Hygrothermal aging of a filled epoxy resin - Schneider Electric

Hygrothermal aging of a filled epoxy resin - Schneider Electric

Hygrothermal aging of a filled epoxy resin - Schneider Electric

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Technical collection<br />

<strong>Hygrothermal</strong> <strong>aging</strong> <strong>of</strong> a <strong>filled</strong><br />

<strong>epoxy</strong> <strong>resin</strong><br />

2007 - Conferences publications<br />

E. Brun<br />

P. Rain<br />

G. Teissédre<br />

C. Guillermin<br />

S. Rowe

<strong>Schneider</strong> <strong>Electric</strong> 2007 - Conferences publications<br />

2007 InternationalConferenceon Solid Dielectrics, Winchester, UK, July 8-13, 2007<br />

<strong>Hygrothermal</strong> <strong>aging</strong> <strong>of</strong> a <strong>filled</strong> <strong>epoxy</strong> <strong>resin</strong>.<br />

E. Brun 2 , P. Rain 1* , G. Teissèdre 1 , C. Guillermin 2 , S. Rowe 2<br />

1 Grenoble <strong>Electric</strong>al Engineering Lab (G2Elab), CNRS- Université de Grenoble, Grenoble - France<br />

2 <strong>Schneider</strong> <strong>Electric</strong>, Grenoble, France<br />

* E-mail : pascal.rain@grenoble.cnrs.fr<br />

Abstract: The hygrothermal conditioning <strong>of</strong> an <strong>epoxy</strong><br />

<strong>resin</strong> at 80°C under 80% RH has been followed by<br />

weight measurements, thermogravimetric analysis<br />

(TGA) and dynamical mechanical analysis (DMA). The<br />

samples are either <strong>filled</strong> with 60% by weight <strong>of</strong> silica<br />

flour or are not <strong>filled</strong>. Above an apparent saturation<br />

value <strong>of</strong> about 1.5% reached within a few days, a slight<br />

but significant mass uptake was observed in the <strong>filled</strong><br />

<strong>resin</strong>, especially after 50 days. The TGA showed an<br />

evolution <strong>of</strong> the <strong>filled</strong> samples with conditioning after<br />

50 days as well, which was not observed on un<strong>filled</strong><br />

samples. For the <strong>filled</strong> samples, the elastic modulus in<br />

the rubbery state decreased with conditioning. These<br />

evolutions have been attributed to the formation <strong>of</strong> a<br />

degraded inter-phase region due to hydrolysis occurring<br />

after the debonding <strong>of</strong> the filler-matrix interface caused<br />

by the absorbed water.<br />

INTRODUCTION<br />

Filled <strong>epoxy</strong> <strong>resin</strong> has been used for many years in<br />

electrical engineering. The material is submitted to<br />

thermal and electrical stress and is in contact with the<br />

environment. The mechanisms leading to the occurrence<br />

<strong>of</strong> electrical breakdown are still not properly<br />

understood. A great variety <strong>of</strong> electrical, thermal,<br />

mechanical, chemical phenomena may be involved in<br />

the ageing <strong>of</strong> these polymeric insulations. Since the<br />

material may be exposed to a humid environment, the<br />

present work focuses on the specific influence <strong>of</strong> water<br />

on the material and its effects on the electrical rigidity.<br />

From an electrical point <strong>of</strong> view, the impact <strong>of</strong> water on<br />

the dielectric behaviour <strong>of</strong> <strong>filled</strong> <strong>epoxy</strong> <strong>resin</strong>s has been<br />

extensively described. As concerns the electrical<br />

rigidity, the breakdown voltages <strong>of</strong> wet materials may<br />

fall by a factor <strong>of</strong> 5 to 10 in comparison with a dry<br />

material [1-3]. In composites, the interfaces between the<br />

matrix and the mineral fillers are known to be zones <strong>of</strong><br />

weakness [4-6]. The shape <strong>of</strong> the fillers may also<br />

influence the breakdown voltage [7]. Furthermore, the<br />

deleterious influence <strong>of</strong> water on <strong>epoxy</strong> <strong>resin</strong> is well<br />

known [8]. The main mechanisms leading to physical<br />

and chemical degradation <strong>of</strong> <strong>epoxy</strong> <strong>resin</strong> have been<br />

