Business Overview 2007 - Synthes

Business Overview 2007 - Synthes

Business Overview 2007 - Synthes

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Our Values & Principles<br />

Annual Report <strong>2007</strong>

Our Values & Principles<br />

Annual Report <strong>2007</strong>

Preface<br />

Our Values & Principles<br />

This year’s Annual Report focuses upon our Values & Principles.<br />

They capture the inherent culture of <strong>Synthes</strong> and have been,<br />

are, and will be at the core of our activities as a company and<br />

as individuals. Guided by these Values & Principles, we make<br />

every effort to deliver on our mission of improving patient care.<br />

Patient Driven<br />

Surgeon Focus<br />

Striving every day to<br />

improve patient care<br />

Listening to surgeons<br />

and helping them<br />

achieve the best possible<br />

patient outcomes<br />

Innovation<br />

Quality<br />

Constantly developing<br />

breakthrough products,<br />

services, and better<br />

ways of doing business<br />

Maintaining the highest<br />

standard of excellence<br />

in all that we deliver to<br />

internal and external<br />

customers<br />

Education<br />

Partnership<br />

Integrity<br />

Continually educating<br />

and developing<br />

our customers and<br />

employees<br />

Leveraging the insights<br />

of surgeons, the AO,<br />

strategic partners and<br />

our global network<br />

of <strong>Synthes</strong> employees<br />

Acting ethically and<br />

respectfully at all times

<strong>Synthes</strong>. Annual Report <strong>2007</strong>

Content<br />

Company Profile 3<br />

Significant Facts 6<br />

Letter to Shareholders 8<br />

<strong>Business</strong> Report<br />

Management Discussion 13<br />

Regional Highlights 15<br />

Corporate Citizenship<br />

Innovation and Education 23<br />

Employee Structure and Challenges 27<br />

Ethical <strong>Business</strong> Conduct 29<br />

Product Highlights<br />

Trauma. LCP Volar Column Plate 32<br />

Spine. In-Space 34<br />

CMF. MatrixNEURO Cranial Plating System 36<br />

Biomaterials. chronOS Strip 38<br />

Power Tools. Colibri/Small Battery Drive 40<br />

Corporate Governance<br />

Group Structure and Shareholders 44<br />

Capital Structure 45<br />

Board of Directors 46<br />

Group Management Committee 52<br />

Compensation, Shareholdings and Loans 53<br />

Shareholders’ Participation 55<br />

Changes of Control and Defense Measures 57<br />

Auditors 58<br />

Information Policy 59<br />

1

Company Profile<br />

2

<strong>Synthes</strong>. Annual Report <strong>2007</strong><br />

Company Profile<br />

<strong>Synthes</strong>, headquartered in West Chester, PA (USA), is a leading global medical device company, employing over<br />

9,000 people whose mission is to improve patient care around the world. In <strong>2007</strong>, we generated revenues of<br />

US$ 2.8 billion and net earnings of US$ 612.6 million. Over the last 10 years (1997–<strong>2007</strong>) <strong>Synthes</strong> has increased<br />

its revenues from US$ 364.3 million to US$ 2.8 billion, representing a CAGR of 22.4%, including the acquisition<br />

of Stratec Medical in 1999 and Mathys in 2004.<br />

Through its five business units (Trauma, Spine, Cranio-Maxillofacial,<br />

Biomaterials and Power Tools), <strong>Synthes</strong> develops, produces and markets<br />

instruments, implants and biomaterials for the surgical fixation,<br />

correction and regeneration of the human skeleton and its soft tissues.<br />

We operate in product markets with high growth, driven by the<br />

aging population and improvements in technology that allow treating<br />

more patients with better implants.<br />

<strong>Synthes</strong> establishes the foundations for its excellent market position<br />

by continuously developing better solutions. Our goal is to provide<br />

the safest and most advanced implants, instruments and technologies<br />

that ensure reliable operating procedures, rapid recovery and a<br />

pain-free life after surgery. We guarantee high quality, constant innovation<br />

and total concentration on the needs of our customers.<br />

<strong>Synthes</strong> is the world leader in traumatology, ranks among the top<br />

three companies for spinal devices and is at the forefront of the cranio-maxillofacial<br />

business. We are an innovative pioneer in the field<br />

of biomaterials such as resorbable implants and bone graft substitutes,<br />

and have become a leader in non-fusion technologies with our<br />

lumbar and cervical disc replacements.<br />

Global Functional Structure<br />

North America<br />

Asia Pacific<br />

Europe<br />

Latin America,<br />

Middle East and Africa<br />

Traumatology<br />

Spine<br />

Cranio-Maxillofacial (CMF)<br />

Biomaterials<br />

Power Tools<br />

Production<br />

Production<br />

Global services: Finance, Human Resources, Information Technology, Legal, Purchasing, Quality, Regulatory Affairs<br />

3

Company Profile<br />

Our Strategy<br />

For many years we have been following our three-pillar-strategy,<br />

which is closely related to our Values & Principles:<br />

Innovation<br />

<strong>Synthes</strong> has a constant inflow of new and innovative<br />

products that serve a clinical need<br />

for improved patient care.<br />

Sales Force<br />

The expansion of the number of sales people<br />

and services <strong>Synthes</strong> offers by providing its<br />

sales force with best-in-class training that<br />

they bring into operating rooms around the<br />

globe.<br />

Education<br />

Various activities and educational programs<br />

provided by <strong>Synthes</strong> or by partnering organizations<br />

to foster the best treatment for patients.<br />

<strong>Business</strong> Units<br />

Trauma<br />

As the global market leader in Trauma,<br />

<strong>Synthes</strong> offers plates and screws, intramedullary<br />

nails and external fixators to fix and<br />

stabilize all types of fractures of almost all<br />

bones with the ultimate goal of restoring<br />

normal anatomy and physiology.<br />

Spine<br />

<strong>Synthes</strong> is one of the top companies in<br />

Spine. The primary market is the surgical<br />

management of back pain treatment<br />

which includes fusion procedures with<br />

cages, plates and pedicle screw-systems,<br />

but also non-fusion treatments such as<br />

interspinous spacers, vertebroplasty and<br />

disc arthroplasty.<br />

CMF<br />

<strong>Synthes</strong> has a worldwide leading position<br />

in CMF (Cranio-Maxillofacial). Within this<br />

market, <strong>Synthes</strong> offers very low-profile implants<br />

to treat fractures of the skull and<br />

mandible. The portfolio includes products<br />

to reconstruct mandibular misalignments<br />

and deformities caused by accidents.<br />

Biomaterials<br />

The <strong>Synthes</strong> Biomaterials Division develops solutions that complement<br />

Trauma, Spine and CMF divisions with three particular<br />

areas of focus. Firstly the reduction of implant related infections,<br />

such as drug-coated implants. Secondly, increase the stability of<br />

implants in the bone (such as cements) and thirdly, bone graft<br />

substitutes to promote bony fusion. The products are sold through<br />

the sales forces in Trauma, Spine and CMF.<br />

Power Tools<br />

<strong>Synthes</strong> Power Tools are centrally developed and – like Biomaterials<br />

– used and sold in conjunction with the Trauma, Spine and<br />

CMF divisions. <strong>Synthes</strong> has over 30 years of experience in designing<br />

and manufacturing surgical power tools and offers a comprehensive<br />

range of air- and battery driven drill systems, reamers<br />

and saws to meet high demands in orthopaedics, traumatology<br />

and neurosurgery.<br />

4

<strong>Synthes</strong>. Annual Report <strong>2007</strong><br />

Recent Highlights<br />

December <strong>2007</strong><br />

The US FDA (Food and Drug Administration) fully approves the Pro-<br />

Disc ® -C Total Disc Replacement (a) for commercial sale and distribution<br />

in the United States. <strong>Synthes</strong> is the first company to offer both<br />

a lumbar as well as a cervical artificial disc replacement on the US<br />

market. Thereby <strong>Synthes</strong> strengthens its market position in the segment<br />

of spinal motion preservation. Artificial disc replacements constitute<br />

a modern way of treating degenerative disc disease and will<br />

benefit from a shift in treatment paradigm.<br />

a<br />

December <strong>2007</strong><br />

With the acquisition of N Spine, <strong>Synthes</strong> enters the posterior spinal<br />

dynamic stabilization market to treat degenerative disc disease as well<br />

as stenosis. The N Spine rod will be used in conjunction with <strong>Synthes</strong>'<br />

leading pedicle screw product lines Pangea (b) and Click'X (c). The<br />

benefits are its low profile, which offers a minimal-invasive approach<br />

and ease-of-use.<br />

b<br />

October <strong>2007</strong><br />

In Biomaterials, chronOS Strip (d) is cleared for sale by the FDA. This<br />

is the first flexible ceramic bone substitute <strong>Synthes</strong> has in its portfolio.<br />

