WIRTGEN GROUP: PARTS AND MORE 2009. - Resansil

WIRTGEN GROUP: PARTS AND MORE 2009. - Resansil

WIRTGEN GROUP: PARTS AND MORE 2009. - Resansil

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>WIRTGEN</strong> <strong>GROUP</strong>:<br />

<strong>PARTS</strong> <strong>AND</strong> <strong>MORE</strong> <strong>2009.</strong><br />

ROAD TECHNOLOGIES<br />

www.wirtgen-group.com

Wirtgen GmbH<br />

Leads the world market for road milling machines<br />

Wirtgen GmbH 6<br />

Picks 8<br />

Top-quality picks 8<br />

Picks for road milling machines 13<br />

Picks for cold recyclers and soil stabilizers 34<br />

Picks for Surface Miners 46<br />

Toolholders 52<br />

Toolholder systems 52<br />

Welded toolholders 62<br />

Ejectors 65<br />

Milling drums 66<br />

Milling drums from the market leader 66<br />

Milling drums for your machine 70<br />

Retrofittings side milling wheel and saw blades 82<br />

Retrofittings Rumble Strip 84<br />

Retrofittings FCS-kits 86<br />

6 © 2009 by Wirtgen GmbH

Milling drum housing 88<br />

Scraper blades and service packages scraper blades 88<br />

Wear protection segments 92<br />

Movable bearing 94<br />

Conveyors 96<br />

Conveyor belts 96<br />

Drive and return pulleys 100<br />

Idle pulleys 102<br />

Belt bearing 106<br />

Belt covers and protective grids 110<br />

Water system 112<br />

Service packages for pump- and nozzle units 112<br />

Levelling 116<br />

Levelling systems for road milling machines 116<br />

Components of the levelling system 124<br />

Retrofit kits – levelling 126<br />

Crawler unit parts 132<br />

Crawler track units 132<br />

Track pads 134<br />

Track rollers 140<br />

Other crawler unit parts 144<br />

Tyres and wheels 146<br />

Engine attachment parts 150<br />

Diesel engines, alternators, starters 150<br />

Exhaust silencer and exhaust system 154<br />

Gearboxes and sealing kits 158<br />

Clutches 164<br />

Power belts, belt pulleys, tensioner system 170<br />

Hydraulic parts 174<br />

Hydraulic pumps and -motors 174<br />

Hydraulic cylinders 184<br />

Other hydraulic parts 188<br />

Hall sensors, proportional amplifiers 192<br />

Electrical accessories 194<br />

Electrical Service Kits 194<br />

Work light, patrol light, horn 196<br />

Control- and joysticks 198<br />

Proximity switch, battery switch, emergency stop switch 200<br />

Emergency Kits for your machine 202<br />

Cabin 204<br />

Operator seat and roof covers 204<br />

Latch closing for all doors/flaps 204<br />

Sun protector CGC-display 204<br />

Tools 206<br />

Tools for milling drums 206<br />

Test Kits 208<br />

Special service tools 210<br />

Filters and service packages for filter 212<br />

Lubricants 224<br />

Maintenance kits 230<br />

Electric and hydraulic vibrators 234<br />

© 2009 by Wirtgen GmbH<br />

7

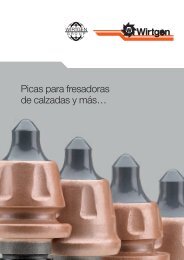

Get ahead with quality picks<br />

for high-performance milling machines<br />

<strong>WIRTGEN</strong> and BETEK –<br />

in partnership for their mutual<br />

customers<br />

A fast advance rate, plus few tool<br />

changes, equals high daily output. To<br />

make this equation for low operating<br />

costs work out right, you need power ful<br />

machines and high-quality tools. Only<br />

picks of the highest quality, which are<br />

closely adapted to the machine and application,<br />

can guarantee a long service<br />

life and flawless rotation.<br />

The yearlong system partnership between<br />

<strong>WIRTGEN</strong> and BETEK purposefully<br />

pursues the path of constant improvement<br />

based on many mutual application<br />

experiences. New applications<br />

are often the impetus for optimisations<br />

or even for new cutting tool developments.<br />

Wirtgen, together with BETEK, recognises<br />

the critical nature of this issue and<br />

has taken steps to ensure better economic<br />

efficiency. The technical expertise<br />

of the two leading manufacturers<br />

has been pooled to result in unique collaboration<br />

in all sectors: development,<br />

production and quality assurance, as<br />

well as sales and advice for the customer<br />

on site.<br />

Despite the high requirements placed<br />

on the engineers in both companies,<br />

short development times up to series<br />

maturity are maintained, another proof<br />

of the collaboration that benefits the<br />

customers.<br />

8 © 2009 by Wirtgen GmbH

Quality as a result of<br />

production, not follow-up<br />

controls<br />

Consistent quality management, certified<br />

to DIN EN ISO 9001 and 9002,<br />

guarantees high quality at BETEK in<br />

every production step, all the way to<br />

final inspection. Similarly, the environmental<br />

friendliness of the production<br />

process is certified to DIN ISO 14 001.<br />

Optimum milled results ensure<br />

the customer’s success<br />

The result is coordinated system components<br />

with a high savings potential<br />

for users. The user gets everything he<br />

needs from a single source and reliable<br />

delivery to any job site around the globe.<br />

Comprehensive support is provided to<br />

the user, even on a job site if necessary.<br />

If problems or questions arise, a solution<br />

is elaborated immediately, even if<br />

it means providing special tools for difficult<br />

milling tasks. Rising sales figures<br />

confirm the effectiveness of this formula<br />

for success, the main objective of which<br />

is to ensure customer satisfaction.<br />

© 2009 by Wirtgen GmbH<br />

9

Original Wirtgen-Betek picks for road milling<br />

machines: Low operating costs in daily use<br />

The tried-and-tested E design for picks has been<br />

developed further and extended<br />

to the complete tool system:<br />

The Rotary System …<br />

… the pick system with improved wear characteristics<br />

ensuring the best possible milling performance<br />

…the pick<br />

Extremely long tool life<br />

due to the optimized carbide tip<br />

Pick with E design<br />

Shank is less inclined to break<br />

due to larger transition radii<br />

Optimized retaining loops<br />

10 © 2009 by Wirtgen GmbH

… the plate<br />

Larger outside diameter of 45 mm<br />

reduces toolholder wear<br />

Larger and more precisely bevelled seat<br />

ensures that the pick is held more securely<br />

Smaller inside diameter<br />

increases pretension of the R-sleeve<br />

for easier pick assembly<br />

E design in the outer edge of the plate<br />

…the R-sleeve<br />

New Twin-Stop retaining loops<br />

ensure more reliable retention and less wear<br />

Longer sleeve life due to thicker wall (+5%)<br />

Longer service life due to new sleeve material<br />

Smaller gap on the R-sleeve increases retention<br />

Greater hardness (46-50 HRC)<br />

improves retention and service life<br />

High-quality coating for reliable assembly<br />

and disassembly<br />

© 2009 by Wirtgen GmbH<br />

11

State-of-the-art picks<br />

for optimum milling performance<br />

Cutting-edge technology<br />

There are different types of carbide<br />

metal. To withstand the extreme temperature<br />

stresses resulting when milling<br />

road pavements, the carbide metal<br />

tips of our cutting tools are manufactured<br />

from particularly coarse-grained<br />

tungsten carbide components. They<br />

conduct the heat away much better<br />

than conventional carbide metal alloys,<br />

a feature that noticeably reduces wear<br />

and tear.<br />

The welding<br />

The carbide metal tip of the cutting tool<br />

is firmly welded to a steel body. Carbide<br />

metal and steel expand to different<br />

degrees when exposed to heat. To<br />

ensure that this “tension-filled” bond<br />

withstands even peak loads safely and<br />

durably, we use a specially developed<br />

brazing method characterized by exceptionally<br />

high strength. This highly<br />

important quality feature is checked<br />

and assured continually by carrying out<br />

stringent endurance tests during the<br />

manufacturing process.<br />

The steel body<br />

The tool head must withstand tremendous<br />

shear stresses and impact loads.<br />

At the same time, the tool must sit in the<br />

toolholder safely and durably during its<br />

entire service life. Wirtgen cutting tools<br />

have a steel body combining both qualities<br />

in an optimum manner. To achieve<br />

this, the tool head and tool shaft are<br />

manufactured to different degrees of<br />

hardness in a special operation. While<br />

the tough tool shaft effectively absorbs<br />

the forces occurring close to the toolholder,<br />

the tool head is specially hardened,<br />

making it highly wear-resistant<br />

when in direct contact with the material<br />

to be milled.<br />

The plate<br />

Wirtgen road cutting tools feature a<br />

wear plate that is tailored to accurately<br />

fit the toolholder. It fully covers the<br />

upper part of the holder and absorbs<br />

a large percentage of the wear exposure.<br />

The plate consists of 4 mm thick, highgrade<br />

tempered spring steel and is bevelled<br />

towards the shaft, i.e. has a conical<br />

shape. The bevel fits precisely into<br />

the holder guide, ensuring that the cutting<br />

tool is continuously aligned in the<br />

holder.<br />

Secure hold and fast<br />

replacement<br />

Wirtgen road cutting tools feature a cylindrical<br />

clamping sleeve. Length and<br />

diameter of the sleeve are subject to extremely<br />

narrow tolerances in the manufacturing<br />

process. This feature not only<br />

results in distinctly less wear and tear of<br />

the tools and toolholders but additionally<br />

prevents the tools from falling out,<br />

thus avoiding unnecessary downtimes<br />

and higher costs for wearing parts. A<br />

high-quality coating enables the new<br />

cutting tools of the rotation series to be<br />

mounted and removed quite easily.<br />

12 © 2009 by Wirtgen GmbH

The complete delivery range of picks 2009<br />

for milling machines<br />

Carbide tip<br />

Carbide weight<br />

Miniature picks<br />

Standard with<br />

extractor groove<br />

Standard without<br />

extractor groove<br />

Ø 13 Ø 20 Ø 20 Ø 20<br />

Special models<br />

W4<br />

19.68 g<br />

WM4 / 13<br />

Part No.<br />

182598<br />

Page 16<br />

W4 E R<br />

Part No.<br />

2088082<br />

Page 18<br />

W5<br />

23.40 g<br />

W5 E R<br />

Part No.<br />

2088085<br />

Page 19<br />

W5 E H R<br />

Part No.<br />

2088095<br />

Page 20<br />

W6<br />

30.17 g<br />

W6 R<br />

Part No.<br />

2069413<br />

Page 21<br />

W6 H R<br />

Part No.<br />

2069412<br />

Page 22<br />

W6 S R<br />

Part No.<br />

2088106<br />

Page 25<br />

W6 SG<br />

22.89 g<br />

W6 SG R<br />

Part No.<br />

2088110<br />

Page 26<br />

W6 AOC<br />

32.5 g<br />

W6 AOC R<br />

Part No.<br />

2088108<br />

Page 30<br />

W6 E<br />

32.87 g<br />

W6 E R<br />

Part No.<br />

2088087<br />

Page 23<br />

W6 E H R<br />

Part No.<br />

2088103<br />

Page 24<br />

W7<br />

41.50 g<br />

W7 E R<br />

Part No.<br />

2069414<br />

Page 27<br />

W7 E H R<br />

Part No.<br />

2064871<br />

Page 28<br />

W8 E<br />

48.37 g<br />

W8 E H R<br />

Part No.<br />

2088104<br />

Page 29<br />

W1-8 9.01 g<br />

WM1 / 13<br />

Part No.<br />

193701<br />

Page 17<br />

W1-10 24.59 g<br />

W1-10 R<br />

Part No.<br />

2088081<br />

Page 31<br />

W1-13 38.78 g<br />

W1-15 47.82 g<br />

W1-13 R<br />

Part No.<br />

2088090<br />

Page 32<br />

W1-15 R<br />

Part No.<br />

2088093<br />

Page 33<br />

© 2009 by Wirtgen GmbH<br />

13

Selection table 2009<br />

for road milling machines<br />

Machine type<br />

Used in<br />

soft asphalt medium-hard asphalt hard asphalt concrete<br />

SF300 C, W 350, W 350 E<br />

W 35, W 35 DC,<br />

SF 500 C-C/3-C/4, W 500,<br />

W 50, W 50 DC*<br />

WM4 / 13<br />

Part No.: 182598<br />

Page 16<br />

WM1 / 13<br />

Bestell Nr.: 193701<br />

Page 17<br />

SF 300 C<br />

W 350, W 350 E<br />

W 35, W 35 DC<br />

SF 500 C-C/3-C/4<br />

W4 E R<br />

Part No.: 2088082<br />

Page 18<br />

W1-10 R<br />

Bestell Nr.: 2088081<br />

Page 31<br />

W 500<br />

W 50, W 50 DC<br />

500 DC<br />

SF 1000 C / CBA<br />

W5 E R<br />

Part No.: 2088085<br />

Page 19<br />

W6 E R<br />

Bestell Nr.: 2088097<br />

Page 23<br />

W 600 DC / W 1000 L<br />

W1-13 R<br />

Bestell Nr.: 2088090<br />

Page 32<br />

W 1000<br />

W 60 / W 100<br />

W5 E H R<br />

Part No.: 2088095<br />

Page 20<br />

W6 E H R<br />

Bestell Nr.: 2088103<br />

Page 24<br />

*Version with fine milling drums and micro fine milling drums with toolholder system HT4 and HT04<br />