illustrated or at least foreseen [9]. With the use <strong>of</strong> a<br />

FTIR spectrometer, water layers <strong>of</strong> a few hundred nm<br />

have been measured at an <strong>epoxy</strong>/glass interface [10].<br />

This order <strong>of</strong> magnitude is in accordance with the MEB<br />

observations reported in [3]. Water may accumulate at<br />

the interfaces and lead to a filler/matrix debonding,<br />

which may be followed by mechanical cracks<br />

propagating in the bulk material [11].<br />

For a better understanding <strong>of</strong> the overall mechanisms,<br />

the impact <strong>of</strong> the hygrothermal conditioning on the<br />

physical properties have thus been carried out first.<br />

<strong>Electric</strong>al characterisations will ensue. In the following,<br />

mass uptakes, thermogravimetric analyses and dynamic<br />

mechanical analyses are reported.<br />

EXPERIMENTAL PART<br />

Materials, Sampling and Conditioning<br />

The material used is a DGEBA based <strong>epoxy</strong> <strong>resin</strong> <strong>filled</strong><br />

or not with silica flour and cured with an anhydrid acid.<br />

The filler content is 60% by weight. The fillers’ sizes<br />

range between a few 0.1 μm and 200 μm.<br />

The components were mixed, cast in a mould then<br />

maintained at 100°C during one hour. After crosslinking,<br />

samples were demoulded and then cured at<br />

130°C during 16 hours. The sheets are 0.5 mm thick.<br />

Glass transition temperatures <strong>of</strong> the <strong>filled</strong> and un<strong>filled</strong><br />

samples are 72°C and 70°C respectively.<br />

Samples are cleaned with alcohol and dried in an oven<br />

at 50°C for 24 hours. After this preparation, their initial<br />

mass was measured. The samples were then conditioned<br />

in a climatic chamber at 80°C under 80%RH.<br />

Characterisations<br />

Moisture uptake measurements: Samples were<br />

periodically withdrawn from the climatic chamber.<br />

Before mass measurements were made, the temperature<br />

and hygrometry <strong>of</strong> the samples were stabilized. For this<br />

purpose, they were laid in a small quantity <strong>of</strong> water<br />

initially at 80°C. After 15 minutes, both water and<br />

sample were at ambient temperature. Samples were then<br />

dried with a suitable paper. The mass uptake was<br />

measured with an electronic Ohauss balance Explorer.<br />

Thermogravimetric analysis (TGA): The thermal<br />

stability <strong>of</strong> the materials has been evaluated throughout<br />

conditioning by TGA with a TA instruments® 2050.<br />

The mass loss <strong>of</strong> the samples was measured during a<br />

temperature rise <strong>of</strong> 3°C/min between -40°C and 850°C.<br />

Experiments were carried under nitrogen to avoid added<br />

oxidation. A gas flow <strong>of</strong> 45 mL/min inside the oven<br />

allowed the extraction <strong>of</strong> the thermolysis by-products.<br />

The relative mass loss <strong>of</strong> samples with initial mass <strong>of</strong> 10<br />

1-4244-0750-8/07/$20.00©2007 IEEE.<br />

239

<strong>Schneider</strong> <strong>Electric</strong> 2007 - Conferences publications<br />

to 20 mg is reported hereafter.<br />

Dynamic Mechanical Analysis (DMA): The evolution<br />

<strong>of</strong> mechanical properties and thermal transitions during<br />

conditioning were measured by DMA with a TA<br />

instruments® 2980 using the 3-point bending mode.<br />

Taking into account the elastic domain <strong>of</strong> the material,<br />

the measurement conditions were the following: a<br />

dynamic magnitude <strong>of</strong> 50µm and a static force <strong>of</strong> 140%<br />

<strong>of</strong> the dynamic force. The samples were rectangular in<br />

shape 40×10×0.5mm 3 . The frequency was 1Hz and the<br />

temperature rise was 3°C/min from -40°C to 140°C.<br />

RESULTS AND DISCUSSION<br />

Moisture uptake results<br />

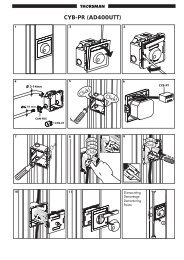

Three different samples, either <strong>filled</strong> or not <strong>filled</strong>, were<br />

measured for each conditioning duration. Mean values<br />

and standard deviations are reported in Figure 1. For a<br />

better comparison <strong>of</strong> the two materials, mass variations<br />

<strong>of</strong> the <strong>filled</strong> samples were calculated taking into account<br />

the initial mass <strong>of</strong> un<strong>filled</strong> <strong>resin</strong>, evaluated by the mean<br />