The easy-to-use new product offers surgeons increased handling<br />

options and leverages two areas of expertise for <strong>Synthes</strong>: osteoconductive<br />

ceramics and resorbable biocompatible polymers.<br />

c<br />

April <strong>2007</strong><br />

Michel Orsinger is appointed CEO. Prior to joining <strong>Synthes</strong> in 2004<br />

as COO, Mr. Orsinger spent 10 years with Novartis in various executive<br />

management positions, most recently as the CEO and President<br />

of OTC Worldwide. He has a track record of leadership positions and<br />

has been instrumental in transforming <strong>Synthes</strong> into a leading global<br />

company.<br />

d<br />

Financial Highlights <strong>2007</strong> vs. 2006<br />

<strong>2007</strong> 2006<br />

Net Sales US$ 2,759.7 million US$ 2,391.6 million<br />

Gross Profit Margin 81.0% 81.9%<br />

Operating Profit Margin 32.8% 31.9%<br />

Net Earnings Margin 22.2% 21.3%<br />

Free Cashflow US$ 602.0 million US$ 343.6 million<br />

Employees at year-end 9,070 8,451<br />

SWX Swiss Exchange / VirtX<br />

Symbol: SYST.VX<br />

Market Capitalization at year-end <strong>2007</strong>: CHF 16,689 m<br />

5

Company Profile<br />

Significant Facts<br />

Sales per region <strong>2007</strong> (US$ millions)<br />

North America<br />

Europe<br />

Asia Pacific<br />

Rest of world<br />

1,721.0<br />

637.3<br />

248.4<br />

153.0<br />

Asia Pacific 9.0%<br />

Rest of World 5.5%<br />

Europe 23.1% North America 62.4%<br />

Operating Expenses (US$ millions)<br />

Selling and Promotion<br />

% of Net Sales<br />

General and Administrative<br />

% of Net Sales<br />

Research and Development *<br />

% of Net Sales<br />

2003 2004 2005 2006 <strong>2007</strong><br />

331.7 491.7 592.6 704.6 802.3<br />

27.0% 27.6% 28.5% 29.5% 29.1%<br />

113.5 191.2 247.8 266.4 294.6<br />

9.2% 10.7% 11.9% 11.1% 10.7%<br />

281.2 109.5 114.8 125.6 148.6<br />

22.9% 6.2% 5.5% 5.3% 5.4%<br />

* 2003 includes US$ 215.0 million IPR&D write-off due to<br />

acquisition of Spine Solutions, Inc. in April 2003.<br />

US$ millions<br />

900<br />

800<br />

700<br />

600<br />

500<br />

400<br />

300<br />

200<br />

100<br />

0<br />

2003 2004 2005 2006 <strong>2007</strong><br />

Selling and<br />

Promotion<br />

General and<br />

Administrative<br />

Research and<br />

Development<br />

Profitability (US$ millions)<br />

Net Sales<br />

Gross Profit Margin<br />

Operating Profit Margin<br />

Net Earnings Margin<br />

2003 2004 2005 2006 <strong>2007</strong><br />

1,229.0 1,779.3 2,078.2 2,391.6 2,759.7<br />

81.1% 78.2% 82.5% 81.9% 81.0%<br />

18.6% 28.4% 31.9% 31.9% 32.8%<br />

6.1% 18.2% 21.0% 21.3% 22.2%<br />

US$ millions<br />

3,000<br />

2,500<br />

2,000<br />

1,500<br />

1,000<br />

500<br />

0<br />

2003 2004 2005 2006 <strong>2007</strong><br />

Net<br />

Sales<br />

Gross<br />

Profit<br />

Operating<br />

Profit<br />

Net<br />

Earnings<br />

6

<strong>Synthes</strong>. Annual Report <strong>2007</strong><br />

FCF and Capital Expenditure (US$ millions)<br />

Free Cashflow<br />

CapEx<br />

2003 2004 2005 2006 <strong>2007</strong><br />

203.3 301.1 337.1 343.6 602.0<br />

122.3 141.3 184.0 190.3 223.1<br />

US$ millions<br />

700<br />

600<br />

500<br />

400<br />

300<br />

200<br />

100<br />

0<br />

2003 2004 2005 2006 <strong>2007</strong><br />

Free<br />

Cashflow<br />

CapEx<br />

Assets <strong>2007</strong> (US$ millions)<br />

Current Assets<br />

Property, Plant & Equipment<br />

Intangible Assets<br />

Goodwill<br />

Other Assets<br />

1,588.4<br />

603.4<br />

1,843.1<br />

1,051.3<br />

101.8<br />

Goodwill 20.3%<br />

Other Assets 2.0%<br />

Current Assets 30.6%<br />

Intangible Assets 35.5%<br />

Property, Plant &<br />

Equipment 11.6%<br />

Liabilities and Equity <strong>2007</strong> (US$ millions)<br />

Current Liabilities<br />

608.7<br />

Long-term Liabilities<br />

493.3<br />

Retained Earnings<br />

1,834.7<br />

Other Equity<br />

2,251.3<br />

Other Equity 43.4%<br />

Current Liabilities 11.7%<br />

Long-term Liabilities 9.5%<br />

Retained Earnings 35.4%<br />

Employees 2003 2004 2005 2006 <strong>2007</strong><br />

Total Employees (at year-end)<br />

4,290 6,711 7,627 8,451 9,070<br />

Change in Employees<br />

13% 56% 14% 11% 7%<br />

Sales Force as % of Total Employees<br />

24% 25% 25% 25% 27%<br />

10,000<br />

8,000<br />

6,000<br />

4,000<br />

2,000<br />

0<br />

2003 2004 2005 2006 <strong>2007</strong><br />

60%<br />

50%<br />

40%<br />

30%<br />

20%<br />

10%<br />

0%<br />

Total<br />

Employees<br />

Sales<br />

Force<br />

Change in<br />

Employees %<br />

7

Letter to Shareholders<br />

Letter to Shareholders<br />

<strong>2007</strong> was another successful year for <strong>Synthes</strong>. We enhanced our leading market position in both Trauma and<br />

Cranio-Maxillofacial specialties. We also acquired N Spine to further strengthen our position in Spine. On an<br />

organizational level, we created new global functions to increase productivity and to gain efficiency as a strategic<br />

response to the changing market environment.<br />

Dear shareholders, employees and friends of <strong>Synthes</strong><br />

We look back with satisfaction on a successful <strong>2007</strong>. It is with great<br />

pleasure that we report net sales of US$ 2.8 billion, representing an<br />

increase of 15.4% versus 2006. All business units contributed to the<br />

success of the <strong>2007</strong> results. The higher-than-market sales growth of<br />

Trauma and CMF both represent a particularly satisfactory achievement<br />

given the large worldwide market share <strong>Synthes</strong> has in these<br />

segments.<br />

Within our Trauma division, we expanded our global product portfolio<br />

in <strong>2007</strong> with the introductions of the Volar Column Distal Radius<br />

Plate System, the Expert Lateral Entry Femoral Recon Nail, the Japanese<br />

Proximal Femoral Nail and further penetration of our LCP systems.<br />

We also implemented several customer-focused programs that<br />

have contributed to our successful year. The first of these programs<br />

is the <strong>Synthes</strong> Resident Program, an online educational platform for<br />

young surgeons in the field of Trauma. <strong>Synthes</strong> also established several<br />

