Arc & Gas Welding & Cutting Equipment - Murex

Arc & Gas Welding & Cutting Equipment - Murex

Arc & Gas Welding & Cutting Equipment - Murex

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Arc</strong> & <strong>Gas</strong> <strong>Welding</strong> &<br />

<strong>Cutting</strong> <strong>Equipment</strong>

R<br />

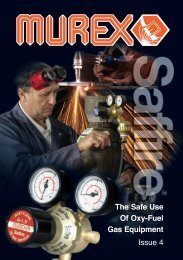

OVER 50 YEARS OF SAFFIRE – THE SAFE REVOLUTION<br />

<strong>Murex</strong> <strong>Welding</strong> Products Saffire brand celebrated its 50th anniversary<br />

in 2006. Since the introduction of the first Saffire nozzle mix gas welding<br />

and cutting system, the brand has become synonymous with absolute<br />

safety in all aspects of oxy-fuel welding and cutting.<br />

1956 was the debut year of the Saffire nozzle mix gas welding and cutting<br />

system, which fundamentally rewrote the principles and working methods of<br />

gas mixing along the lines of safety.<br />

The idea of using a nozzle mixing, high-pressure system was quite well<br />

known at the time, but although its safety advantages were recognised,<br />

Saffire was the first to put it into practice.<br />

Consequently, Saffire was enormously successful from day one. A market<br />

leader from the start, Saffire has grown and changed with improvements<br />

since then, but the principle – Safety First – has always been the motivating<br />

force behind all developments.<br />

One of the immediate effects Saffire had was the simplifying of the oxy/fuel<br />

welding and cutting procedure, and by making the equipment virtually<br />

maintenance free, we had also ensured that mixing and handling two of the<br />

most reactive gases known was no longer a high-risk operation.<br />

In 1966 the new innovative blowpipe, Saffire 3, won a Design Centre Award.<br />

The original Saffire nozzle mix gas welding and cutting blowpipe has today<br />

evolved in the Saffire 5. In 2005 is was estimated that there could have been<br />

as many as half a million in use throughout the world. Versatility in use and<br />

on-going product developments have been instrumental to the success of<br />

the Saffire brand. Its application area is immense throughout all sectors of<br />

industry and it can be used for heating with acetylene and propane, flame<br />

cleaning, rivet cutting, circle cutting, gouging and sheet cutting. It is a<br />

system that provides a solution for so many jobs on a day-to-day basis in<br />

the workplace.<br />

From the original nozzle mix system, the Saffire gas product range has been<br />

dramatically developed to embrace flashback arrestors, regulators and other<br />

devices all synonymous with Safety First. Today flashback arrestors are<br />

fitted to all oxy-fuel welding/cutting systems and the use of this product is<br />

universally recognised as good procedure by Health & Safety Executives and<br />

factory inspectors. All Saffire products are now supplied under the quality<br />

management system of BS EN ISO 9001.<br />

Saffire was, and still is, a truly earth shaking revolution – and it remains the<br />

safest yet. As we’ve said since 1956, “Make it Saffire, Keep it Safe.”<br />

33

R<br />

Saffire 300 Series 2+ Multi-Stage Regulators<br />

The Multi-stage series employ the principles of 2-stage gas control<br />

to provide precise and accurate delivery pressures under all<br />

conditions. This ensures the regulators are able to cover a full range<br />

of service requirements from fusion welding through to high integrity<br />

laboratory applications.<br />

The Saffire 300 Series 2+ regulators are the flagship models of the Saffire<br />

range. These multi-stage regulators are fully 300 bar capable whilst retaining<br />

the sensitivity and accuracy necessary for precise control.<br />

The regulators are fully compliant and certified to BS EN ISO 2530.<br />

As with all Saffire products these are manufactured under the quality<br />

management systems of BS EN ISO 9001.<br />

• 1st stage reduces the inlet pressure allowing very accurate adjustment<br />

through the 2nd stage<br />

• Fully compliant and certified to BS EN ISO 2503 with quality<br />

management to ISO 9001<br />

• High strength brass body with operational data permanently engraved<br />

• High specification safety device to protect the user<br />

• Full 300 bar inlet capability<br />

• Solid bulkhead gauges<br />

• Stainless and Neoprene diaphragms<br />

• KelF micro valve in first stage<br />

• Broad seat A92 valve in second stage<br />

Laboratory Regulators<br />

The Saffire Laboratory range provides<br />

both top and side entry connections<br />

to accommodate different cylinder<br />

valves. All components are purpose<br />

designed for non-corrosive high<br />

pressure gas service.1st stage<br />

diaphragm is coated stainless steel<br />

for high integrity leak tightness<br />

needed for “light” gases.<br />

NEVOC Regulator<br />

The trend in Europe to increased<br />

cylinder filling pressures has led to<br />

the adoption of a separate cylinder<br />

valve connection for industrial<br />

applications above 250 bar.<br />

The connection is designated<br />

“NEVOC” – New European Valve<br />

Outlet Connection. In practice<br />

cylinders filled above 250 bar and<br />

up to and including 300 bar will be<br />

fitted with NEVOC valves. Cylinders<br />

filled up to and including 250 bar<br />

will continue to use the standard<br />

BS 341 connection. This change<br />

will have the added benefit of being<br />

adopted across Europe.<br />

34

R<br />

● BRASS BODY<br />

Forged compact body to sit<br />

within the cylinder diameter.<br />

● GAUGES<br />

Solid bulkhead construction<br />

and easy-read faces.<br />

● DIAPHRAGMS<br />

Stainless steel 1st stage<br />

for control of full cylinder<br />

pressure. Flexible neoprene<br />

2nd stage diaphragm for<br />

control and accuracy.<br />

● P.A. KNOB<br />

Markings to show gas<br />

type and pressure.<br />

● SAFETY VALVE<br />

High discharge unit – which resets<br />

when safe condition restored<br />

(high pressure regulators only).<br />

● BONNET<br />

New conical high strength<br />

bonnet to safely contain the<br />

increased cylinder pressures.<br />

● CONTROL VALVE<br />

For acetylene service<br />

giving greater precision<br />

and control.<br />

BCGA CP7 Mark<br />

Shows when the regulator needs<br />

replacement or refurbishment.<br />

● INLET FILTER<br />

Prevents foreign matter entering the<br />

regulator. Reduces the velocity of incoming<br />

gas and protects the mechanism.<br />

Footnote<br />

Connections are RH for Oxygen, Argon.<br />

LH for Acetylene, Propane.<br />

Max Inlet Pressure - Acetylene & Propane 25 bar (362lbf/In 2 ) Oxygen 300 bar (4350lbf/In 2 )<br />

2010<br />

INSPECTION<br />

REPLACEMENT<br />

* It is recommended that flashback arrestors are fitted when using these regulators for oxy/fuel gas processes.<br />

Maximum pressures are those achievable<br />

with flowrates as defined in BS EN ISO 2503<br />

Maximum flow is achievable at Max Outlet Pressure Max Flow Model<br />

expense of pressure. bar lbf/In2 Lit/Min Ft3/h (<strong>Gas</strong>-Bar) Part No<br />

