Vaderstad Rapid A Drill Brochure - LiveUpdater

Vaderstad Rapid A Drill Brochure - LiveUpdater

Vaderstad Rapid A Drill Brochure - LiveUpdater

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

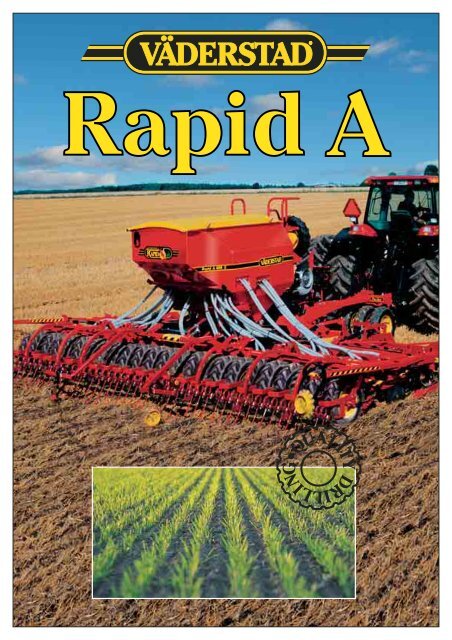

QUALITY DRILLING•

In partnership with<br />

European agriculture<br />

Väderstad is a family owned Swedish manufacturing company started<br />

in 1962 by Rune and Siw Stark to produce equipment for local farmers.<br />

From these humble beginnings the company has grown to occupy a<br />

26,000 m 2 state-of-the-art factory employing more than 370 dedicated<br />

and highly skilled staff.<br />

Working in partnership with the farmer, our aim is to ensure that the<br />

machine performs in accordance with expectations, and as a company<br />

our objective is to strive for excellence, and to enhance the European<br />

farming community’s competitiveness globally.<br />

For example, our objective with the <strong>Rapid</strong> drills is to build versatile<br />

and precise drilling tools that have an unsurpassed level of performance<br />

in all working conditions, such as direct drilling, working in<br />

trash or on light and heavy ploughed land.<br />

The <strong>Rapid</strong> drill has won several awards and the most important being<br />

that there are more than 10000 satisfied customers who underwrite<br />

the performance and high engineering quality of the drill.<br />

Väderstad <strong>Rapid</strong> was in 2004 awarded by the<br />

RASE (Royal Agricultural Society of England)<br />

with a gold medal, motivated by the contribution<br />

the machine has made to the agriculture<br />

in United Kingdom.