Geriatric Fracture Centers of Excellence in the US this past year<br />

and will continue to expand the program in 2008 worldwide. The<br />

Geriatric program aims to improve the treatment of elderly fracture<br />

patients by developing innovative products for complex fractures,<br />

educating the orthopedic community on the benefits of treating patients<br />

using an interdisciplinary approach, and ultimately establishing<br />

centers which utilize co-managed care and standardized protocols.<br />

Notable activities within Spine in <strong>2007</strong> include the US Food and Drug<br />

Administration’s approval for sale of ProDisc-C and our acquisition of<br />

N Spine. With the approval of ProDisc-C, our product for cervical total<br />

disc replacement, we became the only Spine Company to offer<br />

both lumbar and cervical artificial disc replacement systems. In spite<br />

of the slower than expected initial adoption of this revolutionary technology,<br />

we are confident that artificial disc replacements will prevail<br />

as the preferred treatment option. Our acquisition of N Spine has enhanced<br />

our position within the dynamic stabilization segment of the<br />

lumbar Spinal market by offering an innovative posterior system compatible<br />

with our Click’X and Pangea pedicle screw product lines. We<br />

also look forward to further developing spine technologies with the<br />

addition of the N Spine team to the <strong>Synthes</strong> organization.<br />

Our Cranio-Maxillofacial business outpaced the aggregate global<br />

market through stronger than average growth in each region. Of particular<br />

note was the performance of the neurosurgery segment,<br />

driven by the new MatrixNEURO cranial plating system, and global<br />

success with Patient Specific Implants. In <strong>2007</strong>, the CMF business<br />

group also expanded the content and frequency of specialized technical<br />

educational activities in the Sternal/Chest Wall and Neurotrauma<br />

fields, further establishing <strong>Synthes</strong> as a partner in patient care<br />

worldwide.<br />

8

<strong>Synthes</strong>. Annual Report <strong>2007</strong><br />

Strategic initiatives<br />

<strong>Synthes</strong> continues to make progress with our key global initiatives to<br />

reduce the time-to-market of new product launches, to further optimize<br />

the global supply chain, and to ensure a global product lifecycle<br />

management tool to more efficiently develop and launch new products<br />

across the globe. Our efforts with these key initiatives are critical<br />

to positively position ourselves within the challenges of our everchanging<br />

market environment of shorter product lifecycles and higher<br />

regulatory hurdles for product approvals.<br />

At <strong>Synthes</strong>, the highest professional and ethical standards are essential.<br />

In <strong>2007</strong>, the medical technology industry was subject to significant<br />

governmental scrutiny with regards to the relationship between<br />

companies and their surgeon customers and we continuously review<br />

and reinforce our global compliance guidelines with our employees.<br />

Resident Program in North America will be expanded to other divisions<br />

and to Europe. In Spine, we will leverage the acquisition of N Spine,<br />

but also launch important new additions to the product portfolio.<br />

Finally, we will also utilize new technologies in CMF to expand<br />

our offering to maxillofacial and cardiothoracic surgeons, ear-noseand-throat<br />

and plastic surgeons and also neurosurgeons. These portfolios<br />

will be enhanced with complimentary products from our Biomaterials<br />

and Power Tools divisions.<br />

<strong>Synthes</strong>’ success depends on the skills and commitment of our employees<br />

whose ongoing contribution we deeply appreciate. In particular,<br />

we want to thank you, our shareholders and our other stakeholders<br />

for your continued support and confidence in <strong>Synthes</strong>.<br />

In <strong>2007</strong>, the executive management team was further enhanced with<br />

the transition of Michel Orsinger to President and CEO, the addition<br />

of a global Vice President of Operations and a global Vice President<br />

of Human Resources.<br />

Outlook<br />

We have begun 2008 with high confidence for the continuing success<br />

of our company in delivering on our mission of improving patient<br />

care. The majority of our achievements in <strong>2007</strong> were driven by<br />

our commitment to innovation, education and to the high service level<br />

delivered by our own sales force. Going forward, we will maintain<br />

our special focus on innovation with differentiated products and<br />

growth in all regions where we see yet unrealized potential. We remain<br />

optimistic about the future growth opportunities in all our fields<br />

of activities. Furthermore, we expect our global initiatives to enhance<br />

our efficiency and to help sustain our gross and operating margins.<br />

Hansjörg Wyss<br />

Chairman of the Board<br />

Michel Orsinger<br />

President and CEO<br />

In Trauma, <strong>Synthes</strong> will further strengthen its market position by introducing<br />

several new products. The successfully implemented <strong>Synthes</strong><br />

9

<strong>Business</strong> Report<br />

10

<strong>Synthes</strong>. Annual Report 2006<br />

<strong>Business</strong> Report<br />

Management Discussion 13<br />

Regional Highlights 15<br />

11

<strong>Business</strong> Report. Management Discussion<br />

Patient Driven<br />

Striving every day to<br />

improve patient care<br />

12

<strong>Synthes</strong>. Annual Report <strong>2007</strong><br />

<strong>Business</strong> Report. Management Discussion<br />

<strong>Synthes</strong> once again posted double-digit sales growth of 15.4% in US-Dollars and 12.5% in local currencies.<br />

This performance is a result of our best-in-class products, high service levels and a comprehensive array of educational<br />

activities, which we conducted throughout the world.<br />

North America continued to be the major growth engine for <strong>Synthes</strong>,<br />

with Trauma as the main contributor to this achievement. Outside the<br />

US, performance in Asia Pacific is particularly noteworthy, where in<br />

<strong>2007</strong> we achieved market leadership in the Japanese Trauma market.<br />

China and India have become the fastest growing countries for sales<br />

of <strong>Synthes</strong> products in the emerging Asia markets.<br />

In spite of important investments in research and development spending<br />

as a percentage of sales, we have been able to grow our operating<br />

income by 17.0% in local currencies. Productivity improvement<br />

programs contributed to a reduction in selling and promotion and<br />

general and administrative expenses as a percentage of sales. In addition,<br />

royalty payments to the AO Foundation declined.<br />

In Europe, where competition and pressure on pricing and reimbursement<br />

of our products has increased, we were able to grow our business<br />

significantly with 13.4% local currency growth versus 2006. Latin<br />

America continued with strong sales growth at approximately<br />

19% in local currencies, with particularly strong growth in Spine.<br />

A significant share of our aggregate sales growth (approximately<br />

45%) is attributed to new products providing increased benefits and<br />

products which cover needs previously unmet.<br />

Gross profit margin in <strong>2007</strong> (absent inventory obsolescence expense)<br />

represents a slight improvement over prior year. This is among the<br />

highest in the industry. Our continuous progress in manufacturing efficiency<br />

helped make this development possible despite our expansion<br />

into countries with relatively lower market prices and our inventory<br />

reduction program, which was evident in <strong>2007</strong>.<br />

Net earnings of US$ 612.6 million improved as a percentage of sales<br />

to 22.2% for the year, representing 18.7% growth in local currencies.<br />

Foreign exchange rate differences favorably impacted sales and<br />

earnings by 2.9 and 1.7 percentage points, respectively, in <strong>2007</strong> and<br />

2006. Earnings per share increased by 16.2% in local currencies to<br />

US$ 5.16.<br />

In <strong>2007</strong>, we increased our staffing by 7.3% to 9,070 employees, with<br />

the majority of new hires in our sales organization. Our global sales<br />

force now consists of approximately 2,400 highly educated and trained<br />

sales personnel.<br />

13

<strong>Business</strong> Review. Regional Highlights<br />

Surgeon Focus<br />

Listening to surgeons<br />

and helping them<br />

achieve the best possible<br />

patient outcomes<br />

14

<strong>Synthes</strong>. Annual Report <strong>2007</strong><br />

<strong>Business</strong> Report. Regional Highlights<br />

In <strong>2007</strong>, <strong>Synthes</strong> achieved considerable growth in all regions. Sales in North America rose to US$ 1.7 billion<br />