filling content <strong>of</strong> 60%.<br />

Water saturation <strong>of</strong> not <strong>filled</strong> samples is observed after<br />

about 5 days. The water uptake was then <strong>of</strong> 1.5%. The<br />

mass uptake <strong>of</strong> <strong>filled</strong> samples is lower at the beginning<br />

than the one <strong>of</strong> un<strong>filled</strong> ones: the kinetics <strong>of</strong> water<br />

absorption is slower. The water diffusion is impeded by<br />

the silica grains, which slow down its propagation<br />

throughout the whole material. After 5 days<br />

conditioning, the mass variation was close to the one <strong>of</strong><br />

un<strong>filled</strong> samples but measurements tend to indicate that<br />

the mass uptake continues to progress after the quasi–<br />

saturation has been reached. This specific behaviour <strong>of</strong><br />

<strong>filled</strong> samples has already been reported in [12].<br />

Furthermore, a slope increasing after about 50 days has<br />

been observed in a similar way to that shown in [13].<br />

These measurements will be completed to confirm this<br />

tendency. This difference observed between the two<br />

materials can be attributed to phenomena taking place at<br />

the <strong>epoxy</strong>/silica interfaces. The following mechanism<br />

can be proposed. Firstly, water molecules break the<br />

physical bounds between the silica grains and the <strong>resin</strong><br />

and form H-bounds with the polymer. Then, some water<br />

mass uptake (%)<br />

2<br />

1.8<br />

1.6<br />

1.4<br />

1.2<br />

1<br />

0.8<br />

0.6<br />

0.4<br />

0.2<br />

0<br />

Un<strong>filled</strong> samples<br />

Filled samples<br />

0 20 40 60 80<br />

Conditioning time (days)<br />

Figure 1: Weight gain in un<strong>filled</strong> () and <strong>filled</strong> ()<br />

samples as a function <strong>of</strong> conditioning time.<br />

accumulates between the two phases, part <strong>of</strong> which<br />

possibly reacts with the <strong>resin</strong>.<br />

TGA results<br />

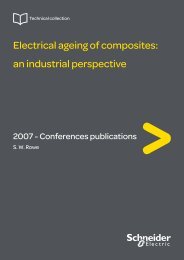

Thermogravimetric analysis was carried out for <strong>filled</strong><br />

and not <strong>filled</strong> samples after until 70 days <strong>of</strong><br />

conditioning. The thermal behaviour <strong>of</strong> unaged sample<br />

are mentioned as “reference” in the figures. The dots on<br />

the graphics are not measurements points but are added<br />

to improve visualisation <strong>of</strong> the data.<br />

The thermograms are displayed in Figure 2 for un<strong>filled</strong><br />

samples. The derivatives <strong>of</strong> the mass loss curves are<br />

also displayed to highlight the differences between the<br />

samples. A detail <strong>of</strong> the curves between 50°C and<br />

200°C is enlarged. This shows a significant decreasing<br />

<strong>of</strong> the mass between 50°C and 120°C in aged samples,<br />

which is not observed in reference samples. This mass<br />

loss is slightly lower than the water uptake measured by<br />

gravimetry. It corresponds to the evaporation <strong>of</strong><br />

absorbed water. Xu et al [13] observed an initial, weak,<br />

peak <strong>of</strong> the derivative weight in the same temperature<br />

range that they attributed to the evaporation <strong>of</strong> water<br />

contained only in the free volumes. They considered<br />

that the bound water was released at 200-300°C where<br />

they observe a slight difference between as-cured and<br />

aged samples. Our results do not confirm this point. The<br />

main mass loss occurred between 300 and 450°C. For<br />

all aged un<strong>filled</strong> samples investigated so far, the<br />

derivative weights display a maximum at about 398°C<br />

and a shoulder (maximum <strong>of</strong> the second derivative) at<br />

364°C. This corresponds to <strong>resin</strong> decomposition. At<br />

800°C, a residual mass <strong>of</strong> about 6% was measured<br />

which was not observed in similar experiment under<br />

oxygen flow. MEB analysis showed the presence <strong>of</strong><br />

carbon with low quantities <strong>of</strong> oxygen. MEB photos<br />

showed blackish sheets. This residue was then mainly<br />

composed <strong>of</strong> carbon graphite.<br />

For <strong>filled</strong> samples, residual masses were scattered and<br />

not correlated with the duration <strong>of</strong> conditionning. The<br />

mean value was 64%. Taking into account the residual<br />

Figure 2: Weight loss during a TGA dynamic test for<br />

un<strong>filled</strong> samples before (•) and after conditioning at<br />

80°C and 80%HR during 5 (+), 14 () and 50 () days.<br />

240

<strong>Schneider</strong> <strong>Electric</strong> 2007 - Conferences publications<br />