Acetylene<br />

Oxygen<br />

Oxygen<br />

Inert<br />

Inert<br />

All welding, cutting &<br />

process applications 1.3 18.75 350 740 A-1.5 0701281211*<br />

Precision welding & laboratory<br />

or process applications 4 60 880 1860 O-4 0701281209*<br />

Heavy cutting & process<br />

applications 10 145 1093 2317 O-10 0701281210*<br />

Purging & pressurising<br />

leak detection 4 60 895 1900 N-4 0701281217<br />

Purging & pressurising<br />

leak detection 10 145 1108 2350 N-10 0701281218<br />

Inert “NEVOC” Inert gas applications 10 145 1108 2350 N-10 NEVOC 0701282018<br />

Hydrogen<br />

Laboratory & food<br />

processing applications 10 145 4133 8760 H-10 0701281212*<br />

Helium Laboratory & testing applications 10 145 2933 6220 He-10 0701281215<br />

CO 2<br />

Laboratory, farming &<br />

foundry applications 10 145 - - CO 2 -10 0701281216<br />

35

R<br />

Saffire 300 Series 1ec Single-Stage Regulators<br />

The single stage range of Saffire regulators continue the Saffire<br />

tradition of providing a comprehensive selection of robust and reliable<br />

units for the control of industrial fuel gases.<br />

The Saffire “Heart Valve” is at the heart of every regulator and provides full<br />

encapsulation of the working parts for maximum dependability. This component<br />

is custom designed for the specific gas service with both high tensile brass<br />

and stainless steel variants as appropriate.<br />

All the Saffire 300 Series 1ec regulators are fully compliant and certified to<br />

BS EN ISO 2503.<br />

• Solid forged brass body with all operational data permanently engraved<br />

• Fully compliant and certified to BS EN ISO 2503<br />

• Unique encapsulated valve design for maximum control<br />

• Easy read gauge faces calibrated in bar and psi<br />

• High strength bonnet to provide full 300 bar inlet capability<br />

• Solid bulkhead gauges with clear faces<br />

For very heavy duty applications in<br />

arduous conditions both gaugeless<br />

and indicator regulators are available.<br />

The indicator provides a reference<br />

to the contents of the cylinder but<br />

cannot be easily damaged like a<br />

gauge. Ideal for site work and<br />

scrap reclamation.<br />

36

R<br />

● AUDIBLE SAFETY VALVE<br />

High discharge unit which<br />

resets when safe conditions<br />

are restored.<br />

● GAUGES<br />

Solid bulkhead construction<br />

and easy-read faces.<br />

● DIAPHRAGMS<br />

At the heart of Series 1ec Regulators –<br />

a real breakthrough in design, being so<br />

simple in concept and yet so effective<br />

in service. The unbroken surface<br />

suspended between springs ensures<br />

the full area is available for use.<br />

● FORGED BODY<br />

Solid construction to fully contain<br />

the 300 bar service pressure.<br />

● BONNET<br />

New conical high strength<br />

bonnet to safely contain the<br />

increased cylinder pressures.<br />

● P.A. KNOB<br />

Markings to show gas type<br />

and pressure.<br />

● HEART VALVE<br />

Unique encapsulated control<br />

valve for maximum dependability<br />

and accurate control.<br />

● BCGA CP7 MARK<br />

Shows when the regulator needs<br />

replacement or refurbishment.<br />

● INLET FILTER<br />

Prevents foreign matter entering the<br />

regulator. Reduces the velocity of incoming<br />

gas and protects the mechanism.<br />

Footnote<br />

Connections are RH for Oxygen, Argon.<br />

LH for Acetylene, Propane.<br />

Max Inlet Pressure – Acetylene & Propane 25 bar (362lbf/In 2 ) Oxygen 300 bar (4350lbf/In 2 )<br />

2010<br />

INSPECTION<br />

REPLACEMENT<br />

* It is recommended that flashback arrestors are fitted when using these regulators for oxy/fuel gas processes.<br />

Maximum pressures are those achievable<br />

with flowrates as defined in BS EN ISO 2503<br />

Maximum flow is achievable at expense Max Outlet Pressure Max Flow Model<br />

of pressure. bar psi Lit/Min Ft 3 /h (<strong>Gas</strong>-Bar) Part No<br />

Acetylene<br />

General welding, cutting &<br />

heating applications 1.3 18.75 313 650 A-1.5 0701282685*<br />

Oxygen General cutting & welding 4 60 820 1740 O-4 0701282681*<br />

Oxygen <strong>Cutting</strong> & heating 10 145 1170 2480 O-10 0701282682*<br />

Inert<br />

Purging & pressurising<br />

leak detection 10 145 500 1060 N-10 0701300011<br />

Single Stage Gaugeless Regulators, Indicator and Propane Versions<br />

Acetylene<br />

Oxygen<br />

Propane<br />

Scrap cutting & heating,<br />

welding & cutting 1.3 18.75 313 650 A-1.5 Indicator 0701282686*<br />

Scrap cutting & heating,<br />

welding & cutting 10 145 1170 2480 O-10 Indicator 0701282683*<br />

Scrap cutting & heating,<br />

welding & cutting 4 60 267 560 P-4 Gaugeless 0701282687*<br />

37

R<br />

Shielding <strong>Gas</strong>es<br />

The range provides for both MIG and TIG variants based on the<br />

BS EN 13918 : 2003. Both units are calibrated to ensure maximum gas<br />

efficiency for the gas shielded arc welding processes.<br />

• Purpose designed for process<br />

• Full 300 bar inlet capability<br />

• Metered outlet orifice coupled with a highly efficient flow gauge gives<br />

accuracy and therefore economy when MIG welding<br />

• Factory calibrated and quality managed through ISO 9001 system<br />

<strong>Arc</strong>-35L & Co2-35L<br />

These two gauge single-stage regulators will cope with the majority of<br />

MIG/MAG welding applications and are small enough to sit within the<br />

circumference of the cylinder. Fitted with a flow gauge instead of the<br />

vulnerable bobbin type flowmeter, they have proved themselves ideal in the<br />

very rugged situations this equipment often has to withstand.<br />

Ar-2TIG<br />

This single-stage regulator has been preset at 2 bar (30psi) to give a constant<br />

performance. It has been designed specifically for Argon-Tig welding and can<br />

be used by itself or with a bobbin type flowmeter.<br />

Argoshield <strong>Arc</strong>-40L<br />

Proved to be the most economic regulator for use with Argon and Argon<br />

mixtures. The two stage design eliminates the pulsating of gases which is so<br />

wasteful. It will overcome the problem in the most economic and efficient<br />

manner. Fitted with a flow gauge which is coloured to indicate recommended<br />

flow rates, this regulator will cope with heavy duty service where high flow<br />

(up to 40L/M-80ft 3 /hr) is required. The two stages and large diaphragm greatly<br />

reduce the possibility of freezing.<br />

38

R<br />

Saffire MK4 <strong>Gas</strong> Economiser<br />

This device provides economy in the use of gas in welding operations up to<br />

nozzle size 25. During non-welding periods the blowpipe can be hung safely<br />

on the hooked lever which operates the gas shut-off valves in the economiser.<br />

