Clinch Fastening Systems

Clinch Fastening Systems

Clinch Fastening Systems

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Clinch</strong> <strong>Fastening</strong> <strong>Systems</strong><br />

Product Catalog<br />

Applied creativity. Breakthrough solutions.

<strong>Clinch</strong> <strong>Fastening</strong> <strong>Systems</strong> from Acument Global Technologies<br />

Table of Contents<br />

Introduction<br />

Innovation and technology . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2<br />

Overview of fasteners . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3<br />

Strux® <strong>Clinch</strong> Products<br />

Bolts/Studs<br />

Features and installation example. . . . . . . . . . . . . . . . . . . . . . 4<br />

Dimensional and performance data. . . . . . . . . . . . . . . . . . . . 5<br />

Nuts<br />

Features and installation example. . . . . . . . . . . . . . . . . . . . . . 6<br />

Dimensional and performance data. . . . . . . . . . . . . . . . . . . . 7<br />

Rivtex® <strong>Clinch</strong> Products<br />

Bolts/Studs Type TCB<br />

Features and installation example. . . . . . . . . . . . . . . . . . . . . . 8<br />

Dimensional and performance data. . . . . . . . . . . . . . . . . . . . 9<br />

Rivtex® Pierce-<strong>Clinch</strong> Nuts<br />

Type TSPN<br />

Features and installation example. . . . . . . . . . . . . . . . . . . . . 10<br />

Dimensional and performance data. . . . . . . . . . . . . . . . . . . 11<br />

Installation Equipment<br />

Autoriv systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12<br />

Autoriv 100 system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13<br />

Autoriv 210 system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16<br />

Other Autoriv systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18<br />

Warranty<br />

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19<br />

Contact Information<br />

Global contacts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .back cover<br />

1

<strong>Clinch</strong> <strong>Fastening</strong> <strong>Systems</strong> from Acument Global Technologies<br />

As the demand for thin sheet steel and aluminum<br />

sheet applications increases, so do solutions for<br />

fastening them. Acument Global Technologies<br />

continues its product development to meet these<br />

changing needs.<br />

The Strux® line of clinch nuts and studs from<br />

Acument are designed to provide an external or<br />

internal thread in sheet metal stack-ups 1.5mm and<br />

thicker. Based on the proven performance of Strux®<br />

fasteners, Acument has developed the Rivtex® line<br />

of clinch and pierce-clinch fasteners to meet the<br />

needs of sheet metals as thin as 0.75mm.<br />

Acument can provide a wide range of automated<br />

feed, placement and transfer options for both lines<br />

of fasteners.<br />

Features<br />

• Unlike spot welding, joints can be created<br />

in-die with clinch fasteners and automated<br />

equipment<br />

• Can be used where welding is impossible<br />

or undesirable, such as joining dissimilar<br />

materials, pre-coated sheets, and highstrength<br />

thin sheet metals<br />

• Unlike welding, clinch fasteners do not create<br />

a heat zone in the materials during installation<br />

• Can be installed after the painting or coating<br />

process, with virtually no aesthetic damage to<br />

the application<br />

• Allows simple visual inspection to determine<br />

proper fastener seating<br />

Benefits<br />

• Lowers in-place costs<br />

• Can eliminate welding operations and its<br />

environmental and safety hazards<br />

• Maximizes assembly flexibility<br />

• Changes and damage to the application<br />

materials are minimized<br />

• Cross-threading and other problems caused<br />

by coated or painted threads can be avoided<br />

• Joints do not require destructive testing to<br />

determine installed strength<br />

• Use of threaded fasteners ease servicing<br />

while providing high joint strength<br />

2

<strong>Clinch</strong> <strong>Fastening</strong> <strong>Systems</strong> from Acument Global Technologies<br />

