to exchange keys<br />

between national implementations of ERTMS as a precondition<br />

for trains to be able to travel seamlessly from one country to the<br />

next under the control of ERTMS. Key exchange across national<br />

4<br />

<strong>IRSE</strong> NEWS | ISSUE <strong>176</strong> | MARCH 20<strong>12</strong>

orders is covered by the specification of the off-line key<br />

management system (Ref. 3), which requires a secure<br />

implementation of a national key management centre for each<br />

country; the standard specifies a minimum set of security<br />

requirements that each national key management centre must<br />

meet.<br />

This is important because the security of ERTMS depends on<br />

the security of the key infrastructure – trains can only operate<br />

<strong>with</strong>in a given area if the RBC for that area and the train share a<br />

secret key, since otherwise they would not be able to<br />

communicate via Euroradio. So keys need to be distributed in<br />

advance as part of setting up cross-border train operations, and<br />

each national authority must be prepared to entrust its own keys<br />

to another national authority, which means that it needs to be<br />

satisfied that those keys will be managed securely by the foreign<br />

key management centre.<br />

There is also a requirement that all keys should be sufficiently<br />

strong and that no country should generate weak keys, since, if it<br />

were possible for an attacker to guess a national key, they could<br />

masquerade as a train or an RBC from that country, not only in<br />

the country whose keys had been compromised but also in any<br />

foreign country that had an interoperability agreement <strong>with</strong> that<br />

country.<br />

ETCS – Balise<br />

Balises are essentially unsecured devices and therefore represent<br />

a potential vulnerability in ERTMS. In particular, there are no<br />

robust authentication or integrity checks on the information<br />

provided by balises. However, some protection is built into the<br />

ETCS application.<br />

Specifically, ETCS distinguishes between linked balises and<br />

unlinked balises. Linked balises provide position references, and<br />

each movement authority contains details about the expected<br />

position of all the linked balises that the train should encounter<br />

during passage through that section of track. Because the<br />

movement authority is sent from the RBC to the train via a secure<br />

channel, this information is considered trustworthy. The ETCS<br />

application is designed to tolerate missing or misplaced balises,<br />

but these are assumed to be due to equipment failure or<br />

maintenance error rather than a deliberate attack.<br />

However, ETCS is also willing to accept information from<br />

balises that are not known to the RBC or that it is not informed<br />

about in advance. Such balises are known as unlinked balises<br />

and represent a major vulnerability to the system because an<br />

attacker can use an unlinked balise to feed malicious and<br />

untrustworthy commands to a train via a channel that the train<br />

implicitly trusts.<br />

The ERTMS/ETCS specifications presumably allow unlinked<br />

balises because there is an operational requirement for balises to<br />

be deployed temporarily, <strong>with</strong>out the need to re-programme the<br />