Saffire CO 2 Heater<br />

Specifically designed for use with Carbon Dioxide this unit allows flows of<br />

up to 40cfh without the risk of freezing or noticeable changes in the flow or<br />

pressure. They are available in 230V, 150 Watt versions.<br />

Flowmeter<br />

The vantage flowmeters are damage resistant tough poly carbonate with solid<br />

brass body and fittings. Two models are available, which are designed for use<br />

with the MIG or TIG process.<br />

• Calibrated flow at 0 – 15 or 40 litres/minute<br />

Model Description Part No.<br />

Saffire Economiser MK4 <strong>Gas</strong> economy device 0701282575<br />

Flowmeter Argon/CO 2 14 L/m Dry bobbin type, 0-14 L/m 0701300021<br />

Flowmeter Argon/CO 2 30 L/m Dry bobbin type, 0-30 L/m 0701300022<br />

CO2 Heater 230V 200W Cylinder mounted vaporiser for CO 2 0701020010<br />

Shielding <strong>Gas</strong> Regulators<br />

Rated Flow<br />

Model <strong>Gas</strong> Lit/Min ft3/h Applications Part No.<br />

<strong>Arc</strong>-40L Argon and Argon Mixtures 40 80 MIG <strong>Welding</strong> with argon rich mixture 0701281229<br />

<strong>Arc</strong>-35L Argon and Argon Mixtures 35 70 MIG <strong>Welding</strong> 0701282684<br />

CO2-35L CO 2 35 70 MAG <strong>Welding</strong> 0701282688<br />

Ar-2 TIG Argon Preset at 2 bar pressure TIG <strong>Welding</strong> with flowmeter 0701282689<br />

39

R<br />

Saffire Heavy Duty & Pipeline Regulators<br />

For extra high performance, this range of regulators is process designed and engineered to a high<br />

standard of excellence. Incorporating 230 bar safety with sophistication, the instrument can meet<br />

better service demands.<br />

M600 GP Regulator<br />

This unique regulator is in widespread use throughout the industry.<br />

It has a proven performance in applications where stable high pressures<br />

and flows are required. Many of these are of a critical nature such as<br />

diving, cable pressurisation, power generation and a wide variety of<br />

laboratory applications in universities, nuclear and the chemical industry.<br />

Full 230 bar capability.<br />

OUTLET PRESSURE<br />

lb/in 2<br />

600<br />

400<br />

200<br />

bar<br />

41.5<br />

27.5<br />

14.0<br />

INLET PRESSURE 69 to 172 bar<br />

1000 to2500 lb/in 2<br />

MAX INLET PRESSURE 230 bar/3335 lb/in 2<br />

FLOW CHARACTERISTICS - M600 OG<br />

• Working pressure of 0.40 bar/600psi<br />

• Flow rate of 3200l/m (6800ft 3 /h)<br />

• Inlet pressure 69 to 172 bar<br />

• Maz inlet pressure 230 bar/3335 lb/in 2<br />

590 1180 1770 2360 2950 L/MIN<br />

1250 2500 3750 5000 6250 ft 3 /hr<br />

FLOW (AIR)<br />

High Flow OR 14<br />

High flow-oxygen single stage with two gauges. For cylinder or pipeline.<br />

Working pressure 0 to 14 bar (0 to 200lbf/in 2 ).<br />

lb/in 2<br />

200<br />

bar<br />

14.0<br />

A-INLET 124 bar/1800 lb/in 2<br />

B-INLET 14 bar/200 lb/in 2<br />

MAX INLET PRESSURE 230 bar/3335 lbf/in 2<br />

FLOW CHARACTERISTICS - OR 14<br />

• Heavy duty cutting<br />

• Thermic lancing<br />

• Steel scarfing<br />

• Maximum flow – cylinder 4000l/m (8500 ft 3 /h)<br />

• Maximum flow – pipeline 2595l/m (5500 ft 3 /h)<br />

• Supplied with adaptor<br />

OUTLET PRESSURE<br />

150<br />

100<br />

75<br />

50<br />

30<br />

10.5<br />

7.0<br />

5.0<br />

3.5<br />

2.0<br />

B<br />

A<br />

B<br />

B<br />

B<br />

B<br />

B<br />

A<br />

A<br />

A<br />

A<br />

A<br />

0 427 944 1416 1888 2360 2832 3303 3775 4248<br />

L/MIN<br />

1000 2000 3000 4000 5000 6000 7000 8000 9000 ft 3 /hr<br />

FLOW (AIR)<br />

High Flow S150-OL2<br />

A high flow-oxygen regulator designed for heavy duty machine cutting,<br />

lancing and scarfing. The two gauge regulator has a working pressure<br />

of up to 10 bar.<br />

• Super high flow<br />

• Maximum flow 8495l/m (18,000 ft 3 /h)<br />

• Pipeline applications<br />

• Inlet pressure 17bar/250 16/in 2<br />

• Max inlet pressure 24 bar/350 16/in 2<br />

OUTLET PRESSURE<br />

lb/in 2<br />

150<br />

100<br />

50<br />

25<br />

INLET PRESSURE 17 bar/250 lb/in 2<br />

MAX INLET PRESSURE 24 bar/350 lb/in 2<br />

FLOW CHARACTERISTICS - S 150 OL2<br />

bar<br />

10.5<br />

7.0<br />

3.5<br />

1.7<br />

0 944<br />

2000<br />

1888<br />

4000<br />

2832<br />

6000<br />

3775 4719 5663 6607 7551 8495 9438 L/MIN<br />

8000 10,000 12,000 14,000 16,000 18,000 20,000 ft 3 /hr<br />

FLOW (AIR)<br />

High Pressure Single S-Type<br />

For very high pressure service these regulators permit active gas control of up<br />

to 2500 psi (170 bar). Safe and utterly reliable, the high pressure S Series have<br />

