On-Site Power Generation Systems

On-Site Power Generation Systems

On-Site Power Generation Systems

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

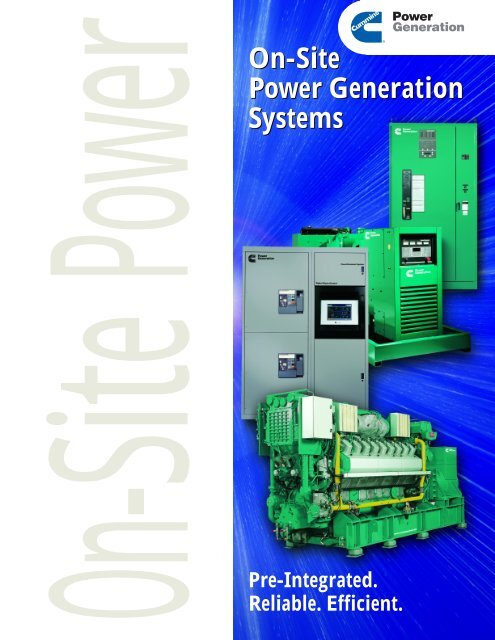

<strong>On</strong>-<strong>Site</strong> <strong>Power</strong><br />

<strong>On</strong>-<strong>Site</strong><br />

<strong>Power</strong> <strong>Generation</strong><br />

<strong>Systems</strong><br />

Pre-Integrated.<br />

Reliable. Efficient.