14 © 2009 by Wirtgen GmbH

Machine type<br />

Used in<br />

soft asphalt medium-hard asphalt hard asphalt concrete<br />

W 1000 F, W 1200 F,<br />

W 1300 F<br />

W 100 F, W 120 F,<br />

W 130 F<br />

1300 - 1500 DC<br />

W6 E R<br />

Bestell Nr.: 2088097<br />

Page 23<br />

W6 R<br />

Bestell Nr.: 2069413<br />

Page 21<br />

W 150<br />

1900 - 2000 DC<br />

W1-13 R<br />

Bestell Nr.: 2088090<br />

Page 32<br />

W 1500<br />

W6 E H R<br />

Bestell Nr.: 2088103<br />

Page 24<br />

W6 H R<br />

Bestell Nr.: 2069412<br />

Page 22<br />

W 1900<br />

W 2000<br />

2100 DC<br />

W6 R<br />

Bestell Nr.: 2069413<br />

Page 21<br />

W 2100<br />

W 2200<br />

W6 H R<br />

Bestell Nr.: 2069412<br />

Page 22<br />

W7 E H R<br />

Bestell Nr.: 2064871<br />

Page 28<br />

W8 E H R<br />

Bestell Nr.: 2088104<br />

Page 29<br />

W1-15 R<br />

Bestell Nr.: 2088093<br />

Page 33<br />

© 2009 by Wirtgen GmbH<br />

15

Pick WM4 / 13<br />

for road milling machines<br />

Our delivery service<br />

Packaging:<br />

Handy toolbox<br />

Quantity:<br />

200 picks per toolbox<br />

Weight:<br />

approx. 18.4 kg per toolbox<br />

Dimensions:<br />

approx. 26 x 18.5 x 22 cm<br />

Quantity standard palette:<br />

12000 picks<br />

Quantity overseas palette:<br />

10800 picks<br />

ø 16<br />

ø 8.5<br />

16<br />

11<br />

Optimum changing time WM4 / 13<br />

The miniature pick with a shank diameter of 13 mm<br />

for super-fine milling drums<br />

WM4 / 13<br />

Part No.: 182598<br />

Optimized carbide tip<br />

for low cutting forces<br />

and long service life<br />

28<br />

Special brazing process<br />

ensuring a high strength connection<br />

between carbide and steel body<br />

55<br />

Hardened pick head<br />

for optimized pick life<br />

ø 26<br />

Pick head with ridges<br />

for improved asphalt break-up<br />

and optimum pick rotation<br />

Thick-walled cylindrical R-sleeve<br />

of quenched and tempered steel<br />

for constant tensioning force,<br />

even during long duty periods.<br />

ø 13<br />

Unit of<br />

measurement in mm<br />

16 © 2009 by Wirtgen GmbH

Pick WM1 / 13<br />

for road milling machines<br />

Our delivery service<br />

ø 8<br />

Packaging:<br />

Handy toolbox<br />

Quantity:<br />

200 picks per toolbox<br />

Weight:<br />

approx. 18.4 kg per toolbox<br />

Dimensions:<br />

approx. 26 x 18.5 x 22 cm<br />

Quantity standard palette:<br />

12000 picks<br />

Quantity overseas palette:<br />

10800 picks<br />

15<br />

11<br />

Optimum changing time WM1 / 13<br />

The miniature pick with 13 mm shank diameter<br />

for super-fine milling drums for milling concrete<br />

WM1 / 13<br />

Part No.: 193701<br />

Cylindrical carbide tip<br />

for use in hard milling materials,<br />

ensuring low cutting forces<br />

and a long service life<br />

28<br />

Optimized carbide tip<br />

for low cutting forces<br />

and long service life<br />

55<br />

Special brazing process<br />

ensuring a high strength connection<br />

between carbide and steel body<br />

ø 26<br />

Hardened pick head<br />

for optimized pick life<br />

Thick-walled cylindrical R-sleeve<br />

of quenched and tempered steel<br />

for constant tensioning force,<br />

even during long duty periods.<br />

ø 13<br />

Unit of<br />

measurement in mm<br />

© 2009 by Wirtgen GmbH<br />

17

Pick W4 E R<br />

for road milling machines<br />

NEW!<br />

Our delivery service<br />

Packaging:<br />

Handy toolbox<br />

Quantity:<br />

50 picks per toolbox<br />

Weight:<br />

approx. 13.6 kg per toolbox<br />

Dimensions:<br />

approx. 26 x 18.5 x 22 cm<br />

Quantity standard palette:<br />

3000 picks<br />

Quantity overseas palette:<br />

2700 picks<br />

ø 16<br />

ø 8.5<br />

16<br />

9.1<br />

Optimum changing time W4 E R<br />

The all-round pick for use on any site<br />

in small milling machines<br />

W4 E R<br />

Part No.: 2088082<br />

Optimized carbide tip for low cutting forces<br />

and long service life<br />

Special brazing process<br />

ensuring a high strength connection<br />

between carbide and steel body<br />

Pick head with ridges<br />

for improved asphalt break-up<br />

and optimum pick rotation<br />

48<br />

Hardened pick head<br />

for optimized pick life<br />

Extractor groove in pick head<br />

for extracting picks with a pick puller<br />

Wear plate with outer diameter of 45 mm<br />

for low degree of toolholder wear<br />

and optimum pick rotation<br />

Centring function on the wear plate<br />

for low wear toolholder bore<br />

R-sleeve with Twin-Stop<br />

retaining loops for long toolholder life<br />

ø 45<br />

ø 30<br />

88<br />

R-sleeve with smaller gap<br />

to reduce wear on the tool shank<br />

Thick-walled, cylindrical R-sleeve<br />

for a constant clamping force,<br />

even over a long period of service<br />

4<br />

Prestressed R-sleeve for simple<br />

and rapid pick assembly<br />

Long R-sleeve to minimize wear<br />

to the toolholder bore<br />

ø 20<br />

Unit of<br />

measurement in mm<br />

18 © 2009 by Wirtgen GmbH

NEW!<br />

Pick W5 E R<br />

for road milling machines<br />

Our delivery service<br />

Packaging:<br />

Handy toolbox<br />

Quantity:<br />

50 picks per toolbox<br />

Weight:<br />

approx. 14.8 kg per toolbox<br />

Dimensions:<br />

approx. 26 x 18.5 x 22 cm<br />

Quantity standard palette:<br />

3000 picks<br />

Quantity overseas palette:<br />

2700 picks<br />

ø 17.5<br />

ø 9.5<br />

16<br />

8.6<br />

Optimum changing time W5 E R<br />

The universal pick in the one-metre class<br />

for all job sites<br />

W5 E R<br />

Part No.: 2088085<br />

All-round carbide tip for tough operations<br />

in small milling machines and<br />

machines of the one-metre class<br />

Special brazing process<br />

ensuring a high strength connection<br />

between carbide and steel body<br />

Pick head with ridges<br />

for improved asphalt break-up<br />

and optimum pick rotation<br />

48<br />

Hardened pick head<br />

for optimized pick life<br />

Extractor groove in pick head<br />

for extracting picks with a pick puller<br />

Wear plate with outside diameter 45<br />

for low toolholder wear<br />

and optimum pick rotation<br />

Centring function on the wear plate<br />

for low wear toolholder bore<br />

R-sleeve with Twin-Stop<br />

retaining loops for long toolholder life<br />

ø 45<br />

ø 34<br />

88<br />

R-sleeve with smaller gap<br />

to reduce wear on the tool shank<br />

Thick-walled cylindrical R-sleeve<br />

of quenched and tempered steel for constant<br />

tensioning force, even during long duty periods<br />

4<br />

Pre-tensioned, coated R-sleeve<br />

for quick and easy pick assembly<br />

Long R-sleeve to minimize wear<br />

to the toolholder bore<br />

ø 20<br />

Unit of<br />

measurement in mm<br />

© 2009 by Wirtgen GmbH<br />

19

Pick W5 E H R<br />

for road milling machines<br />

NEW!<br />

Our delivery service<br />

Packaging:<br />

Handy toolbox<br />

Quantity:<br />

50 picks per toolbox<br />

Weight:<br />

approx. 15 kg per toolbox<br />

Dimensions:<br />

approx. 26 x 18.5 x 22 cm<br />

Quantity standard palette:<br />

3000 picks<br />

Quantity overseas palette:<br />

2700 picks<br />

ø 17.5<br />

ø 9.5<br />

16<br />

8.8<br />

Optimum changing time W5 E H R<br />

The pick with the excellent price-performance ratio<br />

W5 E H R<br />

Part No.: 2088095<br />

All-round carbide tip for tough operations<br />