Continuing Technology<br />

The Strux® line of clinch fasteners was introduced<br />

in 1976. They provide optimal performance in<br />

steel and aluminum sheet applications that are<br />

2.0mm and over, but too thin to provide adequate<br />

thread engagment from screws or bolts.<br />

Originally featuring a TORX® configuration on the<br />

displacement lobes, other configurations are also<br />

used to meet specific application requirements.<br />

The Rivtex® line of clinch fasteners were<br />

designed to meet the needs of thinner sheet<br />

metal applications. These include high-strength<br />

thin sheet steel, where welding can reduce the<br />

material’s performance.<br />

Benefits<br />

• Provides high resistance to rotation and pushout<br />

• Can eliminate welding operations in standard<br />

materials and be used with material<br />

combinations that can not be welded<br />

• Provides a cleaner appearance then welded<br />

fasteners<br />

• Many automated installation systems available<br />

• Can be installed in-die, unlike welding<br />

operations<br />

• Speeds the assembly process<br />

• Lowers in-place costs<br />

Testing of actual applications is required to<br />

determine optimal fastener selection and assembly<br />

parameters. Please contact an Acument Global<br />

Technologies applications engineer for assistance.<br />

Strux® Fasteners<br />

• Three products:<br />

– STRUX clinch studs<br />

(external threads)<br />

– STRUX clinch nuts<br />

(internal threads)<br />

– unthreaded STRUXtite®<br />

nuts for use with<br />

TAPTITE® thread-rolling<br />

fasteners are available as specials<br />

• Available in sizes M4 – M12 (#8 – 1/2")<br />

• Optimum performance in sheet metals over<br />

1.5mm thick<br />

Rivtex® Fasteners<br />

• Two products:<br />

– Rivtex clinch studs<br />

(external threads)<br />

– Rivtex pierce-clinch<br />

nuts (internal threads);<br />

eliminate need for<br />

punched or drilled holes<br />

• Available in sizes M5<br />

– M10<br />

• For thinner sheet metals, including high strength<br />

thin steel sheets and aluminum sheets<br />

– clinch products: 0.75mm to 2.0mm<br />

– pierce-clinch nuts: 0.75mm to 2.0mm (steel);<br />

0.75mm to 3.0mm (aluminum)<br />

Specials<br />

Unthreaded pins, engineered threads, double-end studs, preassembled<br />

subcomponents and more are available.<br />

3

<strong>Clinch</strong> Studs<br />

Strux® <strong>Fastening</strong> <strong>Systems</strong><br />

retaining groove<br />

lobular<br />

configuration<br />

retaining ring<br />

displacement<br />

lobes<br />

Features<br />

• Displacement lobes in TORX® configuration or<br />

others as required<br />

• Locking/retaining groove<br />

• Shear/retaining ring<br />

• External threads<br />

• Available in sizes M4 – M16 (#8 – 5/8)<br />

before installation<br />

after installation<br />

Installation Sequence (Representative Sample)<br />

Application material must be drilled or<br />

punched. Two-sided access is required<br />

during installation.<br />

Installation equipment applies pressure onto the head of the stud and the opposite<br />

side of the application material. As pressure continues, the application material cold<br />

flows into the locking groove.<br />

4

Strux® <strong>Fastening</strong> <strong>Systems</strong><br />

<strong>Clinch</strong> Studs<br />

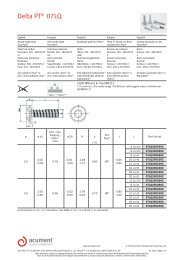

Strux Studs Dimensional & Performance Data – Metric Sizes (all dimensions shown in millimeters)<br />

Thread<br />

Size<br />

S<br />

+0.07<br />

C<br />

±0.13<br />

D<br />

±0.25<br />

M4 x 0.7 4.61 1.40 7.75<br />

M5 x 0.8 5.61 1.75 8.75<br />

M6 x 1.0<br />

M8 x 1.25<br />

6.61 2.10 11.00<br />

8.61 2.80 15.25<br />

M10 x 1.5 10.61 3.50 19.75<br />

M12 x 1.75 12.61 3.80 20.00<br />

K<br />

Ref.<br />

Material<br />

Thickness<br />

Min<br />

Recommended<br />

Hole Size<br />

Min Max<br />

Approx.*<br />

Staking Force<br />

kN<br />

Approx.*<br />

Pushout<br />

kN<br />

Approx.* Unsupported<br />

Torsional Resistance<br />

Nm<br />

1.5 1.0<br />

13.3 1.04 4.80<br />

4.68 4.78<br />

2.3 1.5 16.9 2.27 5.01<br />

1.5 1.0<br />

13.3 1.09 4.00<br />

5.68 5.78<br />

2.3 1.5 16.5 2.22 10.73<br />

1.5 1.0<br />

20.2 1.42 7.69<br />

2.3 1.5 6.68 6.78<br />

25.8 2.56 15.22<br />

3.4 2.3 26.7 4.78 15.22<br />

2.3 1.5<br />

35.6 2.40 26.78<br />

3.4 2.3 8.68 8.78<br />

42.3 6.09 40.06<br />

4.6 3.0 45.4 9.06 40.06<br />

3.4 2.3<br />

66.7 5.92 60.49<br />

10.68 10.78<br />

4.6 3.0 73.4 8.82 84.80<br />

3.4 2.3<br />

73.4 7.26 81.14<br />

12.68 12.78<br />

4.6 3.0 77.8 13.91 124.25<br />

NOTES: Other sizes available upon request. * Tests conducted into low carbon steel with a maximum hardness of Rockwell B70.<br />

Underhead shape and dimensions controlled by manufacturer to meet<br />

performance requirements.<br />

Performance data shown are typical results obtained under laboratory<br />

conditions. It is recommended that each application be tested individually<br />

for precise values. For performance in materials other than steel, individual<br />

testing is a requirement. This data is not to be considered a specification.<br />