Most models UL 2200-listed. See your distributor for specific details.<br />

<strong>Power</strong> Output Rating<br />

Model Standby (kW) Prime <strong>Power</strong> (kW)<br />

60 Hz 50 Hz 60 Hz 50 Hz<br />

DNAC 7.5 N/A 6.8 N/A<br />

DNAD 11.5 N/A 10.4 N/A<br />

DKAC * 15.0 N/A 13.5 N/A<br />

DNAE 16.0 N/A 14.4 N/A<br />

DKAE * 20.0 N/A 18.0 N/A<br />

DNAF 20.0 N/A 18.0 N/A<br />

DKAF * 25 N/A 23 18<br />

DGBB * 35 28 32 25<br />

DGGD 35 28 30 25<br />

DGBC * 40 32 35 29<br />

DGHD 40 32 36 29<br />

DGCA * 50 40 45 36<br />

DGHE 50 40 45 36<br />

DGCB * 60 50 55 45<br />

DGCG 80 65 72 60<br />

DGDA * 80 N/A 72 N/A<br />

DGDB * 100 85 90 80<br />

DGDK ° 125 100 113 90<br />

DGFA 150 140 135 125<br />

DSHAA* 150 N/A 135 N/A<br />

DGFB 175 150 160 135<br />

DSHAB* 175 N/A 160 N/A<br />

DGFC 200 176 180 160<br />

DSHAC* 200 N/A 180 N/A<br />

DGFS 230 N/A N/A N/A<br />

DFAB 230 200 210 180<br />

DFAC 250 220 225 200<br />

DQAD 250 220 220 200<br />

DQDAA 250 220 225 200<br />

DFBF 275 250 250 227<br />

DQAE 275 250 250 227<br />

DQDAB 275 250 250 227<br />

DQDAC 300 265 270 240<br />

DQAF 300 275 270 250<br />

DFCB 300 275 270 250<br />

DFCC 350 310 315 282<br />

DFEG * 350 N/A 320 N/A<br />

DFEB 400 330 350 300<br />

DFEH * 400 352 350 320<br />

DFCE 400 N/A N/A N/A<br />

DFEC 450 400 410 360<br />

DFEJ * 450 400 410 364<br />

DFED 500 450 455 400<br />

DFEK * 500 440 455 400<br />

DQCA 600 545 545 500<br />

DFGB 600 550 545 500<br />

DFHA ° 750 620 680 560<br />

DQCB 750 660 680 600<br />

DQFAA* 750 N/A 680 N/A<br />

DFGE 750 N/A N/A N/A<br />

DFHB ° 800 700 725 640<br />

DQCC 800 720 725 656<br />

DQFAB* 800 N/A 725 N/A<br />

DFHC 900 800 818 725<br />

DQFAC* 900 N/A 818 N/A<br />

DFHD ° 1000 880 900 800<br />

DQFAD* 1000 N/A 900 N/A<br />

DFLC 1250 1120 1100 1000<br />

DQGAA* 1250 N/A 1100 N/A<br />

DFLE ° 1500 1290 1250 1100<br />

DQGAB* 1500 N/A 1350 N/A<br />

DQKB ° 1750 1500 1600 1350<br />

DQKAA* 1750 N/A 1600 N/A<br />

DQKC ° 2000 1650 1825 1500<br />

DQKD N/A 1800 N/A 1600<br />

DQKAB* 2000 N/A 1825 N/A<br />

DQKH 2250 2000 N/A N/A<br />

DQLA 2700 N/A 2435 N/A<br />

DQLB N/A 2660 N/A 2400<br />

DIESEL GENERATOR SETS<br />

Our 7.5 to 25 kW liquid-cooled diesel generator sets offer our traditional<br />

rugged designs, durability and reliability for applications ranging from nursing<br />

homes to wireless services, to prime power for small, remote, unattended sites.<br />

User-friendly operation and maintenance features include:<br />

• Heavy-duty engines and high performance alternators<br />

• Mechanical or electronic governing systems, and electronic voltage regulation<br />

• Optional control systems for automatic, local, or remote start applications<br />

• Optional weather-protective and sound attenuated enclosures, coolant<br />

heaters, and other features to enhance performance and reliability in<br />

extreme ambient environments<br />

• Complete set of accessory devices designed for use with the generator<br />

set to simplify installation and enhance reliability<br />

Cummins-powered diesel generator sets are available in sizes ranging from 35<br />

to 2700 kW. Whether your application is for prime or continuous power, or if<br />

reliable standby power is critical to your business, Cummins provides standard<br />

features that have no equal. Heavy-duty Cummins engines are known for their<br />

stingy fuel efficiency, responsive transient performance, and rugged reliability. Each<br />

generator set includes a cooling system that is designed to provide guaranteed<br />

performance in high ambient temperatures,<br />

so you get all the power<br />

you pay for. High performance<br />

Cummins-manufactured alternators<br />

offer optimum performance in<br />

demanding applications, such as<br />

data centers and industrial plants.<br />

POWERCOMMAND ® CONTROLS<br />

<strong>On</strong>ly Cummins generator sets are available with the industry-leading<br />

<strong>Power</strong>Command Control. This unique, field-proven control system offers<br />

features, performance, and reliability. A dazzling array of standard features<br />

includes not only integrated digital governing and voltage regulation, but also: both<br />

analog and digital metering; digital engine monitoring systems; smart-starting<br />

systems that actually regulate the fuel system based on engine temperature to<br />

improve stability, starting time and limit smoke; battery monitoring systems<br />

that test the genset batteries; AmpSentry true alternator protection; and more.<br />

<strong>Power</strong>Command controls offer the capability of integrated digital paralleling<br />

substituting less reliable, complex, and expensive paralleling equipment with<br />

simple, off the shelf solutions.<br />

° Available with EPA Nonroad TPEM Program *Available with EPA Nonroad Emissions Certifications (60 Hz)

SPARK-IGNITED GENERATOR SETS<br />

Our spark-ignited generator sets, 6 to 150 kW, are available with natural gas,<br />

propane, and combined fuel systems. They can be used in a variety of life-support<br />

and related applications, including small health care facilities and retail<br />

businesses. Installation and hookup to the fuel source lines is both basic<br />

and convenient. As with our diesel generator sets, a complete selection of<br />

voltages, accessories, generator set, and control options are available for<br />

customizing to your specific needs. Major features include:<br />

• Multiple control system options including those that<br />

are NFPA 110 compliant<br />

• Natural Gas, Propane, or combination fuel systems<br />

• Weather protective and sound attenuated enclosures<br />

(steel or aluminum)<br />

QUIETSITE SOUND ATTENUATED GENERATOR SETS<br />

Quiet<strong>Site</strong> provides two levels of sound attenuation to comply with stringent<br />

noise requirements. Steel or aluminum sound attenuated enclosures can be<br />

factory installed or up fitted on existing generator sets by the local distributor<br />

as requirements emerge.<br />

All features, options, and accessories of Cummins <strong>Power</strong> <strong>Generation</strong>® diesel<br />

gensets up to 1000 kW and spark-ignited gensets from 6 to 150 kW are available<br />

with Quiet<strong>Site</strong> enclosures. And Quiet<strong>Site</strong> can be configured for other stationary<br />

or trailerized applications.<br />

Quiet<strong>Site</strong> enclosures silence and protect the complete generator set, optimizing<br />

both genset performance and sound treatment to achieve low noise performance.<br />

