You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

- Subject to modifications -<br />

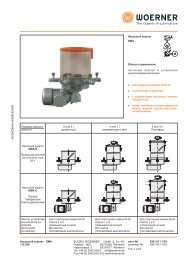

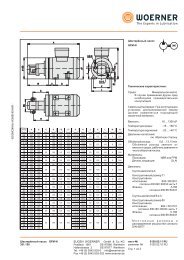

<strong>Delivery</strong> <strong>pump</strong> <strong>GMI</strong>-A<br />

105.200<br />

View X<br />

1-point<br />

2-point<br />

3-point<br />

4-point<br />

Coil and socket rotatable<br />

in steps of 90°<br />

Dimensions within brackets are applicable<br />

to a one-digit unit<br />

EUG<strong>EN</strong> WOERNER GmbH & Co. KG<br />

Postfach 1661 DE-97866 Wertheim<br />

Hafenstrasse 2 DE-97877 Wertheim<br />

Tel. +49 (0) 9342 803-0 info@woerner.de<br />

Fax.+49 (0) 9342 803-202 www.woerner.de<br />

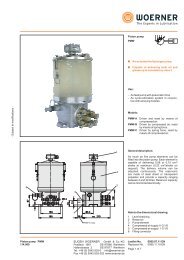

<strong>Delivery</strong> <strong>pump</strong> <strong>GMI</strong>-A<br />

�<br />

�<br />

�<br />

Up to four outlets<br />

Compact const<strong>ru</strong>ction<br />

Different driving power<br />

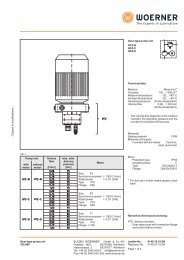

Technical data:<br />

<strong>Delivery</strong> volume<br />

per stroke and outlet: 30 mm³<br />

Number of strokes max.: approx. 100 min<br />

Viscosity-dependent! Please confer<br />

with us, if necessary<br />

Actuation time min.: approx. 0,1 s<br />

The actuation and off-times depend on<br />

the electric magnet, the number of<br />

digits, and the medium.<br />

Lubricant: Oil from 11 to 1900 cP<br />

Ambient temperature: -10 ... +50 °C<br />

Reservoir capacity: 0,7 l<br />

<strong>Delivery</strong> pressure:<br />

The maximum delivery pressure mainly<br />

depends on the variant of the electromagnet<br />

and the number of outlets.<br />

In case of units provided with several<br />

outlets, the counter pressures at the<br />

outlets should preferably be equal.<br />

The table below shows the maximum<br />

delivery pressures per outlet each:<br />

Number<br />

of outlets<br />

1<br />

2<br />

3<br />

4<br />

Version without reservoir:<br />

Suction connection: G1/4<br />

Mounting position: Suction connection<br />

above<br />

Nozzle tube length: min. 25 mm<br />

max. 1000 mm<br />

The ø4 nozzle tube can be bent<br />

manually.<br />

Material:<br />

Pump body: Aluminium<br />

Reservoir: Polyethylene, transparent<br />

Gaskets: Viton<br />

Weight:<br />

<strong>GMI</strong>-A/../0 1,15 kg<br />

<strong>GMI</strong>-A/../7 1,40 kg<br />

Level switch 0,10 kg<br />

Lubricant: The intended lubricant must be<br />

suitable for use with centralized lubrication<br />

equipment.<br />

Data sheet <strong>P0655</strong>.03.12 <strong>EN</strong><br />

Replaces <strong>P0655</strong>.04.11 <strong>EN</strong><br />

Page 1 of 5<br />

Electromagnet variant<br />

15% ED 100% ED<br />

60 bar 20 bar<br />

30 bar 10 bar<br />

20 bar 7 bar<br />

15 bar 5 bar<br />

-1

Level switch in the reservoir lid: Level switch in the reservoir bottom:<br />

Electrical connection diagrams<br />

Electric magnet Level switch<br />

Measures shown in<br />

brackets apply to a<br />

1-digit unit<br />

Alternating voltage Direct voltage NO contact NC contact<br />

EUG<strong>EN</strong> WOERNER GmbH & Co. KG<br />

Postfach 1661 DE-97866 Wertheim<br />

Hafenstrasse 2 DE-97877 Wertheim<br />

Tel. +49 (0) 9342 803-0 info@woerner.de<br />

Fax.+49 (0) 9342 803-202 www.woerner.de<br />

Version without reservoir:<br />

In the version without reservoir, a G1/4<br />

female thread connection piece is mounted.<br />

Electrical data:<br />

Level switch with minimal control:<br />

Switching capacity: 10 W<br />

30 VA<br />

Switching current max.: 0,5A<br />

Switching voltage max.: 230 VUC<br />

Protection type: IP65<br />

Plug connector: DIN 43650<br />

Electric magnet:<br />