balise linking information held by RBCs (e.g., during track<br />

maintenance work). Whether this trade-off between risk and<br />

convenience is appropriate is debatable. Unfortunately, even<br />

though a national authority might decide not to deploy unlinked<br />

balises as part of its operational procedures, the potential<br />

vulnerability would remain because ERTMS requires all trains to<br />

NOT FOR RE-PRINTING<br />

©<br />

recognise unlinked balises and there is no facility for disabling<br />

this mechanism on a national basis.<br />

The list of commands that an ETCS system is willing to accept<br />

from an unlinked balise is not arbitrary; the specification<br />

attempts to make a distinction between information that is safety<br />

critical and should not be provided via an untrusted channel<br />

(e.g., movement authorities and track information), and<br />

information that it may be necessary to send from a balise for<br />

operational reasons (e.g., temporary speed restrictions).<br />

For example, unlinked balises cannot be used to issue an<br />

emergency stop command, although such commands can be<br />

issued via the RBC. This is presumably because there are more<br />

appropriate ways of alerting train drivers to an emergency<br />

situation (e.g., by using the emergency group call facility<br />

provided by GSM-R).<br />

However, almost all of the commands that can be issued by<br />

an unlinked balise could be exploited by an attacker to a greater<br />

or lesser extent. Most of these attacks would result in some<br />

form of denial of service, but some commands can be used to<br />

create a hazardous situation.<br />

Summary<br />

On-board channels of communication between components of<br />

ERTMS/ETCS are assumed not to need protection because the<br />

channels are not exposed to an attacker. Radio communications<br />

between the train and the trackside are protected by encryption,<br />

but the security of the system depends on the security of the<br />

underlying key management infrastructure. Communications<br />

across the air gap between balises and the train are protected<br />

from electromagnetic interference by an elaborate encoding<br />

scheme, but otherwise balises are assumed to be trustworthy<br />

and are not authenticated.<br />

The ETCS application provides some protection at the<br />

application level, but the safeguards are designed to protect<br />

against equipment failure and maintenance errors rather than<br />

deliberate attacks, and unlinked balises represent a particular<br />

threat. However, such an attack would require physical access to<br />

the track and could not be launched remotely or electronically.<br />

ERTMS FROM A SAFETY PERSPECTIVE<br />

The ERTMS safety analysis (Ref. 4) is based on a series of Failure<br />

Modes and Effects Analysis documents that identify “potentially<br />

catastrophic events that could exist at the mandatory boundaries<br />

of the UNISIG reference architecture”. The analysis considers<br />

the impact of these “potentially catastrophic events” on the<br />

overall safety of the ETCS application, and apportions the<br />

tolerable hazard rate to each subsystem accordingly. However,<br />

“failures that do not affect the safety of a passenger on the train<br />

are classed as RAM issues”. Thus, the focus is on safety rather<br />

than security, and events that might affect the availability of the<br />

service are not considered to be a threat to its safety, although<br />

they would be considered relevant from a security perspective.<br />

Nevertheless, a complete set of failure modes is identified for<br />

each interface, so the list of failure modes is still useful, even if<br />

the effects analysis is not always appropriate.<br />

<strong>IRSE</strong> NEWS | ISSUE <strong>176</strong> | MARCH 20<strong>12</strong> 5

MARCH TECHNICAL PAPER<br />

The function of ETCS is specified as follows (all quotations are<br />

from Ref. 4): “To provide the Driver <strong>with</strong> information to allow<br />

him to drive the train safely and to enforce respect of this<br />

information”.<br />

Thus the core hazard for the reference architecture is defined<br />

as: “Exceedance of the safe speed / distance as advised to ETCS”.<br />

The maximum rate of occurrence for the core hazard, which is<br />

“derived from consideration of the consequences that an<br />

occurrence of the ETCS core hazard would have on a single<br />

passenger travelling on a train for 1 hour”, is required to be:<br />

“2 × 10 -9 per hour per train”.<br />

This is the maximum Tolerable Hazard Rate (THR) for ETCS<br />

and should be interpreted as the rate per hour for a typical<br />

passenger journey. It is “inclusive of both random equipment<br />

failures and any systematic failures that could be introduced as a<br />

result of the design process”.<br />

However, “failures due to operators (e.g., Driver, signalman,<br />

maintenance staff) and operational rules are not included in this<br />

core hazard or THR”.<br />

Given these caveats, it is clear that the THR is solely<br />

concerned <strong>with</strong> the technical safety of ETCS, and does not<br />

represent the level of operational safety that can be achieved in<br />

practice <strong>with</strong> ETCS. Moreover, it does not take into account the<br />

effect of deliberate attacks on the security of the system.<br />

Fault Tree<br />

Part 1 of the ERTMS Safety Analysis presents a generic functional<br />

fault tree for ETCS based on the failure modes of the ETCS<br />

macro functions, which are derived from the SRS and arranged in<br />

a hierarchy leading up to the core-level hazard.<br />

“The objective of producing the generic functional fault tree<br />

is to provide a system-wide view of functional interactions so that<br />

the migration of base events that have been identified as being<br />

potentially catastrophic can be analysed. The base events were<br />

identified by the FMEA analyses of the mandatory interfaces.”<br />

The fault tree “provides full traceability to the set of system<br />

macro functions as defined in the SRS, whether or not the failure<br />

leads to a catastrophic event”. Thus the fault trees are neutral<br />

<strong>with</strong> respect to the underlying causes of the failure, and are<br />

equally valid for a safety or security analysis.<br />

The ETCS system function splits naturally into two parts, and<br />

this is reflected in the structure of the fault tree:<br />

NOT FOR RE-PRINTING<br />

©<br />

The information function keeps the driver informed of the<br />

speed and distance limits that he must observe in order to<br />

maintain safety;<br />

The enforcement function protects the train from breaching<br />

a safe speed and distance envelope, by intervening <strong>with</strong> a<br />

request for a pre-emptive application of the brake.<br />

Because of the need to keep both the display and the supervision<br />

parameters consistent, there are some common mode<br />

issues in the system:<br />

“if the information provided to the train carried system is<br />

incorrect in terms of a safe speed and distance, then the driver<br />

will be shown the wrong targets. If he drives to these incorrect<br />

targets he will be allowed to do so <strong>with</strong>out being protected from<br />