Major features include:<br />

• Level 1: 65 to 85 dB(a) with full load at 7 meters<br />

• Level 2: 61 to 78 dB(a) with full load at 7 meters<br />

• Compact footprint, low profile design<br />

• Easy access to all major generator, engine, and<br />

control components for servicing<br />

• Enclosed, protective exhaust systems<br />

• Upgrade kits<br />

• Sub-based fuel tanks available<br />

• UL 2200 listed<br />

<strong>Power</strong> Output Rating<br />

Standby Prime <strong>Power</strong><br />

Model Fuel (kW) (kW)<br />

60Hz 50Hz 60Hz 50Hz<br />

GNAA Natural Gas 6.0 4.7 5.4 4.2<br />

Propane (Vapor) 7.0 5.5 6.3 5.0<br />

GNAB Natural Gas 10.0 7.8 9.0 7.0<br />

Propane (Vapor) 11.5 9.0 10.4 8.1<br />

GNAC Natural Gas 14.0 10.9 12.6 9.8<br />

Propane (Vapor) 16.0 12.5 14.4 11.3<br />

GGDB Natural Gas 20 16 N/A N/A<br />

Propane* 20 16 N/A N/A<br />

GGFD Natural Gas 35 N/A 30 N/A<br />

Propane* 35 N/A 30 N/A<br />

GGFE Natural Gas 42 30 36 25<br />

Propane* 47 35 40 30<br />

GGHE Natural Gas 60 N/A 51 N/A<br />

Propane* 60 N/A 51 N/A<br />

GGHF Natural Gas 70 55 60 47<br />

Propane* 75 60 64 51<br />

GGHG Natural Gas 85 N/A N/A N/A<br />

Propane* 85 N/A N/A N/A<br />

GGHH Natural Gas 100 75 N/A N/A<br />

Propane* 100 75 N/A N/A<br />

GGKB Natural Gas 125 105 115 95<br />

Propane* 125 105 115 95<br />

GGKC Natural Gas 140 110 125 100<br />

Propane* 140 110 125 100<br />

GGKD Natural Gas 150 115 135 105<br />

GGLA Natural Gas 125 N/A 100 N/A<br />

GGLB Natural Gas 150 N/A N/A N/A<br />

* Liquid or Vapor

LEAN BURN GAS GENERATOR SETS<br />

Cummins lean-burn gas gensets are designed to provide premier performance,<br />

Lean Burn Technology is<br />

Clean-Burning Technology<br />

BMEP (bar)<br />

20<br />

18<br />

16<br />

14<br />

12<br />

10<br />

1 bar = 14.5 PSI NOx Efficiency<br />

DETONATION<br />

OPERATING<br />

WINDOW<br />

MISFIRE<br />

8<br />

0.6 0.8 1.0 1.2 1.4 1.6 1.8 2.0<br />

Air Excess (lambda)<br />

fuel efficiency and low emissions for high-hour peaking baseload and CHP<br />

applications. Using a lean mixture of fuel and air, combustion temperatures<br />

are significantly reduced, which minimizes the production of nitrogen oxides.<br />

The result is high power output with maximum thermal efficiency and minimal<br />

emissions. Already proven in over 500,000 hours of continuous duty operation<br />

around the world, these generators meet most federal, state, and local emissions<br />

requirements. SCR after treatment options reduce NOx levels (as low as 0.15<br />

grams/BHP-hr or less) to the most stringent air quality standards. Capable of<br />

running on variable quality gas — from pipe-line natural gas to field gas or bio-gas<br />

with a methane number over 45, Cummins gas reciprocating engine technology<br />

and standard <strong>Power</strong>Command controls provide maximum operational<br />

flexibility for power generation applications.<br />

Model <strong>Power</strong> Output Ratings Continuous (kW)<br />

60 Hz 50Hz<br />

334GFBA 334 ––<br />

315GFBA –– 315<br />

1160GQKA –– 1160<br />

1400GQKA 1400 ––<br />

1250GQNA 1250 ––<br />

1370GQMA –– 1370<br />

1540GQNA –– 1540<br />

1570GQMB –– 1570<br />

1750GQNB –– 1750<br />

1750GQPB 1750 ––<br />

2000GQNC –– 2000<br />

2000GQPC 2000 ––

COMBUSTION TURBINES<br />

Cummins <strong>Power</strong> <strong>Generation</strong> combustion turbines range from 1.4 MW to<br />