in small milling machines and<br />

machines of the one-metre class<br />

Special brazing process<br />

ensuring a high strength connection<br />

between carbide and steel body<br />

Pick head with ridges<br />

for improved asphalt break-up<br />

and optimum pick rotation<br />

48<br />

Hardened pick head<br />

for optimized pick life<br />

Wear plate with outside diameter 45<br />

for low toolholder wear<br />

and optimum pick rotation<br />

Centring function on the wear plate<br />

for low wear toolholder bore<br />

R-sleeve with Twin-Stop<br />

retaining loops for long toolholder life<br />

R-sleeve with smaller gap<br />

to reduce wear on the tool shank<br />

ø 45<br />

ø 34<br />

88<br />

Thick-walled cylindrical R-sleeve<br />

of quenched and tempered steel for constant<br />

tensioning force, even during long duty periods<br />

4<br />

Pre-tensioned, coated R-sleeve<br />

for quick and easy pick assembly<br />

Long R-sleeve to minimize wear<br />

to the toolholder bore<br />

ø 20<br />

Unit of<br />

measurement in mm<br />

20 © 2009 by Wirtgen GmbH

NEW!<br />

Pick W6 R<br />

for road milling machines<br />

Our delivery service<br />

Packaging:<br />

Handy toolbox<br />

Quantity:<br />

50 picks per toolbox<br />

Weight:<br />

approx. 15.1 kg per toolbox<br />

Dimensions:<br />

approx. 26 x 18.5 x 22 cm<br />

Quantity standard palette:<br />

3000 picks<br />

Quantity overseas palette:<br />

2700 picks<br />

ø 19<br />

ø 10.5<br />

17.5<br />

9.4<br />

Optimum changing time W6 R<br />

One of the top-selling large milling machine picks worldwide<br />

for use on all job sites<br />

W6 R<br />

Part No.: 2069413<br />

Long, sturdy carbide tip<br />

for all-round use in large milling machines<br />

Special brazing process<br />

ensuring a high strength connection<br />

between carbide and steel body<br />

Pick head with ridges<br />

for improved asphalt break-up<br />

and optimum pick rotation<br />

48<br />

Hardened pick head<br />

for optimized pick life<br />

Extractor groove in pick head<br />

for extracting picks with a pick puller<br />

Wear plate with outside diameter 45<br />

for low toolholder wear<br />

and optimum pick rotation<br />

ø 34<br />

88<br />

Centring function on the wear plate<br />

for low wear toolholder bore<br />

R-sleeve with Twin-Stop<br />

retaining loops for long toolholder life<br />

ø 45<br />

R-sleeve with smaller gap<br />

to reduce wear on the tool shank<br />

Thick-walled cylindrical R-sleeve<br />

of quenched and tempered steel for constant<br />

tensioning force, even during long duty periods<br />

4<br />

Pre-tensioned, coated R-sleeve<br />

for quick and easy pick assembly<br />

Long R-sleeve to minimize wear<br />

to the toolholder bore<br />

ø 20<br />

Unit of<br />

measurement in mm<br />

© 2009 by Wirtgen GmbH<br />

21

Pick W6 H R<br />

for road milling machines<br />

NEW!<br />

Our delivery service<br />

Packaging:<br />

Handy toolbox<br />

Quantity:<br />

50 picks per toolbox<br />

Weight:<br />

approx. 15.8 kg per toolbox<br />

Dimensions:<br />

approx. 26 x 18.5 x 22 cm<br />

Quantity standard palette:<br />

3000 picks<br />

Quantity overseas palette:<br />

2700 picks<br />

ø 19<br />

ø 10.5<br />

17.5<br />

9.4<br />

Optimum changing time W6 H R<br />

The cost-efficient “excavating pick” for large job sites<br />

W6 H R<br />

Part No.: 2069412<br />

Long, sturdy carbide tip<br />

for all-round use in large milling machines<br />

Special brazing process<br />

ensuring a high strength connection<br />

between carbide and steel body<br />

Pick head with ridges<br />

for improved asphalt break-up<br />

and optimum pick rotation<br />

48<br />

Hardened pick head<br />

for optimized pick life<br />

Wear plate with outside diameter 45<br />

for low toolholder wear<br />

and optimum pick rotation<br />

Centring function on the wear plate<br />

for low wear toolholder bore<br />

ø 34<br />

88<br />

R-sleeve with Twin-Stop<br />

retaining loops for long toolholder life<br />

ø 45<br />

R-sleeve with smaller gap<br />

to reduce wear on the tool shank<br />

Thick-walled cylindrical R-sleeve<br />

of quenched and tempered steel for constant<br />

tensioning force, even during long duty periods<br />

Pre-tensioned, coated R-sleeve<br />

for quick and easy pick assembly<br />

4<br />

Long R-sleeve to minimize wear<br />

to the toolholder bore<br />

ø 20<br />

Unit of<br />

measurement in mm<br />

22 © 2009 by Wirtgen GmbH

NEW!<br />

Pick W6 E R<br />

for road milling machines<br />

Our delivery service<br />

Packaging:<br />

Handy toolbox<br />

Quantity:<br />

50 picks per toolbox<br />

Weight:<br />

approx. 15.2 kg per toolbox<br />

Dimensions:<br />

approx. 26 x 18.5 x 22 cm<br />

Quantity standard palette:<br />

3000 picks<br />

Quantity overseas palette:<br />

2700 picks<br />

ø 19<br />

ø 10.5<br />

19.6<br />

11.6<br />

Optimum changing time W6 E R<br />

The cost-effective pick for high milling performance<br />

W6 E R<br />

Part No.: 2088087<br />

Extremely long carbide tip<br />

for long service life<br />

Special brazing process<br />

ensuring a high strength connection<br />

between carbide and steel body<br />

Pick head with ridges<br />

for improved asphalt break-up<br />

and optimum pick rotation<br />

48<br />

Hardened pick head<br />

for optimized pick life<br />

Extractor groove in pick head<br />

for extracting picks with a pick puller<br />

Wear plate with outside diameter 45<br />

for low toolholder wear<br />

and optimum pick rotation<br />

ø 34<br />

88<br />

Centring function on the wear plate<br />

for low wear toolholder bore<br />

R-sleeve with Twin-Stop<br />

retaining loops for long toolholder life<br />

ø 45<br />

R-sleeve with smaller gap<br />

to reduce wear on the tool shank<br />

Thick-walled cylindrical R-sleeve<br />

of quenched and tempered steel for constant<br />

tensioning force, even during long duty periods<br />

4<br />

Pre-tensioned, coated R-sleeve<br />

for quick and easy pick assembly<br />

Long R-sleeve to minimize wear<br />

to the toolholder bore<br />

ø 20<br />

Unit of<br />

measurement in mm<br />

© 2009 by Wirtgen GmbH<br />

23

Pick W6 E H R<br />

for road milling machines<br />

NEW!<br />

Our delivery service<br />

Packaging:<br />

Handy toolbox<br />

Quantity:<br />

50 picks per toolbox<br />

Weight:<br />

approx. 16.3 kg per toolbox<br />

Dimensions:<br />

approx. 26 x 18.5 x 22 cm<br />

Quantity standard palette:<br />

3000 picks<br />

Quantity overseas palette:<br />

2700 picks<br />

ø 19<br />

ø 10.5<br />

19.6<br />

11.6<br />

Optimum changing time W6 E H R<br />

The pick with an impressive service life<br />

W6 E H R<br />

Part No.: 2088103<br />

Extremely long carbide tip<br />

for long service life<br />

Special brazing process<br />

ensuring a high strength connection<br />

between carbide and steel body<br />

Pick head with ridges<br />

for improved asphalt break-up<br />

and optimum pick rotation<br />

48<br />

Hardened pick head<br />

for optimized pick life<br />

Wear plate with outside diameter 45<br />

for low toolholder wear<br />

and optimum pick rotation<br />

Centring function on the wear plate<br />

for low wear toolholder bore<br />

ø 34<br />

88<br />

R-sleeve with Twin-Stop<br />

retaining loops for long toolholder life<br />

ø 45<br />

R-sleeve with smaller gap<br />

to reduce wear on the tool shank<br />

