Clinch Fastening Systems

Clinch Fastening Systems

Clinch Fastening Systems

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Autoriv Installation <strong>Systems</strong><br />

<strong>Clinch</strong> <strong>Fastening</strong> <strong>Systems</strong><br />

• Controls and operator interface ease tracking of<br />

installation problems<br />

– Micro-controller or PLC monitors fastener in all<br />

critical locations, ensuring fasteners are ready<br />

for setting<br />

– Heavy-duty LED panel displays system status<br />

and exact fault locations, permitting it to be<br />

dealt with directly and quickly<br />

– System interacts with press to stop process if<br />

an abnormality is sensed<br />

– Rotary operator panel with system layout and<br />

checks; can always be turned to the press<br />

operator<br />

• Press simulation unit can be created<br />

– Allows complete system check (punch head,<br />

signal exchange and feeding unit) outside the<br />

press<br />

– Feeding system and punch heads can also be<br />

checked manually<br />

Benefits<br />

• Shortens downtime for changeovers<br />

• Highly-accurate positioning<br />

• Eases troubleshooting<br />

• Helps prevent damage to press<br />

• Reduces potential for scrapped or reworked<br />

assemblies<br />

• Withstands demanding assembly environments<br />

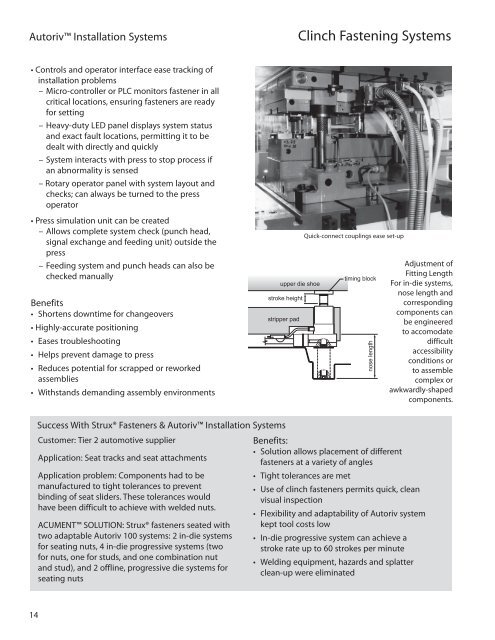

Quick-connect couplings ease set-up<br />

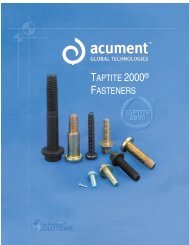

Adjustment of<br />

Fitting Length<br />

For in-die systems,<br />

nose length and<br />

corresponding<br />

components can<br />

be engineered<br />

to accomodate<br />

difficult<br />

accessibility<br />

conditions or<br />

to assemble<br />

complex or<br />

awkwardly-shaped<br />

components.<br />

Success With Strux® Fasteners & Autoriv Installation <strong>Systems</strong><br />

Customer: Tier 2 automotive supplier<br />

Benefits:<br />

• Solution allows placement of different<br />

Application: Seat tracks and seat attachments<br />

fasteners at a variety of angles<br />

Application problem: Components had to be<br />

• Tight tolerances are met<br />

manufactured to tight tolerances to prevent<br />

• Use of clinch fasteners permits quick, clean<br />

binding of seat sliders. These tolerances would<br />

visual inspection<br />

have been difficult to achieve with welded nuts.<br />

ACUMENT SOLUTION: Strux® fasteners seated with<br />

two adaptable Autoriv 100 systems: 2 in-die systems<br />

for seating nuts, 4 in-die progressive systems (two<br />

for nuts, one for studs, and one combination nut<br />

and stud), and 2 offline, progressive die systems for<br />

seating nuts<br />

• Flexibility and adaptability of Autoriv system<br />

kept tool costs low<br />

• In-die progressive system can achieve a<br />

stroke rate up to 60 strokes per minute<br />

• Welding equipment, hazards and splatter<br />

clean-up were eliminated<br />

14