17.2 MW. With natural gas and liquid fuel capabilities, these prime movers<br />

are well suited to applications requiring low emissions, small foot<br />

print, high reliability and low vibration. Each turbine/generator<br />

set is designed for long service intervals, rapid installation and<br />

low maintenance thereby achieving high annual availability.<br />

• Dry low emissions (DLE): mitigated as low as<br />

15 ppm NOx, 50 ppm CO<br />

• Catalytic combustion emissions: 3ppm NOx, 10ppm CO<br />

• Fuel transfers “on the fly” capability<br />

• Weatherproof, sound-attenuated enclosures<br />

• Low installation costs<br />

(less concrete, no cooling circuit, smaller crane required)<br />

• Included packaged operational auxiliaries and advanced<br />

control system<br />

• High hour usage: Availability ≥ 95% annually<br />

• <strong>Power</strong>ed by Kawasaki<br />

As distributed generation, base load applications are diverse<br />

ranging from factory manufacturing facilities to heath care<br />

and government facilities to university campuses.<br />

• Cogeneration installation supplying steam for facility process<br />

• Combined Heat & <strong>Power</strong> (CHP) — heating or absorption cooling<br />

• Combined Cycle installation — increased overall electrical efficiency<br />

Gas Turbine Catalytic Combustion M1A-13X<br />

Fuel Injector<br />

Mixer<br />

59°F Ambient Temperature<br />

Required Electric Steam Electrical Overall<br />

Gas Pressure Output Production Efficiency Efficiency NOx CO VOC<br />

Model psig kW lb/hr* % %(kW) ppmvd at 15% O 2<br />

GPB15X 283 1,423 11,100 23.4 77.1 3 10 2<br />

Electric <strong>Power</strong> 1.4MWe, Steam 5.5t/h, Dry Low Emissions<br />

GPB15 DLE 206 1,434 11,216 23.6 77.4 15 50 2<br />

Electric <strong>Power</strong> 1.4MWe, Steam 5.5t/h, Dry Low Emissions<br />

GPB60 DLE 242 5,265 32,139 28.9 80.7 25 50 2<br />

Electric <strong>Power</strong> 5.3MWe, Steam 16t/h, Dry Low Emissions<br />

Sea level, intake/exhaust pressure loss: 4/10 inches of water Generator efficiency: 95%<br />

Preburner<br />

Catalyst Module<br />

Burnout Zone<br />

GPB70 DLE 300 6,500 36,915 29.7 79.2 25 50 2<br />

Electric <strong>Power</strong> 6.5MWe, Steam 18t/h, Dry Low Emissions<br />

GPB180 DLE 360 17,170 84,437 32.6 79.5 23 25 2<br />

Electric <strong>Power</strong> 17.2MWe, Steam 42t/h, Dry Low Emissions<br />

Sea level, intake/exhaust pressure loss: 4/14 inches of water Generator efficiency: 97%<br />

Fuel is natural gas with LHV=905 BTU/scf<br />

* Steam production is based on deaerated feedwater temperature of 228°F,<br />

2% continuous blowdown, 125 psig saturated steam at non return valve outlet.

DIGITAL PARALLELING AND POWER TRANSFER EQUIPMENT<br />

Paralleling is an integrated function of our microprocessor based<br />

genset control, <strong>Power</strong>Command. In addition to monitoring, protection,<br />

governing, and voltage regulation functions, this single control provides<br />

paralleling control functions, including synchronizing, load sharing,<br />

and paralleling protection. <strong>Power</strong>Command controls even provide<br />

utility (mains) paralleling functions such as import/export control<br />

and var/power factor control. The same microprocessor-based control<br />

technology is also found on our full line of transfer switches;<br />

optimizing performance and simplifying operation and<br />

service. <strong>On</strong>ly with Cummins <strong>Power</strong> <strong>Generation</strong> can you get<br />

a pre-integrated digital power system—systems that are designed,<br />

built, tested and serviced by one manufacturer.<br />

Digital MasterControl<br />

The <strong>Power</strong>Command Model 200 and 300 Digital MasterControl, with its<br />

unique industrial PC-based touchscreen operator interface and software-based<br />

design, is a perfect complement to the <strong>Power</strong>Command generator set control for<br />

applications that demand maximum ease of use and extensive control capabilities.<br />