making an unsafe move by the ETCS supervision and intervention<br />

functions.”<br />

Moreover, it is important that the ETCS is supplied <strong>with</strong><br />

correct train data, since otherwise the calculation of the Most<br />

Restrictive Speed Profile (MRSP) and the braking algorithm<br />

calculation will be incorrect:<br />

“There is nothing that ETCS can do if a driver confidently<br />

enters and acknowledges erroneous data. Thus rigorous checks<br />

outside ETCS will be essential, particularly if data is modified<br />

during a journey or under emergency conditions where an<br />

independent check may be difficult to initiate.”<br />

Other sources of common mode errors include the incorrect<br />

calculation of speed and distance, and mistakes in the placement<br />

of balises or the information supplied to the system about the<br />

track topography.<br />

Fault Tree Analysis<br />

Part 2 of the ERTMS Safety Analysis contains an analysis of the<br />

fault trees from a safety perspective. It enumerates the various<br />

failure modes that have been identified, considers their impact<br />

and criticality on the various ETCS functions in different<br />

operating modes, and suggests possible mitigating conditions.<br />

Although this analysis is from a safety perspective, much of it is<br />

still relevant from a security perspective because the failure<br />

modes and consequences are the same, regardless of whether<br />

the failure is accidental or malicious.<br />

Figure 2, which is taken from Section 8 of Part 2 of Ref. 4,<br />

provides a useful overview of the failure modes and their impact<br />

on the different components of the ERTMS/ETCS reference<br />

architecture.<br />

Many of the failure modes are internal to the on-board ETCS<br />

system and are therefore less relevant to a security analysis, as<br />

noted previously. For example, there are 34 kernel-level failure<br />

events, which would be triggered by faults in the ETCS<br />

Figure 2: Failure modes<br />

6<br />

<strong>IRSE</strong> NEWS | ISSUE <strong>176</strong> | MARCH 20<strong>12</strong>

implementation itself. Although it might be possible for an<br />

attacker to exploit such design faults, this would need to be<br />

determined as part of the security assessment of an actual ETCS<br />

implementation and such failures are therefore out of scope for<br />

an analysis of the security implications of the ERTMS/ETCS<br />

specifications.<br />

However, failure events at the edge of the reference<br />

architecture, particularly those that relate to transmission of<br />

information and commands, or the provision of external data, are<br />

more obvious attack vectors that could compromise the security<br />

implications of ERTMS and therefore need to be adequately<br />

protected.<br />

ENG Events<br />

The first category of such events is the ENG events, which relate<br />

to “engineering data processing and installation procedures”<br />

and are considered to be outside the scope of the safety<br />

analysis. However, this does not consider the possibility of<br />

deliberate sabotage of the trackside data, for example, by<br />

repositioning the balises (ENG-1a). Providing false radio data<br />

(ENG-1b) for transmission by the RBCs would be more tricky, but<br />

might be possible via a proprietary operational interface to the<br />

RBCs that was outside the scope of the ERTMS/ETCS<br />

specifications. Note that this failure mode is distinct from the<br />

various failure modes that can occur during radio transmission<br />

(TRANS-RADIO-X).<br />

EXT events<br />

The second category of such events is the EXT events, which<br />

relate to external systems outside the scope of ETCS. EXT-1<br />

relates to a failure of the interlocking to provide correct route<br />

data, EXT-2 is another failure of engineering data processing,<br />

and EXT-3 is a failure to send an emergency message when<br />

conditions demand it. Again, it might be possible for an attacker<br />

to trigger some of these events by sabotaging the trackside<br />

equipment or exploiting vulnerabilities in proprietary interfaces<br />

to this equipment.<br />

DRV Events<br />

The third category of events is the DRV events, which relate to<br />

driver errors. Clearly, the driver is a trusted component of the<br />

system, and therefore a potential vulnerability that could be<br />

exploited by an attacker. Five driver-related failures are<br />

identified, some of which are classified as safety-related rather<br />

than safety-critical, but in order to cause a system-level failure it<br />

would be necessary for the driver to disable or mislead the<br />

supervisory function of the ETCS by entering false data.<br />

NOT FOR RE-PRINTING<br />

TRANS Events<br />

©<br />

The fourth category of events is the TRANS events, which relate<br />

to various kinds of transmission errors in either the balise-train air<br />

gap interface, or the RBC-train or RBC-RBC radio interface. The<br />

balises are designed to operate in a hostile physical environment<br />

and telegrams are encoded using a robust encoding scheme,<br />

<strong>with</strong> further levels of protection provided by balise linking at the<br />

application level.<br />

Because of the physical constraints, it would be very difficult<br />

for an attacker to trigger a TRANS-BALISE event – it is much<br />

easier to insert a malicious unlinked balise or move a linked<br />

balise, which would correspond to an ENG-1 failure event.<br />

In contrast, the various TRANS-RADIO events, which divide<br />

into trackside and train-track transmissions, are protected by the<br />

safety layer of the Euroradio protocol and are therefore<br />

dependent on the integrity of the underlying key management<br />

and crypto protocols, which might be easier to attack.<br />

Furthermore, by jamming the GSM-R radio signal, it would be<br />

possible to cause a denial of service attack, which is considered<br />

to be a RAM issue rather than a safety issue and has therefore<br />

been excluded from the safety analysis.<br />

TI and MMI Events<br />

Finally, the TI events and MMI events relate to failures of the<br />

train interface (braking functions) or driver console. Although it<br />

might be possible for an attacker to sabotage these interfaces<br />

on a particular train, it would require physical access to the train<br />

and therefore the attack cannot be performed remotely and<br />

does not scale (unless the design and manufacturing process of a<br />

widely deployed ERTMS system can be sabotaged or<br />

compromised in some way).<br />

Apportioning the tolerable hazard rate<br />

Part 3 of the ERTMS Safety Analysis is concerned <strong>with</strong><br />

apportioning the approved Tolerable Hazard Rate for technical<br />

failures of ETCS (THR ETCS ) to the various components of the<br />

reference architecture. The apportionment is made <strong>with</strong> respect<br />