Equip your <strong>Rapid</strong> - ad<br />

System Agrilla<br />

Two rows of Agrilla tines in front<br />

of the single Crossboard.<br />

• hydraulically operated<br />

from the cab<br />

• individually adjustable axles<br />

through a linkage system<br />

• the aggressive tines lift and aerate<br />

the soil, presenting a loose tilth<br />

for the Crossboard to level out

apted to your needs<br />

System Disc<br />

Two rows of curved serrated<br />

rubber sprung discs in front of<br />

the single Crossboard<br />

• hydraulically adjustable on the<br />

move<br />

• individually adjustable axles<br />

through a linkage system<br />

• disc diameter 410 mm<br />

• this truly versatile tool provides<br />

the possibility to direct drill,<br />

drill into trash or drill into<br />

ploughed ground

Simple and functional.<br />

<strong>Rapid</strong> A is now available with<br />

hydraulic drive of the Fenix<br />

seed feed units. This feature<br />

allows easy adjustment of seed<br />

rate on the go and makes calibration<br />

very simple.<br />

GPS<br />

See over<br />

Easy adjustment with hy<br />

❹ Control-Station. When the seed<br />

rate has to be adjusted during work,<br />

for example higher on heavy clay<br />

areas and lower on light soils, this is<br />

easily achieved. Enter the desired<br />

percentage change into the Control-<br />

Station before beginning to drill.<br />

Pressing plus or minus on the extra<br />

module on the Control- Station then<br />

instantly changes the seed rate on<br />

the move.<br />

❹

aulic drive and radar<br />

❶ Remote control. The seed rate can be easily calibrated<br />

without the driver having to climb in and out of the<br />

tractor. A cleverly sited remote control beside the fan<br />

allows you to fill the Fenix seed feed housing (+ button)<br />

before you fill the calibration<br />

bags to the<br />

required level by pressing<br />

the seed button.<br />

Weigh the sample and key<br />

the value into the<br />

Control-Station in the<br />

driver’s cab. This<br />

enters the required<br />

seed rate onto the system<br />

and drilling can<br />

begin.<br />

❶<br />

❸<br />

❷<br />

❷ Soil radar. During work, a<br />

soil radar unit measures the<br />

speed of the <strong>Rapid</strong> seed drill<br />

and sends information to the<br />

Control-Station that directs the<br />

hydraulic motor.<br />

❸ Hydraulic motor. Both seed feed units<br />

are powered by a hydraulic motor which<br />

changes its speed according to the information<br />

it receives from the soil radar. In<br />

this way, the exact seed rate is measured<br />

in relation to the working speed.

Contact with space. GPS-technology<br />

was originally designed for military<br />

use but has since been developed<br />

for use in civilian life. An<br />

example of this is the GPS option<br />

now available on <strong>Rapid</strong> A Seed and<br />

<strong>Rapid</strong> A Combi with hydraulic drive.<br />

With the help of satellites in<br />

space that move in a circuit<br />

around the Earth, the position of<br />

the tractor and <strong>Rapid</strong> seed drill<br />

can be identified precisely on<br />

every area of the field. This provides<br />

a great opportunity for the<br />

farmer. If soil type varies greatly<br />

from one part of the field to the<br />

next, the seed or fertilizer rate can<br />

be adjusted automatically according<br />

to how conditions appear in<br />

every patch. You can increase the<br />

seed rate on hard clay areas where<br />

germination conditions are poorer,<br />

while you can save seed and costs<br />

on light, humus-rich and easy<br />

areas. A shining example of technological<br />

advance that improves the<br />

economic situation by adjusting to<br />

the biological conditions.

Simple adjustment. The working depth of System Disc can<br />

now be adjusted hydraulically from the driver’s cab. In this<br />

way, the <strong>Rapid</strong> can easily be set to work a little harder on<br />

headlands or other areas where deeper tillage is required.<br />

3 m<br />

Narrow in transport. RDAS is equipped with mechanical wheel<br />

retraction. By releasing the locks on each wing section, the<br />

wheels can be retracted to 3 metres transport width.

<strong>Rapid</strong> A 400S/450S<br />

The <strong>Rapid</strong> A 400S ist the most<br />

popular A model machine.<br />

The <strong>Rapid</strong> A 400S and 450S<br />

consist of three sections. The<br />

front tools on the wing sections<br />

are operated by the middle<br />

section´s hydraulic ram<br />

whilst the depth setting on the<br />

wings are set with levers. The<br />

<strong>Rapid</strong> A 400S and 450S drills<br />

are hydraulically foldable for 3<br />

metre transport width.<br />

<strong>Rapid</strong> A 600S<br />

This is the versatile workhorse<br />

amongst the <strong>Rapid</strong> A drills.<br />

The <strong>Rapid</strong> A 600S is a three<br />

sectioned machine with the<br />

tools and the depth setting on<br />

the wings fully hydraulically<br />

governed by Väderstad’s<br />

Master and Slave System. The<br />

depth setting is achieved centrally<br />

in one place by adjusting<br />

the depth control setting on<br />

the master ram, which only<br />

takes seconds.<br />

The power requirement for<br />

<strong>Rapid</strong> drills is about 30 - 40 Hp<br />

per metre working width depending<br />

on front tools on the drill,<br />

working speed, soil type, degree<br />

of hills and tillage system.