Thick-walled cylindrical R-sleeve<br />

of quenched and tempered steel for constant<br />

tensioning force, even during long duty periods<br />

4<br />

Pre-tensioned, coated R-sleeve<br />

for quick and easy pick assembly<br />

Long R-sleeve to minimize wear<br />

to the toolholder bore<br />

ø 20<br />

Unit of<br />

measurement in mm<br />

24 © 2009 by Wirtgen GmbH

NEW!<br />

Pick W6 S R<br />

for road milling machines<br />

Our delivery service<br />

Packaging:<br />

Handy toolbox<br />

Quantity:<br />

40 picks per toolbox<br />

Weight:<br />

approx. 13.8 kg per toolbox<br />

Dimensions:<br />

approx. 26 x 18.5 x 22 cm<br />

Quantity standard palette:<br />

2400 picks<br />

Quantity overseas palette:<br />

2160 picks<br />

ø 19<br />

ø 10.5<br />

17.5<br />

9.4<br />

Optimum changing time W6 S R<br />

The high-performance pick with a reinforced steel base<br />

for milling and stabilizing work<br />

W6 S R<br />

Part No.: 2088106<br />

Long, sturdy carbide tip<br />

for all-round use in large milling machines<br />

Special brazing process<br />

ensuring a high strength connection<br />

between carbide and steel body<br />

Hardened pick head<br />

for optimized pick life<br />

48<br />

Particularly large pick head<br />

for long service life<br />

Wear plate with outside diameter 45<br />

for low toolholder wear<br />

and optimum pick rotation<br />

Centring function on the wear plate<br />

for low wear toolholder bore<br />

ø 37<br />

88<br />

R-sleeve with Twin-Stop<br />

retaining loops for long toolholder life<br />

R-sleeve with smaller gap<br />

to reduce wear on the tool shank<br />

ø 45<br />

Thick-walled cylindrical R-sleeve<br />

of quenched and tempered steel for constant<br />

tensioning force, even during long duty periods<br />

Pre-tensioned, coated R-sleeve<br />

for quick and easy pick assembly<br />

4<br />

Long R-sleeve to minimize wear<br />

to the toolholder bore<br />

ø 20<br />

Unit of<br />

measurement in mm<br />

© 2009 by Wirtgen GmbH<br />

25

Pick W6 SG R<br />

for road milling machines<br />

NEW!<br />

Our delivery service<br />

Packaging:<br />

Handy toolbox<br />

Quantity:<br />

40 picks per toolbox<br />

Weight:<br />

approx. 14 kg per toolbox<br />

Dimensions:<br />

approx. 26 x 18.5 x 22 cm<br />

Quantity standard palette:<br />

2400 picks<br />

Quantity overseas palette:<br />

2160 picks<br />

ø 19<br />

10<br />

1.5<br />

Optimum changing time W6 SG R<br />

The all-round pick for milling materials<br />

which are tough or interspersed with stones<br />

W6 SG R<br />

Part No.: 2088110<br />

Optimized carbide tip<br />

for low cutting forces and long service life<br />

Thanks to new hard-metal technology,<br />

particularly fracture-resistant<br />

for recycling and stabilisation<br />

Special hard soldering process<br />

to ensure a high-strength joint<br />

between the carbide and the steel base<br />

41<br />

Hardened pick head<br />

for optimized pick life<br />

Particularly large pick head<br />

for long service life<br />

Wear plate with outer diameter of 45 mm<br />

for low degree of toolholder wear<br />

and optimum pick rotation<br />

ø 37<br />

80<br />

Centring function on the wear plate<br />

for low wear toolholder bore<br />

ø 45<br />

R-sleeve with Twin-Stop<br />

retaining loops for long toolholder life<br />

R-sleeve with smaller gap<br />

to reduce wear on the tool shank<br />

Thick-walled cylindrical R-sleeve<br />

of quenched and tempered steel for constant<br />

tensioning force, even during long duty periods<br />

4<br />

Pre-tensioned, coated R-sleeve<br />

for quick and easy pick assembly<br />

Long R-sleeve to minimize wear<br />

to the toolholder bore<br />

ø 20<br />

Unit of<br />

measurement in mm<br />

26 © 2009 by Wirtgen GmbH

NEW!<br />

The new Pick W7 E R<br />

for road milling machines<br />

Our delivery service<br />

Packaging:<br />

Handy toolbox<br />

Quantity:<br />

50 picks per toolbox<br />

Weight:<br />

approx. 16 kg per toolbox<br />

Dimensions:<br />

approx. 26 x 18.5 x 22 cm<br />

Quantity standard palette:<br />

3000 picks<br />

Quantity overseas palette:<br />

2700 picks<br />

ø 20.5<br />

ø 11<br />

20.5<br />

12<br />

Optimum changing time W7 E R<br />

The new pick with the large range of possible uses<br />

W7 E R<br />

Part No.: 2069414<br />

Exceedingly long carbide tip<br />

for long tool life<br />

Special brazing process<br />

ensuring a high strength connection<br />

between carbide and steel body<br />

Pick head with ridges<br />

for improved asphalt break-up<br />

and optimum pick rotation<br />

48<br />

Hardened pick head<br />

for optimum pick life<br />

Extractor groove in pick head<br />

for extracting picks with a pick puller<br />

Wear plate with outer diameter of 45 mm<br />

for low degree of toolholder wear<br />

and optimum pick rotation<br />

ø 34<br />

88<br />

Centring function on the wear plate<br />

for low wear toolholder bore<br />

R-sleeve with Twin-Stop<br />

retaining loops for long toolholder life<br />

ø 45<br />

R-sleeve with smaller gap<br />

to reduce wear on the tool shank<br />

Thick-walled cylindrical R-sleeve<br />

of quenched and tempered steel for constant<br />

tensioning force, even during long duty periods<br />

4<br />

Pre-tensioned, coated R-sleeve<br />

for quick and easy pick assembly<br />

Long R-sleeve to minimize wear<br />

to the toolholder bore<br />

ø 20<br />

Unit of<br />

measurement in mm<br />

© 2009 by Wirtgen GmbH<br />

27

Pick W7 E H R<br />

for road milling machines<br />

NEW!<br />

Our delivery service<br />

Packaging:<br />

Handy toolbox<br />

Quantity:<br />

50 picks per toolbox<br />

Weight:<br />

approx. 16 kg per toolbox<br />

Dimensions:<br />

approx. 26 x 18.5 x 22 cm<br />

Quantity standard palette:<br />

3000 picks<br />

Quantity overseas palette:<br />

2700 picks<br />

ø 20.5<br />

ø 11<br />

20.5<br />

12<br />

Optimum changing time W7 E H R<br />

The pick with an impressive service life<br />

thanks to its large carbide tip<br />

W7 E H R<br />

Part No.: 2064871<br />

Extremely long carbide tip<br />

for long service life<br />

Special brazing process<br />

ensuring a high strength connection<br />

between carbide and steel body<br />

Pick head with ridges<br />

for improved asphalt break-up<br />

and optimum pick rotation<br />

48<br />

Hardened pick head<br />

for optimized pick life<br />

Wear plate with outside diameter 45<br />

for low toolholder wear<br />

and optimum pick rotation<br />

Centring function on the wear plate<br />

for low wear toolholder bore<br />

ø 34<br />

88<br />

R-sleeve with Twin-Stop<br />

retaining loops for long toolholder life<br />

R-sleeve with smaller gap<br />

to reduce wear on the tool shank<br />

ø 45<br />

Thick-walled cylindrical R-sleeve<br />

of quenched and tempered steel for constant<br />

tensioning force, even during long duty periods<br />

Pre-tensioned, coated R-sleeve<br />

for quick and easy pick assembly<br />

4<br />

Long R-sleeve to minimize wear<br />

to the toolholder bore<br />

ø 20<br />

Unit of<br />

measurement in mm<br />

28 © 2009 by Wirtgen GmbH

NEW!<br />

Pick W8 E H R<br />

for road milling machines<br />

Our delivery service<br />

Packaging:<br />

Handy toolbox<br />

Quantity:<br />

50 picks per toolbox<br />

Weight:<br />

approx. 16 kg per toolbox<br />

Dimensions:<br />