been uprated to allow full 230 bar capability.<br />

40

R<br />

M600 GP Regulator<br />

High Pressure Single S-Type,<br />

High Pressure Refrigerant<br />

High Flow OR 14<br />

High Flow S150-OL2<br />

Ordering Information<br />

Description<br />

Part No<br />

High Pressure Multi-Stage M600<br />

M600 GP Nitrogen/Oxygen/Air 0701300020<br />

(40 bar, accurate, high pressure service)<br />

High Pressure Single S-Type<br />

S400 GP Nitrogen/Oxygen/Air 0701300016<br />

(27 bar, High pressure applications 0 to 27 bar)<br />

Ordering Information<br />

Description<br />

Part No<br />

High Flow OR14<br />

OR14 Oxygen 0700151840<br />

(14 bar,Thermic Lancing, Scarfing, <strong>Cutting</strong>)<br />

High-Flow S150-OL2<br />

S150 OL2 Oxygen 0700147726<br />

(10 bar, Profile <strong>Cutting</strong>)<br />

S1500 GP Nitrogen/Oxygen/Air 0701300018<br />

(100 bar, High pressure applications 0 to 100 bar)<br />

S2500 GP Nitrogen/Oxygen/Air 0701300019<br />

(170 bar, High pressure applications 0 to 170 bar)<br />

41

®<br />

® ®<br />

R<br />

Saffire <strong>Welding</strong> and <strong>Cutting</strong> Blowpipes<br />

Saffire 5 Saffire DH 3<br />

5<br />

Saffire 5 is probably the most robust and versatile<br />

gas welding, cutting and process blowpipe<br />

available. The well tried and tested Saffire offers<br />

refinement, precision engineering and a level of<br />

strength and operational safety essential to survive<br />

the rigours of today’s welding environment.<br />

• Full EN ISO 2503 compatible<br />

• Unique aluminium alloy gun drilled handle specially<br />

shaped for comfort and lightness with strength<br />

and reliability<br />

• Parallel torqued inlet fittings with filters for maximum<br />

safety and durability<br />

• Totally encapsulated trim valves for precise gas control<br />

• Heavy chrome finish for maximum wear resistance<br />

• <strong>Cutting</strong> attachment with a host of operational features<br />

As with all Saffire products, the Saffire 5, welding cutting<br />

and process blowpipe is manufactured under the<br />

demanding BS EN ISO 9001 quality Management System.<br />

DH 3<br />

The Saffire DH 3 is a tried and tested blowpipe<br />

designed for lightweight production welding and<br />

maintenance. It is a complete welding and cutting<br />

blowpipe of proven design.<br />

• Exceptionally comfortable in use<br />

• High integrity trim valves<br />

• Accepts standard lightweight and FN nozzles<br />

• Full EN ISO 5172 compatible<br />

<strong>Welding</strong><br />

• Welds from 1mm to 8mm plate<br />

• Light and positive, ideal for high quality welding<br />

• Precision engineered mixer for precise gas control<br />

• All positional facility for nozzles through the serrated<br />

connection teeth<br />

• Accepts all lightweight swaged nozzles and DH tips with<br />

suitable neck<br />

<strong>Cutting</strong><br />

• Cuts up to 50mm plate<br />

• Heating oxygen valve for optimum user control<br />

• Parallel tubes for increased visibility when in use<br />

• High tensile brass head for extended service life<br />

• Piston cutting oxygen valve provides smooth cutting action<br />

• Silver soldered joints throughout<br />

• Uses all standard AFN nozzles<br />

Process<br />

• Accepts multi-flame heating tip to give 500 litres per<br />

hour capacity<br />

• <strong>Cutting</strong> oxygen characteristic allows smooth bevels for<br />

plate edged preparation for welding<br />

42

®<br />

R<br />

5 <strong>Cutting</strong> Attachment<br />

Designed to cope with the rigours of the modern welding and<br />

fabrication environment, the robust Saffire 5 cutting attachment offers<br />

a host of features including a cutting oxygen valve which allows more<br />

control of the cutting oxygen flow for improved cut quality.<br />

The gas tubes between the body and head are in line, giving maximum<br />

visibility of the working area, also connections between the gas tubes and<br />

the head and body of the cutting attachment are brazed for increased<br />

strength. The head itself is equipped with internal threads for the head nut<br />

which greatly reduces the risk of thread damage, and finally the whole of the<br />

cutting attachment has a chrome finish to increase heat reflection and reduce<br />

spatter adhesion.<br />

In addition to welding between 1mm and 25mm and cutting to 200mm using<br />

acetylene, Saffire 5 with its increased flow capacity and using the appropriate<br />

attachments, can be used to perform a wide range of oxy fuel gas processes<br />

which include:<br />

• Heating with acetylene<br />

• Heating with propane<br />

• Flame cleaning<br />

• Rivet cutting<br />

• Gouging<br />

• Circle cutting<br />

WELDING AND CUTTING OPERATIONS<br />

Ordering Information<br />

Description<br />

Part No<br />

Saffire 5 <strong>Equipment</strong><br />

Shank – 3/8 in. BSP connections 0701256723<br />

<strong>Welding</strong> mixer – acetylene 0700143537<br />

Heavy duty mixer – acetylene 0700143525<br />

Mixer – propane 0700143758<br />

<strong>Cutting</strong> attachment 0701256941<br />

Small circle cutting attachment 0700143640<br />

Large circle cutting attachment 0700144928<br />

700mm bent neck – propane 0700157553<br />

200mm bent neck – acetylene 0700143884<br />

<strong>Cutting</strong> Nozzles – Acetylene<br />

A-SNM-Sheet 0700126533<br />

A-NM 1/32 in 3-6mm 0700143016<br />

A-NM 3/64 in 5-12mm 0700143017<br />

A-NM 1/16 in 10-75mm 0700143018<br />

A-NM 5/64 in 70-100mm 0700143019<br />

A-NM 3/32 in 90-150mm 0700143020<br />

ANME 1/32 in 3-6mm 0700016120<br />

ANME 3/64 in 5-12mm 0700016121<br />

ANME 1/16 in 10-75mm 0700016122<br />

ANME 5/64 in 70-100mm 0700016123<br />

ANME 3/32 in 90-150mm 0700016124<br />

PNM <strong>Cutting</strong> nozzles – Propane<br />

P-NM 1/32 in 3-6mm 0700143780<br />

P-NM 3/64 in 5-12mm 0700143781<br />

P-NM 1/16 in 10-75mm 0700143782<br />

Acetylene – Gouging<br />

AGNM 13 0700126809<br />

Acetylene heating nozzles<br />

A-HT size 25 0700126134<br />

A-HT size 50* 0700126135<br />

A-HT size 100* 0700126136<br />

Propane super heating nozzles<br />

Saffire 1H 0700157557<br />

Saffire 2H 0700157558<br />

Saffire 3H 0700157559<br />

Saffire 4H 0700157560<br />

Saffire 5H 0700157561<br />

* Requires use of H.D. Mixer 0700143525<br />

HEATING OPERATIONS<br />

Saffire DH 3<br />

Shank 1/4in BSP Connections 0701281934<br />

<strong>Cutting</strong> Attachment 0701257523<br />

Mixer 0701256673<br />

Saffire DH 3 Accessories<br />

Heating Tip and Neck Assembly 0701256652<br />

43

®<br />

®<br />

R<br />

Saffire <strong>Welding</strong> and <strong>Cutting</strong> Blowpipes<br />

The range of Saffire NM cutters continues the tradition of nozzle mix<br />

design with the quality and reliability synonymous with Saffire. A proven<br />

design incorporating the latest technical features necessary to meet<br />

the changing service requirements of the hand cutting market.<br />

• Nozzle mix principle for maximum safety<br />

• Backfire resistant design<br />

• Progressive “bleed” characteristics<br />

• Two length options<br />

• 90° and 75° cutting heads<br />

• Robust engineering<br />

Ordering Information<br />

Description<br />

Part No<br />

Saffire NM 250 0701256484<br />

Saffire NM 400 0701256482<br />

Saffire NM250 and NM400 Accessories<br />

Small circle cutting attachment 0700143640<br />

Large circle cutting attachment 0700144928<br />

Saffire super heating adaptor 0701250458<br />

B.S. Note: Where applicable blowpipes and<br />

nozzles are designed and manufactured to<br />

comply with BS EN 150 5172.<br />

All Saffire Cutters are equally suitable for Acetylene and Propane service simply by<br />

changing the nozzle.<br />

Saffire cutters have the benefit of a unique cutting oxygen flow valve which through<br />

the cutting lever acts indirectly to bring in the oxygen stream. This important feature<br />

gives a true “bleed” characteristic to create splash free starts and progressive<br />

piercing and the smoothest possible cutting conditions.<br />

Saffire NM Cutters are designed to BS EN 150 5172 “Handheld Blowpipes for<br />

<strong>Welding</strong> and <strong>Cutting</strong>” and manufactured under the quality management systems<br />

of BS EN ISO 9001.<br />

NM 250<br />

The NM 250 Model is principally intended for general workshop cutting up to<br />

250mm (10") capacity. The balance and trim combined with 500mm (18") length<br />

make it ideally suited for most industrial applications.<br />

NM 400<br />

This model has the benefit of a 75° head and 700m (27") length combined with a<br />

cutting capacity of 400mm (16"). The cutter is designed for heavy duty fabrication<br />

and scrap cutting applications where the combinations of head angle and extended<br />

length create both positive and comfortable working conditions for the operator.<br />

44

R<br />

45

R<br />

Saffire <strong>Welding</strong>, <strong>Cutting</strong> and Process Nozzles<br />