Contact an Acument Global Technologies applications engineer for assistance.<br />

Strux Studs Dimensional & Performance Data – Inch Sizes<br />

Thread<br />

Size<br />

S<br />

+0.002<br />

-0.003<br />

C<br />

±.005<br />

D<br />

±0.010<br />

K<br />

Ref.<br />

Material<br />

Thickness<br />

Min<br />

Recommended<br />

Hole Size<br />

Min Max<br />

Approx.<br />

Staking Force<br />

Tons<br />

Approx.<br />

Pushout<br />

lb.<br />

Approx. Unsupported<br />

Torsional Resistance<br />

in/lb.<br />

#8 .176 .060 .350<br />

.060 .036 (20 ga)<br />

.095 .060 (16 ga)<br />

.178 .182<br />

#10 .204 .070 .370<br />

.060 .036 (20 ga)<br />

.095 .060 (16 ga)<br />

.206 .210<br />

.060 .036 (20 ga)<br />

1/4" .270 .090 .470<br />

5/16" .331 .110 .600<br />

.095 .060 (16 ga)<br />

.135 .090 (13 ga)<br />

.095 .060 (16 ga)<br />

.135 .090 (13 ga)<br />

.272 .276<br />

.333 .337<br />

*Application testing is required to determine specific<br />

performance data for inch-sized studs.<br />

Please contact an Acument Global Technologies<br />

applications engineer for assistance.<br />

.180 .120 (11 ga)<br />

3/8" .398 .130 .690<br />

.135 .090 (13 ga)<br />

.180 .120 (11 ga)<br />

.400 .404<br />

1/2" .530 .175 .950<br />

.135 .090 (13 ga)<br />

.180 .120 (11 ga)<br />

.532 .536<br />

NOTE: Other sizes available upon request.<br />

5

<strong>Clinch</strong> Nuts<br />

Strux® <strong>Fastening</strong> <strong>Systems</strong><br />

retaining ring<br />

lobular<br />

configuration<br />

retaining<br />

groove<br />

displacement<br />

lobes<br />

Features<br />

• Displacement lobes in TORX® configuration or<br />

others as required<br />

• Locking/retaining groove<br />

• Squeeze/retaining ring<br />

• Internal threads<br />

• Available in sizes M4 – M12 (#8 – 1/2")<br />

• Can be used in sheet metal 1.5mm and thicker<br />

• Unthreaded nuts available for use with TAPTITE®<br />

fasteners<br />

before installation<br />

after installation<br />

Installation Sequence (Representative Sample)<br />

Punched or drilled hole required. If needed, a locating pin holds the nut in place (shown). Installation equipment applies<br />

pressure onto the head of the nut and the opposite side of the application material. As pressure continues, the application<br />

material cold flows into the retaining/locking groove.<br />

6

Strux® <strong>Fastening</strong> <strong>Systems</strong><br />

<strong>Clinch</strong> Nuts<br />

Strux Nuts Dimensional & Performance Data – Metric Sizes (all dimensions shown in millimeters)<br />

Thread<br />

Size<br />

S<br />

±0.07<br />

C<br />

±0.19<br />

D<br />

±0.13<br />

K<br />

Ref.<br />

Material<br />

Thickness<br />

Min<br />

Recommended<br />

Hole Size<br />

Min Max<br />

Approx.<br />

Staking Force<br />

kN<br />

Approx.<br />

Pushout<br />

kN<br />

Approx. Unsupported<br />

Torsional Resistance<br />

Nm<br />

M4 x 0.7 7.13 3.19 10.16 1.5 1.5 7.20 7.30 13.3 0.91 6.19<br />

M5 x 0.8 7.61 4.19 11.30<br />

1.5 1.5<br />

26.7 1.04 12.00<br />

7.68 7.78<br />

1.9 1.9 30.2 1.68 21.32<br />

1.5 1.5<br />

38.7 1.39 18.85<br />

M6 x 1.0 8.61 4.71 14.10 1.9 1.9 8.68 8.78<br />

40.0 2.57 21.04<br />

2.3 2.3 42.3 3.22 32.52<br />

1.5 1.5<br />

44.5 1.53 21.17<br />

M8 x 1.25 10.61 5.93 16.64 1.9 1.9 10.68 10.78<br />

48.9 2.41 41.94<br />

2.3 2.3 57.8 4.58 54.23<br />

M10 x 1.5 13.09 7.20 18.42<br />

2.3 2.3<br />

53.4 4.16 57.21<br />

13.16 13.26<br />

3.4 3.4 57.8 4.28 65.65<br />

M12 x 1.75 15.61 9.61 23.88<br />

2.3 2.3<br />

108.3 4.75 75.39<br />

15.68 15.78<br />

3.4 3.4 109.0 7.66 124.32<br />

NOTES: Other sizes available upon request. * Tests conducted into low carbon steel with a maximum hardness of Rockwell B70.<br />

