Page-01 of 23 - Indian Railways

Page-01 of 23 - Indian Railways

Page-01 of 23 - Indian Railways

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

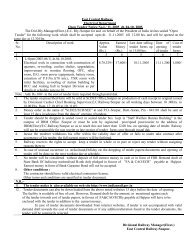

Sl.<br />

No<br />

19<br />

Co<br />

ntd<br />

..<br />

Description <strong>of</strong> work Qty. Rate in Figure Rate in Words unit<br />

wherever required to bridge the track to<br />

designed level and grade with one katcha<br />

packing and two round <strong>of</strong> through packing for<br />

permitting speed <strong>of</strong> 45 Km ph. The item also<br />

including dressing and boxing <strong>of</strong> ballast to<br />

proper pr<strong>of</strong>ile as per availability <strong>of</strong> ballast and<br />

direction <strong>of</strong> PWI at site.<br />

17 <strong>of</strong> 24<br />

20 3 rd . round consolidation packing. Nil T/Mt.<br />

Per Metre.<br />

Nil<br />

21. Fabrication <strong>of</strong> level crossing Check rail<br />

90R/52Kg. including fittings complete in all<br />

respects as per instruction <strong>of</strong> site In-charge.<br />

22 Supply <strong>of</strong> petrol at site <strong>of</strong> work @ 1.6 ltrs. For<br />

welding <strong>of</strong> 52 Kg/ 90R rail joints and 1.8 ltrs.<br />

For welding <strong>of</strong> 60 Kg. rail joints including<br />

supply <strong>of</strong> necessary skilled and unskilled<br />

labourers for welding <strong>of</strong> 52Kg/60Kg/90R rail<br />

joints in SITU by SKV process including all<br />

operations in line providing gap at joints<br />

levelling , digging <strong>of</strong> rail by JIM crowing<br />

where necessary, fixing <strong>of</strong> wooden block to<br />

support the rail ends by shifting 2/3 sleeper on<br />

either end <strong>of</strong> joints to facilitate providing <strong>of</strong><br />

wooden block below rail, cutting chipping <strong>of</strong><br />

excess welded materials for welded joints and<br />

filling the joints to standard pr<strong>of</strong>ile and epoxy<br />

painting as per direction <strong>of</strong> Engineer at site.<br />

(a) 10 Rail/ 20 Rail to<br />

LWR/CWR<br />

100<br />

joints<br />

Per Joint<br />

(b) 3 Rail to LWR/CWR<br />

200<br />

Joints.<br />

Per joint<br />

(C ) Single Rail to 3 Rail Panel<br />

100<br />

Joints<br />

Per Joint<br />

DEN(2)/DHN<br />

Signature <strong>of</strong> Tenders<br />

Date: