Understanding CDM Methodologies - SuSanA

Understanding CDM Methodologies - SuSanA

Understanding CDM Methodologies - SuSanA

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

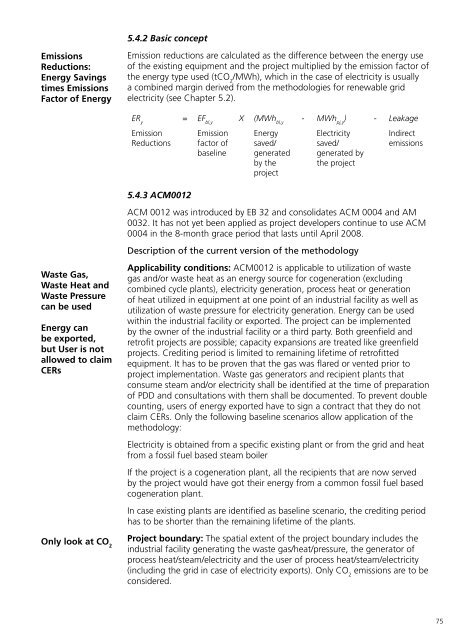

5.4.2 Basic concept<br />

Emissions<br />

Reductions:<br />

Energy Savings<br />

times Emissions<br />

Factor of Energy<br />

Emission reductions are calculated as the difference between the energy use<br />

of the existing equipment and the project multiplied by the emission factor of<br />

the energy type used (tCO 2<br />

/MWh), which in the case of electricity is usually<br />

a combined margin derived from the methodologies for renewable grid<br />

electricity (see Chapter 5.2).<br />

ER y<br />

= EF bl,y<br />

X (MWh bl,y<br />

- MWh pj,y<br />

) - Leakage<br />

Emission<br />

Reductions<br />

5.4.3 ACM0012<br />

Emission<br />

factor of<br />

baseline<br />

Energy<br />

saved/<br />

generated<br />

by the<br />

project<br />

Electricity<br />

saved/<br />

generated by<br />

the project<br />

Indirect<br />

emissions<br />

ACM 0012 was introduced by EB 32 and consolidates ACM 0004 and AM<br />

0032. It has not yet been applied as project developers continue to use ACM<br />

0004 in the 8-month grace period that lasts until April 2008.<br />

Description of the current version of the methodology<br />

Waste Gas,<br />

Waste Heat and<br />

Waste Pressure<br />

can be used<br />

Energy can<br />

be exported,<br />

but User is not<br />

allowed to claim<br />

CERs<br />

Only look at CO 2<br />

Applicability conditions: ACM0012 is applicable to utilization of waste<br />

gas and/or waste heat as an energy source for cogeneration (excluding<br />

combined cycle plants), electricity generation, process heat or generation<br />

of heat utilized in equipment at one point of an industrial facility as well as<br />

utilization of waste pressure for electricity generation. Energy can be used<br />

within the industrial facility or exported. The project can be implemented<br />

by the owner of the industrial facility or a third party. Both greenfield and<br />

retrofit projects are possible; capacity expansions are treated like greenfield<br />

projects. Crediting period is limited to remaining lifetime of retrofitted<br />

equipment. It has to be proven that the gas was flared or vented prior to<br />

project implementation. Waste gas generators and recipient plants that<br />

consume steam and/or electricity shall be identified at the time of preparation<br />

of PDD and consultations with them shall be documented. To prevent double<br />

counting, users of energy exported have to sign a contract that they do not<br />

claim CERs. Only the following baseline scenarios allow application of the<br />

methodology:<br />

Electricity is obtained from a specific existing plant or from the grid and heat<br />

from a fossil fuel based steam boiler<br />

If the project is a cogeneration plant, all the recipients that are now served<br />

by the project would have got their energy from a common fossil fuel based<br />

cogeneration plant.<br />

In case existing plants are identified as baseline scenario, the crediting period<br />

has to be shorter than the remaining lifetime of the plants.<br />

Project boundary: The spatial extent of the project boundary includes the<br />

industrial facility generating the waste gas/heat/pressure, the generator of<br />

process heat/steam/electricity and the user of process heat/steam/electricity<br />

(including the grid in case of electricity exports). Only CO 2<br />

emissions are to be<br />

considered.<br />

75