Underhead shape and dimensions controlled by manufacturer to meet performance<br />

requirements.<br />

Performance data shown are typical results obtained under laboratory conditions.<br />

It is recommended that each application be tested individually for precise values.<br />

For performance in materials other than steel, individual testing is a requirement.<br />

This data is not to be considered a specification.<br />

Contact an Acument Global Technologies applications engineer for assistance.<br />

Strux Nuts Dimensional & Performance Data – Inch Sizes<br />

Thread<br />

Size<br />

S<br />

+0.07<br />

C<br />

±0.13<br />

D<br />

±0.25<br />

#8 .176 .060 .350<br />

#10 .204 .070 .370<br />

1/4" .270 .090 .470<br />

5/16" .331 .110 .600<br />

3/8" .398 .130 .690<br />

1/2" .530 .175 .950<br />

K<br />

Ref.<br />

Material<br />

Thickness<br />

Recommended<br />

Hole Size<br />

Min Min Max<br />

.060 .036 (20 ga)<br />

.095 .060 (16 ga)<br />

.178 .182<br />

.060 .036 (20 ga)<br />

.095 .060 (16 ga) .206 .210<br />

.060 .036 (20 ga)<br />

.095 .060 (16 ga)<br />

.135 .090 (13 ga) .272 .276<br />

.095 .060 (16 ga)<br />

.135 .090 (13 ga)<br />

.180 .120 (11 ga)<br />

.333 .337<br />

.135 .090 (13 ga)<br />

.180 .120 (11 ga)<br />

.400 .404<br />

.135 .090 (13 ga)<br />

.180 .120 (11 ga)<br />

.532 .536<br />

Approx.*<br />

Staking Force<br />

kN<br />

Approx.*<br />

Pushout<br />

kN<br />

Approx.* Unsupported<br />

Torsional Resistance<br />

Nm<br />

*Application testing is<br />

required to determine specific performance data for<br />

inch-sized nuts.<br />

Please contact an Acument Global Technologies<br />

applications specialist<br />

for assistance.<br />

NOTE: Other sizes available upon request.<br />

7

<strong>Clinch</strong> Bolts: Type TCB<br />

Rivtex® <strong>Fastening</strong> <strong>Systems</strong><br />

displacement lobes<br />

displacement lobes<br />

locking/retaining groove<br />

squeeze/retaining ring<br />

Features<br />

• Displacement lobes<br />

• Locking/retaining groove<br />

• Squeeze/retaining ring<br />

• External threads<br />

• Available in sizes M5 – M10<br />

• Can be used in sheet metal 0.75mm – 2.5mm<br />

before installation<br />

Installation Sequence (Representative Sample)<br />

after installation<br />

Application material must be drilled<br />

or punched. Two-sided access is<br />

required during installation.<br />

Installation equipment applies pressure onto the head of the stud and the oppposite<br />

side of the application material. As pressure continues, the application material cold<br />

flows into the locking groove.<br />

8

Rivtex® <strong>Fastening</strong> <strong>Systems</strong><br />

<strong>Clinch</strong> Bolts: Type TCB<br />

D t<br />

Rivtex Studs Dimensional & Performance Data – Metric Sizes (all dimensions shown in millimeters)<br />

Thread<br />

Size<br />

D<br />

(-0.27)<br />

Dt<br />

(± 0.15)<br />

Dr<br />

(-0.2)<br />

R<br />

(+0.2, -0.1)<br />

C<br />

(±0.13)<br />

M5 x 0.8 9 8.3 5.35 0.9 1.8<br />

M6 x 1.0 12 11.0 6.35 1.0 2.1<br />

M8 x 1.25 16 14.5 8.50 1.2 2.8<br />

M10 x 1.5 20 18.0 10.50 1.3 3.5<br />

Material<br />

Thickness<br />

0.75<br />

Recommended<br />

Hole Size<br />

Staking<br />

Force<br />

kN<br />

45<br />

Approx.<br />

Pushout<br />

kN<br />

Approx. Unsupported<br />

Torsional Resistance<br />

Nm<br />

1.5 5.35 (+0.1) 55 *Application testing is required.<br />

2.0 65<br />

0.75<br />

45 1.1 10.0<br />

1.5 6.35 (+0.1) 55 1.7 15.0<br />

2.0 65 2.1 15.0<br />

0.8<br />

65 1.3 13.0<br />

1.5 8.50 (+0.15) 85 2.1 30.0<br />

2.0 100 2.6 35.0<br />

1.0<br />

95<br />

1.5 10.5 (+0.15) 95 *Application testing is required.<br />

2.5 120<br />

Sizes M5 and M10 require application testing to determine specific performance data.<br />

Underhead shape and dimensions controlled by manufacturer to meet performance requirements.<br />