WELDING NOZZLES<br />

Swaged and Lightweight <strong>Welding</strong> Nozzles<br />

Swaged and lightweight nozzles<br />

are manufactured from high<br />

grade swaged tellurium copper.<br />

The unique mandrel swaging<br />

provides smooth accurate gas<br />

passages which, in turn, control<br />

the precise flame shape.<br />

Size<br />

*Plate Thickness<br />

ft 3 /h l/h mm in(swg) Part No<br />

1 26 0.9 (20) 0700122207<br />

2 56 1.2 (18) 0700122208<br />

3 88 2.0 (14) 0700122209<br />

5 142 2.6 (12) 0700122210<br />

7 198 3.2<br />

1 / 8 (10) 0700122211<br />

10 285 4.0 5/ 32 (8) 0700122212<br />

13 360 5.0 3/ 16 (6) 0700122213<br />

18 540 6.5<br />

1 / 4 (3) 0700122214<br />

25 740 8.2 5/ 16 (0) 0700122215<br />

35 1000 10<br />

<strong>Equipment</strong> to be used with Saffire 5.<br />

Saffire Lightweight Swaged Nozzles<br />

3 / 8 (4/0) 0700122216<br />

Size<br />

*Plate Thickness<br />

ft 3 /h l/h mm in(swg) Part No<br />

1 26 0.9 (20) 0700140200<br />

2 56 1.2 (18) 0700140201<br />

3 88 2.0 (14) 0700140202<br />

5 142 2.6 (12) 0700140203<br />

7 198 3.2 1/ 8 (10) 0700140204<br />

10 285 4.0 5/ 32 (8) 0700140205<br />

13 360 5.0 3/ 16 (6) 0700140206<br />

18 540 6.5 1/ 4 (3) 0700140207<br />

25 740 8.2 5/ 16 (0) 0700140208<br />

<strong>Equipment</strong> to be used with Saffire DH Torches.<br />

Model “O” <strong>Welding</strong> Tips<br />

Model “O” tips are precision drilled to<br />

ensure the accuracy of the micro flame.<br />

Size<br />

*Plate Thickness<br />

lead wt ft 3 /h l/h lbs/in 2 Part No<br />

1 0.175 5 2 - 3 0700993260<br />

2 0.425 12 4 - 5 0700993261<br />

3 1.1 31 6 - 8 0700993262<br />

4 2.2 62 10 - 2 0700993263<br />

5 4.5 125 18 - 3 0700993264<br />

CUTTING NOZZLES<br />

Acetylene Nozzle Mix – ANM<br />

Saffire ® ANM Series cutting nozzles are manufactured from<br />

Tellurium Copper and are of solid, one piece drawn construction.<br />

This technology provides the best conditions<br />

for a high velocity gas such as acetylene and<br />

enhances stability and cutting efficiency.<br />

The seats of ANM nozzles are diamond<br />

turned to guarantee “metal to metal” seal<br />

with the blowpipe head. This is essential to<br />

ensure no head seat leaks, thereby<br />

reducing backfire risks.<br />

Size<br />

*Plate Thickness<br />

mm in. mm in. Part No<br />

3 - 6 1/ 32 6 1/ 4 0700143016<br />

5 - 12 3/ 64 12 1/ 2 0700143017<br />

10 - 75 1/ 16 75 1 - 3 0700143018<br />

70 - 100 5/ 64 100 4 0700143019<br />

90 - 150 3/ 32 150 6 0700143020<br />

190 - 300 1/ 8 300 12 0700143022<br />

<strong>Equipment</strong> to be used with Saffire 5, Torches and NM Cutters.<br />

A-NME (ANM Extended)<br />

Size<br />

*Plate Thickness<br />

mm in. mm in. Part No<br />

3 - 6 1/ 32 6 1/ 4 0700016120<br />

5 - 12 3/ 64 12 1/ 2 0700016121<br />

10 - 75 1/ 16 75 1 - 3 0700016122<br />

70 - 100 5/ 64 100 4 0700016123<br />

90 - 150 3/ 32 150 6 0700016124<br />

190 - 300 1/ 8 300 12 0700016125<br />

<strong>Equipment</strong> to be used with Saffire 5, Torches and NM Cutters.<br />

A-SNM<br />

Size<br />

*Plate Thickness<br />

mm mm in (swg) Part No<br />

One size only 3 1/ 8 0700126533<br />

<strong>Equipment</strong> to be used with Saffire 5, Torches and NM Cutters.<br />

A-FN<br />

Size<br />

*Plate Thickness<br />

mm in. mm in. Part No<br />

3 - 6 1/ 32 3 - 6 1/ 8<br />

1/ 4 0700144735<br />

6 - 20 3/ 64 6 - 20 1/ 4<br />

3/ 4 0700144736<br />

20 - 25 1/ 16 20 - 50 3/ 4 2 0700144737<br />

<strong>Equipment</strong> to be used with Portapak & DH3.<br />

<strong>Equipment</strong> to be used with Model ‘O’ blowpipe.<br />

46

R<br />

PNM – <strong>Cutting</strong> Nozzles<br />

Saffire ® PNM Series cutting nozzles are of two piece design made<br />

up of a brass inner nozzle with splines and a hollow drawn copper<br />

outer sheath. The reason that PNM’s differ from ANM is that different<br />

gas mixing criteria apply. Oxy-propane has a lower burning velocity<br />

than oxy-acetylene and this requires two things to develop good<br />

flame conditions. First, turbulence must be<br />

created between the inner and outer parts<br />

of the nozzle to obtain adequate mixing of<br />

the propane and oxygen. Secondly, the<br />

volume of mixed oxy-propane needs to be<br />

more than double that of oxy-acetylene for<br />

the same usable heat. This is achieved by<br />

having very large channels (the splines) to<br />

conduct the greater gas volumes.<br />

Propane Nozzle Mix – PNM<br />

Size<br />

*Plate Thickness<br />

mm in. mm in. Part No<br />

3 - 6 1/ 32 6 1/ 4 0700143780<br />

5 - 12 3/ 64 12 1/ 2 0700143781<br />

10 - 75 1/ 16 75 1- 3 0700143782<br />

70 - 100 5/ 64 100 4 0700143783<br />

90 - 150 3/ 32 150 6 0700143784<br />

190 - 300 1/ 8 300 12 0700143786<br />

<strong>Equipment</strong> to be used with Saffire 5, Torches and NM Cutters.<br />

P-NME (PNM Extended)<br />

Size<br />

*Plate Thickness<br />

mm in. mm in. Part No<br />

3 - 6 1/ 32 6 1/ 4 0700016130<br />

5 - 12 3/ 64 12 1/ 2 0700016131<br />

10 - 75 1/ 16 75 1 - 3 0700016132<br />

70 - 100 5/ 64 100 4 0700016133<br />

90 - 150 3/ 32 150 6 0700016134<br />

190 - 300 1/ 8 300 12 0700016135<br />

Propane Superheating Nozzles<br />

The “H” Series are designed to provide a large flame giving a<br />

broad spread of heat over a large area. The nozzles are widely<br />

used for pre and post heating of<br />

weldments and for the shaping<br />

and forming of steel components.<br />

There are 5 models in the range<br />

provide a range of flame sizes.<br />

Size Btu/h Part No<br />

1H 72,000 - 163,000 0700157557<br />

2H 102,000 - 188,000 0700157558<br />

3H 183,000 - 361,000 0700157559<br />

4H 236,000 - 406,000 0700157560<br />

5H 281,000 - 618,000 0700157561<br />

<strong>Equipment</strong> to be used with Saffire 5, torches with heavy duty mixer<br />