mass <strong>of</strong> 6% measured for the un<strong>filled</strong> samples, this<br />

value leads to a filler content <strong>of</strong> 58% which corresponds<br />

well with the “rated” filler content <strong>of</strong> 60%. To simplify<br />

the comparisons, the variations <strong>of</strong> the residual masses<br />

were neutralized in the results displayed in Figure 3.<br />

This shows the relative mass losses between the initial<br />

mass values <strong>of</strong> the samples and the residual masses.<br />

A mass loss between 50°C and 200°C can be observed,<br />

as in un<strong>filled</strong> samples. In these cases, the variations<br />

correspond well with the water uptake measured before.<br />

The <strong>resin</strong> decomposition can be observed in the same<br />

temperature range as above. As shown in the zoom in<br />

Figure 3, decomposition started at lower temperatures<br />

for longer conditioning periods. This is clear if we<br />

compare the curves for 50 and 70 days, which fit the<br />

curve <strong>of</strong> 14 days until about 200°C and decrease faster<br />

between 200°C and 300°C. This indicates an evolution<br />

<strong>of</strong> the material produced by the hygrothermal<br />

conditioning after about 50 days. Since this effect was<br />

not encountered in samples without fillers, the<br />

<strong>epoxy</strong>/silica interface regions are necessarily involved.<br />

We have already mentioned that the mass measurements<br />

suggest an accumulation <strong>of</strong> matter close to these<br />

interfaces. We may consider that this evolution is due to<br />

an hydrolysis <strong>of</strong> the filler/matrix interface regions which<br />

creates a degraded inter-phase region. Since the filler<br />

content is large, this degraded region may also fill the<br />

whole gap between neighbouring fillers and constitute<br />

“weak” path between them. This hydrolysis occuring<br />

after about 50 days is probably correlated with the<br />

increase <strong>of</strong> the mass uptake observed at the same time.<br />

The possible explanation <strong>of</strong> this is as follows: free space<br />

is created by the hydrolytic reactions consisting mainly<br />

in the attack <strong>of</strong> the ester linkages and creation <strong>of</strong> acid<br />

groups [4]. This allows extra water molecules to<br />

accumulate between the filler and the degraded region.<br />

However, the extra quantity <strong>of</strong> water involved in this<br />

mechanism would be low in comparison with the total<br />

quantity <strong>of</strong> absorbed water, which was almost entirely<br />

lost between 50°C and 150°C. Further experiments are<br />

under way to confirm this hypothesis.<br />

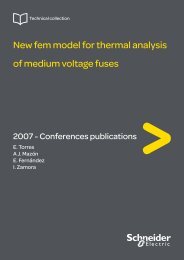

DMA results<br />

The dynamic mechanical analysis was carried out on<br />

four <strong>filled</strong> and four un<strong>filled</strong> samples after 0, 5, 14 and<br />

50 days <strong>of</strong> conditioning. The evolution <strong>of</strong> the elastic<br />

moduli E’ is displayed in Figure 4a. The magnitudes for<br />

the <strong>filled</strong> samples were about three times larger in the<br />

glassy state and five times larger in the rubbery state.<br />

The elastic modulus decreased during conditioning,<br />

especially in the glassy state. In practice, water<br />

molecules break the hydrogen bonds established inside<br />

the network. The bound water increases also the<br />

mobility <strong>of</strong> the polymer chains and causes a decrease <strong>of</strong><br />

the elastic modulus. This is the well-known waterinduced<br />

plasticization effect.<br />

In the rubbery state, we would expect the effect to be<br />

less marked since the chains are already mobile. Thus in<br />

this case, the modulus E’ depends theoretically on the<br />

density <strong>of</strong> cross-links in the <strong>epoxy</strong> network [14].<br />

Nevertheless, the conditioning induced a decrease <strong>of</strong> the<br />

elastic moduli E’ for the <strong>filled</strong> samples. For un<strong>filled</strong><br />

samples, the measurements were conducted at the lower<br />

limit <strong>of</strong> sensitivity <strong>of</strong> the DMA instrument. Such a<br />

decrease <strong>of</strong> the rubbery modulus has already been<br />

observed in [15]. It is not due to the plasticization but<br />

may be attributed to a degradation <strong>of</strong> the polymer,<br />

which probably results from hydrolysis <strong>of</strong> the <strong>resin</strong>.<br />