Major features include:<br />

• Internet/Intranet capable for remote monitoring and alarm dialout<br />

• Broad range of master control products to suit any application<br />

• Isolated and infinite bus (utility mains paralleling) designs<br />

• Easily integrates into other building control systems<br />

• Suitable for applications up to 15,000 VAC, ANSIC 37.2, UL-1670 listed<br />

• <strong>Power</strong> sections available using either stationary or drawout breakers, in<br />

UL-891, UL-1558 CSA or IEC type medium voltage designs, UL-1670 listed<br />

• Front only or front/rear access switchboard designs<br />

Closed Transition ATS<br />

Model # of Poles Size (Amperes)<br />

CHPC 2, 3, 4 125-800 A<br />

Closed Transition, 100ms, high withstand rated, heavy duty switch<br />

PLTH 3, 4 800-3000 A<br />

Closed Transition, 100ms, breaker pair (MCCB) switch<br />

PLTS 3, 4 800-3000 A<br />

Closed Transition, soft load, breaker pair (MCCB) switch<br />

PLTE 3, 4 800-3000 A<br />

Closed Transition, extended paralleling, breaker pair (MCCB) switch<br />

Digital Paralleling Transfer Equipment<br />

and Closed Transition Transfer Switches<br />

Closed transition transfer switches from 125 to 800 amps<br />

operate either open or closed hard transition with enhanced<br />

specific breaker ratings and 3 cycle ratings. Closed transition<br />

includes sync check or optional active sync for short duration<br />

paralleled source operation (50 –70 msec). For installations<br />

rated from 800 – 3,000 amps, our digital paralleling load<br />

transfer (PLT) equipment, specifically designed for closed<br />

transition transfer, transfers power between a generator set<br />

and utility service without interrupting power to critical<br />

loads. Service entrance rating, ground fault protection, and<br />

utility protective relaying are available. UL-891, UL-1008 listed.

Open Transition Transfer Switches<br />

Our open transition transfer switches incorporate a range of controls for<br />

utility-to-utility, utility-to-genset or genset-to-genset applications. They employ<br />

many standard and optional features, including a front panel digital display, bar<br />

graph metering, programmed transition, phase check, and optional simultaneously<br />

switched neutral. Major features include:<br />

• UL 1008 listed withstand and closing ratings up to 200kA<br />

• High visibility LED-indicating lamps provide<br />

at-a-glance source and ATS status for quick summary<br />

of system conditions<br />

• Convenient front panel digital display provides easy<br />

access to review power and load conditions, make<br />

adjustments, review events, and check network status<br />

• Designed to be configurable through the front panel<br />

or In<strong>Power</strong>, a PC-based service tool (OTPC)<br />

Open Transition ATS<br />

Model # of Poles Size (Amperes)<br />

LT III 3 30-260 A<br />

Contractor pair, light duty transfer switch<br />

OTEC 3, 4* 40-1000 A<br />

Basic feature package, heavy duty switch<br />

OTPC 3, 4* 40-3000 A<br />

Fully featured, heavy duty switch<br />

OHPC 2, 3, 4 125-3000 A<br />

Premium featured, high withstand rated, heavy duty switch<br />

PLTO 3, 4 800-3000 A<br />

Open transition, breaker pair (MCCB) switch<br />

* OT switches in 40A, 70A and 125A sizes available in 3 pole only.<br />

Bypass Isolation Transfer Switches<br />

Our bypass isolation transfer switch combines an open transition transfer switch,<br />

a two-source manual bypass switch, a closed door drawout isolation mechanism,<br />

and microprocessor-based controls. The switch allows maintenance, service and<br />

testing of the ATS without disrupting power to critical loads. For environments<br />

with critical power requirements, such as healthcare and data center facilities, the<br />

bypass isolation switch will combine safe reliable service with simple operation.<br />