approx. 26 x 18.5 x 22 cm<br />

Quantity standard palette:<br />

3000 picks<br />

Quantity overseas palette:<br />

2700 picks<br />

ø 22<br />

ø 11.5<br />

23<br />

13.6<br />

Optimum changing time W8 E H R<br />

The pick with a particularly robust carbide tip<br />

for milling the hardest pavements<br />

W8 E H R<br />

Part No.: 2088104<br />

Extremely robust carbide tip<br />

for milling particularly hard pavements<br />

Special brazing process<br />

ensuring a high strength connection<br />

between carbide and steel body<br />

Pick head with ridges<br />

for improved asphalt break-up<br />

and optimum pick rotation<br />

48<br />

Hardened pick head<br />

for optimized pick life<br />

Wear plate with outside diameter 45<br />

for low toolholder wear<br />

and optimum pick rotation<br />

Centring function on the wear plate<br />

for low wear toolholder bore<br />

ø 34<br />

88<br />

R-sleeve with Twin-Stop<br />

retaining loops for long toolholder life<br />

R-sleeve with smaller gap<br />

to reduce wear on the tool shank<br />

ø 45<br />

Thick-walled cylindrical R-sleeve<br />

of quenched and tempered steel for constant<br />

tensioning force, even during long duty periods<br />

Pre-tensioned, coated R-sleeve<br />

for quick and easy pick assembly<br />

4<br />

Long R-sleeve to minimize wear<br />

to the toolholder bore<br />

ø 20<br />

Unit of<br />

measurement in mm<br />

© 2009 by Wirtgen GmbH<br />

29

Pick W6 AOC R<br />

for road milling machines<br />

NEW!<br />

Our delivery service<br />

Packaging:<br />

Handy toolbox<br />

Quantity:<br />

50 picks per toolbox<br />

Weight:<br />

approx. 16 kg per toolbox<br />

Dimensions:<br />

approx. 26 x 18.5 x 22 cm<br />

Quantity standard palette:<br />

3000 picks<br />

Quantity overseas palette:<br />

2700 picks<br />

ø 19<br />

ø 11.5<br />

15.5<br />

9.4<br />

Optimum changing time W6 AOC R<br />

The pick for milling asphalt on concrete<br />

W6 AOC R<br />

Part No.: 2088108<br />

Long, sturdy carbide tip<br />

for all-round use in large milling machines<br />

Special brazing process<br />

ensuring a high strength connection<br />

between carbide and steel body<br />

Pick head with ridges<br />

for improved asphalt break-up<br />

and optimum pick rotation<br />

48<br />

Hardened pick head<br />

for optimized pick life<br />

Wear plate with outside diameter 45<br />

for low toolholder wear<br />

and optimum pick rotation<br />

Centring function on the wear plate<br />

for low wear toolholder bore<br />

ø 34<br />

88<br />

R-sleeve with Twin-Stop<br />

retaining loops for long toolholder life<br />

R-sleeve with smaller gap<br />

to reduce wear on the tool shank<br />

ø 45<br />

Thick-walled cylindrical R-sleeve<br />

of quenched and tempered steel for constant<br />

tensioning force, even during long duty periods<br />

4<br />

Pre-tensioned, coated R-sleeve<br />

for quick and easy pick assembly<br />

Long R-sleeve to minimize wear<br />

to the toolholder bore<br />

ø 20<br />

Unit of<br />

measurement in mm<br />

30 © 2009 by Wirtgen GmbH

NEW!<br />

Pick W1-10 R<br />

for road milling machines<br />

Our delivery service<br />

Packaging:<br />

Handy toolbox<br />

Quantity:<br />

50 picks per toolbox<br />

Weight:<br />

approx. 14.4 kg per toolbox<br />

Dimensions:<br />

approx. 26 x 18.5 x 22 cm<br />

Quantity standard palette:<br />

3000 picks<br />

Quantity overseas palette:<br />

2700 picks<br />

ø 10<br />

25<br />

18.5<br />

Optimum changing time W1-10 R<br />

The robust pick for milling concrete pavements<br />

with small milling machines<br />

W1-10 R<br />

Part No.: 2088081<br />

Cylindrical carbide tip for use<br />

in hard milling materials, ensuring<br />

low cutting forces and a long service life<br />

Special brazing process<br />

ensuring a high strength connection<br />

between carbide and steel body<br />

Pick head with ridges<br />

for improved asphalt break-up<br />

and optimum pick rotation<br />

48<br />

Hardened pick head<br />

for optimized pick life<br />

Extractor groove in pick head<br />

for extracting picks with a pick puller<br />

Wear plate with outside diameter 45<br />

for low toolholder wear<br />

and optimum pick rotation<br />

Centring function on the wear plate<br />

for low wear toolholder bore<br />

R-sleeve with Twin-Stop<br />

retaining loops for long toolholder life<br />

ø 45<br />

ø 30<br />

88<br />

R-sleeve with smaller gap<br />

to reduce wear on the tool shank<br />

Thick-walled cylindrical R-sleeve<br />

of quenched and tempered steel for constant<br />

tensioning force, even during long duty periods<br />

4<br />

Pre-tensioned, coated R-sleeve<br />

for quick and easy pick assembly<br />

Long R-sleeve to minimize wear<br />

to the toolholder bore<br />

ø 20<br />

Unit of<br />

measurement in mm<br />

© 2009 by Wirtgen GmbH<br />

31

Pick W1-13 R<br />

for road milling machines<br />

NEW!<br />

Our delivery service<br />

Packaging:<br />

Handy toolbox<br />

Quantity:<br />

50 picks per toolbox<br />

Weight:<br />

approx. 16.5 kg per toolbox<br />

Dimensions:<br />

approx. 26 x 18.5 x 22 cm<br />

Quantity standard palette:<br />

3000 picks<br />

Quantity overseas palette:<br />

2700 picks<br />

ø 13<br />

25<br />

17.3<br />

Optimum changing time W1-13 R<br />

The pick with an outstanding price-performance ratio<br />

for cutting hard materials<br />

W1-13 R<br />

Part No.: 2088090<br />

Cylindrical carbide tip for use<br />

in hard milling materials, ensuring<br />

low cutting forces and a long service life<br />

Special brazing process<br />

ensuring a high strength connection<br />

between carbide and steel body<br />

Pick head with ridges<br />

for improved asphalt break-up<br />

and optimum pick rotation<br />

48<br />

Hardened pick head<br />

for optimized pick life<br />

Wear plate with outside diameter 45<br />

for low toolholder wear<br />

and optimum pick rotation<br />

Centring function on the wear plate<br />

for low wear toolholder bore<br />

R-sleeve with Twin-Stop<br />

retaining loops for long toolholder life<br />

R-sleeve with smaller gap<br />

to reduce wear on the tool shank<br />

ø 45<br />

ø 33<br />

88<br />

Thick-walled cylindrical R-sleeve<br />

of quenched and tempered steel for constant<br />

tensioning force, even during long duty periods<br />

4<br />

Pre-tensioned, coated R-sleeve<br />

for quick and easy pick assembly<br />

Long R-sleeve to minimize wear<br />

to the toolholder bore<br />

ø 20<br />

Unit of<br />

measurement in mm<br />

32 © 2009 by Wirtgen GmbH

NEW!<br />

Pick W1-15 R<br />

for road milling machines<br />

Our delivery service<br />

Packaging:<br />

Handy toolbox<br />

Quantity:<br />

40 picks per toolbox<br />

Weight:<br />

approx. 17.2 kg per toolbox<br />

Dimensions:<br />

approx. 26 x 18.5 x 22 cm<br />

Quantity standard palette:<br />

3000 picks<br />

Quantity overseas palette:<br />

2700 picks<br />

ø 15<br />

25<br />

15.8<br />

Optimum changing time W1-15 R<br />

The pick for cutting hard materials<br />

with high-performance large milling machines<br />

W1-15 R<br />

Part No.: 2088093<br />

Cylindrical carbide tip for use<br />

in hard milling materials, ensuring<br />

low cutting forces and a long service life<br />

Special brazing process<br />

ensuring a high strength connection<br />

between carbide and steel body<br />

Pick head with ridges<br />

for improved asphalt break-up<br />