Performance data shown above are typical results obtained under laboratory conditions. It is recommended that each application be tested<br />

individually for precise values. For performance in materials other than steel, individual testing is a requirement. This data is not to be<br />

considered a specification.<br />

Contact an Acument Global Technologies applications engineer for assistance.<br />

9

Pierce-<strong>Clinch</strong> Nuts: Type TSPN<br />

Rivtex® <strong>Fastening</strong> <strong>Systems</strong><br />

piercing<br />

ring<br />

locking/retaining<br />

groove<br />

piercing ring<br />

locking/retaining<br />

groove<br />

displacement lobes<br />

Features<br />

• Piercing ring<br />

• Displacement lobes<br />

• Locking/retaining groove<br />

• Internal threads<br />

• Available in sizes M5 – M10<br />

• Can be used in steel sheets 0.75mm – 2.0mm<br />

and aluminum sheets 0.75mm – 2.5mm<br />

• Does not require punched or drilled holes<br />

• Provides high resistance to torque and push-out<br />

Benefits<br />

• May eliminate punching or drilling operations<br />

• Unthreaded nuts available for use with TAPTITE®<br />

fasteners<br />

before installation<br />

after installation<br />

Installation Sequence (Representative Sample)<br />

No punched or drilled<br />

hole required. (Can be<br />

used with existing hole)<br />

material cold flows<br />

into retaining groove<br />

pierced material<br />

falls away<br />

10

Rivtex® <strong>Fastening</strong> <strong>Systems</strong><br />

Pierce-<strong>Clinch</strong> Nuts: Type TSPN<br />

C<br />

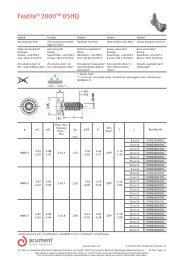

Rivtex TSPN Nuts Dimensional & Performance Data* – Metric Sizes (all dimensions shown in millimeters)<br />

Thread<br />

Size<br />

M5 x 0.8<br />

M6 x 1.0<br />

D<br />

(+0.1)<br />

Dr<br />

(+0.15) Lg<br />

C<br />

(+0.1)<br />

14.0 8.45 5.8 5.0<br />

M8 x 1.25 16.5 10.45 6.9 5.9<br />

M10 x 1.5 18.5 12.45 8.2 7.2<br />

Material<br />

Thickness<br />

0.8<br />

Recommended<br />

Prepunched<br />

Hole Size†<br />

(-0.1)<br />

Approx.<br />

Staking<br />

Force<br />

kN<br />

Approx.<br />

Pushout<br />

kN<br />

Approx. Unsupported<br />

Torsional Resistance<br />

Nm<br />

30 1.5 10.0<br />

1.0 8.65<br />

30 2.8 18.0<br />

1.8 60 4.0 18.0<br />

0.8<br />

40 1.9 13.0<br />

1.0 10.65<br />

40 3.1 32.0<br />

1.8 75 4.3 42.0<br />

1.0<br />

60<br />

1.5 12.65<br />

85<br />

*Application testing is required.<br />

2.0 100<br />

†Prepunched or predrilled holes are recommended for bottom-up installation configurations.<br />

*NOTE: Values shown are for steel materials only. Aluminum applications must be indivdually tested to determine performance parameters. Size<br />

M10 requires application testing whether they are used in steel or aluminum applications.<br />

Underhead shape and dimensions controlled by manufacturer to meet performance requirements.<br />

Performance data shown are typical results obtained under laboratory conditions. It is recommended that each application be tested individually<br />

for precise values. For performance in materials other than steel, individual testing is a requirement. This data is not to be considered a<br />

specification.<br />

Contact an Acument Global Technologies applications engineer for assistance.<br />

This cross-section of an actual<br />

application demonstrates how the<br />

application material cold flows into the<br />

retaining groove of the TSPN nut.<br />

11

Autoriv Installation <strong>Systems</strong><br />

<strong>Clinch</strong> <strong>Fastening</strong> <strong>Systems</strong><br />

The Autoriv line of automated installation<br />

systems was developed to offer component<br />

suppliers and OEMs an economical and reliable<br />

method of setting large quantities of clinch<br />

fasteners into a variety of stamped assemblies.<br />

Both in-die and offline systems are available. This<br />

eliminates welding of fasteners, resulting in cost<br />

savings plus quality and safety advantages.<br />

Sturdy feed, power and placement modules are<br />

engineered to minimize set-up time and downtime<br />

while maximizing assembly flexibility. Add the<br />

process engineering and stamping expertise of<br />

Acument Global Technologies, and the optimal<br />

solution for your assembly needs is readily available.<br />

Benefits<br />

• Minimizes material handling costs<br />

• Minimizes space requirements and costs<br />

• Minimizes personnel requirements<br />

• Increases operator safety<br />

• Provides optimal throughput times<br />

• Lowers installed costs<br />

• Provides more uniform quality<br />

12

<strong>Clinch</strong> <strong>Fastening</strong> <strong>Systems</strong><br />