<strong>Rapid</strong> A 800S<br />

This is the versatile<br />

big acreage tool.<br />

The <strong>Rapid</strong> A 800S drills up to 8<br />

hectares per hour depending<br />

on drilling speed and the quality<br />

of the seed support system<br />

from your farm. Like all <strong>Rapid</strong><br />

drills from 4 metres up to 8<br />

metres <strong>Rapid</strong> easily folds<br />

through the hydraulic folding<br />

system to 3 metres in transport.<br />

The folding system also<br />

works as an equalising system<br />

in the working position. An<br />

adjustable gas accumulator<br />

system on the <strong>Rapid</strong> A 600S<br />

and 800S provides the wings<br />

with a very good land contour<br />

following ability and ensures<br />

that all three sections have the<br />

same weight on the ground.<br />

The 800S is also available with<br />

system disc front tools.

Pre-emergence-marker<br />

Automatically controlled by the<br />

tramlining system. Making it easier<br />

to keep track of the tramlines and<br />

also facilitates pre-emergence<br />

applications.<br />

Individually depthcontrolled,<br />

disc/coulter<br />

pairs<br />

The <strong>Rapid</strong>-principle means that one<br />

press wheel controls the depth of<br />

one pair of discs through a parallel<br />

linkage. This is how the machine<br />

drills to a very precise depth.<br />

Each disc is sprung individually on<br />

a rubber suspension. The suspension<br />

is a soft practically everlasting<br />

device that protects the disc, bearing,<br />

coulter and machine from too<br />

much strain. The rubber suspension<br />

is also a key feature in the<br />

depth control system.<br />

The linkage system, giving unique<br />

depth control, and the disc and<br />

coulter which works in symbiosis,<br />

produces an excellent drilling<br />

result and thus establishment, an<br />

ability that has sold thousands of<br />

<strong>Rapid</strong> drills.<br />

Following harrow<br />

The following harrow can be<br />

adjusted by altering working angle<br />

and downward pressure. The tines<br />

work in between the seedrows.<br />

With the low-lift function engaged,<br />

the harrow stays in work while<br />

turning on the headlands. The following<br />

harrow has a ”trip-system”<br />

that protects the tool from being<br />

damaged when reversing.

Wheel press<br />

Integrated wheel press 400 - 800S<br />

The wheel press in combination<br />

with duals or wide tyres offers a<br />

possibility to press and consolidate<br />

the ground in front of the drill.<br />

Wheel press Pivot 400/450/600S<br />

The pivoting wheels ensure a good<br />

turning character of the wheel<br />

press on the headlands.<br />

Wing packers<br />

With the introduction of the <strong>Rapid</strong><br />

to the cereal fields of Europe, the<br />

concept of “full width packing” was<br />

created. The new wing packers<br />

allow a light but thorough soil firming<br />

across the entire width of the<br />

machine. For drilling on light soils<br />

directly after ploughing, this system<br />

is outstanding.<br />

Simple adjustment<br />

The working depth of System Disc<br />

can now be adjusted hydraulically<br />

from the driver’s cab. In this way,<br />

the <strong>Rapid</strong> can easily be set to work<br />

a little harder on headlands or<br />

other areas where deeper tillage<br />

is required.