to a standard mission profile, and is used to derive a set of safety<br />

requirements for interoperability. Thus, Part 3 is less relevant<br />

from a security perspective, particularly since the analysis is<br />

solely concerned <strong>with</strong> the technical safety of ETCS and does not<br />

include operational or security issues.<br />

Nevertheless, Part 3 contains several points of interest. For<br />

example, given the standard mission profile and a plausible set<br />

of assumptions about security threats, it might be possible to<br />

calculate a more realistic hazard rate, or at least expose the<br />

sensitivity of the safety analysis to security assumptions.<br />

Also, some of the assumptions that underpin the analysis are<br />

worthy of further consideration. Section 6.2 deals <strong>with</strong><br />

transmission events, <strong>with</strong> section 6.2.2 dealing <strong>with</strong> the threat<br />

posed by masquerade messages. According to paragraphs<br />

6.2.2.1 and 6.2.2.2:<br />

“The quantitative safety targets derived in this document are<br />

valid for errors in the communication channels originated by<br />

random events (e.g., corruption due to electromagnetic<br />

interference, abnormal delays or repetitions in the non-trusted<br />

communication system).<br />

“Masqueraded messages, originated by intentional attacks to<br />

the radio transmission system, must be treated separately on the<br />

basis of qualitative considerations, because the rate of malicious<br />

attacks can not be estimated. The protection offered by the<br />

cryptographic safety code defined in the Euroradio specifications<br />

may be considered sufficient provided the organisation<br />

responsible for system operation can demonstrate the<br />

appropriateness of measures to ensure the confidentiality of the<br />

keys.”<br />

<strong>IRSE</strong> NEWS | ISSUE <strong>176</strong> | MARCH 20<strong>12</strong> 7

MARCH TECHNICAL PAPER<br />

In other words, the operational security of the key management<br />

procedures underpins the security of the Euroradio protocol, and<br />

therefore merits careful analysis. Unfortunately, this aspect of<br />

the ERTMS/ETCS specifications is still at the informative stage<br />

and is the subject of some controversy <strong>with</strong> respect to where<br />

responsibility for key management lies. However, according to<br />

the safety analysis here, compromising key management could<br />

compromise the safety of ERTMS.<br />

Similarly, Section 9.3.4 deals <strong>with</strong> the transmission of<br />

Emergency Messages by radio and argues that ensuring the<br />

integrity of such messages is outside the scope of ETCS, but that<br />

the use of the Emergency Message Service should not detract<br />

from the technical safety of the system. In particular, paragraph<br />

9.3.4.2 notes that “[…] the Emergency Message shall use the<br />

high priority channel. Therefore it is not protected <strong>with</strong> the same<br />

safety features as the normal priority channel against corruption<br />

and / or deletion. The ETCS Emergency function is designed for<br />

the shortest possible response time, not for high integrity.”<br />

Whilst this might be appropriate from a safety perspective,<br />

the lack of integrity provides an opportunity for an attacker, who<br />

could abuse the emergency message facility to cause a denial of<br />

service attack.<br />

Finally, in the light of the concerns raised about the security<br />

of unlinked balises, it is interesting to note the following<br />

observation in section 10.2.1 of the conclusions:<br />

“[…] placing total reliance on the detection of un-linked<br />

balises led to requirements on the failure rate for an information<br />

point that is not feasible. This resulted in the requirement for the<br />

use of two separate balise groups each <strong>with</strong> a minimum of two<br />

balises. This requirement eased the target failure rates on both<br />

the onboard and trackside to figures that are feasible.”<br />

Unfortunately, the use of paired balises only protects against<br />

accidental failures of balises, and not against deliberate attacks.<br />

Moreover, the safety analysis recognizes that the system is<br />

particularly vulnerable to TRANS-BALISE events associated <strong>with</strong><br />

unlinked balises, particularly insertion events, which could be<br />

simulated by an attacker placing unlinked balises at strategic<br />

locations.<br />

NOT FOR RE-PRINTING<br />

©<br />

DISCUSSION<br />

Safety and security are both forms of dependability and use<br />

similar techniques to assess the impact of possible failure modes<br />

on the overall behaviour of a system. Thus, it is not surprising<br />

that a security analysis and a safety analysis of ERTMS identify<br />

similar points of vulnerability in the system. Where the two<br />

approaches differ is in their assumptions about the likelihood of<br />

these failure modes. In general, a safety assessment assumes<br />

that failures are accidental rather than malicious, which makes it<br />

easier to estimate the probability of a failure, whereas a security<br />

analysis tends to assume a worst-case scenario in which all<br />

failures are possible.<br />

Nevertheless, safe systems need to be secure; if they are not<br />

secure, then they are not safe. A safety analysis that does not<br />

consider hazards that could be caused by underlying security<br />

vulnerabilities is deficient.<br />

In practice there may be conflicts between security<br />

requirements and safety requirements. For example, in an<br />

emergency situation, a timely response may be more important<br />

than a secure response. Moreover, safety concerns are rather<br />

different from security concerns: confidentiality is not usually a<br />

safety concern, neither is availability. Safety is primarily concerned<br />

<strong>with</strong> integrity – a system should not do something that is<br />

damaging to its environment, and therefore in some circumstances,<br />

doing nothing is the safest option. In contrast, security is traditionally<br />

concerned <strong>with</strong> confidentiality, integrity and availability.<br />