Insulation class: F<br />

Voltage: 24 VDC or 230 VAC<br />

Special voltage available,<br />

upon request!<br />

Variante "A" "C"<br />

Nominal power: (W) 30 165<br />

Energized duty rating: (%) 100 15<br />

Current at 24 VDC: (A) 1,27 -<br />

Current at 230 VAC: (A) 0,15 0,59<br />

Protection type: IP65<br />

Plug connector: DIN 43650<br />

The electric magnet should always be<br />

operated by direct voltage. When connecting<br />

to an alternating voltage, direct voltage<br />

will be generated in the mains socket via the<br />

rectifier. Then the direct voltage at the<br />

electric magnet will be approximately 10%<br />

lower than the alternating voltage at the<br />

mains socket.<br />

Data sheet <strong>P0655</strong> <strong>EN</strong><br />

Page 2 of 5<br />

Electric magnet<br />

- Subject to modifications -

- Subject to modifications -<br />

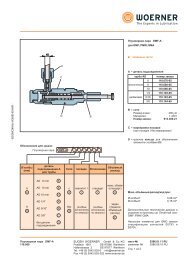

Function scheme:<br />

Suction phase<br />

Pressure phase<br />

Suction connection<br />

(reservoir)<br />

Check valve<br />

Order-designation:<br />

<strong>Delivery</strong> <strong>pump</strong> <strong>GMI</strong>-A<br />

for<br />

pipe-AD4<br />

1-point<br />

2-point<br />

3-point<br />

4-point<br />

Outlets<br />

Order-example:<br />

Connection<br />

thread G1/8<br />

1-point<br />

1R<br />

2-point<br />

2R<br />

<strong>Delivery</strong> <strong>pump</strong> <strong>GMI</strong>-A, two-point, reservoir<br />

0,7 l, pipe length 100 mm, level switch<br />

(NCC) in the reservoir lid, without function<br />

control, 100% ED, 24 VDC.<br />

Reservoir Pipe<br />

length<br />

(l) (mm)<br />

0,7<br />

without<br />

Order-designation:<br />

<strong>Delivery</strong> <strong>pump</strong><br />

<strong>GMI</strong>-A/ 2 / 7 / 100 / 8 / 0 /A/ G1<br />

Level switch Function<br />

control<br />

in the<br />

reservoir lid:<br />

NO contact<br />

NC contact<br />

in the<br />

reservoir bottom:<br />

NO contact<br />

NC contact<br />

without without<br />

EUG<strong>EN</strong> WOERNER GmbH & Co. KG<br />

Postfach 1661 DE-97866 Wertheim<br />

Hafenstrasse 2 DE-97877 Wertheim<br />

Tel. +49 (0) 9342 803-0 info@woerner.de<br />

Fax.+49 (0) 9342 803-202 www.woerner.de<br />

without<br />

Operation:<br />

The delivery <strong>pump</strong> consits of a piston <strong>pump</strong>,<br />

an electric magnet and an oil reservoir.<br />

Suction phase:<br />

The pistons are reset by spring force<br />

with the lubricant being sucked in from<br />

the reservoir by virtue of the vacuum<br />

generated.<br />

Compression phase:<br />

Upon electric magnet actuation, the pistons<br />

start to deliver to lubricant through the<br />

nozzles to the lubricating points.<br />

De-aerating:<br />

In order to ensure a steady delivery, the<br />

delivery <strong>pump</strong> and the nozzle tubes need to<br />

be vented. To do this, the electric magnet is<br />

repeatedly operated until the lubricant in the<br />

nozzle appears free of air.<br />

This operation can be shortened by<br />

ascending the nozzle tubes towards the<br />

outlet.<br />

Assembly note:<br />

The piston space is connected with the<br />

reservoir. Therefore the reservoir needs to<br />

be emptied prior to the electric magnet's<br />

disassembly.<br />

1)<br />

2)<br />

Magnets are available with special<br />

voltage upon request<br />

without electric magnet (spare part)<br />

Data sheet <strong>P0655</strong> <strong>EN</strong><br />

Page 3 of 5<br />

Electric magnet Connecting<br />

Energized voltage<br />

duty rating<br />

ED (%)<br />

24 VDC<br />

230 VAC<br />

Special magnet 1)<br />

* *<br />

without electric magnet 2)