(+ US$ 195.9 million) with Trauma and CMF performing particularly well and Spine contributing substantially.<br />

In Europe, <strong>Synthes</strong> increased its sales by 13.4% (in local currencies) to US$ 637.3 million and achieved market<br />

leadership in its three major divisions. Countries in Asia Pacific showed double-digit sales growth rates except<br />

for Japan. In Latin America, sales increased by almost 19%.<br />

North America<br />

In North America we achieved US$ 1.7 billion or 62.4% of our <strong>2007</strong><br />

consolidated net sales. Once again, this region was our biggest<br />

growth contributor with a growth of 12.6% over the prior year in local<br />

currencies. This was mostly due to our Trauma and CMF divisions<br />

where we outgrew the market and gained share despite our marketleading<br />

position.<br />

In Trauma, the Volar Column Distal Radius Plate System and the Expert<br />

Lateral Entry Femoral Recon Nail Systems were two notable systems<br />

released in <strong>2007</strong>. Regional performance was mainly fueled by further<br />

penetration and portfolio expansion of our LCP (Locking Compression<br />

Plate) systems, along with the performance from our Trochanteric<br />

Fixation Nail (TFN) and our Retrograde/Antegrade Femoral Nail<br />

(RAFN) intramedullary nailing systems.<br />

Other important accomplishments within the Trauma division in <strong>2007</strong><br />

included our successful implementation of the <strong>Synthes</strong> Resident Program<br />

in the US. This program is both an online training center and a<br />

series of workshops offered by our sales force directly to young trauma<br />

surgeons who can benefit from education by the market leader<br />

and earn credit points that can later be redeemed for textbooks. By<br />

the end of <strong>2007</strong>, more than 70% of all US Residents were already<br />

enrolled in the <strong>Synthes</strong> Resident Program. This program will be extended<br />

to Spine and CMF in the coming year.<br />

Notable new product launches in our Spine division in <strong>2007</strong> include<br />

Antegra, a new plating system used to stabilize degenerated lumbar<br />

spine segments anteriorly, and Synapse, a comprehensive system of<br />

instruments and implants designed for posterior stabilization of the<br />

upper spine. The continued rollout of SynFix-LR contributed strongly<br />

to our North American Spine growth this past year.<br />

Our acquisition of the N Spine organization in December was a highlight<br />

for our Spine division. N Spine’s unique and proprietary technology<br />

will allow us to enter the dynamic stabilization market, one of<br />

the fastest growing segments of non-fusion technology in Spine.<br />

Since the launch of ProDisc-L in the fall of 2006, there have been<br />

more than 1,000 surgeries in the US in <strong>2007</strong>, which resulted in an<br />

even lower complication rate than during the FDA study. This is a testament<br />

to our training program, and a similar surgeon training strategy<br />

will be applied to ProDisc-C which was approved for sale by the<br />

FDA at the end of <strong>2007</strong>. The major challenge has been and continues<br />

to be the adequate reimbursement by insurance companies, but we<br />

continue to focus on this area and have had success in <strong>2007</strong> with more<br />

insurance companies covering the cost of treatment with ProDisc-L. It<br />

is with confidence that we look into a promising 2008 for Spine.<br />

In our CMF division, the MatrixNEURO system was a strong growth<br />

driver this past year. This system was fully released in the US and will<br />

be expanded to other indications in 2008. It complemented continued<br />

growth with our Patient Specific Implants (PSI). CMF also grew<br />

through increased clinical treatment with its sternal fixation and reconstruction<br />

system.<br />

Another highlight of <strong>2007</strong> was the continued expansion of the <strong>Synthes</strong><br />

Inventory Management Solution (SIMS). By the end of <strong>2007</strong>, over<br />

80% of our US volume is handled through SIMS, which is comprised<br />

of a storage system as well as a computerized solution to make reorders<br />

as easy as possible for the hospital.<br />

In the US we have a very streamlined training concept in place for our<br />

surgeons through our partnership with AO Foundation. We also complement<br />

AO educational activities with specialized courses sponsored<br />

by <strong>Synthes</strong>. A larger number of AO courses was offered in the<br />

North America in <strong>2007</strong>, e.g. the first AO cadaver course in CMF and<br />

other more specialized courses. We will continue to expand on this<br />

fruitful concept and our collaboration with the AO to remain the number<br />

one provider of excellent education and scientific platforms.<br />

Overall, we are dedicated to increasing our high-level of service to<br />

customers by offering total customer solutions in all our activities, including<br />

technical service, inventory management and training.<br />

Europe<br />

Despite an unusually warm winter with fewer fractures associated<br />

with skiing and other accidents typical of snow and icy conditions,<br />

we achieved 13.4% growth in local currencies in Europe. The mild<br />

temperatures affected sales in the traditional winter sport countries<br />

of Germany, Switzerland and Austria. The relatively slow start to the<br />

year was made up for with above average sales performance after<br />

the first quarter.<br />

15

<strong>Business</strong> Review. Regional Highlights<br />

<strong>2007</strong> is the first year in which we achieved market leadership in all<br />

three major divisions, Trauma, Spine and CMF. Continuous expansion<br />

of the sales force and far reaching educational activities have been<br />

one of the largest contributing factors to success in the past year. During<br />

the latter half of <strong>2007</strong> we were able to further strengthen our<br />

product portfolio with new product introductions. The high standard<br />

of our sales force has increased our presence in the operating rooms<br />

and also our ability to train OR staff on the use of our products to<br />

help improve patient outcomes.<br />

One of our goals has been to overcome the changing environments<br />

in our major European markets. Price increases have only been possible<br />

through new product introductions and holding prices of existing<br />

products at previous levels has only been possible through the<br />

strengthening of our value added services. The roll-out of the electronic<br />

<strong>Synthes</strong> Inventory Management Solution (eSIMS) across the major<br />

markets such as the United Kingdom and Germany has further<br />

strengthened our presence at the hospital level. Further, the change<br />

in the reimbursement system in France (TIPS) has given us the opportunity<br />

to launch new products in the local Trauma market.<br />

Once again, we have outperformed market growth in all divisions and<br />

have gained market share throughout Europe. A strong performance<br />

in the United Kingdom, good performance in the Eastern European<br />

markets and the countries on the Mediterranean rim have made up<br />

for the below average first quarter. The completion of the Expert Nail<br />

product lines, the introduction of the LCP DHS and LCP DHS Blade<br />

and the introduction of the EPOCA shoulder prosthesis have driven<br />

growth in the Trauma division.<br />

Our Spine sales have been strengthened through the successful introduction<br />

of In-Space and Vertecem and the line additions to products<br />

launched in 2006, such as Pangea. The introduction of a milling<br />

system has vastly improved the surgical procedure for Prodisc-C.<br />

In <strong>2007</strong>, our CMF division achieved the highest growth percentage.<br />

The introduction of the MatrixNEURO system was the main driver behind<br />

this positive performance while the launch of the Sternal Closure<br />

systems and the improvement in the supply chain of the Patient<br />

Specific Implant (PSI) have also contributed to the strong CMF growth.<br />

The region of Africa and the Middle East has also shown increased<br />

sales and stability. Since the Middle East markets are strongly influenced<br />

by tender activity, much of our sales in <strong>2007</strong> stem from tenders<br />

won in 2006. With the tenders awarded in <strong>2007</strong> for delivery in<br />

2008, it is clear that in this region we have gained significant market<br />

share as well. A re-organization of our distribution arrangements in<br />

large markets, such as Turkey and Greece, has been completed and<br />

will contribute to strong growth in the coming years.<br />

Going forward, we will continue our drive to expand our sales force<br />

and increase our educational opportunities. It is important to support<br />

this team with a strong middle management layer which our Human<br />

Resources group is currently establishing as a high priority. New product<br />

introductions will continue to support our growth in 2008. In<br />

order to get closer to the needs of our surgeons and their patients,<br />

we have established new Innovation Centers in Europe with the most<br />

recent being the Innovation Center in Salzburg, Austria, opened in<br />

October of <strong>2007</strong>. Situated in the Hansjörg Wyss House of the Paracelsus<br />