A failure of confidentiality would not be considered a safety<br />

concern, but would definitely be a security concern. Similarly,<br />

fail-safe behaviour is important from a safety perspective but<br />

conflicts <strong>with</strong> the security requirement to maintain availability.<br />

CONCLUSIONS<br />

Safety is always paramount in railway systems, and ERTMS is<br />

designed to be a safe system. The general philosophy is ‘if in<br />

doubt, stop the train’, which means that it is very difficult for an<br />

attacker to engineer a train accident. However, it is possible for<br />

an attacker to exploit the ‘fail safe’ behaviour of ERTMS, and<br />

create a situation that causes a train to halt. Thus, denial of<br />

service attacks are possible, and could be launched at a time and<br />

place of the attacker’s choosing, perhaps designed to cause<br />

maximum disruption or passenger discomfort (e.g., causing a<br />

train to halt in a tunnel). Causing an accident is more difficult<br />

but not impossible; however, it is important to remember that<br />

ERTMS does not drive the train, and it is therefore the driver<br />

who is ultimately responsible for the safety of the train.<br />

Subsequent work has explored these issues further, including<br />

the identification of specific vulnerabilities, and our results have<br />

been presented to representatives of the UK rail industry and the<br />

European Railway Agency (ERA). Some of the vulnerabilities we<br />

have identified depend very much on the specific details of the<br />

national implementation of ERTMS and GSM-R. Moreover, some<br />

of the most critical parts of an ERTMS implementation (e.g., the<br />

interface between the control centre and the RBCs) are outside<br />

the scope of the ERTMS/ETCS specifications, which are only<br />

concerned <strong>with</strong> interoperability and do not address<br />

implementation issues <strong>with</strong>in a national implementation. Thus,<br />

there is a need to extend the scope of our security review to<br />

include the whole of the national railway infrastructure. More<br />

generally, it is important to ensure that security issues are taken<br />

into account when preparing safety cases, and further work in<br />

this area is planned.<br />

ACKNOWLEDGEMENTS<br />

This work was commissioned by CPNI on behalf of the UK rail<br />

industry and was performed by the Centre for Software<br />

Reliability, City University London. The authors would like to<br />

acknowledge the contributions of Dr Ilir Gashi and Richard<br />

Bloomfield.<br />

REFERENCES<br />

Ref 1. UNISIG SUBSET-026, System Requirement Specification,<br />

Version 2.3.0<br />

Ref 2. UNISIG SUBSET-037, Euroradio FIS, Version 2.3.0<br />

Ref 3. UNISIG SUBSET-038, Off-line Key Management FIS,<br />

Version 2.1.9<br />

Ref 4. UNISIG SUBSET 088, ETCS Application Levels 1 & 2 -<br />

Safety Analysis, Version 2.3.0<br />

(See www.era.europa.eu)<br />

8<br />

<strong>IRSE</strong> NEWS | ISSUE <strong>176</strong> | MARCH 20<strong>12</strong>

WEN ZHOU<br />

Wen Zhou: What went wrong?<br />

By George Nikandros, F<strong>IRSE</strong><br />

(This article was originally written for the newsletter of the Australian Safety Critical Systems Association and<br />

has been recently updated by the Author. If any member has further information perhaps they could let the<br />

