Assembly solutions - Ingersoll Rand

Assembly solutions - Ingersoll Rand

Assembly solutions - Ingersoll Rand

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

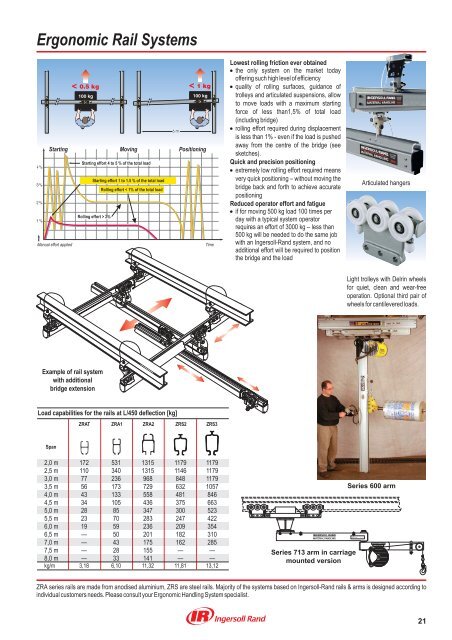

Ergonomic Rail Systems<br />

< 0.5 kg<br />

100 kg<br />

< 1 kg<br />

100 kg<br />

6m<br />

Starting Moving Positioning<br />

Starting effort 4 to5%ofthetotal load<br />

Starting effort 1 to 1.5 % of the total load<br />

Rolling effort < 1% of the total load<br />

Rolling effort > 2%<br />

Manual effort applied<br />

Time<br />

Lowest rolling friction ever obtained<br />

the only system on the market today<br />

offering such high level of efficiency<br />

quality of rolling surfaces, guidance of<br />

trolleys and articulated suspensions, allow<br />

to move loads with a maximum starting<br />

force of less than1,5% of total load<br />

(including bridge)<br />

rolling effort required during displacement<br />

is less than 1% - even if the load is pushed<br />

away from the centre of the bridge (see<br />

sketches).<br />

Quick and precision positioning<br />

extremely low rolling effort required means<br />

very quick positioning – without moving the<br />

bridge back and forth to achieve accurate<br />

positioning<br />

Reduced operator effort and fatigue<br />

if for moving 500 kg load 100 times per<br />

day with a typical system operator<br />

requires an effort of 3000 kg – less than<br />

500 kg will be needed to do the same job<br />

with an <strong>Ingersoll</strong>-<strong>Rand</strong> system, and no<br />

additional effort will be required to position<br />

the bridge and the load<br />

Articulated hangers<br />

Light trolleys with Delrin wheels<br />

for quiet, clean and wear-free<br />

operation. Optional third pair of<br />

wheels for cantilevered loads.<br />

Example of rail system<br />

with additional<br />

bridge extension<br />

Load capabilities for the rails at L/450 deflection [kg]<br />

ZRAT ZRA1 ZRA2 ZRS2 ZRS3<br />

Span<br />

2,0 m 172 531 1315 1179 1179<br />

2,5 m 110 340 1315 1146 1179<br />

3,0 m 77 236 968 848 1179<br />

3,5 m 56 173 729 632 1057<br />

4,0 m 43 133 558 481 846<br />

4,5 m 34 105 436 375 663<br />

5,0 m 28 85 347 300 523<br />

5,5 m 23 70 283 247 422<br />

6,0 m 19 59 236 209 354<br />

6,5 m — 50 201 182 310<br />

7,0 m — 43 175 162 285<br />

7,5 m — 28 155 — —<br />

8,0 m — 33 141 — —<br />

kg/m 3,18 6,10 11,32 11,81 13,12<br />

Series 713 arm in carriage<br />

mounted version<br />

Series 600 arm<br />

ZRA series rails are made from anodised aluminium, ZRS are steel rails. Majority of the systems based on <strong>Ingersoll</strong>-<strong>Rand</strong> rails & arms is designed according to<br />

individual customers needs. Please consult your Ergonomic Handling System specialist.<br />

21