Fall - InsideOutdoor Magazine

Fall - InsideOutdoor Magazine

Fall - InsideOutdoor Magazine

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Optimer, 180’s Settle<br />

Infringement Case<br />

Optimer Performance Fibers has settled with 180’s<br />

concerning a patent and trademark infringement upon<br />

its Dri-release with FreshGuard product. The original<br />

complaint identified work wear shirts sold online by<br />

180’s under its Gorgonz label as far back as 2005 that,<br />

although marked with the Dri-release with FreshGuard<br />

patent number, did not contain Dri-release yarn. It also<br />

identified 180’s ear warmers also not made of Drirelease<br />

that were sold bearing the Dri-release with<br />

FreshGuard logo.<br />

“Dri-release is well known in many markets as a<br />

highly effective moisture management technology<br />

brand. This action is critical to protect our patent<br />

as well as the integrity of Dri-release products sold<br />

to trusting consumers,” says Beth Moore, Optimer<br />

director of operations.<br />

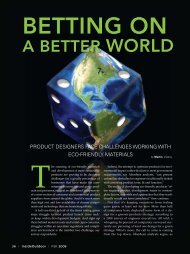

Green Springs across<br />

the Supply Chain<br />

As most would expect, the recent OR Summer<br />

Market was awash in new eco-friendly offerings and<br />

sustainability stories, with news and new materials<br />

generated from up and down the supply chain.<br />

Among the bigger stories, buyers of nylon 6.6 now<br />

have a new alternative, as both Toray Industries and<br />

Unifi separately announced nylon yarns made from<br />

recycled material.<br />

Both options utilize pre-consumer nylon fiber<br />

waste, or “off-spec” yarn, that is collected during<br />

the production of traditional virgin nylon fiber and<br />

converted to the recycled nylon. While this process<br />

doesn’t take plastic bottles out of landfills, as Unifi’s<br />

Repreve recycled polyester does, Repreve Nylon<br />

conserves the equivalent of 6 million gallons of<br />

Making Virgin Nylon Versus Making Repreve<br />

Virgin Nylon 6.6 Process<br />

Crude oil wellhead<br />

Crude oil refinery<br />

Benzene<br />

Cyclohexane<br />

Hexamethylene & adipic acid<br />

Nylon salt<br />

Polymerization<br />

Extrusion<br />

Texturing<br />

Source: Unifi<br />

Repreve Nylon 6.6 Process<br />

Process eliminated<br />

Process eliminated<br />

Process eliminated<br />

Process eliminated<br />

Process eliminated<br />

Process eliminated<br />

Repreve chip production<br />

Extrusion<br />

Texturing<br />

gasoline annually compared to the production of<br />

virgin nylon or polyester, says the company. In other<br />

words, for every pound of Repreve nylon yarn, 77,000<br />

BTUs are conserved, or the equivalent of 0.6 gallons<br />

of gasoline.<br />

Meanwhile, Toray’s new ecodream requires only<br />

15 percent of the energy consumption required to<br />

produce virgin nylon, say Toray sources, while the<br />

greenhouse gas emissions are only 20 percent of<br />

virgin nylon production.<br />

Unifi has partnered with Burlington Worldwide and<br />

United Knitting in the development of new woven and<br />

knit fabrics using Repreve nylon. Burlington will feature<br />

Repreve nylon under the Generations Collection,<br />

targeting technical sportswear. United Knitting will<br />

introduce Repreve nylon in a series of new eco-friendly<br />

knit fabrics for activewear.<br />

And speaking of Unifi, Polartec has fully embraced<br />

Repreve recycled polyester for many of its offerings.<br />

The company says it will save 38 million pounds of<br />

CO2 annually by using recycled yarns, and by 2009<br />

expects 20 percent of all Polartec products to contain<br />

at least 50 percent recycled material.<br />

<strong>Fall</strong> 2008 | <strong>InsideOutdoor</strong> | 41