<strong>IRSE</strong> NEWS know and it will be published for all to read)<br />

THE ACCIDENT<br />

On 22 July 2011 at about 20:37 two high speed trains collided<br />

on a viaduct near Wen Zhou, resulting in 40 deaths and more<br />

than 200 injuries, raising concerns about the safety of high<br />

speed rail in China (Ref 1). In December 2011, an official<br />

report (in Mandarin Chinese) was released; however the cause<br />

of the accident still remains a mystery. The report however<br />

supports the media statements made by Chinese Government<br />

and Railways officials since the accident.<br />

From these media statements, the Wen Zhou accident was<br />

caused by a failure of a safety-critical system; at least that<br />

seems to be the consensus. According to a South China<br />

Morning Post article by Stephen Chen, the December 20<strong>12</strong><br />

report about on the investigation into the accident raises<br />

unnerving questions about the safety of the mainland’s highspeed<br />

rail network <strong>with</strong>out supplying any answers. According<br />

to the article a serious software bug in the main computer of<br />

the train control system at a station was pivotal in the accident,<br />

although details are as yet unknown. Since the accident there<br />

has been much speculation even conjecture as to why and how<br />

the signalling system failed so catastrophically. The on-line<br />

Wall Street Journal (3 October 2011) (Ref 2) even suggests that<br />

protection of intellectual property (copyright) was a contributing<br />

factor.<br />

According to a Railway Gazette article (Ref 3), the recentlyappointed<br />

head of the Shanghai Railway Bureau, An Lusheng,<br />

appearing before the independent investigation panel<br />

established by the State Council, said that ‘design flaws’ in the<br />

signalling on the Ningbo – Wen Zhou high speed line led to<br />

the fatal rear-end collision near Wen Zhou on July 22. He<br />

added that having been struck by lightning, the signal system<br />

at Wenzhou South station failed to turn a Green light to Red.<br />

On the same day, the Beijing National Railway Research &<br />

Design Institute of Signal & Communication issued an apology<br />

for the accident.<br />

The railway between Ningbo and Wenzhou South is<br />

equipped <strong>with</strong> lineside signals overlaid <strong>with</strong> CTCS-2 (Chinese<br />

Train Control System) to provide automatic train protection<br />

which apparently has a similar functionality to the ETCS<br />

(European Train Control System) Level 1, using balises to<br />

provide intermittent updates to the on-train equipment. The<br />

line is designed for mixed traffic operation <strong>with</strong> a maximum<br />

speed of 250 km/h.<br />

A link to a timeline of events from the Wen Zhou Control<br />

Centre published by a Chinese newspaper in Mandarin<br />

Chinese was posted to the Safety Critical Mailing List by Oleg<br />

Lisagor on 28 July, 2011. The timeline was considered to be<br />

from a trustworthy source. An interpretation of the translated<br />

timeline of events follows. Figure 2 is provided to aid<br />

understanding:<br />

NOT FOR RE-PRINTING<br />

©<br />

Figure 1: Chinese rescue workers by the wreckage of train cars in Wen Zhou<br />

7:34 pm Wen Zhou south advised that train D32<strong>12</strong> on the 4th road<br />

whilst approaching the starter signal at Proceed, had<br />

passed the station starter signal at Stop. (The signal<br />

appears to have changed to stop as the train D32<strong>12</strong><br />

approached it.) Control (Shanghai Control Centre) then<br />

asked the driver if the train was moving. Upon confirmation<br />

from the driver that the train was not moving,<br />

Control cancelled the re-clearing request of this signal.<br />

7:36 pm Because Wen Zhou south 4th road station starter signal<br />

has no way of clearing, Control arranged for Wen Zhou<br />

south station to be transferred to emergency control.<br />

7:39 pm The Yong Jia to Wen Zhou South down line section, three<br />

approach track sections to Wen Zhou south station<br />

showed up as occupied / failed as a result of a lightning<br />

strike. Civil/Signal maintenance staff and traction<br />

overhead maintenance staff were notified.<br />

7:44 pm Control (Shanghai) received the following report from Wen<br />

Zhou south station: Station communication centre screen<br />

showed that three consecutive approach sections in the<br />

down direction were failed/occupied, station (Control)<br />

CTC screen didn’t show anything. After train D32<strong>12</strong><br />

departed the 4th road, control arranged for normal station<br />

control to be returned to Wen Zhou South station.<br />

7:45 pm Wen Zhou South station reported to Yong Jia and Ou Hai<br />

station that the approaching and departing sections were<br />

shown as occupied.<br />

7:51 pm Train D3115 arrives at Yong Jia station.<br />

7:53 pm Control (Shanghai) arranged for Wen Zhou south station to<br />

transfer to emergency control.<br />

7:54 pm Yong Jia station was transferred to emergency control.<br />

7:55 pm Control (Shanghai) arranged for Ou Hai to transfer to<br />

emergency control. Wen Zhou south station transferred to<br />

emergency control.<br />

8:06 pm The officers in charge of Yong Jia station made a special<br />

call to the driver of D301 advising Yong Jia station is under<br />

emergency control.<br />

<strong>IRSE</strong> NEWS | ISSUE <strong>176</strong> | MARCH 20<strong>12</strong> 9