Part No. 0700143758. NM250 with adaptor Part No. 0701250458.<br />

Note – up to 766,000 Btu/h can be obtained from 5H when used on NM250<br />

with adaptor.<br />

Acetylene Heating Nozzles<br />

AHT heating nozzles are designed to<br />

provide intense focussed heat. They are<br />

used for spot heating of small areas<br />

quickly. There are 3 sizes in the range<br />

designated by their consumption of gas.<br />

Size BTU/h Part No<br />

25 52,000 0700126134<br />

* 50 91,000 0700126135<br />

* 100 139,000 0700126136<br />

<strong>Equipment</strong> to be used with *Saffire 5, torches with heavy duty mixer<br />

Part No. 0700143525.<br />

Note – Plate thickness refers to mild steel.<br />

<strong>Equipment</strong> to be used with Saffire 5, Torches and NM Cutters.<br />

PROCESS NOZZLES<br />

Acetylene Gouging Nozzles<br />

AGNM nozzles employ the nozzle mix principle for gouging.<br />

In application the nozzle cuts a “U” shaped groove in the plate.<br />

The most common use is to “back gouge” butt welds to remove any<br />

defects prior to laying the final sealing run.<br />

They also find application in the removal of<br />

defective welds or flaws in steel plates.<br />

The use of oxy-acetylene allows for high<br />

speed cost effective production. There<br />

are 3 models in the range each providing<br />

a “U” groove of different dimensions.<br />

Gouging – A-GNM<br />

Size Depth (in) Groove width (in) Part No<br />

13 1/ 8 - 3 / 8<br />

1/ 4 - 5 / 16 0700126809<br />

19 1/ 4 - 7 / 16<br />

5/ 16 - 7 / 16 0700126810<br />

25 3/ 8 - 1 / 2<br />

3/ 8 - 1 / 2 0700126811<br />

<strong>Equipment</strong> to be used with Saffire 5, Torches and NM Cutters.<br />

Note – Where applicable, blowpipes and nozzles are designed and<br />

manufactured to comply with BS EN 150 5172.<br />

47

R<br />

Safety Devices<br />

Saffire 36ec Flashback Arrestors<br />

Flashback Arrestors are essential safety devices which provide the<br />

maximum protection for the operator and his equipment in the event<br />

of a flashback.<br />

A flashback can be caused by a variety of conditions such as sustained<br />

backfire, incorrect hose purging or simply the wrong gas pressure. Most are<br />

attributable to operator errors.<br />

When a flashback occurs the flame front and pressure wave retreat into the<br />

blowpipe and hose at a very high speed. This can cause detonation within the<br />

system. It is essential that the regulator and more particularly the cylinder are<br />

protected from the effect of a flashback.<br />

The well proven 36ec conforms to the requirements of BS EN 730-1. The unit<br />

offers comprehensive protection from the dangers of flashback and has the<br />

following important safety features:<br />

• Reset Button – this is protected<br />

within the body of the unit to<br />

protect against damage. Very<br />

important. The “pop-up” feature<br />

indicates when a flashback has<br />

occurred and the arrestor<br />

activated. Simply lift to reset<br />

• Sintered Metal Flame Arresting<br />

Element – very large diameter with<br />

extensive surface area – designed<br />

to arrest the flashback flame<br />

quickly. The element size is<br />

important to long service life and<br />

to allow high flow use<br />

• Non-return Valve – upstream of<br />

the flame arresting element<br />

ensures no gas can backfeed to<br />

ignite incoming gases<br />

• Thermal Cut-off Device –<br />

designed to completely isolate the<br />

system by cutting off all incoming<br />

gases in the event of a fire<br />

• Pressure Sensitive Cut-off Valve –<br />

in the event of a flashback the<br />

pressure wave will activate the<br />

valve to cut off the gas supply<br />

automatically<br />

48

R<br />

Indicator button<br />

In normal operation a<br />

green safety band shows<br />

around the button. After a<br />

flashback the band does<br />

not show and the outer<br />

shroud must be lifted to<br />

reset the unit.<br />

Non-return valve<br />

Upstream of the flame<br />

arresting element, this unit<br />

ensures no gas can<br />

backfeed and ignite<br />

incoming gases.<br />

Sintered metal flame<br />

arresting element<br />

Extensive surface area<br />

designed to arrest a<br />

flashback flame quickly.<br />

The element surface area<br />

is important to ensure<br />

long service life and to<br />

permit high gas flow in<br />

normal operation.<br />

Pressure sensitive<br />

cut-off valve<br />

In the event of a<br />

flashback the pressure<br />

wave will activate the<br />

valve to cut off the gas<br />

supply automatically.<br />

Thermal cut off device<br />

Designed to cut off the<br />

gas in the event of<br />

extreme temperatures<br />

such as a hose fire. The<br />

unit is activated at 95ºC.<br />

In the event of a flashback<br />

the flame front strikes the<br />

retaining plate thereby<br />

displaying much of the<br />

flashback force. The flame<br />

front passes into the<br />

absorbtion chamber and is<br />

quenched as it enters the<br />

flame arresting element.<br />

The following pressure wave<br />

passes through the filter<br />

and activates the flow cut<br />

off valve by its pressure.<br />

This causes the reset button<br />

to move downwards.<br />

This equipment is thus<br />

rendered safe with the<br />

flashback flame extinguished<br />

and the incoming gas<br />

supply stopped.<br />

Saffire XL5 Flashback Arrestors<br />

The Saffire ® XL cylindrical flashback arrestors, are of advanced design giving<br />

a higher flow rate. Internally the XL is equipped with a large cylindrical flame<br />

arresting element, an automotive reset non-return valve and a heat sensitive<br />

automatic cut-off.<br />

• Automatic reset non-return valve<br />

• Heat sensitive cut-off valve<br />

• High flow flame arresting element<br />

• Inlet filter for internal mechanism<br />

• Conforms to BS EN 730-1<br />

Saffire Hose Check Valves<br />

A vital piece of equipment protecting against<br />

backfeed. The <strong>Murex</strong> hose check valve is a<br />

self-aligning non return valve which Is spring<br />

loaded and detects reverse gas flow; it<br />

automatically closes, therefore preventing the<br />

conditions which lead to flashback. Conforms<br />

to BS EN 730-2.<br />

Ordering Information<br />

Description<br />

Part No<br />

FBA Model 36ec Acet/ Propane 0701282274<br />

FBA Model 36ec Acet/ Oxygen 0701282274<br />

FBA XL Acet/ Propane 0701258986<br />

FBA XL Oxygen 0701258985<br />

BV 12 Hose Check Valve<br />

1/4" x 6.3mm LH 0701261904<br />

BV 12 Hose Check Valve<br />

1/4" x 6.3mm RH 0701261905<br />

BV 12 Hose Check Valve<br />

3/8" x 6.3mm LH 0701261906<br />

BV 12 Hose Check Valve<br />

3/8" x 6.3mm RH 0701261907<br />

BV 12 Hose Check Valve<br />

3/8" x 10mm LH 0701261910<br />

BV 12 Hose Check Valve<br />

3/8" x 10mm RH 0701261911<br />

Flashback arrestors should always be used<br />

in conjunction with hose check valves as<br />

these help to prevent the backflow which leads<br />

to flashback.<br />

All Saffire ® Safety Devices fully conform to BS EN 730-1 and BS EN 730-2.<br />

49

R<br />

Saffire Hose and Fittings<br />

Saffire welding hoses<br />

The Saffire Multiplex range of hoses meet the requirements of the European<br />

Standard BS EN 559. “Rubber hoses for welding, cutting and allied processes.”<br />