and optimum pick rotation<br />

48<br />

Hardened pick head<br />

for optimized pick life<br />

Wear plate with outside diameter 45<br />

for low toolholder wear<br />

and optimum pick rotation<br />

Centring function on the wear plate<br />

for low wear toolholder bore<br />

R-sleeve with Twin-Stop<br />

retaining loops for long toolholder life<br />

R-sleeve with smaller gap<br />

to reduce wear on the tool shank<br />

ø 45<br />

ø 33<br />

88<br />

Thick-walled cylindrical R-sleeve<br />

of quenched and tempered steel for constant<br />

tensioning force, even during long duty periods<br />

4<br />

Pre-tensioned, coated R-sleeve<br />

for quick and easy pick assembly<br />

Long R-sleeve to minimize wear<br />

to the toolholder bore<br />

ø 20<br />

Unit of<br />

measurement in mm<br />

© 2009 by Wirtgen GmbH<br />

33

The complete delivery range of picks 2009<br />

for recycler<br />

Carbide tip<br />

Carbide weight<br />

Stabilizing<br />

and recycling<br />

Ø 22 Ø 25<br />

Stabilizing<br />

and recycling<br />

W6<br />

30.17 g<br />

W6 / 22 R<br />

Part No.<br />

2064872<br />

Page 36<br />

W6 SG<br />

22.89 g<br />

W6 SG / 22 R<br />

Part No.<br />

2064870<br />

Page 37<br />

WR6-SG<br />

Part No.<br />

2051324<br />

Page 42<br />

W7<br />

41.50 g<br />

W7 / 22 R<br />

Part No.<br />

2088113<br />

Page 38<br />

W8<br />

43.61 g<br />

W8 / 22 R<br />

Part No.<br />

2088117<br />

Page 39<br />

WR8-E<br />

Part No.<br />

129041<br />

Page 43<br />

W1-13 38.78 g<br />

W1-13 / 22 R<br />

Part No.<br />

2088111<br />

Page 40<br />

W1-15 47.82 g<br />

WR-15<br />

Part No.<br />

116074<br />

Page 44<br />

W1-17 73.69 g<br />

W1-17 / 22 R<br />

Part No.<br />

2088112<br />

Page 41<br />

W1-19 89.66 g<br />

WR-19<br />

Part No.<br />

2056891<br />

Page 45<br />

34 © 2009 by Wirtgen GmbH

Selection table 2009<br />

for recycler<br />

Machine type<br />

Shank diameter<br />

Used in<br />

Soil stabilization<br />

Stabilization<br />

of stony soil<br />

Cold recycling<br />

20 mm<br />

W6 S R<br />

Part No.:<br />

2088106<br />

Page 25<br />

W6 SG R<br />

Part No.:<br />

2088110<br />

Page 26<br />

WS 2000 / WS 2500<br />

WS 220 / WS 250<br />

22 mm<br />

W6 / 22 R<br />

Part No.:<br />

2064872<br />

Page 36<br />

W6 SG / 22 R<br />

Part No.:<br />

2064870<br />

Page 37<br />

W1-17 / 22 R<br />

Part No.:<br />

2088112<br />

Page 41<br />

25 mm<br />

WR8-E<br />

Part No.:<br />

129041<br />

Page 43<br />

WR-15<br />

Part No.:<br />

116074<br />

Page 44<br />

WR6-SG<br />

Part No.:<br />

2051324<br />

Page 42<br />

20 mm<br />

W6 S R<br />

Part No.:<br />

2088106<br />

Page 25<br />

W6 SG R<br />

Part No.:<br />

2088110<br />

Page 26<br />

W6 S R<br />

Part No.:<br />

2088106<br />

Page 25<br />

W6 / 22 R<br />

Part No.:<br />

2064872<br />

Page 36<br />

W6 SG / 22 R<br />

Part No.:<br />

2064870<br />

Page 37<br />

W7 / 22 R<br />

Part No.:<br />

2088113<br />

Page 38<br />

22 mm<br />

WR 2000<br />

WR 2400<br />

RACO 350<br />

WR 2500 / WR 2500 S<br />

W8 / 22 R<br />

Part No.:<br />

2088117<br />

Page 39<br />

W1-17 / 22 R<br />

Part No.:<br />

2088112<br />

Page 41<br />

W8 / 22 R<br />

Part No.:<br />

2088117<br />

Page 39<br />

25 mm<br />

WR8-E<br />

Part No.:<br />

129041<br />

Page 43<br />

WR-19<br />

Part No.:<br />

2056891<br />

Page 45<br />

WR6-SG<br />

Part No.:<br />

2051324<br />

Page 42<br />

WR6-SG<br />

Part No.:<br />

2051324<br />

Page 42<br />

WR8-E<br />

Part No.:<br />

129041<br />

Page 43<br />

© 2009 by Wirtgen GmbH<br />

35

Pick W6 / 22 R<br />

for cold recyclers/soil stabilizers<br />

NEW!<br />

Our delivery service<br />

Packaging:<br />

Handy toolbox<br />

Quantity:<br />

40 picks per toolbox<br />

Weight:<br />

approx. 16.5 kg per toolbox<br />

Dimensions:<br />

approx. 26 x 18.5 x 22 cm<br />

Quantity standard palette:<br />

2400 picks<br />

Quantity overseas palette:<br />

2160 picks<br />

ø 19<br />

ø 10.5<br />

17.5<br />

9.4<br />

Optimum changing time W6 / 22 R<br />

The economical all-round pick for recycling<br />

and soil stabilizing<br />

W6 / 22 R<br />

Part No.: 2064872<br />

Long, sturdy carbide tip<br />

for all-round use in large milling machines<br />

Special brazing process<br />

ensuring a high strength connection<br />

between carbide and steel body<br />

Hardened pick head<br />

for optimized pick life<br />

Pick head with ridges<br />

for optimum pick rotation<br />

51<br />

Particularly large pick head<br />

for long service life<br />

Wear plate with outside diameter 45<br />

for low toolholder wear<br />

and optimum pick rotation<br />

ø 40<br />

92<br />

Centring function on the wear plate<br />

for low wear toolholder bore<br />

R-sleeve with Twin-Stop<br />

retaining loops for long toolholder life<br />

ø 45<br />

R-sleeve with smaller gap<br />

to reduce wear on the tool shank<br />

Thick-walled cylindrical R-sleeve<br />

of quenched and tempered steel for constant<br />

tensioning force, even during long duty periods<br />

7<br />

Pre-tensioned, coated R-sleeve<br />

for quick and easy pick assembly<br />

Long R-sleeve to minimize wear<br />

to the toolholder bore<br />

ø 22<br />

Unit of<br />

measurement in mm<br />

36 © 2009 by Wirtgen GmbH

NEW!<br />

Pick W6 SG / 22 R<br />

for cold recyclers/soil stabilizers<br />

Our delivery service<br />

Packaging:<br />

Handy toolbox<br />

Quantity:<br />

40 picks per toolbox<br />

Weight:<br />

approx. 16 kg per toolbox<br />

Dimensions:<br />

approx. 26 x 18.5 x 22 cm<br />

Quantity standard palette:<br />

2400 picks<br />

Quantity overseas palette:<br />

2160 picks<br />

ø 19<br />

10<br />

1.5<br />

Optimum changing time W6 SG / 22 R<br />

The particularly fracture-resistant and economical pick<br />

for recycling and soil stabilisation<br />

W6 SG / 22 R<br />

Part No.: 2064870<br />

Thanks to new hard-metal technology,<br />

particularly fracture-resistant<br />

for recycling and stabilization<br />

Special brazing process<br />

ensuring a high strength connection<br />

between carbide and steel body<br />

Hardened pick head<br />

for optimized pick life<br />

44<br />

Pick head with ridges<br />

for optimum pick rotation<br />

Particularly large pick head<br />

for long service life<br />

Wear plate with outside diameter 45<br />

for low toolholder wear<br />

and optimum pick rotation<br />

ø 40<br />

84<br />

Centring function on the wear plate<br />

for low wear toolholder bore<br />

R-sleeve with Twin-Stop<br />

retaining loops for long toolholder life<br />

ø 45<br />

R-sleeve with smaller gap<br />

to reduce wear on the tool shank<br />

Thick-walled cylindrical R-sleeve<br />

of quenched and tempered steel for constant<br />

tensioning force, even during long duty periods<br />

7<br />

Pre-tensioned, coated R-sleeve<br />

for quick and easy pick assembly<br />

Long R-sleeve to minimize wear<br />

to the toolholder bore<br />

ø 22<br />

Unit of<br />

measurement in mm<br />

© 2009 by Wirtgen GmbH<br />

37

Pick W7 / 22 R<br />

for cold recyclers/soil stabilizers<br />

NEW!<br />

Our delivery service<br />

Packaging:<br />

Handy toolbox<br />

Quantity:<br />

40 picks per toolbox<br />

Weight:<br />

approx. 15.2 kg per toolbox<br />

Dimensions:<br />

approx. 26 x 18.5 x 22 cm<br />

Quantity standard palette:<br />

2400 picks<br />