(a)<br />

M(Minitial-Mfinal)%<br />

100<br />

90<br />

80<br />

70<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

0<br />

REF<br />

5 days<br />

14 days<br />

50 days<br />

70 days<br />

REF<br />

5 days<br />

14 days<br />

50 days<br />

70 days<br />

0 100 200 300 400 500 600<br />

T(°C)<br />

Figure 3: Weight loss during a TGA dynamic test for<br />

<strong>filled</strong> samples before (•) and after conditioning at 80°C<br />

and 80%HR during 5 (+), 14 (), 50 () and 70 () days<br />

with a zoom in the temperature range 0-350°C between<br />

92 and 100%.<br />

(b)<br />

Figure 4: Elastic modulus E’ (a) and loss modulus E’’<br />

(b) vs temperature <strong>of</strong> un<strong>filled</strong> (---) samples and <strong>filled</strong><br />

( ___ ) samples before (•) and after conditioning at 80°C,<br />

80%HR during 5(+), 14() and 50 () days.<br />

241

<strong>Schneider</strong> <strong>Electric</strong> 2007 - Conferences publications<br />

The glass transition temperatures have been taken at the<br />

maxima <strong>of</strong> the curves <strong>of</strong> loss moduli E’’ (Figure 4b).<br />

For the reference samples, the Tg were 70°C and 72°C<br />

respectively for the un<strong>filled</strong> and <strong>filled</strong> samples. These<br />

maxima shifted towards the low temperatures during<br />

conditioning, thus highlighting water-induced<br />

plasticization. This decrease occurred mainly within the<br />

first days <strong>of</strong> conditioning and is more important in the<br />

un<strong>filled</strong> samples. After a 50 days conditioning, the shift<br />

<strong>of</strong> the Tg values were <strong>of</strong> 14K and 11K for the un<strong>filled</strong><br />

and <strong>filled</strong> samples respectively. Similar evolutions have<br />

been already mentioned [16]. A secondary peak, which<br />

would have indicated the heterogeneity <strong>of</strong> the material<br />

[6, 12, 17], was not visible here.<br />

CONCLUSION<br />

Evidence <strong>of</strong> <strong>aging</strong> <strong>of</strong> <strong>filled</strong> <strong>epoxy</strong> <strong>resin</strong> conditionned at<br />

80°C and 80%RH were provided by weight<br />

measurements, thermogravimetric analysis (TGA) and<br />

dynamical mechanical analysis (DMA).<br />

Above an apparent saturation value <strong>of</strong> about 1.5%<br />

reached within a few days, a slight but significant mass<br />

uptake was observed in the <strong>filled</strong> <strong>resin</strong>. An<br />

accumulation <strong>of</strong> water at the <strong>epoxy</strong>/silica interface can<br />

be inferred, part <strong>of</strong> which may have chemically reacted<br />

with the polymer.<br />

Thermogravimetric analysis showed a degradation <strong>of</strong><br />

<strong>filled</strong> samples after a conditioning period longer than 50<br />

days, which does not occur in un<strong>filled</strong> samples.<br />

The decrease <strong>of</strong> the elastic modulus E’ and <strong>of</strong> the glass<br />

transition temperature Tg underlined the plasticization<br />

<strong>of</strong> the samples during conditioning. For the <strong>filled</strong><br />

samples, the elastic modulus in the rubbery state<br />

decreased with conditioning.<br />

These results suggest the creation <strong>of</strong> a degraded interphase<br />

region between the silica and the <strong>epoxy</strong> matrix<br />

due to the hydrolysis <strong>of</strong> the <strong>resin</strong>.<br />

REFERENCES<br />

[1] H.C. Kärner and M. Ieda, “Technical aspects <strong>of</strong><br />

interfacial phenomena in solid insulating”, Proc. <strong>of</strong><br />

the 3 rd IEEE Int. Conf. On Prop and Appl <strong>of</strong> Diel<br />

Mat, p. 592-597, 1991.<br />

[2] T. Kumazawa, M. Oishi and M. Todoki, “Highhumidity<br />

deterioration and internal structure change<br />

<strong>of</strong> <strong>epoxy</strong> <strong>resin</strong> for electrical insulation”, IEEE<br />

