Clinch Fastening Systems

Clinch Fastening Systems

Clinch Fastening Systems

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Rivtex® <strong>Fastening</strong> <strong>Systems</strong><br />

Pierce-<strong>Clinch</strong> Nuts: Type TSPN<br />

C<br />

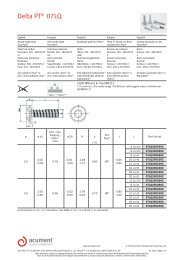

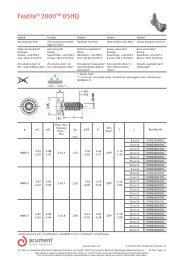

Rivtex TSPN Nuts Dimensional & Performance Data* – Metric Sizes (all dimensions shown in millimeters)<br />

Thread<br />

Size<br />

M5 x 0.8<br />

M6 x 1.0<br />

D<br />

(+0.1)<br />

Dr<br />

(+0.15) Lg<br />

C<br />

(+0.1)<br />

14.0 8.45 5.8 5.0<br />

M8 x 1.25 16.5 10.45 6.9 5.9<br />

M10 x 1.5 18.5 12.45 8.2 7.2<br />

Material<br />

Thickness<br />

0.8<br />

Recommended<br />

Prepunched<br />

Hole Size†<br />

(-0.1)<br />

Approx.<br />

Staking<br />

Force<br />

kN<br />

Approx.<br />

Pushout<br />

kN<br />

Approx. Unsupported<br />

Torsional Resistance<br />

Nm<br />

30 1.5 10.0<br />

1.0 8.65<br />

30 2.8 18.0<br />

1.8 60 4.0 18.0<br />

0.8<br />

40 1.9 13.0<br />

1.0 10.65<br />

40 3.1 32.0<br />

1.8 75 4.3 42.0<br />

1.0<br />

60<br />

1.5 12.65<br />

85<br />

*Application testing is required.<br />

2.0 100<br />

†Prepunched or predrilled holes are recommended for bottom-up installation configurations.<br />

*NOTE: Values shown are for steel materials only. Aluminum applications must be indivdually tested to determine performance parameters. Size<br />

M10 requires application testing whether they are used in steel or aluminum applications.<br />

Underhead shape and dimensions controlled by manufacturer to meet performance requirements.<br />

Performance data shown are typical results obtained under laboratory conditions. It is recommended that each application be tested individually<br />

for precise values. For performance in materials other than steel, individual testing is a requirement. This data is not to be considered a<br />

specification.<br />

Contact an Acument Global Technologies applications engineer for assistance.<br />

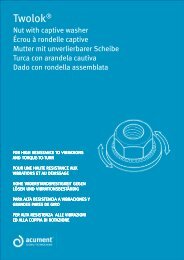

This cross-section of an actual<br />

application demonstrates how the<br />

application material cold flows into the<br />

retaining groove of the TSPN nut.<br />

11