QUALITY DRILLING•<br />

Hydraulic depth control<br />

Väderstad´s Master and Slave system<br />

is unbeatable in its simplicity<br />

and operation. The hydraulic cylinders<br />

move in synchronisation with<br />

millimetre precision. <strong>Drill</strong>ing depth<br />

is preset with an adjustable stop<br />

on the master cylinder which simply<br />

shuts off the oil flow when the<br />

required depth setting is reached.<br />

The hydraulic system is synchronized<br />

and bled automatically each<br />

time the drill is fully raised. The<br />

same type of hydraulic system<br />

operates the hydraulic Crossboard.<br />

Narrow transport width<br />

Fast and safe transport is important<br />

in order to achieve high capacity<br />

and good operational logistics<br />

through the drilling season. The<br />

<strong>Rapid</strong> A drills fold hydraulically to<br />

3 metres transport width and an<br />

automatic locking device ensures<br />

that maximum safety is maintained.<br />

By equipping the tractor with wide<br />

low pressure tyres low ground<br />

compaction, maximum traction<br />

and low transport width (maximum<br />

3 metres) can be combined.<br />

Several large <strong>Rapid</strong> A drills are<br />

pulled by CAT Challengers, a combination<br />

that combines very low<br />

ground pressure, outstanding traction<br />

and low transport width beautifully.<br />

3m

Hydraulically driven fan<br />

When the tractor has an efficient<br />

hydraulic system we always recommend<br />

the hydraulically driven fan.<br />

It has much lower maintenance<br />

and is safer than a PTO driven fan.<br />

The system has an oil capacity<br />

requirement of about 25 litres per<br />

minute. To ensure oil cooling and<br />

safe function of other hydraulic<br />

systems on the drill the tractor<br />

should have at least 60 litres per<br />

minute oil capacity. A greater oil<br />

flow will be needed if hydraulic<br />

seed drive is specified.<br />

Prepared for auger<br />

To enable easy handling of small<br />

bags, most <strong>Rapid</strong> A drills can be<br />

equipped with an auger. The auger<br />

is delivered as a kit and can easily<br />

be retrofitted on most <strong>Rapid</strong> drills.<br />

The auger is hydraulically driven<br />

and is powered by the hydraulic<br />

fan circuit. In transport the auger is<br />

folded away. All drills have a rear<br />

inspection window to view the<br />

seed level when filling.<br />

∅ 410 mm<br />

A large high quality disc<br />

The seed discs and the System<br />

Disc toolbar have large discs manufactured<br />

from special hardened<br />

steel (V-55), which force their way<br />

aggressively into the soil. The V-55<br />

disc has been shown to have a lifetime<br />

up to 50% longer than that of<br />

the former type. Maintenance is<br />

thus minimised. The large disc<br />

diameter also makes for low maintenance,<br />

which is further improved<br />

by the protective coating of wolfram<br />

carbide on the seed coulters.<br />

This coating keeps the coulter<br />

sharp and pointed, so drilling precision<br />

can be maintained even after<br />

many hectares of work. One of the<br />

great advantages of the <strong>Rapid</strong> is its<br />

potential to combine powerful soil<br />

tillage under practically all kinds of<br />

conditions with precision drilling.

Soil preparation and drilling<br />

with the <strong>Rapid</strong> System<br />

<strong>Rapid</strong> allows all possibilities!<br />

Excellent soil preparation<br />

Equip you <strong>Rapid</strong> A drill according to your cropping<br />

and soil conditions. The <strong>Rapid</strong> is a combination tool<br />

which performs two operations in one pass, very precisely<br />

and at high speed. 13 - 14 km/h is not unusual.<br />

Soil preparation is mainly carried out by the front<br />

tools; either discs, spring tines or double Crossboard.<br />

The cultivation ability of the machine is so powerful<br />

that drilling is often performed directly into ploughed<br />

land. The seed placement is carried out by hardened<br />

disc coulters. The disc cuts the slot and mills a layer<br />

of fine soil on which the seed is placed. The individual<br />

rear press wheels firm the seedbed, but also<br />

maintain an accurate drilling depth of a pair of disc<br />

coulters irrespective of forward speed. The depth is<br />

simply set by one handle on the main lift ram. The<br />

pneumatic seed transport system ensures perfect<br />

seed placement in all conditions.