Transactions on dielectrics an <strong>Electric</strong>al<br />

Insulation, vol. 1, n°1, p. 133-138, 1994.<br />

[3] T. Kumazawa, M. Oishi, M. Todoki and T.<br />

Watanabe, “Physical and chemical structure change<br />

<strong>of</strong> <strong>filled</strong> <strong>epoxy</strong> due to water absorption”, 5 th IEEE<br />

int.Conf. on Prop and Appl <strong>of</strong> Diel Mat, p. 491-494,<br />

1997.<br />

[4] M.K. Antoon and J.L. Koenig, “Irreversible effects<br />

<strong>of</strong> moisture on the <strong>epoxy</strong> matrix in glass-reinforced<br />

composites”, J.Polym. Sci. Phy. Ed., vol. 19, p.<br />

197-212, 1981.<br />

[5] Janssen H., Seifert J.M. and Kärner H.C., Interfacial<br />

phenomena in comopsite high voltage insulation,<br />

IEEE Transactions on dielectrics an <strong>Electric</strong>al<br />

Insulation, vol. 6, 1999, p. 651-659.<br />

[6] D.H. Kaelble and P.J. Dynes, “<strong>Hygrothermal</strong> <strong>aging</strong><br />

<strong>of</strong> composite materials”, J. Adhesion, vol. 8, p. 195-<br />

212, 1977.<br />

[7] M. Ezoe, M. Nakanishi and J. ShouGou, “Effects <strong>of</strong><br />

water absorption on interfacial phenomena in HV<br />

insulating materials”, IEEE High Voltage<br />

Engineering Symposium, 1999, 4.244-4.247, 1999.<br />

[8] A.C. May, Epoxy <strong>resin</strong>s, New York, Dekker<br />

Edition, 1988.<br />

[9] J. Verdu, Action de l’eau sur les plastiques, Paris,<br />

Techniques de l’ingénieur, vol AM 3 165.<br />

[10] T. Nguyen, E. Byrd and D. Bentz, “In situ<br />

measurement <strong>of</strong> water at the organic<br />

coating/substrate interface”, Progress in organic<br />

coatings, vol. 27, p. 181-193, 1996.<br />

[11] K.A. Kasturiarachchi and G. Pritchard, Scanning<br />

electron microscopy <strong>of</strong> <strong>epoxy</strong>-glass exposed to<br />

humid condition, J. <strong>of</strong> Mat. SC., vol. 20, p. 2038-<br />

2044, 1985.<br />

[12] M.J. Adamson, “Thermal expansion and swelling<br />

<strong>of</strong> cured <strong>epoxy</strong> <strong>resin</strong> used in graphite/<strong>epoxy</strong><br />

composite materials”, J. Mater. Sci., vol. 15, p.<br />

1736-1745, 1980.<br />

[13] S. Xu and D.A. Dillard, “Environmental <strong>aging</strong><br />

effects on thermal and mechanical properties <strong>of</strong><br />

electrically conductive adhesives”, J. Adhesion, vol.<br />

79, p. 699-723, 2003.<br />

[14] T. Murayama and J.P. Bell, “Relation between the<br />

network structure and dynamic mechanical<br />

properties <strong>of</strong> a typical amine-cured <strong>epoxy</strong><br />

polymer”, J. Polym. Sci., vol. 8, p. 437-445, 1970.<br />

[15] K.I. Ivanova, R.A. Pethrick and S. Affrossman,<br />

“Investigation <strong>of</strong> hydrothermal <strong>aging</strong> <strong>of</strong> a <strong>filled</strong><br />

rubber toughened <strong>epoxy</strong> <strong>resin</strong> using dynamic<br />

mechanical thermal analysis and dielectric<br />

spectroscopy”, Polymer, vol. 41, p. 6787-6796,<br />

2000.<br />

[16] A. Apicella, L. Egiziano, L. Nicolais and V. Tucci,<br />

“Environmental degradation <strong>of</strong> the electrical and<br />

thermal properties <strong>of</strong> organic insulating materials”,<br />

J. Mater. Sci., vol. 23, p. 729-735, 1988.<br />

[17] L. Wang, K. Wang, L. Chen, C. He, L. Wang et al,<br />

“<strong>Hygrothermal</strong> effects on the thermomechanical<br />

properties <strong>of</strong> high performance <strong>epoxy</strong>/clay<br />

nanocomposites”, Polymer Engineering and<br />

Science, p. 215-221, 2006.<br />

242