University, this Center is ideally located to offer surgeons the<br />

platform to work closely with our engineers in order to bring new<br />

products and new surgical solutions to the market.<br />

Asia Pacific<br />

We are pleased with our <strong>2007</strong> results in Asia Pacific. Although our<br />

growth was stymied by ongoing price cuts in Japan which resulted in<br />

a sales growth rate of 8.7% (in local currencies) for the full year, the<br />

rest of the region showed a double-digit sales growth rate as well as<br />

a double digit increase in volume.<br />

Prices in Japan are completely controlled by the Ministry of Health,<br />

Labor and Welfare (MHLW). The MHLW implemented two price cuts<br />

in <strong>2007</strong> (January and April) that affected our Trauma result in Japan<br />

quite significantly (10%–15%). Nevertheless our achievement in Japan<br />

continues to be strong: the market share of <strong>Synthes</strong> was expanded<br />

in all divisions and we are now the market leader in Trauma.<br />

Exceptional growth was achieved in both China and India. The challenge<br />

in these countries lies within the supply of service through the<br />

education of our employees and our distributors, and also in our competition<br />

with locally produced products.<br />

16

<strong>Synthes</strong>. Annual Report <strong>2007</strong><br />

Innovation<br />

Constantly developing<br />

breakthrough products,<br />

services, and better<br />

ways of doing business<br />

17

<strong>Business</strong> Review. Regional Highlights<br />

Quality<br />

Maintaining the highest<br />

standard of excellence<br />

in all that we deliver to<br />

internal and external<br />

customers<br />

18

<strong>Synthes</strong>. Annual Report <strong>2007</strong><br />

A milestone for the region was the inauguration of the CMF business<br />

in India. This was done in conjunction with an AO course and a <strong>Synthes</strong><br />

symposium on sub-condylar fractures at the International Congress<br />

for Oral and Maxillofacial Surgery in Bangalore, where 800 surgeons<br />

attended. These events gave our CMF division a real jump-start and<br />

we are looking forward to adding people, service and products to<br />

serve our CMF customers in India.<br />

Latin America<br />

Once again our result in Latin America was outstanding. In local currencies,<br />

sales in this region grew by almost 19%. This result was primarily<br />

due to our strong performance in Brazil and Colombia. There<br />

is still great potential in Latin America because of the large population,<br />

continued economic growth and the relative political stability of<br />

the region as a whole.<br />

Another highlight was our launch in the first half of <strong>2007</strong> of the PFNA<br />

Japan (Proximal Femoral Nail Anti-rotational nail) which was a great<br />

success. This is our first product which is specifically adapted for the<br />

unique qualities of the Asian femoral anatomy; it is an intramedullary<br />

nail used to treat proximal fractures of the femur.<br />

The AO has created a dedicated group of surgeons to consider Asiaspecific<br />

training and product needs. With the establishment of the<br />

AO Asia Pacific Trauma Expert Group, we look forward to an expanded<br />

offering of dedicated Asia-specific product lines with the addition<br />

of tibia plates, distal radius plates and an orthognathic CMF system.<br />

In order to more appropriately react to market needs, we have created<br />

two additional sub-regions that are led by separate <strong>Synthes</strong> managers<br />

(North-Asia and South-East Asia). This should allow us to train<br />

the people in our sales force, along with our distributors’ employees<br />

in an equally professional way. We will also improve our response time<br />

by increasing the number of inventory holding offices, as well as accelerating<br />

our rate of new product introduction. New offices with<br />

better warehousing capabilities as well as training facilities have already<br />

been opened in Singapore, India, Malaysia, China and Australia.<br />

Our goal is clearly to expand our activities in this important region.<br />

Apart from the launch of new products and more educational activities,<br />

we will also focus on individual country-specific challenges. One<br />

such challenge is to establish better reimbursement environments in<br />

countries where this is not yet the case (such as India), and also to<br />

provide adequate solutions for an ever increasing number of people<br />

with osteoporosis in the emerging markets. This will be a major task<br />

for us for the coming years.<br />

Six countries in Latin America have <strong>Synthes</strong> sales organizations; nine<br />

other countries are covered by distributorship agreements, and two<br />

distributors service the Caribbean region.<br />

The Spine business unit has shown the most growth as the result of<br />

new product introductions combined with close cooperation with AO<br />

Spine Latin America. Power Tools also showed exceptional growth<br />

due to specialized training of the sales force and the support from a<br />

dedicated regional repair facility based in Costa Rica.<br />

Our results in some countries are influenced by our long-term strategy<br />

of sustainable, ethical business operations. <strong>Synthes</strong> has a clear policy<br />

that does not allow for kickbacks and other unprincipled business<br />

practices and we will always operate according to these principles.<br />

Apart from the increase in our sales force to keep up with the increased<br />

demand, we now have an excellent training organization in place.<br />

It allows for our own trainers to train other local trainers and make<br />

sure that product and technical knowledge is distributed evenly<br />

among our sales people and surgeons.<br />

Our relationship with the AO Foundation continued to be very strong.<br />

With their help almost 2,500 surgeons have been trained in over 50<br />

courses in <strong>2007</strong>. We are also complementing AO courses with <strong>Synthes</strong>-courses<br />

that are more technology and new product oriented.<br />

We expect this region to continue to grow at a substantially higher<br />

rate than more mature markets. In addition, we expect to increase<br />

market share as a result of the training programs mentioned above,<br />

combined with other initiatives that improve the level of service and<br />

overall efficiency of our Latin American operations.<br />

19

Corporate Citizenship<br />

20

<strong>Synthes</strong>. Annual Report <strong>2007</strong><br />

Corporate Citizenship<br />

Innovation and Education 23<br />

Employee Structure and Challenges 27<br />

Ethical <strong>Business</strong> Conduct 29<br />

21

Corporate Citizenship. Innovation and Education<br />

Education<br />

Continually educating<br />

and developing<br />

our customers and<br />

employees<br />

22

<strong>Synthes</strong>. Annual Report <strong>2007</strong><br />

Corporate Citizenship. Innovation and Education<br />

Innovation and education have always been main pillars of <strong>Synthes</strong>' strategy and will always be so in the future.<br />

Innovations by <strong>Synthes</strong> are always based on clinical problems. Our product development centers and<br />

innovation task forces allow us to respond to the increasing demand for innovative solutions. <strong>Synthes</strong>’ ongoing<br />

commitment to education permeates all aspects of our interaction with surgeons and OR personnel. In <strong>2007</strong>,<br />

several of our educational initiatives were launched or further developed.<br />

In <strong>2007</strong>, as in the past, clinical problems were the engine behind<br />

<strong>Synthes</strong>' innovations. Perpetual innovation is reflected in an extensive<br />

pipeline of ideas and in numerous new solutions for clinical problems.<br />

<strong>Synthes</strong> is determined to proactively search for clinical challenges and<br />

tries to solve them, in close cooperation with our clinical and scientific<br />

partners.<br />

Surgical treatment of musculoskeletal diseases<br />

Over the last 50 years, the treatment of musculoskeletal disorders has<br />

evolved and dramatically improved the clinical outcome and patients'<br />

lives. Innovations by <strong>Synthes</strong> are always based on scientific findings,<br />

clinical experience and patient needs. Therefore, our engineers and<br />

project team members understand the clinical needs and are aware<br />

of today’s limits in treating musculoskeletal disorders. To ensure the<br />

involvement of the best leaders in all these disciplines, our engineers<br />

and designers are part of one of the largest worldwide medical and<br />

scientific networks.<br />

The surgical treatment of musculoskeletal diseases is no longer a pioneering<br />

effort, as it has evolved into a well accepted and proven treatment<br />

therapy. This transition was only possible, with the use of standardized<br />

treatment methods and high quality products which work<br />

well in the hands of the majority of trained surgeons.<br />

Today, the needs for innovative solutions have increased. The reason<br />

for this growth, on one side, is the longer lifespan, patient expectation<br />

and the specialization of the surgical professionals. On the other<br />

side, new technologies in the field of materials, biomaterials, diagnostics<br />

and visualization are very promising tools for improving the<br />

surgical treatment.<br />

Development teams located globally<br />

In <strong>2007</strong>, <strong>Synthes</strong> reacted to the increased need for innovation by substantially<br />

extending our development resources, especially in the early<br />

stages of emerging technologies and new treatment methods. To<br />

understand the needs of our local surgical partners, the locations of<br />

our development teams are spread globally. By doing so, we can keep<br />

our focus and dedication as a competent and pro-active partner for<br />

the medical community.<br />

On the one hand, we have dedicated product development centers<br />

for all our divisions, both in the US and in Europe. Engineers and business<br />

people in these organizations make sure that the right innovations<br />

reach the right surgeons at the right time.<br />

On the other hand, to further maintain this awareness and to be even<br />

closer to the real surgical environment, some of <strong>Synthes</strong>' project<br />

teams are physically located at medical centers and at universities.<br />

The resulting interdisciplinary collaboration is fast-paced and very<br />

effective in developing innovative solutions for clinical problems yet<br />

unsolved.<br />

From <strong>Synthes</strong>’ history we have learned that innovations do not end<br />

with the development of a product. Evaluating the clinical results and<br />

proactively exchanging those results with our clinical network are necessary<br />

to be able to validate new implants, instruments, or surgical<br />

techniques. This process ensures that an innovation fulfills the high<br />

standard of a <strong>Synthes</strong> product. For any new and innovative surgical<br />

technique or product, extensive educational programs for surgeons<br />

and OR personnel are key elements in these product releases.<br />

Educational offers for surgeons and OR staff<br />

<strong>Synthes</strong> has always placed a very strong emphasis on educating surgeons<br />

and operating room personnel in a way that compliments the<br />

well-known and highly respected tradition of AO education activities.<br />

During its 50-year history, the AO has developed effective channels<br />

for educating surgeons and OR personnel on AO goals, principles,<br />

and techniques. The AO emphasis on education as a key pillar of its<br />

success made it an early ingredient of the <strong>Synthes</strong> culture and has<br />

now become a major reason for <strong>Synthes</strong>’ success and excellent<br />

reputation.<br />

<strong>Synthes</strong>’ ongoing commitment to education permeates all aspects of<br />

our interaction with surgeons and OR personnel. The most common<br />

form of education that <strong>Synthes</strong> offers can be found on a daily basis<br />

in operating rooms worldwide as highly trained <strong>Synthes</strong> sales consultants<br />

provide valuable technical expertise to the surgeons and OR<br />

staff who use their products. <strong>Synthes</strong> also provides more refined and<br />

more formalized education activities and events, as well as web-based<br />

resources, fellowships, and other opportunities for surgeons to<br />

observe and practice new technologies.<br />

<strong>Synthes</strong> Resident Program to be expanded<br />

Several of <strong>Synthes</strong>’ educational initiatives originated in the United<br />

23

Corporate Citizenship. Innovation and Education<br />

States, and they are now spreading to other areas of the world. An<br />

example is the <strong>Synthes</strong> Resident Program (SRP), a comprehensive educational<br />

program for surgical residents in the United States to enhance<br />

the learning they receive at their teaching institutions.<br />

Introduced in early <strong>2007</strong>, the SRP features technique-specific courses<br />

that allow orthopaedic residents the opportunity to practice and<br />

review their fracture fixation skills. The main element of the program<br />

is a web site that provides on-line courses and resources, including<br />

interactive simulated surgical procedures. The local <strong>Synthes</strong> sales consultant<br />

is actively involved in the SRP, conducting hands-on workshops<br />

in the hospitals with the residents.<br />

Residents who participate in the SRP earn “points” in recognition of<br />

their participation in both the on-line and live learning activities. These<br />

points are used toward the acquisition of medical textbooks that<br />

are a valuable resource that they can use for their entire medical career.<br />

The SRP has been quite well received, with 90% of American<br />

orthopaedic residents utilizing the program. The SRP will be expanded<br />

to <strong>Synthes</strong> Spine and <strong>Synthes</strong> CMF, as well as into the European<br />

and Latin American markets in 2008.<br />

focused on surgical access and less invasive surgical techniques featuring<br />

<strong>Synthes</strong> Spine products.<br />

<strong>Synthes</strong> CMF provides programs consistent with <strong>Synthes</strong>’ commitment<br />

to education. Workshops and courses for neurosurgeons and<br />

cardiothoracic surgeons were conducted in <strong>2007</strong> to educate surgeons<br />

on new <strong>Synthes</strong> products and technologies which are not in the<br />

standard AO product portfolio.<br />

On-line course offerings for OR personnel<br />

Education for operating room personnel (ORP) has been one of <strong>Synthes</strong>’<br />

most well-known attributes, with thousands of nurses, technicians,<br />

and other ORP being educated by local sales consultants and<br />

at workshops and courses worldwide. In <strong>2007</strong>, <strong>Synthes</strong> continued its<br />

tradition of supporting this important part of the surgical team by enhancing<br />

its on-line course offering. These courses enable ORP to learn<br />

and practice fracture fixation techniques and to become familiar<br />

with the instruments and implants using interactive simulation technology.<br />

Participants earn continuing education credit for these online<br />

courses without the need to travel or take time away from their<br />

busy work schedules.<br />

Training in new technologies<br />

Another form of education offered by <strong>Synthes</strong> is the Advanced Technology<br />

Symposia. These Symposia, focused on new technologies that<br />

have not yet been included in the AO Education curriculum, are designed<br />

to give participants hands-on experience with new <strong>Synthes</strong><br />

products. Surgeons who attend this 1-day course, which is conducted<br />

locally in their area, are given the opportunity to be briefed on the<br />

new technology by surgeon experts and to practice the new products<br />

on plastic bones or cadaver specimens. Hundreds of these courses<br />

were conducted world wide in <strong>2007</strong> for all <strong>Synthes</strong> specialties.<br />

Consistent with the Advanced Technology Symposia in <strong>2007</strong> was the<br />

focus on surgeon training for ProDisc-L. Spine surgeons were trained<br />

in small forums allowing for highly individualized and interactive training.<br />

These one-and-a-half day forums featured lecture presentations,<br />

in-depth review of surgical cases (provided by the participants),<br />

hands-on training on cadaver specimens, and observation of a live<br />

ProDisc surgical procedure via interactive video. This intensive ProDisc<br />

training was usually preceded by other <strong>Synthes</strong> surgeon courses that<br />

Finally, <strong>Synthes</strong> participates in numerous professional society meetings<br />

around the world, where we sponsor hands-on learning activities<br />

for the meeting participants. Professional societies appreciate<br />

<strong>Synthes</strong>’ unique commitment to education and they have learned to<br />

expect <strong>Synthes</strong> to deliver the finest quality education for their members.<br />

<strong>2007</strong> was no exception to this trend, as <strong>Synthes</strong> provided education<br />

at society meetings for all major surgeon and ORP specialties<br />

that we serve.<br />

<strong>Synthes</strong>’ commitment to education is without equal in the markets<br />

we serve. In <strong>2007</strong>, <strong>Synthes</strong> conducted over 1,600 courses worldwide,<br />

with over 30,000 participants. This effort, combined with the<br />

highly regarded courses offered by the AO, is a remarkable testimony<br />

to the importance of education within the <strong>Synthes</strong> core values and<br />

principles.<br />

24

<strong>Synthes</strong>. Annual Report <strong>2007</strong><br />

Activities <strong>2007</strong> (1,540)<br />

Latin America 4%<br />

Asia Pacific 5%<br />

North America 13%<br />

Europe 78%<br />

Participants <strong>2007</strong> (34,219)<br />

Asia Pacific 19%<br />

Latin America 5% North America 6%<br />

Europe 70%<br />

25

Corporate Citizenship. Employee Structure and Challenges<br />

Partnership<br />

Leveraging the insights<br />

of surgeons, the AO,<br />

strategic partners and<br />

our global network<br />

of <strong>Synthes</strong> employees<br />

26

<strong>Synthes</strong>. Annual Report <strong>2007</strong><br />

Corporate Citizenship. Employee Structure and Challenges<br />

On December 31, <strong>2007</strong> <strong>Synthes</strong>, Inc. employed more than 9,000 employees worldwide. With targeted programs,<br />