Saffire Multiplex Hose is a machine extruded hose having high strength and<br />

maximum Flexibility whilst maintaining its essential lightness. The range is<br />

designed for both standard and heavy duty cutting and welding applications.<br />

Ordering Information<br />

Description<br />

Saffire Lite Fitted Hoses<br />

Oxygen – Blue<br />

6.3mm x 5M 1/4" RH<br />

6.3mm x 5M 3/8" RH<br />

6.3mm x 10M 3/8" RH<br />

10mm x 5M 3/8" RH<br />

10mm x 10M 3/8" RH<br />

10mm x 20M 3/8" RH<br />

Acetylene – Red<br />

6.3mm x 5M 1/4" LH<br />

6.3mm x 5M 3/8" LH<br />

6.3mm x 10M 3/8" LH<br />

10mm x 5M 3/8" LH<br />

10mm x 10M 3/8" LH<br />

10mm x 20M 3/8" LH<br />

Propane – Orange<br />

10mm x 10M 3/8" LH<br />

10mm x 20M 3/8" LH<br />

Part No<br />

071262251P<br />

071262254P<br />

071262255P<br />

071262103P<br />

071262259P<br />

071262260P<br />

071262201P<br />

071262204P<br />

071262205P<br />

071262102P<br />

071262209P<br />

071262210P<br />

071261175P<br />

071261176P<br />

5<br />

2<br />

Saffire Hose Fittings<br />

Nut Couplings 1<br />

Nut Coupling 3/8"<br />

BSP LH Pack of 10 0700032034<br />

Nut Coupling 3/8"<br />

BSP RH Pack of 10 0700032035<br />

Nipples 2<br />

Nipple for 6.3mm Bore Hose 3/8"<br />

BSP Nut Pack of 5 0700151405<br />

Nipple for 8mm Bore Hose 3/8"<br />

BSP Nut Pack of 10 0700932030<br />

Nipple for 10mm Bore Hose 3/8"<br />

BSP Nut Pack of 5 0700151314<br />

Hose Couplers 3<br />

Hose Coupler Equal 3/8"<br />

BSP LH Pack of 10 0700033234<br />

Hose Coupler Equal 3/8"<br />

BSP RH Pack of 10 0700033235<br />

1<br />

Hose Splicers 4<br />

Hose Splicer for 6.3mm Hose<br />

Pack of 10 0700016160<br />

Hose Splicer for 10mm Hose<br />

Pack of 10 0700016161<br />

4<br />

3<br />

‘O’ Clips 5<br />

O Clip for 6.3mm Hose<br />

Pack of 10 0700888910<br />

O Clip for 10mm Hose<br />

Pack of 10 0700888911<br />

50

R<br />

IMP Flame <strong>Cutting</strong> Machines<br />

The IMP flame cutting machine represents the latest development in<br />

portable machine technology descending from a long line of tried and<br />

trusted predecessors. The IMP incorporates a great many user<br />

benefits not usually available on this class of machine and can operate<br />

on a variety of gas types such as acetylene, propane and natural gas.<br />

The machine lends itself to multiple blowpipe operation and has a capacity to<br />

cut 150mm plate as standard. Infinitely variable speed control and free running<br />

clutch extend its range of applications. The IMP is highly portable being light,<br />

well balanced and easy to carry and position. Whether on track or free<br />

standing, the inherent stability of design guarantees smooth, accurate cuts<br />

across the whole range of plate thicknesses.<br />

Ordering Information<br />

Description<br />

Part No<br />

IMP Portable <strong>Cutting</strong> Machine-Single Blowpipe<br />

Comprises:-<br />

Tractor with 10m input cable, Hose set<br />

(blowpipe to valve block) blowpipe, Blowpipe<br />

holder and 342mm blowpipe bar, Radius<br />

bar and balance weight for circle cutting<br />

75-1380mm diameter, Head nut spanner,<br />

Instruction manual<br />

IMP Machine Single B/pipe-NM 240V 0701254163<br />

IMP Machine SingleB/pipe-NM 110V 0401254164<br />

IMP Portable <strong>Cutting</strong> Machine-Double Blowpipe<br />

Comprises:-<br />

Tractor with 10m input cable, Double hose set<br />

(blowpipe to valve block), Two blowpipes,<br />

Two blowpipe holders, Two 525mm blowpipe<br />

bars, Radius bar and balance weight for circle<br />

<strong>Cutting</strong> 75-1740mm diameter, Headnut spanner,<br />

Instruction manual<br />

IMP Machine Double B/pipe-NM 240V 0701254169<br />

Options of 40V, 32V machines are available plus<br />

24V DC for site work. (Both Single Blowpipe<br />

and Double Blowpipe versions.)<br />

Optional <strong>Equipment</strong><br />

Interlocking extruded aluminium<br />

guide track 2m long including<br />

spring clip 0701254178<br />

Track extension clips – Pack of 5 0701254179<br />

51

R<br />

Saffire <strong>Welding</strong>, <strong>Cutting</strong> and Heating Outfits<br />

Saffire Outfits<br />

The range of <strong>Murex</strong> range of Saffire <strong>Welding</strong> and <strong>Cutting</strong> outfits offers the most comprehensive selection<br />

available. Purpose designed following an intensive programme of market research, each outfit is tailored<br />

to the needs of a particular market sector, ranging from heavy duty industrial down to micro welding.<br />

The Saffire outfits, which include use of both the Saffire DH3 and Saffire 5 blowpipes, meet the requirements<br />

of BS EN 1505172 and are manufactured under the quality management systems of BS EN ISO 9001.<br />

A range to suit all types of welding and cutting applications.<br />

Saffire 5 SupAcet UK<br />

The Saffire SupAcet is a heavy-duty gas cutting<br />

and welding outfit offering a comprehensive<br />

package at an exceptionally competitive price.<br />

The blowpipe employs the world-renowned<br />

Saffire “tip mix” principle for operational simplicity<br />

and economy. Ergonomically designed, the<br />

Saffire Shank and precision mixer ensures full<br />

operational safety by creating a modulated blend<br />

of gases at the tip for smooth burning.<br />

• Plate <strong>Cutting</strong> up to 75mm<br />

• Full welding facility up to 5mm<br />

Ordering Information<br />

Description<br />

Part No<br />

Saffire 5 SupAcet UK 0700016050<br />

Package Comprises: -<br />

Saffire Single Stage Oxygen Regulator 0-10<br />

Saffire Single Stage Acetylene Regulator A-1.5<br />

Saffire 5 Shank and <strong>Cutting</strong> Attachment<br />

Saffire 5 <strong>Welding</strong> Mixer<br />

<strong>Cutting</strong> Nozzle ANM 1/16"<br />

<strong>Welding</strong> Nozzles 5, 7, 13<br />

Saffire XL5 Flashback arrestors – Oxygen<br />

Saffire XL5 Flashback arrestor – Acetylene<br />

Factory fitted hose Assemblies – twin constructed<br />

Spark Lighter<br />

Cylinder Key<br />

Nozzle Cleaner Set<br />

Goggles<br />

Service Spares<br />

Operating Instructions<br />

Saffire 5 <strong>Welding</strong>, <strong>Cutting</strong> & Heating Outfit<br />