WEN ZHOU<br />

8:<strong>12</strong> pm Train D301 arrives at Yong Jia station.<br />

8:14 pm Control (Shanghai) arranged for train D3115 to<br />

depart Yong Jia station, informing the driver to<br />

proceed <strong>with</strong> vigilance On-Sight mode at<br />

20 km/h upon encountering a Red signal<br />

(aspect) <strong>with</strong>in the section.<br />

8:15 pm Train D3115 departs Yong Jia station.<br />

8:20 pm Wen Zhou south station reported that four<br />

approach down line (track) sections had failed<br />

(they showed up as flashing on the screen), but<br />

the section going to Ou Hai was clear.<br />

8:24 pm Train D301 departs Yong Jia station.<br />

8:25 pm Train D3115 stopped at three track sections<br />

from Wen Zhou, and then proceeded on<br />

On-Sight mode.<br />

8:26 pm Control (Shanghai) contacted Wen Zhou south<br />

station. (Wen Zhou south) station reports train<br />

D3115 was approaching and was three signal<br />

sections away. CTC (Control) system showed<br />

that the occupied sections had already cleared.<br />

Because train D3115 train spent a long time in<br />

the section, Southern Wen Zhou station<br />

contacted the driver of D3115 train. The driver<br />

answered saying that the signal aspects <strong>with</strong>in<br />

the section were not stable. The officers in<br />

charge of Wen Zhou south station reported<br />

this to the officers in charge of Yong Jia<br />

station.<br />

8:?? pm When D301 was <strong>with</strong>in 6-7 signal sections away<br />

from D3115, Wen Zhou South station made a<br />

special call to the driver of D301 advising the<br />

driver that “Train D3115 is <strong>with</strong>in this section,<br />

proceed <strong>with</strong> caution.” The driver of D301<br />

acknowledged this in response. (The precise<br />

time is unknown; however it must some time<br />

after the departure of train D301from Yong Jia.<br />

i.e. after 8:24 pm.)<br />

8:31 pm Driver of train D3115 reported (to Shanghai<br />

Control) that passengers have pressed the<br />

emergency stop button and the train<br />

pantograph has retracted.<br />

8:37 pm Control (Shanghai) arranged for Wen Zhou<br />

South station to contact the driver of D301 to<br />

apply braking<br />

8:39 pm Control (Shanghai) received the following<br />

report from Wen Zhou south station: The train<br />

driver for D3115 reported that the rear<br />

carriages of the train had derailed, and there is<br />

half a section of carriage hanging off the<br />

bridge.<br />

Train D301 and train D3115 collided head to tail<br />

between Yong Jia (@570k680m) and Wen Zhou South<br />

(@588k863m) close to 585k700m, causing train D3115<br />

carriages 13, 14, 15, 16 to derail, and train D301 carriages<br />

1 to 4 to derail (of which carriages 1 and 2 fell off the<br />

bridge, the bridge being approximately 15 metres in the<br />

air).<br />

NOT FOR RE-PRINTING<br />

©<br />

Figure 2: Schematic showing location of time line events<br />

WHY DID THE ACCIDENT HAPPEN?<br />

Until the precise cause is identified, one can only speculate as to how the<br />

accident happened. However the timeline of events provides some clues.<br />

From the extent of physical damage to the trains, it is reasonable to<br />

conclude that this was a high speed collision. So what caused the driver<br />

of train D301 to travel at such a high speed knowing that train D3115<br />

being ahead and travelling at slow speed and that there was signalling<br />

problems at Wen Zhou?<br />

The most plausible explanation is that the driver of train D301 must<br />

have got an “all clear” signal despite train D3115 being ahead and<br />

travelling at 20km/h. This can only arise if the signalling system fails in an<br />

unsafe way. A Ministry of Railways official supposedly said (Ref 4) that a<br />

lightning strike damaged a fuse which caused the lights in the lineside<br />

signals to go out; thus there were no signals at RED for the driver of train<br />

D301 to see.<br />

One event that does not seem plausible is the application of the<br />

emergency brake by a passenger on train D3115, particularly as the train<br />

had not long stopped when it encountered a signal at RED and was<br />

10<br />

<strong>IRSE</strong> NEWS | ISSUE <strong>176</strong> | MARCH 20<strong>12</strong>

INDUSTRY NEWS<br />

travelling slowly (20 km/h), assuming that the driver was following the<br />

instructions from Train Control. Also, given that the pantograph retracted<br />

strongly suggests that this was a system response to a signalling violation<br />

i.e. the train passed a signal at RED or some other system failure.<br />

The Red signal encountered by train D3115 aligns <strong>with</strong> the indications of<br />

failed track sections to the station staff at Wen Zhou and is evidence that<br />

the signalling system was failed in the usual safe mode. The report from the<br />

driver of train D3115 that the “signal aspects were not stable”, suggests<br />

that the maintenance staff were on-site attempting repair; they were<br />

notified at 7:39 pm, well before train D3115 departed Yong Jia for Wen Zhou<br />

at 8:15 pm.<br />

It appears that the part of the signalling system which creates and issues<br />

the movement authority for train D301 contained a state of the track ahead<br />

which was not consistent <strong>with</strong> state of the track at the local signalling system<br />

at Wen Zhou.<br />

Without knowledge of the particular signalling system technology or its<br />

architecture it is not possible to draw any conclusions as to how such an<br />

inconsistency eventuated. It may be that the data might not have been<br />

refreshed due to equipment damage cased by lightning; there was a storm<br />

at the time.<br />

Hopefully the investigation will identify the cause and that cause(s) be<br />

made public. There is no doubt that there would be important lessons for<br />

the rail industry. It would be a shame if pride and reputation prevents<br />

learning from this accident.<br />

According to a South China Morning Post article, the December 2011<br />

report on the accident investigation adds to the speculation that protection<br />

of intellectual property may have been a contributing factor.<br />

The supplier of the on-board Automatic Train Protection system was<br />

Hollysys Automation Technologies Ltd, a Beijing based company.<br />

According to the on-line Wall Street Journal, the systems supplied by<br />

Hollysys were branded as proprietary to Hollysys and contained tailor-made<br />

components from Hitachi (Japan).<br />

Apparently, Hitachi concealed the inner workings of the tailor-made<br />

components fearing loss of their intellectual property, so as to make it<br />

harder to clone. Whilst one can understand the action to conceal the inner<br />

workings to protect their intellectual property, Hitachi’s view that Hollysys<br />