Major features include:<br />

• Non-load break bypass operation maintains<br />

service to critical loads when the ATS is drawn<br />

out of service<br />

• External manual operation capability for the ATS<br />

• Dead source interlocks prevent the operator<br />

from connecting loads to a failed utility or<br />

generator source<br />

• Full mechanical interlock system prevents<br />

accidental interconnection of the power sources<br />

Non-Automatic Transfer Switches<br />

Our non-automatic transfer switches are operated<br />

electrically through a front panel mounted control<br />

switch. They are available from 40 to 3,000 amps.<br />

Bypass Isolation ATS<br />

Model # of Poles Size (Amperes)<br />

BTPC 3, 4 150-3000 A<br />

Fully featured, bypass isolation, heavy duty switch<br />

Non-Automatic Transfer Switch<br />

Model # of Poles Size (Amperes)<br />

OT III 3, 4* 40-3000 A<br />

Non-Automatic, heavy duty switch<br />

* OT switches in 40A, 70A and 125A sizes available in 3 pole only.

THE POWER SUITE<br />

<strong>Power</strong>Command Network<br />

<strong>Power</strong>Command Network is an innovative,<br />

Windows ® -based, distributed system for<br />

operating and maintaining emergency standby<br />

or prime power systems. Regardless of the<br />

equipment manufacturer, this microprocessorbased<br />

network system allows: local or remote<br />

monitoring and control, real-time data<br />

collection, retention, and report generation<br />

on generator sets, transfer switches, paralleling<br />

controls, switchgear, and other related power<br />

generation and distribution equipment. We also<br />

have standard interfaces with all leading building<br />

management systems and automation packages<br />

that allow you to communicate effectively with<br />

your energy management operations.<br />

Minimum personal computer requirements:<br />

Hardware: 64 MB Ram and 70 MB free Hard Drive space<br />

Software: Microsoft Windows 95, 98, NT, or 2000<br />

Microsoft Internet Explorer 5.01, Microsoft Word<br />

and Adobe Acrobat Reader 4.0<br />

The <strong>Power</strong> Suite, on CD-ROM, is available from your local Cummins distributor.<br />

This tool contains easy-to-use generator set sizing software,<br />

product specification and data sheets, key drawings in<br />

both viewable image and CAD formats along with other<br />

application technical information. This comprehensive<br />

set of product information and software tools is designed<br />

to assist the user in selecting appropriate power generation<br />

products and identifying facility design and installation<br />

requirements. The <strong>Power</strong> Suite includes:<br />

GenSize<br />

A comprehensive, easy-to-use generator set sizing software that allows the user<br />

to quickly determine the optimum Cummins generator set required for power<br />

generation applications. Simply enter project requirements and electrical loads<br />

and GenSize calculates generator loading, required generator performance, and<br />

provides product recommendations.<br />

Library<br />

This is the electronic version of our <strong>Power</strong> <strong>Systems</strong> Manual containing all product<br />

specification and data sheets plus much more. The Library also contains outline<br />

and schematic drawings, even in CAD format. After using GenSize to determine<br />

which Cummins generator set best meets project requirements, the Library can<br />

be used to acquire documentation containing information needed for facility<br />

design. Also included are application manuals and technical papers on a variety<br />

of power generation topics.<br />

GenCalc<br />

Contains software tools to assist in generator set installation design including<br />

alternator decrement curves for short circuit studies and tools to aid in sizing fuel<br />

and exhaust system components.<br />

GenSpec<br />

Includes a series of product Sample Specifications in Word format that can be<br />

used as a source for power generation project specifications.<br />

1400 73rd Avenue N.E., Minneapolis, MN 55432 Phone: 763-574-5000 Fax: 763-574-5811<br />

Cummins <strong>Power</strong> <strong>Generation</strong> is a registered trademark of Cummins Inc. <strong>Power</strong>Command, AmpSentry<br />

and The <strong>Power</strong> of <strong>On</strong>e are trademarks of Cummins <strong>Power</strong> <strong>Generation</strong>. Cummins is a registered trademark<br />

of Cummins Inc. All other trademarks are owned by their respective companies.<br />

Backfeed to a utility system can cause electrocution and/or property damage. Do not connect to any<br />

building’s electrical system except through an approved device or after building main switch is opened.<br />

Specifications are subject to change without notice.<br />

Printed in the U.S.A.<br />

© 2005 Cummins <strong>Power</strong> <strong>Generation</strong> Bulletin F-1186 Rev 11/05<br />

www.cumminspower.com