<strong>Synthes</strong> has continued to expand its workforce to support its strategic priorities in the areas of Product<br />

Development and Sales. <strong>Synthes</strong> is focused on attracting, retaining and developing the best talents in the industry<br />

and on fostering the individual potential of all its employees through continuing education, job rotation,<br />

job enrichment and empowerment.<br />

During <strong>2007</strong> <strong>Synthes</strong> grew its global headcount by more than 7%.<br />

As of December 31, <strong>2007</strong>, <strong>Synthes</strong> employed 9,070 staff in about 40<br />

countries around the world. Globally, the alignment to our strategy<br />

of sales consultant expansion and the delivery of superior technical<br />

support and service led to a 15% increase in our Field Sales organization.<br />

The continuing focus on operational efficiencies such as the<br />

introduction of Lean Manufacturing and Value Stream Mapping allowed<br />

our global Operations group to support the volume resulting<br />

from our sales growth with minimal additional headcount. Our ongoing<br />

expansion in the strategic growth markets of the Asia Pacific<br />

and Latin America regions resulted in double-digit growth in employees<br />

in those locations.<br />

Structure of <strong>Synthes</strong>’ global workforce in %<br />

Other professionals 21%<br />

Manufacturing/<br />

Operations 43%<br />

Product Development 9%<br />

Sales 27%<br />

In the prospect of further global expansion our aim is to offer attractive<br />

opportunities for ambitious and highly skilled individuals who want<br />

to realize their potential in the fields of applied science, engineering,<br />

technical operations, manufacturing, sales and business management.<br />

To maintain a leading position, we must continue to attract,<br />

retain and develop the best talents in the industry. It is of utmost importance<br />

that our talent pool reflects the diverse structure of our business<br />

both now and for the future.<br />

Our global New Employee Orientation program is designed for the<br />

quick integration of new employees, providing them with an understanding<br />

of the company’s heritage, global course, and the values<br />

and principles we will maintain in reaching our goals. This ensures<br />

that new employees quickly understand what contribution they make<br />

to the development of our products and services.<br />

Enhancing global understanding<br />

To support the global development of <strong>Synthes</strong>, we have, and will continue,<br />

to increase our investment in the number of employees active<br />

in our international assignment program. As part of our ongoing efforts<br />

to build and share knowledge, drive innovation and refine our<br />

global business processes, the program supports employees on both<br />

short and long-term assignments to <strong>Synthes</strong> operations around the<br />

world. During <strong>2007</strong> the number of employees on assignment grew<br />

by more than 25%.<br />

At our many sites around the world, we actively strive to maintain an<br />

exciting and modern working environment that makes internal<br />

growth and development a priority. Our human resources policy is<br />

centered around fostering the individual potential of employees<br />

through continuing education and development programs to help<br />

them reconcile career and private goals. Our ambitious efforts in these<br />

areas make us an attractive employer worldwide.<br />

As an organization, <strong>Synthes</strong> understands that our success is the result<br />

of highly talented, motivated and trained individuals coming together<br />

with a common purpose. We maintain our commitment to<br />

their growth, well-being and success.<br />

Attracting and retaining talents<br />

It remains a priority at <strong>Synthes</strong> to attract young talent to the organization.<br />

We are expanding our partnerships with some of the world’s<br />

leading business schools to bring recent graduates to the company.<br />

Through a structured MBA recruitment and development initiative,<br />

individuals experience a 24-month rotational development program<br />

that equips them with experience and insights across major disciplines<br />

within the company.<br />

27

Corporate Citizenship. Ethical <strong>Business</strong> Conduct<br />

Integrity<br />

Acting ethically and<br />

respectfully at all times<br />

28

<strong>Synthes</strong>. Annual Report <strong>2007</strong><br />

Corporate Citizenship. Ethical <strong>Business</strong> Conduct<br />

Ethical behavior is the cornerstone of how <strong>Synthes</strong> does business. Our Global Code of <strong>Business</strong> Conduct and<br />

Ethics guides our, daily decisions and interactions that define how we treat and do business with our customers,<br />

shareholders, suppliers, stakeholders, partners, and each other. The corresponding Compliance program<br />

ensures that business practices and decisions are in line with our ethical values.<br />

At <strong>Synthes</strong> we value the trust and respect of our patients, customers,<br />

and of the medical community. We believe that our reputation is our<br />

greatest asset; an important and integral part of our <strong>Synthes</strong> brand.<br />

To maintain our reputation, we are dedicated to fairness, dignity and<br />

respect, to open and honest relationships with our customers, affiliated<br />

physicians and business partners, to the responsible and efficient<br />

use of our assets. These are keys to our mission as a business, and<br />

are central responsibilities for our employees.<br />

A guide to <strong>Synthes</strong>’ global standards of ethics and<br />

regulatory compliance<br />

Striving to operate with the utmost integrity has long been integral<br />

to our success. Our Global Code of <strong>Business</strong> Conduct and Ethics provides<br />

us with a single, company-wide statement and with an ethical<br />

and behavioral framework to guide our actions. Organized into six<br />

broad principles, our Global Code guides our actions across all of our<br />

activities. It elaborates on aspects such as the responsibility of the individual<br />

employee and the relationship among our employees; the relationships<br />

with our customers, vendors, suppliers and other contractors;<br />

as well as with regulators, communities and competitors.<br />

Whenever we encounter ethical issues, our employees are required<br />

to take personal responsibility to respond in a manner that reflects<br />

the shared values promoted by the Global Code of <strong>Business</strong> Conduct<br />

and Ethics. Through their contracts with us, we require our distributors<br />

and similarly-situated business partners to join us in these principles<br />

as well.<br />

From guidelines to action<br />

To assure ethical or legal compliance and to support our Global Code,<br />

we have developed our corporate compliance program, a system of<br />

standards and procedures, education and training, communication<br />

efforts, monitoring techniques, employee incentives and policy enforcement<br />

designed to facilitate consistent, company-wide adherence<br />

to our Global Code and other standards.<br />

In order to obtain the legal benefits of good corporate citizenship,<br />

we have also designed our corporate compliance program to satisfy<br />

defined government and industry standards for effective compliance<br />

programs around the world. These standards include the United<br />

States Government’s Sentencing Commission Guidelines, applicable<br />

provisions include the Swiss Code of Obligations, the Australian Standard<br />

- 3806-1998 (Compliance Programs), the Organization for Economic<br />

Cooperation and Development’s Guidelines for Multinational<br />

Enterprises, and the International Organization for Standardization’s<br />

standards for quality management systems. With all the above initiatives,<br />

we feel that <strong>Synthes</strong> has reaffirmed and strengthened its commitment<br />

to strong Ethical <strong>Business</strong> Conduct practices throughout the<br />