would not integrate the equipment into a broader safety-signalling system<br />

<strong>with</strong>out Hitachi’s intimate knowledge and know-how appears to have been<br />

a major miscalculation.<br />

It is well known that China does not abide by or support international<br />

laws <strong>with</strong> respect to copyright and intellectual property.<br />

This however raises ethical issues. In many other countries there are<br />

laws which mandate the disclosure of information on the safe use of your<br />

goods; not only for their intended use, but also <strong>with</strong> respect to foreseeable<br />

misuse. Purposely hiding information, particularly relating to something that<br />

may not be obvious, that could prevent harm, would be a contravention of<br />

these laws. It would also contravene the ethics of most professional bodies.<br />

Hopefully this article will prompt further <strong>IRSE</strong> NEWS contributions on<br />

this topic.<br />

NOT FOR RE-PRINTING<br />

©<br />

REFERENCES<br />

Ref 1: http://china.org.cn/china/2011-09/16/content_23429796.htm<br />

Ref 2: http://online.wsj.com/article/<br />

SB10001424053111904353504576568983658561372.html<br />

Ref 3: http://www.railwaygazette.com/nc/news/single-view/view/signalfailure-suspected-in-wenzhou-crash.html<br />

Ref 4: http://blog.english.caixin.com/article/361/<br />

Turkish State Railways ERTMS<br />

A joint venture of Invensys Rail and Turkish civil<br />

engineering company Fermak has been awarded a<br />

76 million project from Turkish State Railways (TCDD)<br />

to install advanced European Rail Traffic Management<br />

System (ERTMS) signalling and communications on the<br />

310 km Bandirma-Menemen railway - the main rail<br />

link between the <strong>Mar</strong>maray and Mediterranean seas.<br />

Invensys Rail’s share of the award, worth 59m,<br />

will see the company design, supply, install, test and<br />

commission its industry leading FUTUR ERTMS<br />

systems both onboard trains and on the lineside.<br />

The whole route will run under the sophisticated and<br />

proven ERTMS Level 2 regime. Invensys Rail will also<br />

install automatic train stop equipment, WESTRACE<br />

electronic interlockings, FS3000 jointless track<br />

circuits, level crossing safety systems, GSM-R voice<br />

and data communications, and a Central Traffic<br />

Control Centre in Balikesir.<br />

Last November, Invensys Rail signed a contract to<br />

supply the signalling and communications for the<br />

high-profile <strong>Mar</strong>maray link, which will see a new<br />

undersea tunnel link both halves of Istanbul by rail.<br />

This link will see Invensys Rail deploy both its ERTMS<br />

system for conventional rail and its Communications<br />

Based Train Control technology for commuter trains<br />

on the same railway - the first time this has been<br />

done anywhere in the world.<br />

Croatia commissions ERTMS<br />

The first railway line in Croatia to be equipped <strong>with</strong><br />

ERTMS / ETCS technology has begun operations.<br />

The Bombardier INTERFLO 250 ERTMS / ETCS<br />

Level 1 system is now operating on the upgraded<br />

33.5 km section of the Pan European Corridor X<br />

between Austria and Greece.<br />

The signalling system was delivered by a consortium<br />

of Bombardier and Site on the 33.5 km section<br />

of the Vinkovci - Tovarnik line to the Serbian border.<br />

As part of the project the company had provided a<br />

next generation Lock 950 computer-based interlocking<br />

system and wayside equipment, certification<br />

of the system allowing trains to run at a speed up to<br />

160 km/h (100 mph).<br />

Monorail System for Delhi<br />

The Delhi Government in India has given an inprinciple<br />

approval for the construction of a 10.8 km<br />

elevated monorail line forming a link between the<br />

Shastri Park Metro station and Trilokpuri through<br />

Laxmi Nagar in east Delhi.<br />

The proposed monorail will be straddle-type and<br />

run on an elevated line built on 9 metre high pillars.<br />

The system is expected to be functional by 2017.<br />

<strong>IRSE</strong> NEWS | ISSUE <strong>176</strong> | MARCH 20<strong>12</strong> 11

<strong>IRSE</strong> CONVENTION - PART 2<br />

Some individual views of the <strong>IRSE</strong> International Convention to Singapore and Kuala Lumpur<br />

<strong>IRSE</strong> International Convention: Tuesday 11 October 2011<br />

By Trevor Foulkes<br />

Photos: Trevor Foulkes and Ian James Allison<br />

On the weekend immediately prior to the convention, the final<br />

section of the Singapore Circle Line came into operation. As a<br />

result, I read in The Straits Times, that Mr Packiam Malayamanar<br />

gets an additional thirty minutes to enjoy his breakfast. This line<br />

was bought into use and is run by SMRT and they were the<br />

focus of the second day of the convention.<br />