Autoriv Installation <strong>Systems</strong><br />

Autoriv 100 In-Die Installation System<br />

This robust system is engineered to accommodate<br />

applications with tight tolerances and/or<br />

complicated part geometries. Its durable<br />

construction withstands tough production<br />

environments.<br />

Features<br />

• Mobile feeding units (on casters)<br />

– Easily adapt to different size fasteners via<br />

change-over kits<br />

– House two independent feeding bowls<br />

– Separate incorrectly-oriented nuts which could<br />

cause damage to the die. The incorrectly<br />

positioned nut can then be removed quickly<br />

through a hinged opening<br />

– Guarantee that only a certain amount of<br />

fasteners are contained in the vibratory<br />

bowl at any one time to help prevent wear of<br />

fastener surface coatings<br />

– Durable plastic covers minimizes dust<br />

intrusion and noise levels<br />

• Placing heads allow flexible assembly<br />

– Can be easily designed into dies<br />

– Can be easily removed and replaced without<br />

removing the die from the press<br />

– When placing nuts, heads can be mounted at<br />

any angle to accommodate a variety of part<br />

geometries and tolerance requirements<br />

Autoriv 100 units<br />

Representative in-die set-up<br />

• Quick-release connections on all punching heads<br />

and feed bowls for air, electric and charging<br />

tubes<br />

– Prevents incorrect connections and resulting<br />

malfunctions. No individual plugging of<br />

contacts is required.<br />

– The system automatically recognizes which<br />

insertion heads have been connected.<br />

Fasteners are only blown to these punching<br />

heads.<br />

Interior of Autoriv 100 unit is configured<br />

to meet your specific needs<br />

13

Autoriv Installation <strong>Systems</strong><br />

<strong>Clinch</strong> <strong>Fastening</strong> <strong>Systems</strong><br />

• Controls and operator interface ease tracking of<br />

installation problems<br />

– Micro-controller or PLC monitors fastener in all<br />

critical locations, ensuring fasteners are ready<br />

for setting<br />

– Heavy-duty LED panel displays system status<br />

and exact fault locations, permitting it to be<br />

dealt with directly and quickly<br />

– System interacts with press to stop process if<br />

an abnormality is sensed<br />

– Rotary operator panel with system layout and<br />

checks; can always be turned to the press<br />

operator<br />

• Press simulation unit can be created<br />

– Allows complete system check (punch head,<br />

signal exchange and feeding unit) outside the<br />

press<br />

– Feeding system and punch heads can also be<br />

checked manually<br />

Benefits<br />

• Shortens downtime for changeovers<br />

• Highly-accurate positioning<br />

• Eases troubleshooting<br />

• Helps prevent damage to press<br />

• Reduces potential for scrapped or reworked<br />

assemblies<br />

• Withstands demanding assembly environments<br />

Quick-connect couplings ease set-up<br />

Adjustment of<br />

Fitting Length<br />

For in-die systems,<br />

nose length and<br />

corresponding<br />

components can<br />

be engineered<br />

to accomodate<br />

difficult<br />

accessibility<br />

conditions or<br />

to assemble<br />

complex or<br />

awkwardly-shaped<br />

components.<br />

Success With Strux® Fasteners & Autoriv Installation <strong>Systems</strong><br />

Customer: Tier 2 automotive supplier<br />

Benefits:<br />

• Solution allows placement of different<br />

Application: Seat tracks and seat attachments<br />

fasteners at a variety of angles<br />

Application problem: Components had to be<br />

• Tight tolerances are met<br />

manufactured to tight tolerances to prevent<br />

• Use of clinch fasteners permits quick, clean<br />

binding of seat sliders. These tolerances would<br />

visual inspection<br />

have been difficult to achieve with welded nuts.<br />

ACUMENT SOLUTION: Strux® fasteners seated with<br />

two adaptable Autoriv 100 systems: 2 in-die systems<br />

for seating nuts, 4 in-die progressive systems (two<br />

for nuts, one for studs, and one combination nut<br />

and stud), and 2 offline, progressive die systems for<br />

seating nuts<br />

• Flexibility and adaptability of Autoriv system<br />

kept tool costs low<br />

• In-die progressive system can achieve a<br />

stroke rate up to 60 strokes per minute<br />

• Welding equipment, hazards and splatter<br />

clean-up were eliminated<br />

14

<strong>Clinch</strong> <strong>Fastening</strong> <strong>Systems</strong><br />

Autoriv Installation <strong>Systems</strong><br />

Autoriv 100 System – Technical Data<br />

Rated current:<br />

Rated voltage:<br />

Frequency:<br />

10 amp<br />

115V (24V Control Voltage)<br />

60Hz<br />

Fuse protection: 12.5A<br />

Number of phases: 1<br />

Compressed air supply:<br />

Pressure control device:<br />

Air-borne noise:<br />

Machine dimensions: Height: 1500mm (59")<br />

Width: 1100mm (42.3")<br />

Length: 1450mm (57")<br />

Weight:<br />

Service pressure ....................................................................................................6 bar (80 psi)<br />