organization.<br />

To achieve its goals, our program is organized<br />

around seven basic functions:<br />

1. We have assigned oversight responsibility to our Chief Compliance<br />

Officer, and have provided him with the authority, independence<br />

and resources to implement an effective compliance function.<br />

Our Chief Compliance Officer reports directly to the Chairman of<br />

our Board of Directors and to the Audit Committee of our Board.<br />

2. We have established and continue to develop compliance standards<br />

and procedures that are designed to effectively prevent, detect<br />

and address instances of ethical and legal non-compliance.<br />

These standards include appropriate standards and procedures relevant<br />

to each country in which we operate our business.<br />

3. In conjunction with our Legal, Human Resources and Training Departments,<br />

we design and regularly conduct employee training<br />

programs.<br />

4. We regularly encourage communication between our employees<br />

and those persons who can best answer their questions or concerns.<br />

5. We monitor the compliance of business operations, and audit specific<br />

areas of potential compliance risk, to ensure adherence to<br />

compliance-related standards and procedures.<br />

6. We promote and enforce our standards and procedures through<br />

providing employees with incentives to comply, and by applying<br />

consistent and effective discipline when non-compliance occurs.<br />

7. We review potential instances of non-compliance promptly and<br />

appropriately, and responding appropriately. All investigations are<br />

performed by or under the supervision of our Chief Compliance<br />

Officer or our Legal Department.<br />

29

Product Highlights<br />

30

<strong>Synthes</strong>. Annual Report <strong>2007</strong><br />

Product Highlights<br />

Trauma. LCP Volar Column Plate 32<br />

Spine. In-Space 34<br />

CMF. MatrixNEURO Cranial Plating System 36<br />

Biomaterials. chronOS Strip 38<br />

Power Tools. Colibri/Small Battery Drive 40<br />

31

Product Highlights. Trauma<br />

Trauma. LCP Volar Column Plate<br />

The Locking Compression Plate (LCP) Distal Radius System offers 28 individual locking compression plates to manage<br />

every wrist injury pattern that requires surgical intervention. It consists of dorsal and volar plates for fractures<br />

and osteotomies of the wrist, i.e. the distal radius. The LCP Volar Column Distal Radius Plate, a recent addition to<br />

the successful product line, provides extra advantages which strengthen our leading position with this versatile product<br />

line.<br />

Today’s trauma surgeon is faced with an increasing number of complex<br />

injuries. The situation is all the more challenging given that patients<br />

have higher expectations of making a quick and complete recovery.<br />

Further, an aging population means poor bone quality in many<br />

cases and a steady increase in fracture incidences.<br />

Fractures of the wrist, i.e. the distal radius, occur more frequently<br />

than any other single fracture in humans. A fall on an outstretched<br />

hand is the most common mechanism of injury and its incidence is<br />

increasing as people grow older and stay active longer. While nondisplaced<br />

fractures can still be treated conservatively, displaced fractures<br />

usually require active intervention.<br />

Locking plates as new standard<br />

Historically, that intervention has included a combination of closedreduction<br />

and casting, percutaneous pinning and casting, external fixation,<br />

and non-locking plate and screw fixation. Treatment of the<br />

more complex fracture patterns was usually managed with either external<br />

fixation or non-locking plates and screws.<br />

With the advent of locked plating, open reduction and internal fixation<br />

with locking plates and screws were shown to have short-term<br />

advantages over external fixation in these complex fractures. Postoperative<br />

care was less complicated when using internal locking plates<br />

and screws. These advantages have resulted in this treatment method<br />

becoming the new standard of care for distal radius fractures.<br />

Anatomically contoured volar distal radius plates<br />

<strong>Synthes</strong> released the LCP Distal Radius System to the market in early<br />

2004. The LCP Volar Column Distal Radius Plate was released in <strong>2007</strong><br />

to compliment the existing product line. The product offering includes<br />

a total of twelve new Volar Column plates that provide the surgeon<br />

with many options to treat a wide variety of distal radius fracture<br />

patterns.<br />

Three Column Theory<br />

Since Rikli and Regazzoni have shown the majority of the axial load<br />

transmitted through the wrist is concentrated on the intermediate<br />

column, the new Volar Column Distal Radius Plate was designed to<br />

provide more distal buttressing capability and focus sufficient locking<br />

screw options into the intermediate column. At the same time, additional<br />

locking screw fixation options are also directed into the radial<br />

styloid. The remainder of the locking screw holes are evenly distributed<br />

across the distal radius to ensure that there are sufficient locking<br />

screw options to address almost any fracture pattern.<br />

The LCP combination holes in the shaft of the plate allow for either<br />

compression or angular stability. Surgeons can decide intraoperatively<br />

on the best strategy for treating the fracture. In the case of simple<br />

fractures, the system permits compression with standard screws<br />

when primary healing is desired. In more complex fractures with significant<br />

bone defects or in patients with poor bone quality, locking<br />

screws can be locked into the plate to provide stable fracture fixation<br />

independent of bone quality. Locking Screws increase stability, minimize<br />

the risk of the screws stripping in bone, and allow for secondary<br />

healing. The increased stability permits immediate mobilization<br />

and allows the patient to begin early rehabilitation.<br />

With the addition of the LCP Volar Column Plate, <strong>Synthes</strong>’ LCP Distal<br />

Radius System strengthens its position in the market as the most<br />

comprehensive system for treating distal radius fractures. It helps surgeons<br />

to substantially improve surgical outcomes for their patients.<br />

In the near future, <strong>Synthes</strong> will introduce several new instruments and<br />

an upgraded case assortment to compliment the Volar Column Plate<br />

and minimize time spent in the operating room.<br />

Each plate is designed and manufactured to provide an anatomical<br />

fit on the volar aspect of the distal radius, which minimizes the need<br />

for intra-operative plate contouring. The screw trajectories of the Volar<br />

Column plates were developed to focus locking screw fixation options<br />

where they are needed most.<br />

32

<strong>Synthes</strong>. Annual Report <strong>2007</strong><br />

Radial Column<br />

Intermediate Column<br />

Ulnar Column<br />

Recent studies show that more axial load is transmitted<br />

through the intermediate column of the distal radius.<br />

Therefore, the Volar Column Distal Radius Plate was designed<br />

to provide more buttressing capability and focus<br />

sufficient locking screw options into the intermediate<br />

column.<br />

33

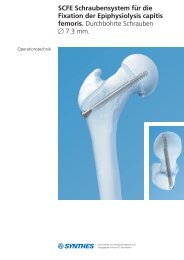

Product Highlights. Spine<br />

Spine. In-Space<br />

Lumbar Spinal Stenosis (LSS) usually affects middle-aged and older adults with debilitating pain in their buttocks or<br />

legs. The traditional surgical procedure to relieve patients from pain caused by lumbar spinal stenosis involves removing<br />

the bone and soft tissues of the spine that are pinching the nerves. In-Space is an implant that facilitates<br />

the interspinous distraction by widening the openings that accommodate the nerves or the spinal cord.<br />

LSS is a widespread pathology which leads to decreased physical activity<br />

levels. The patients most often experience numbness, weakness,<br />

or cramping while standing upright or walking for any distance. This<br />

leg pain is intensified when the patient bends backwards and decreases<br />

when the patient sits down or leans forward. The reason for this<br />

is a compression of neural structures in the posterior part of the spine<br />

when it is in extension. It is caused by a tendency of the foramen<br />

(openings where the nerve roots exit the spine or canal that accommodates<br />

the spinal cord) to narrow in the elderly population. At some<br />

stage, these openings cannot accommodate the nerve roots or spinal<br />

cord any longer without causing pain. Bending backwards (extending)<br />

narrows these openings even more, which explains the intensifying<br />

of pain in this situation.<br />

People in their 60s or 70s are typical patients suffering from Lumbar<br />

Spinal Stenosis (LSS). In fact, LSS is the most common indication for<br />

surgery in people over 60 years old in the United States. It is estimated<br />

that as many as 250,000 to 500,000 people in the US alone have<br />

symptoms of spinal stenosis. This represents about 5 of every 1000<br />

Americans older than 50 years and this number is expected to grow<br />

as members of the baby boomer generation reach their 60s over the<br />

next decade. The trend is global, with the majority of the world’s older<br />

persons residing in Asia (53 percent), and Europe having the next<br />

largest share (25 percent).<br />

spinous processes in a procedure that generally does not last longer<br />

than twenty minutes. It acts as a mechanical block that prevents the<br />

painful extension of the spine and slightly distracts the affected spinal<br />

segment on the back, thus widening the openings that accommodate<br />

the nerve roots or the spinal cord. This is achieved with much<br />

less damage to muscles and ligaments, since the device is implanted<br />

percutaneously through a tiny incision on the side and through a small<br />

tube, leaving all the important structures intact. The implant is secured<br />