A highly versatile outfit for the general<br />

fabrication industry. Fully BS EN ISO 5172<br />

designed. As with all Saffire 5 combinations<br />

the outfit can be uprated to take all Saffire<br />

accessories and has the benefit of a multiflame<br />

heating head as standard which much<br />

improves the outfit’s total capability.<br />

• Plate <strong>Cutting</strong> up to 75mm<br />

• Full welding facility up to 8mm<br />

• Heats consumes 500 L/hr<br />

Ordering Information<br />

Description<br />

Part No<br />

Saffire 5 <strong>Welding</strong>, <strong>Cutting</strong> and<br />

Heating Outfit 0701256727<br />

Package Comprises: -<br />

Saffire 5 shank and cutting attachment<br />

Saffire 5 <strong>Welding</strong> Mixer<br />

Swaged welding nozzles 2, 5, 7 10, 13, 25<br />

<strong>Cutting</strong> Nozzles ANM 3/64, 1/16<br />

Saffire Multi Flame heating tip assembly<br />

Spark Lighter<br />

Nozzle Cleaner Set<br />

Operating Instructions<br />

Carrying Case<br />

Saffire DH3 <strong>Welding</strong> Outfit<br />

A general-purpose outfit for production and<br />

maintenance welding. The DH3 is purpose<br />

designed for lightweight welding and is<br />

exceptionally comfortable in use.<br />

• Full welding facility up to 26mm<br />

Ordering Information<br />

Description<br />

Part No<br />

Saffire DH3 <strong>Welding</strong> Outfit 0701282228<br />

Package Comprises: -<br />

Saffire DH3 Shank<br />

Saffire DH Mixer<br />

Lightweight swaged nozzles 2, 3, 5<br />

Carrying Case<br />

Operating Instructions<br />

52

R<br />

Saffire Model ‘O’ Microset<br />

For use in a variety of fine welding applications<br />

including jewellery, electronics, dental and lead<br />

welding.The Model ‘O’ Microset is a finally<br />

balanced injector blowpipe ideally suited to fine<br />

welding and brazing applications.The injector<br />

capability makes the blowpipe equally suitable<br />

for use with acetylene or hydrogen fuel gas and<br />

thereby lends itself to use in the electronics,<br />

jewellery and medical engineering fields.<br />

Ordering Information<br />

Description<br />

Part No<br />

Saffire Saffire Model<br />

‘O’ Microset 0701256500<br />

Package Comprises: -<br />

Saffire Model ‘O’ Blowpipe and Neck<br />

Saffire Model ‘O’ Tips 1, 2, 3, 4, 5<br />

Spanner<br />

Operating Instructions<br />

Carrying Case for blowpipe<br />

• Welds 0 – 1.5mm<br />

Saffire Portapak<br />

Portapak gives the user a complete workshop<br />

on wheels; light in weight and safe, it can be<br />

easily transported in a car boot or a van for all<br />

those difficult to reach locations. Equally suited<br />

to the light industrial engineer, plumber or do-ityourself<br />

enthusiast the Portapak has many<br />

unique operational and safety features.<br />

• Full welding facility up to 5mm<br />

• Steel plate cutting up to 20mm<br />

• Engineered trolley for functional<br />

stability with Flamepak 10 or 20 cylinders<br />

• Flashback Arrestors to BS EN 730-1<br />

specification<br />

• Carry or wheel anywhere, the<br />

Portapak weighs only 26kg<br />

• Compact trolley with fully retractable<br />

handle for simple storage<br />

Ordering Information<br />

Description<br />

Part No<br />

Saffire Portapak (exc cylinders) 0701256509<br />

Package Comprises: -<br />

Saffire DH Shank, mixer and cutting attachment<br />

Saffire single stage oxygen regulator 0-10<br />

Saffire single stage acetylene regulator A-1.5<br />

Saffire AFN 3/64 cutting nozzles<br />

Saffire lightweight welding nozzles 2, 5, 10<br />

Saffire oxygen hose 5m x 6mm with HCV<br />

Saffire acetylene hose 5m x 6mm with HCV<br />

Saffire XL5 Flashback arrestors– Oxygen<br />

Saffire XL5 Flashback arrestor – Acetylene<br />

Saffire multiflame heating tip assembly<br />

Goggles<br />

Spark Lighter<br />

Nozzle Cleaner Set<br />

Spanner<br />

Cylinder Key<br />

Operating instructions<br />

Trolley with wheels<br />

Carrying case for blowpipe<br />

The contents of each outfit in the Saffire range has been carefully selected to meet the exact user requirements of its targeted market sector.<br />

However no two welding projects, environments or users are exactly the same. To cater for process flexibility <strong>Murex</strong> offer a comprehensive range<br />

of precision engineered accessories designed to enhance and increase the performance of all the outfits should the need arise.<br />

53

R<br />

Certificate of Conformity and Origin<br />

In order to provide legal<br />

protection to our Distributors and<br />

End User Customers <strong>Murex</strong><br />

<strong>Welding</strong> Products offer a full<br />

documentation service.<br />

Under the terms of the<br />

Consumer Protection Act 1987<br />

it is an offence to supply any<br />

consumer goods which fail to<br />

comply with general safety<br />

requirements. For <strong>Murex</strong><br />

Distributors the provision of this<br />

documentation service confirms<br />

compliance with National<br />

Standards and manufacturing<br />

origins. For end users it provides<br />

peace of mind and confirmation<br />

that they are dealing with a long<br />

established, respected and<br />

reliable company. <strong>Murex</strong> <strong>Welding</strong><br />

Products have been established<br />

for nearly 80 years with a<br />

reputation second to none.<br />

Supporting the above, <strong>Murex</strong> provide a full Technical Information Service and would be delighted to answer any customer<br />

questions. To contact them or to obtain your Certificate of Conformity please contact:<br />

<strong>Murex</strong> Technical Information Service<br />

Contact: Paul Woodford<br />

Telephone: 01992 659083<br />

Fax: 01992 788053<br />

Mobile: 07768 602096<br />

54

NOTES<br />

55

56<br />

NOTES

Your Local Distributor<br />

Contact Details<br />

<strong>Murex</strong> <strong>Welding</strong> Products are available from a Nationwide Distributor<br />

Network. For information about <strong>Murex</strong> <strong>Welding</strong> Products call us<br />

on 01992 710000, visit you local <strong>Murex</strong> Distributor or visit the <strong>Murex</strong><br />

<strong>Welding</strong> Products website: www.murexwelding.co.uk<br />

Portfolio of Products<br />

<strong>Murex</strong> <strong>Welding</strong> Products offer a comprehensive range of:<br />

• <strong>Arc</strong> <strong>Welding</strong> and <strong>Cutting</strong> <strong>Equipment</strong><br />

• <strong>Gas</strong> <strong>Welding</strong> and <strong>Cutting</strong> <strong>Equipment</strong><br />

• <strong>Welding</strong> Consumables<br />

• Personal Protection <strong>Equipment</strong> and <strong>Welding</strong> Accessories<br />

<strong>Murex</strong> <strong>Welding</strong> Products<br />

Hanover House, Britannia Road, Waltham Cross, Hertfordshire EN8 7TF<br />

Telephone: +44 (0)1992 710000 Facsimile: +44 (0)1992 719191<br />

Email: info@murexwelding.co.uk www.murexwelding.co.uk<br />

In the interest of continuous improvement MUREX reserves the right to change the specifications<br />

or design of any of its products without prior notice