Air requirements .................100m3/h (59cfm) (2 out) to 200 m3/h (118cfm) (4 out)<br />

Quality ..................................................................................................................................oil-free<br />

Connection .......................................................................................................................1/2 inch<br />

Factory setting .................................................. Switch-on pressure ≥ 5.3 bar (76.9 psi)<br />

Factory setting ............................................... Switch-off pressure ≤ 4.5 bar (65.26 psi)<br />

Measuring process ....................................................................... In-process measurement<br />

Measuring device ................................................................................................... DIN IEC 651<br />

Measuring code .....................................................................................................DIN 45645-2<br />

External noise ...................................................................................... Automatic conditions<br />

Measuring point ................................................. Using position, 1.5m above floor level<br />

Measuring distance 1m, cover closed:<br />

Sm .............................................................. Min: 75.9 dB(A), Max: 86.3 dB(A), Ø 81.1dB(A)<br />

Measuring distance 1m, cover open:<br />

Sm ............................................................Min: 75.9 dB(A), Max: 102.3 dB(A), Ø 89.1dB(A)<br />

Measuring distance >3m, cover open:<br />

Sm ....................................................................................................................................

Autoriv Installation <strong>Systems</strong><br />

<strong>Clinch</strong> <strong>Fastening</strong> <strong>Systems</strong><br />

Autoriv 210 Pedestal Workstation<br />

This C-frame manual workstation is designed for lowvolume<br />

placement of clinch fasteners.<br />

Features<br />

• Automatic feed with vibratory bowl standard<br />

– Multi-bowl feed or magazine feed also available<br />

– Bowl changeover kits are available to allow the<br />

same workstation to place different fasteners<br />

• Air/oil hydraulic system<br />

– Provides maximum 80Kn (18,000 lbs) setting<br />

force; adjustable peak force allows setting of many<br />

different clinch/pierce-clinch fastener styles<br />

– Adjustable dwell time<br />

– Force monitoring standard; stroke monitoring also<br />

available<br />

• Machine cycle time: 3 seconds<br />

• Standard C-frame<br />

– Throat depth: 450mm<br />

– Daylight: 70mm<br />

– Custom C-frames available to meet specific<br />

application needs<br />

• Heavy-duty operator panel<br />

– LED displays system status and fault locations<br />

• Integrated safety system<br />

– Allows use of foot pedal<br />

– Light curtains or palm buttons available<br />

Benefits<br />

• Adjustable feeding and placement settings provide<br />

greater versatility and usage<br />

• Eases troubleshooting<br />

• Withstands demanding assembly environments<br />

• Reduces potential for scrapped or reworked<br />

assemblies<br />

16

<strong>Clinch</strong> <strong>Fastening</strong> <strong>Systems</strong><br />

Autoriv Installation <strong>Systems</strong><br />

Autoriv 210 System – Technical Data<br />

Rated current:<br />

Rated voltage:<br />

Frequency:<br />

Fuse protection:<br />

Compressed air supply:<br />

Air-borne noise:<br />

7A<br />

115V (24V control voltage)<br />

60Hz<br />

15A<br />

Machine dimensions: Height: 2800mm (110")<br />

Width: 1080mm (42.5")<br />

Length: 1385mm (54.5")<br />

Weight:<br />

Service pressure ................................................................................................. 6 bar (87 p.s.i.)<br />

Air requirements ................................................................................. 800L/min. (28.25 cfm)<br />

Type .......................................................................................................................................oil-free<br />

Connection ...............................................................................................................................1/2"<br />

Measuring process ....................................................................... In-process measurement<br />

External noise ...................................................................................... production workshop<br />

Measuring point ............................................ operator’s place, ground clearance 1.6m<br />

Noise .............................................................................................................................. 77.5 dB(A)<br />

1000 kg (2,200 lb)<br />

Foundations: Load-bearing capacity .................................................................. 1500 kg/m2 (307 lb/ft 2 )<br />

Part thickness capacity 0.7mm to 3.0mm (0.027" to 0.118")<br />

Performance/cycle time:<br />

Power cylinder:<br />

3 seconds per part in automatic mode<br />

80Kn (18,000 lb)<br />

Throat depth: 450mm (17")<br />

Daylight 70mm (2.75")<br />

Compressed air system:<br />

Control system:<br />

C-frame maximum allowable load:<br />

NOTE: The information in this manual is not to be considered a specification.<br />

Manufacturer ...................................................................................................................... FESTO<br />

Manufacturer ..................................................................................................................Siemens<br />

.............................................................................................................10 metric ton (22000 lbf)<br />