Quantity overseas palette:<br />

2160 picks<br />

ø 20.5<br />

ø 11<br />

20.5<br />

12<br />

Optimum changing time W7 / 22 R<br />

The pick with fracture-proof carbide tip<br />

W7 / 22 R<br />

Part No.: 2088113<br />

Extremely long carbide tip<br />

for long service life<br />

Special brazing process<br />

ensuring a high strength connection<br />

between carbide and steel body<br />

Hardened pick head<br />

for optimized pick life<br />

Pick head with ridges<br />

for improved asphalt break-up<br />

and optimum pick rotation<br />

53<br />

Wear plate with outside diameter 45<br />

for low toolholder wear<br />

and optimum pick rotation<br />

Centring function on the wear plate<br />

for low wear toolholder bore<br />

ø 30<br />

92<br />

R-sleeve with Twin-Stop<br />

retaining loops for long toolholder life<br />

R-sleeve with smaller gap<br />

to reduce wear on the tool shank<br />

ø 45<br />

Thick-walled cylindrical R-sleeve<br />

of quenched and tempered steel for constant<br />

tensioning force, even during long duty periods<br />

Pre-tensioned, coated R-sleeve<br />

for quick and easy pick assembly<br />

7<br />

Long R-sleeve to minimize wear<br />

to the toolholder bore<br />

ø 22<br />

Unit of<br />

measurement in mm<br />

38 © 2009 by Wirtgen GmbH

NEW!<br />

Pick W8 / 22 R<br />

for cold recyclers/soil stabilizers<br />

Our delivery service<br />

Packaging:<br />

Handy toolbox<br />

Quantity:<br />

40 picks per toolbox<br />

Weight:<br />

approx. 17.2 kg per toolbox<br />

Dimensions:<br />

approx. 26 x 18.5 x 22 cm<br />

Quantity standard palette:<br />

2400 picks<br />

Quantity overseas palette:<br />

2160 picks<br />

ø 22<br />

ø 11.5<br />

20<br />

11<br />

Optimum changing time W8 / 22 R<br />

The robust pick for recycling and soil stabilizing<br />

W8 / 22 R<br />

Part No.: 2088117<br />

Extremely robust carbide tip<br />

for milling particularly hard pavements<br />

Special brazing process<br />

ensuring a high strength connection<br />

between carbide and steel body<br />

Hardened pick head<br />

for optimized pick life<br />

Particularly large pick head<br />

for long service life<br />

51<br />

Wear plate with outside diameter 45<br />

for low toolholder wear<br />

and optimum pick rotation<br />

Centring function on the wear plate<br />

for low wear toolholder bore<br />

R-sleeve with Twin-Stop<br />

retaining loops for long toolholder life<br />

R-sleeve with smaller gap<br />

to reduce wear on the tool shank<br />

Thick-walled cylindrical R-sleeve<br />

of quenched and tempered steel for constant<br />

tensioning force, even during long duty periods<br />

Pre-tensioned, coated R-sleeve<br />

for quick and easy pick assembly<br />

Long R-sleeve to minimize wear<br />

to the toolholder bore<br />

ø 45<br />

ø 40<br />

7<br />

92<br />

ø 22<br />

Unit of<br />

measurement in mm<br />

© 2009 by Wirtgen GmbH<br />

39

Pick W1-13 / 22 R<br />

for cold recyclers/soil stabilizers<br />

NEW!<br />

Our delivery service<br />

Packaging:<br />

Handy toolbox<br />

Quantity:<br />

40 picks per toolbox<br />

Weight:<br />

approx. 17.2 kg per toolbox<br />

Dimensions:<br />

approx. 26 x 18.5 x 22 cm<br />

Quantity standard palette:<br />

2400 picks<br />

Quantity overseas palette:<br />

2160 picks<br />

ø 13<br />

25<br />

18.5<br />

Optimum changing time W1-13 / 22 R<br />

The pick for soil stabilization jobs<br />

in material studded with stones<br />

W1-13 / 22 R<br />

Part No.: 2088111<br />

Special brazing process<br />

ensuring a high strength connection<br />

between carbide and steel body<br />

Hardened pick head<br />

for optimized pick life<br />

Particularly large pick head<br />

for long service life<br />

Wear plate with outside diameter 45<br />

for low toolholder wear<br />

and optimum pick rotation<br />

53<br />

Centring function on the wear plate<br />

for low wear toolholder bore<br />

R-sleeve with Twin-Stop<br />

retaining loops for long toolholder life<br />

R-sleeve with smaller gap<br />

to reduce wear on the tool shank<br />

Thick-walled cylindrical R-sleeve<br />

of quenched and tempered steel for constant<br />

tensioning force, even during long duty periods<br />

Pre-tensioned, coated R-sleeve<br />

for quick and easy pick assembly<br />

Long R-sleeve to minimize wear<br />

to the toolholder bore<br />

ø 45<br />

ø 40<br />

7<br />

92<br />

ø 22<br />

Unit of<br />

measurement in mm<br />

40 © 2009 by Wirtgen GmbH

NEW!<br />

Pick W1-17 / 22 R<br />

for cold recyclers/soil stabilizers<br />

Our delivery service<br />

Packaging:<br />

Handy toolbox<br />

Quantity:<br />

40 picks per toolbox<br />

Weight:<br />

approx. 17.9 kg per toolbox<br />

Dimensions:<br />

approx. 26 x 18.5 x 22 cm<br />

Quantity standard palette:<br />

2400 picks<br />

Quantity overseas palette:<br />

2160 picks<br />

ø 17<br />

28.5<br />

18.3<br />

Optimum changing time W1-17 / 22 R<br />

The extremely robust pick for soil stabilizing<br />

under extreme conditions<br />

W1-17 / 22 R<br />

Part No.: 2088112<br />

Very large and robust cylindrical carbide tip<br />

for use with particularly high impact loads<br />

Special brazing process<br />

ensuring a high strength connection<br />

between carbide and steel body<br />

Hardened pick head<br />

for optimized pick life<br />

Particularly large pick head<br />

for long service life<br />

51<br />

Wear plate with outside diameter 45<br />

for low toolholder wear<br />

and optimum pick rotation<br />

Centring function on the wear plate<br />

for low wear toolholder bore<br />

ø 40<br />

92<br />

R-sleeve with Twin-Stop<br />

retaining loops for long toolholder life<br />

R-sleeve with smaller gap<br />

to reduce wear on the tool shank<br />

ø 45<br />

Thick-walled cylindrical R-sleeve<br />

of quenched and tempered steel for constant<br />

tensioning force, even during long duty periods<br />

7<br />

Pre-tensioned, coated R-sleeve<br />

for quick and easy pick assembly<br />

Long R-sleeve to minimize wear<br />

to the toolholder bore<br />

ø 22<br />

Unit of<br />

measurement in mm<br />

© 2009 by Wirtgen GmbH<br />

41

Pick WR6-SG<br />

for soil stabilizers<br />

Our delivery service<br />

ø 19<br />

1.5<br />

Packaging:<br />

Handy toolbox<br />

Quantity:<br />

20 picks per toolbox<br />

Weight:<br />

approx. 14.4 kg per toolbox<br />

Dimensions:<br />

approx. 26 x 18.5 x 22 cm<br />

Quantity standard palette:<br />

1200 picks<br />

Quantity overseas palette:<br />

1080 picks<br />

10<br />

Optimum changing time WR6-SG<br />

The pick for soil stabilization jobs<br />

in material studded with stones<br />

WR6-SG<br />

Part No.: 2051324<br />

Hardened pick head<br />

for optimized pick life<br />

64<br />

Special brazing process<br />

ensuring a high strength connection<br />

between carbide and steel body<br />

Pick head with ridges<br />

for optimum pick rotation<br />

121<br />

Particularly large pick head<br />

for long service life<br />

ø 60<br />

ø 25<br />

Unit of<br />

measurement in mm<br />

42 © 2009 by Wirtgen GmbH

Pick WR8-E<br />

for soil stabilizers<br />

Our delivery service<br />

Packaging:<br />

Handy toolbox<br />

Quantity:<br />

20 picks per toolbox<br />

Weight:<br />

approx. 14 kg per toolbox<br />

Dimensions:<br />

approx. 26 x 18.5 x 22 cm<br />

Quantity standard palette:<br />

1200 picks<br />

Quantity overseas palette:<br />

1080 picks<br />