EUG<strong>EN</strong> WOERNER GmbH & Co. KG<br />

Postfach 1661 DE-97866 Wertheim<br />

Hafenstrasse 2 DE-97877 Wertheim<br />

Tel. +49 (0) 9342 803-0 info@woerner.de<br />

Fax.+49 (0) 9342 803-202 www.woerner.de<br />

Spare parts:<br />

Pos. Designation Order-no.<br />

Version for pipe-AD4:<br />

1 Pump body, including<br />

Pos. 1.1, 1.2<br />

1 - point "1": <strong>GMI</strong>-A/ 1 / * / 0 / 0 / 0 / 0 / 0<br />

2 - point "2": <strong>GMI</strong>-A/ 2 / * / 0 / 0 / 0 / 0 / 0<br />

3 - point "3": <strong>GMI</strong>-A/ 3 / * / 0 / 0 / 0 / 0 / 0<br />

4 - point "4": <strong>GMI</strong>-A/ 4 / * / 0 / 0 / 0 / 0 / 0<br />

1.1Union screw<br />

(1x per outlet) 803.871-01<br />

1.2Double-cone ring<br />

(1x per outlet) 953.300-01<br />

2 Nozzle tube 100 mm 330.278-65<br />

Nozzle tube 500 mm 330.312-65<br />

Nozzle tube 1000 mm 330.286-65<br />

Version with thread connection G1/8:<br />

1 Pump body<br />

1 - point "1R":<br />

<strong>GMI</strong>-A/ 1R / * / 0 / 0 / 0 / 0 / 0<br />

2 - point "2R":<br />

<strong>GMI</strong>-A/ 2R / * / 0 / 0 / 0 / 0 / 0<br />

Version without reservoir:<br />

3 Base plate G1/4 330.370-65<br />

Version without level switch:<br />

4 Reservoir 0,7 l without lid 330.360-65<br />

Lid 165.327-65<br />

Version level switch in the reservoir lid:<br />

4 Reservoir 0,7 l without lid 330.360-65<br />

5 Level switch with reservoir lid<br />

6 (NO contact) 165.328-65<br />

8 (NC contact) 165.329-65<br />

Version level switch in the<br />

reservoir bottom:<br />

6 Reservoir 0,7 l with lid 330.377-65<br />

7 Level switch<br />

6A ( NO contact)<br />

477.053-65<br />

8A ( NC contact)<br />

468.213-65<br />

Electric magnet:<br />

8 Electric magnet A/G1<br />

24 VDC 100% ED<br />

Electric magnet A/W1<br />

330.392-65<br />

230 VAC 100% ED<br />

Electric magnet C/W1<br />

330.394-65<br />

230 VAC 15% ED 330.396-65<br />

without picture:<br />

Gasket set 105.206-64<br />

Assembly note:<br />

Before dismantling the electro magnet,<br />

the reservoir must be emptied.<br />

Data sheet <strong>P0655</strong> <strong>EN</strong><br />

Page 4 of 5<br />

- Subject to modifications -

- Subject to modifications -<br />

Important information about this data sheet<br />

Reproduction, also in extracts, only permitted with the approval of the firm of EUG<strong>EN</strong><br />

WOERNER GmbH & Co. KG.<br />

All the information in this data sheet has been examined for correctness with great care.<br />

Nevertheless, WOERNER cannot assume any liability for losses or damage resulting<br />

directly or indirectly from the application of the information contained in this data sheet.<br />

All products from WOERNER may only be used as intended and corresponding to the<br />

information in this data sheet.<br />

For products supplied with operating inst<strong>ru</strong>ctions, the additional directives and information<br />

contained in them are to be complied with.<br />

Materials deviating from those mentioned in this data sheet and the technical documents<br />

which further apply may only be poured into and processed in the appliances and systems<br />

manufactured and supplied by WOERNER by following agreement with and written<br />

approval by WOERNER.<br />

The safety and danger information stated in the safety data sheets of the substances used<br />

must be taken into account at all costs.<br />

Transportation of gases, liquefied gases, gases under pressure, vapours and liquids, the<br />

vapour pressure of which is more than 0,5 bar above normal atmospheric pressure<br />

(1013 mbar) at the maximum admissible temperature, of easy inflammable or explosive<br />

media as well as transportation of foodstuffs is forbidden.<br />

Information on EU Directive 2002/95/EC (RoHS)<br />

With Directive 2002/95/EC of January 27, 2003, for the limitation of the use of certain<br />

hazardous substances in electrical and electronic devices (RoHS) material bans come into<br />

effect from July 2006 for electrical and electronic devices newly placed on the market for<br />

lead, cadmium, hexavalent chromium, mercury and brominated flame retardants.<br />

In its controls and switching devices, WOERNER only uses materials which fulfil the criteria<br />

of EU Directive 2002/95/EC.<br />

To the extent that hexavalent chromium has been used as corrosion protection in the parts<br />

which we produce ourselves, it has already been replaced by other environmentally<br />

tolerable protective measures.<br />

The mechanical devices supplied by WOERNER are not affected by EU Directive<br />

2002/95/EC.<br />

But as WOERNER is conscious of its responsibility towards the environment, we shall also<br />

use materials fulfilling the requirements of the Directive for devices not covered by EU<br />

Directive 2002/95/EC as soon as they are generally available and their use is technically<br />

possible.<br />

EUG<strong>EN</strong> WOERNER GmbH & Co. KG<br />

Postfach 1661 DE-97866 Wertheim<br />

Hafenstrasse 2 DE-97877 Wertheim<br />

Tel. +49 (0) 9342 803-0 info@woerner.de<br />

Fax.+49 (0) 9342 803-202 www.woerner.de<br />

Data sheet <strong>P0655</strong> <strong>EN</strong><br />

Page 5 of 5