A complete technical manual for the Autoriv 210 system is available upon request.<br />

17

Autoriv Installation <strong>Systems</strong><br />

<strong>Clinch</strong> <strong>Fastening</strong> <strong>Systems</strong><br />

Other Autoriv <strong>Systems</strong><br />

In addition to the Autoriv 100 and Autoriv 210<br />

systems, additional systems are available to<br />

provide installation solutions for all applications and<br />

manufacturing environments. Fully-integrated systems,<br />

robotic-mounted placing heads, and multi-headed<br />

systems are possible.<br />

Please contact Acument Global Technologies for more<br />

information.<br />

Autoriv 220<br />

CNC-Controlled System<br />

• Able to press up to<br />

4 different fasteners<br />

without tool change<br />

• Preferred for large and<br />

heavy sheet metals<br />

Autoriv 230 Articulated C-Frame<br />

• C-frame with automated feeding system<br />

• Set-up for robot use<br />

• Complete robot cells available<br />

Autoriv 240<br />

Cell-Integrated Pedestal<br />

Workstation<br />

• Stationary assembly<br />

stations<br />

• Robotic component<br />

handles applications<br />

• Very flexible solution<br />

Autoriv 250 Multi-head Fully-Automated<br />

System<br />

• Fully-automated systems allows<br />

simultaneous placement of multiple<br />

fasteners, even at different angles<br />

• Recommended for high service<br />

production and short cycle times<br />

18

Acument Global Technologies<br />

Warranty Information<br />

Acument Global Technologies, Inc. hereby provides the following limited warranty to the initial retail<br />

customer and original installer (“the Warranty Holder”) that its products will be free from defects in<br />

material and workmanship, provided that the products are used in accordance with the instructions as to<br />

maintenance, operation and use of Acument Global Technologies, Inc.<br />

The Warranty Holder’s exclusive remedy and the only obligation of Acument Global Technologies, Inc. in<br />

the event of a defect or failure in the products, is that Acument Global Technologies, Inc. will, at its sole<br />

option, repair, replace, or rework the products, but in no case shall the cost of the foregoing exceed the<br />

invoice price of the products.<br />

This limited warranty shall be void if any person seeking to make a claim for defective or failed products<br />

(1) fails to notify Acument Global Technologies, Inc. within thirty (30) days of receipt of fasteners and<br />

within one year of receipt of tools and spare parts that the product is defective or has failed, or (2) if said<br />

person fails to provide Acument Global Technologies, Inc. with such evidence as is reasonably requested<br />

in relation to the claimed defect or failure, including without limitation, evidence of the date of purchase<br />

and date of installation.<br />

THIS LIMITED WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, AND ANY<br />

IMPLIED WARRANTIES OF AS TO QUALITY, FITNESS FOR PURPOSE, OR MERCHANTABILITY ARE HEREBY<br />

SPECIFICALLY DISCLAIMED AND EXCLUDED BY ACUMENT GLOBAL TECHNOLOGIES, INC. UNDER NO<br />

CIRCUMSTANCES SHALL ACUMENT GLOBAL TECHNOLOGIES, INC. BE LIABLE FOR INCIDENTAL OR<br />

CONSEQUENTIAL DAMAGES ARISING FROM ANY DEFECT OR FAILURE IN ITS PRODUCTS.<br />

NOTE: The properties, strengths, dimensions, installed characteristics and all other information in<br />

this catalog is for guidance only to aid in the correct selection of the products described herein<br />

and is not intended or implied as part of the above warranty. All applications should be evaluated<br />

for functional stability and available samples of the described parts can be requested for installed<br />

tests, suitability and evaluations.<br />

All inquiries concerning this Limited Warranty should be sent to:<br />

Acument Global Technologies, Inc.<br />

Attention: Legal Department<br />

6125 Eighteen Mile Road<br />

Sterling Heights, Michigan 48314<br />

1-800-544-6117<br />

19

6125 Eighteen Mile Road<br />

Sterling Heights, Michigan 48314<br />

1-800-544-6117<br />

acument.com<br />

camcarsolutions.com<br />

ringscrew.com<br />

NOTE: The information in this manual is not to be considered a specification.<br />

Strux®, Struxtite®, TORX®, Rivtex®, Autoriv, Speed <strong>Fastening</strong>, Rivscrew®, Briv®, Avex®, Stavex®, Monobolt®, Avdelok®, Fastriv®, Crimptite®, Mag-Form®, TORX PLUS®, and Camcar® are<br />

trademarks of Acument Intellectual Properties, LLC. TAPTITE® and Plastite® are registered trademarks of Research, Engineering & Manufacturing Inc. PT® and Delta PT® are registered<br />

trademarks of EJOT Verbindsdungtechnik & Co. KG.<br />

©2004-2007 Acument Intellectual Properties, LLC. REV: 02/01/07