naval dockyard, mumbai - Irfc-nausena.nic.in

naval dockyard, mumbai - Irfc-nausena.nic.in

naval dockyard, mumbai - Irfc-nausena.nic.in

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

epair of ships or boats or vessels belong<strong>in</strong>g to the Government of India. Therefore the<br />

firms are requested not to quote for service tax.<br />

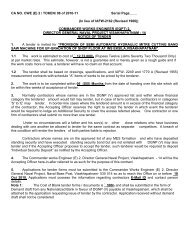

RESPONSE FORMAT TO BE ATTACHED IN TBID<br />

(C)<br />

Related Activities (NOT TO BE QUOTED)<br />

Sl Activity Confirm ability to<br />

meet requirement<br />

(Answer <strong>in</strong> Yes/No)<br />

i) Through Surface preparation of <strong>in</strong>ternal compartments and<br />

external compartments for survey.<br />

ii) Grit blast<strong>in</strong>g /hydro blast<strong>in</strong>g/vacuum blast<strong>in</strong>g of external hull<br />

to bare metal for survey<br />

iii) Pa<strong>in</strong>t<strong>in</strong>g as per the NCD 1481/1491 approved specifications<br />

of U/W hull and A/W hull. Pa<strong>in</strong>t manufacturers performance<br />

guarantee certificate and orig<strong>in</strong>al purchase vouchers for all<br />

pa<strong>in</strong>ts to be submitted to user department<br />

iv) Pa<strong>in</strong>t<strong>in</strong>g of deck <strong>in</strong>ternal compartments and deck fitt<strong>in</strong>gs as<br />

per the NCD/ NCD approved specifications. pa<strong>in</strong>t<br />

manufacturers performance guarantee certificate and<br />

orig<strong>in</strong>al purchase vouchers for all pa<strong>in</strong>ts to be submitted to<br />

user department<br />

v) Air pressure test of all tanks to 0.2 Kg/cm2 more than<br />

atmospheric pressure with drop not exceed<strong>in</strong>g 0.01 Kg/Cm2<br />

after 10 M<strong>in</strong>utes.<br />

vi) All pipes to be Gr “C” heavy galvanized pipes conform<strong>in</strong>g to<br />

IS1239 (Part I) Pipe fitt<strong>in</strong>gs as per IS 4310.<br />

vii) Side shell and deck boundaries are to be double cont<strong>in</strong>uous<br />

welded.<br />

viii) All brackets, connections and all seams and butts are to be<br />

double cont<strong>in</strong>uous welded.<br />

ix) 100% DPT to be undertaken on all weld jo<strong>in</strong>ts.<br />

x) Replacement (with new one) of all fitt<strong>in</strong>gs such as brackets,<br />

panel<strong>in</strong>g, MFMB/lagg<strong>in</strong>g, deck fitt<strong>in</strong>gs, strips etc after<br />

completion of hot work / ma<strong>in</strong> job<br />

xi) Rectifiers would be used by the contractor with suitable<br />

electrodes as approved by MQC(H) for weld<strong>in</strong>g.<br />

xii) Project monitor<strong>in</strong>g of the craft would be done by CCPM and<br />

CCPM would be prepared and presented by the contractor.<br />

Weekly presentation would be given by the contractor to<br />

User Manager and MYCR. MYCR would be the nodal<br />

agency to coord<strong>in</strong>ate CCPM through contractor. Any<br />

clarification <strong>in</strong> this regard would be clarified by contractor to<br />

DYT/INCOD/1213/106(a)/PLYCM/MADHURREFIT/420<br />

53/127

![DGNP[V] - Irfc-nausena.nic.in](https://img.yumpu.com/23509938/1/158x260/dgnpv-irfc-nausenanicin.jpg?quality=85)