ø 22<br />

ø 11.5<br />

20<br />

11.2<br />

Optimum changing time WR8-E<br />

The robust pick for soil stabilization jobs<br />

WR8-E<br />

Part No.: 129041<br />

Special brazing process<br />

ensuring a high strength connection<br />

between carbide and steel body<br />

64<br />

Hardened pick head<br />

for optimized pick life<br />

Pick head with ridges<br />

for optimum pick rotation<br />

121<br />

Particularly large pick head<br />

for long service life<br />

ø 60<br />

ø 25<br />

Unit of<br />

measurement in mm<br />

© 2009 by Wirtgen GmbH<br />

43

Pick WR-15<br />

for soil stabilizers<br />

Our delivery service<br />

Packaging:<br />

Handy toolbox<br />

Quantity:<br />

20 picks per toolbox<br />

Weight:<br />

approx. 14.2 kg per toolbox<br />

Dimensions:<br />

approx. 26 x 18.5 x 22 cm<br />

Quantity standard palette:<br />

1200 picks<br />

Quantity overseas palette:<br />

1080 picks<br />

ø 15<br />

25<br />

16<br />

Optimum changing time WR-15<br />

The all-round pick for soil stabilizing<br />

WR-15<br />

Part No.: 116074<br />

Extremely long carbide tip<br />

or long service life<br />

64<br />

Special brazing process<br />

ensuring a high strength connection<br />

between carbide and steel body<br />

Hardened pick head<br />

for optimized pick life<br />

121<br />

Pick head with ridges<br />

for optimum pick rotation<br />

ø 60<br />

Particularly large pick head<br />

for long service life<br />

ø 25<br />

Unit of<br />

measurement in mm<br />

44 © 2009 by Wirtgen GmbH

Pick WR-19<br />

for soil stabilizers<br />

Our delivery service<br />

Packaging:<br />

Handy toolbox<br />

Quantity:<br />

20 picks per toolbox<br />

Weight:<br />

approx. 14.4 kg je toolbox<br />

Dimensions:<br />

approx. 26 x 18.5 x 22 cm<br />

Quantity standard palette:<br />

1200 picks<br />

Quantity overseas palette:<br />

1080 picks<br />

ø 19<br />

30<br />

17<br />

Optimum changing time WR-19<br />

The exceedingly robust pick for soil stabilization<br />

under extreme conditions<br />

WR-19<br />

Part No.: 2056891<br />

Very large and robust cylindrical carbide tip<br />

for use with particularly high impact loads<br />

Special brazing process<br />

ensuring a high strength connection<br />

between carbide and steel body<br />

64<br />

Hardened pick head<br />

for optimized pick life<br />

121<br />

Pick head with ridges<br />

for optimum pick rotation<br />

ø 60<br />

Particularly large pick head<br />

for long service life<br />

ø 25<br />

Unit of<br />

measurement in mm<br />

© 2009 by Wirtgen GmbH<br />

45

The complete delivery range of picks 2009<br />

for Surface Miner at a glance<br />

Carbide tip Carbide weight Ø 38-30<br />

Ø 42<br />

Without wear cladding<br />

With wear cladding<br />

W1-13 38.78 g<br />

WSM-13<br />

Part No.:<br />

95744<br />

Page 49<br />

W1-15 47.82 g<br />

WSM-15<br />

Part No.:<br />

47571<br />

Page 49<br />

W1-17 73.69 g<br />

WSM-17<br />

Part No.:<br />

48350<br />

Page 49<br />

W1-19 89.66 g<br />

WSM-19<br />

Part No.:<br />

70225<br />

Page 49<br />

WSM-19-42 E<br />

Part No.:<br />

2100411<br />

Page 51<br />

WSM-19-42 EP<br />

Part No.:<br />

2100408<br />

Page 51<br />

W1-22 139.96 g<br />

WSM-22<br />

Part No.:<br />

2056890<br />

Page 49<br />

WSM-22-42 E<br />

Part No.:<br />

2112489<br />

Page 51<br />

WSM-22-42 EP<br />

Part No.:<br />

2091737<br />

Page 51<br />

W1-25 205.17 g<br />

WSM-25<br />

Part No.:<br />

179215<br />

Page 49<br />

WSM-25-42 E<br />

Part No.:<br />

2100414<br />

Page 51<br />

WSM-25-42 EP<br />

Part No.:<br />

2100415<br />

Page 51<br />

Applications<br />

The applications listed here are guide numbers. The cuttability, cutting performance and pick wear depend upon the uniaxial<br />

pressure strength, the tensile strength, abrasiveness, crevasse formation and inhomogenity.<br />

Soft layers<br />

Medium-hard layers<br />

Hard layers<br />

Very hard layers<br />

Asphalt<br />

Sand<br />

Clay<br />

Brown coal<br />

Salt<br />

Concrete<br />

Shelly limestone<br />

Soft limestone<br />

Gypsum<br />

Marl<br />

Shale<br />

Granolithic concrete<br />

Limestone<br />

Hard anthracite<br />

Hard limestone<br />

Hard sandstone<br />

Dolomite<br />

Compressive strength Compressive strength Compressive strength Compressive strength<br />

0 - 20 N/mm 2 20 - 50 N/mm 2 50 - 80 N/mm 2 > 80 N/mm 2<br />

46 © 2009 by Wirtgen GmbH

Selection table 2009<br />

for Surface Miner<br />

Machine type<br />

Shank<br />

diameter<br />

Compressive strength Compressive strength Compressive strength Compressive strength<br />

0 - 20 N/mm 2 20 - 50 N/mm 2 50 - 80 N/mm 2 > 80 N/mm 2<br />

2100 SM 38/30 mm<br />

WSM-13<br />

Part No.:<br />

95744<br />

WSM-15<br />

Part No.:<br />

47571<br />

WSM-17<br />

Part No.:<br />

48350<br />

WSM-19<br />

Part No.:<br />

70225<br />

2200 SM 38/30 mm<br />

WSM-13<br />

Part No.:<br />

95744<br />

WSM-15<br />

Part No.:<br />

47571<br />

WSM-17<br />

Part No.:<br />

48350<br />

WSM-19<br />

Part No.:<br />

70225<br />

38/30 mm<br />

WSM-13<br />

Part No.:<br />

95744<br />

WSM-15<br />

Part No.:<br />

47571<br />

WSM-17<br />

Part No.:<br />

48350<br />

WSM-19<br />

Part No.:<br />

70225<br />

WSM-22<br />

Part No.:<br />

2056890<br />

WSM-25<br />

Part No.:<br />

179215<br />

2500 SM,<br />

3700 SM,<br />

4200 SM<br />

42 mm<br />

WSM-19-42 E<br />

Part No.:<br />

2100411<br />

WSM-22-42 E<br />

Part No.:<br />

2112489<br />

WSM-25-42 E<br />

Part No.:<br />

2100414<br />

WSM-19-42 EP WSM-22-42 EP WSM-25-42 EP<br />

Part No.:<br />

2100408<br />

Part No.:<br />

2091737<br />

Part No.:<br />

2100415<br />

© 2009 by Wirtgen GmbH<br />

47

Pick D = 38/30 mm<br />

for Surface Mining<br />

NEW!<br />

The Wirtgen Surface Miners are being<br />

used in numerous mines and construction<br />

sites worldwide. The operating<br />

costs arising during use can be significantly<br />

reduced by using high-quality<br />

milling picks. Here, the Wirtgen and<br />

Betek system partnership, one of the<br />

world’s leading carbide manufacturers,<br />

is especially successful.<br />

Selecting the appropriate cutting tool is<br />

of decisive importance for good cutting<br />

performance and even for the cutting<br />

tool service life itself.<br />

Very large and robust cylindrical<br />

carbide tip for use with particularly<br />

high impact loads<br />

Special brazing process ensuring a<br />

high strength connection between<br />

carbide and steel body<br />

Hardened pick head for<br />

optimized pick life<br />

Pick head with ridges for optimum<br />

pick rotation<br />

Large pick head for<br />

long service life<br />

Locking ring for defined pick<br />

seating in the toolholder<br />

48 © 2009 by Wirtgen GmbH

The complete delivery range of picks 2009<br />

D = 38/30 mm for Surface Miner<br />

WSM-13 Part No.: 95744<br />

WSM-15 Part No.: 47571<br />

WSM-17 Part No.: 48350<br />

ø 60<br />

ø 13<br />

25<br />

77<br />

77<br />

77<br />

ø 60<br />

ø 60<br />

ø 15<br />

ø 17.5<br />

77<br />

77<br />

24<br />

28.5<br />

Locking ring Part No.: 155281 Locking ring Part No.: 155281 Locking ring Part No.: 155281<br />

WSM-19 Part No.: 70225<br />

WSM-22 Part No.: 2056890<br />

WSM-25 Part No.: 179215<br />

77<br />

ø 60<br />

ø 60<br />

ø 70<br />

ø 19<br />

ø 22<br />

ø 25<br />

30<br />

34<br />

35<br />