CASE S<br />

Minimum<br />

Farm Background<br />

This Estate covers about 1,600 hectares, with approximately<br />

1,390 hectares down to arable crops and the<br />

remainder is grassland and maize, which supports<br />

two dairy herds and young stocks.<br />

The soils are a chalky loam over chalk, with clay caps<br />

in places.<br />

Cropping<br />

Winter Wheat<br />

Winter Barley<br />

Spring Barley<br />

Oilseed Rape<br />

Industrial Rape<br />

Set Aside<br />

Spring Peas<br />

Spring Beans<br />

Maize<br />

Permanent Grass and Grass Leys<br />

Total<br />

670 ha<br />

95 ha<br />

95 ha<br />

117 ha<br />

64 ha<br />

75 ha<br />

145 ha<br />

125 ha<br />

95 ha<br />

125 ha<br />

1606 ha<br />

The farm has moved from ploughing virtually everything<br />

to more minimal non plough cultivations over<br />

this last autumn.<br />

Labour<br />

The full time labour has been reduced from 8 to 5<br />

arable staff including a foreman plus a manager.<br />

3 casuals have been employed over the<br />

harvest/autumn period.<br />

Machinery<br />

Tractors<br />

The tractors and combine harvester are hired on long<br />

term agreements.<br />

Tractor 1 - 270 hp 875 hrs since 1st June<br />

Tractor 2 - 170 hp 873 hrs since 1st June<br />

Tractor 3 - 135 hp<br />

In addition, 3 x 110 hp tractors were hired for 12<br />

weeks this autumn. The dairy staff have their own<br />

tractors.<br />

Cultivation Machinery (Autumn 2000)<br />

5 furrow plough with trailed press<br />

6 m Väderstad <strong>Rapid</strong> System Disc drill<br />

6.5 m Väderstad Carrier Disc<br />

6.0 m rolls<br />

4 m power harrow<br />

Terradiscs and Flatlift<br />

There are also 2 self-propelled sprayers and a forklift<br />

with a pickup trailer hitch.<br />

Cultivation policies<br />

Original System (Fig. 7.5.1.)<br />

This is the first autumn moving almost wholly away<br />

from the plough. The previous system centred around<br />

two 5 furrow ploughs with fixed 14” furrows, each<br />

with presses and two 4 m power harrow drills. Much<br />

of the land was ploughed and drilled on the same day,<br />

so the soil did not have a chance to weather.<br />

The land was also regularly “lifted” (e.g. once in 3<br />

years) either by a Terradisc, which tends to leave the<br />

surface rather flatter, or a Flat-lift. Sometimes just the<br />

tramlines and headlands were broken up prior to<br />

ploughing.<br />

Fig. 7.5.1. Orginal System<br />

Operation Cost per ha. Work Rate Labour<br />

(£) (ha./hr.) (mins./ha.)<br />

Plough & Press 32 1.2 50<br />

4 m Power Harrow <strong>Drill</strong> 30 1.6 37.5<br />

Rolls 10 4.0 15<br />

Totals £ 72 102.5 mins

TUDY<br />

Tillage<br />

Revised Cultivations (Fig 7.5.2.)<br />

Over some 75% of the cereal acreage the straw has<br />

been baled for the dairy herds and some has also<br />

been sold via a straw merchant. This is the first year<br />

using a Väderstad Carrier followed by a Väderstad<br />

6 m System Disc <strong>Rapid</strong> <strong>Drill</strong>. Either one or two cultivation<br />

passes have been used with a spray in between,<br />

followed by a roll which is considered to be important<br />

to conserve moisture in a dry time and to anchor the<br />

straw residue.<br />

The overall establishment time is significantly faster<br />

and costs can be lower.<br />

The figures in brackets are the operations that may<br />

be omitted. The high work rates and good utilisation<br />

make the individual costs per hectare extremely competitive.<br />

It is not as essential to roll after the drill<br />

because of the flat profile tyres at the back but the<br />

farm would normally expect to do so.<br />

Fig. 7.5.2. Revised System<br />

Operation Cost per ha. Work Rate Labour<br />

(£) (ha./hr.) (mins./ha.)<br />

6.5m Carrier 13 5 12<br />

Spray 11 12 5<br />

(6.5m Carrier) (13) (5) (12)<br />

(6m Roll) (10) (4) (15)<br />

6m Väderstad <strong>Drill</strong> 16 4 15<br />

(Rolled) (10) (4) (15)<br />

Totals £ 40 - £ 50 - £ 63 - £ 73 32 - 47 - 59 - 74 mins<br />

Times and Costs<br />

Bearing in mind the different permutations and<br />

that a greater area would receive a final roll in a<br />

more normal year the typical time saving is about<br />

30% i.e. at least 30 minutes per hectare would be<br />

saved over approximately 960 ha in the autumn.<br />

Multiplied up this comes to approximately 480<br />

hours equivalent to 8 x 60 hour weeks at this critical<br />

time of year for a driver and tractor with further<br />

savings expected in the spring.<br />

The average establishment costs this year have<br />

been very variable ranging from a small increase<br />

of £2 per hectare to a saving of £45 per hectare for<br />

the direct drilled crops. In a better autumn more<br />

direct drilling is likely to be done and with more<br />

experience a higher proportion of crops established<br />

with one pass of the cultivator. This is however<br />

not the whole story as there have been substantial<br />

overall “annual” tractor and labour savings<br />

of the order of £70,000 which these methods have<br />

primarily made possible.<br />

On this farm there is a quiet air of confidence and<br />

expectation with attention to detail clearly to the<br />

fore. It is difficult to visualise the revised system<br />

not being a long term success, maintaining or even<br />

improving the overall yields on this soil type.

Complete your soil<br />

preparation programme<br />

Bio<strong>Drill</strong><br />

Using Bio<strong>Drill</strong> on a <strong>Rapid</strong> allows poppy, catch crops<br />

and other small-seeded crops to be co-drilled with the<br />

main crop in a single operation. This saves passes,<br />

time and money. Seed is metered out by the tried and<br />

tested Fenix system with great precision.<br />

The seed nozzles are situated behind the coulter units<br />

and in front of the packer wheels and produce uniform<br />

broadcasting. The seeds are covered over by the<br />

action of the wheels and the following harrow.<br />

Carrier<br />

The Carrier is the versatile tool for cultivation before<br />

drilling. Carrier 4,25 up to 8,20 metre can be<br />

equipped with three different front tools - System<br />

Disc, System Crossboard or System Agrilla/Crossboard.<br />

Carrier 3, 4, 10,25 and 12,25 metre can be<br />

equipped with System Disc front tool. The Carrier<br />

can do a lot of operations on the farm, such as shallow<br />

stubble cultivation, levelling/pressing after<br />

ploughing or discing or just conventional rolling.<br />

The Carrier does an impressive shallow cultivation<br />

at 2 - 10 cm depth and leaves a uniform, well levelled<br />

and consolidated surface. The Carrier/<strong>Rapid</strong> System<br />

Disc is the future concept for versatility.

<strong>Rapid</strong> A 400S - 800S row space 12,5 cm pneumatic seeding system Fenix<br />

Model Transport Weight Hopper Weight with Wheel Spool Remarks<br />

Working width width coulter capacity System Disc dim. valves*<br />

cm m kg litres kg<br />

RDA 400S 3,0 115 2500 4500 740×170-15”<br />

RDA 450S 3,0 110 2500 5050 740×170-15”<br />

RDA 600S 3,0 96 3000 6000 740×170-15”<br />

RDA 800S 3,0 94 3000 8800 740×170-15”<br />

*Free return is required for the hydraulic fan.<br />

Tramlining: (RDAS is delivered with 175 cc tramlining with 2 row shut off as standard)<br />

RDA-400S 2 to 10 multiple widths, centre pair tramlining<br />

RDA-450S 18, 27 m, half a tramline per pass on one side<br />

RDA-600S 2 to 10 multiple widths, centre tramlining<br />

RDA-800S 2 to 10 multiple widths, centre tramlining<br />

2 row shut off 1 row shut off<br />

Centre line 150, 175, 200, 225 and 250 cm Centre line 138, 163, 188, 213 and 238 cm<br />

° °° °<br />

° °° °<br />

° °° °<br />

° °° °<br />

Main office<br />

Subsidiaries<br />

Importer<br />

VÄDERSTAD LTD<br />

VÄDERSTAD OÜ<br />

VÄDERSTAD<br />

VÄDERSTAD SIA<br />

VÄDERSTAD UAB<br />

VÄDERSTAD SARL<br />

VÄDERSTAD GmbH<br />

VÄDERSTAD Sp.z o.o<br />

VÄDERSTAD Kft<br />

VÄDERSTAD Ltd.<br />

Unit One, Ellesmere Business Park<br />

Grantham, Lincolnshire NG31 7XT<br />

Tel. 01476 581 900 • Fax 01476 581 901<br />

www.vaderstad.com<br />

Distributor:<br />

The company retains the right to make changes to specifications and design. Patents awarded and pending.<br />

990000-ENGB Mjölby Tryckeri AB/Desktopteknik AB 2004.09