Page-01 of 23 - Indian Railways

Page-01 of 23 - Indian Railways

Page-01 of 23 - Indian Railways

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

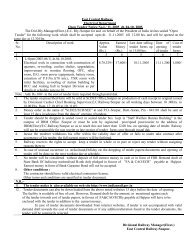

14 <strong>of</strong> 24<br />

Sl.<br />

No.<br />

Description <strong>of</strong> work Qty. Rate in Figure Rate in Words unit<br />

9. Levelling <strong>of</strong> ballast during PQRS work after old<br />

panels are lifted. Ballast to be made levelled for the<br />

requirement <strong>of</strong> placing PRC sleepers. This will also<br />

include removal <strong>of</strong> cess ballast, removal <strong>of</strong> ballast<br />

from track, bridge/turnout approaches to match<br />

level <strong>of</strong> old and new track. Work also includes<br />

assisting <strong>of</strong> PQRS portals for laying <strong>of</strong> service<br />

panels in track i.e. opening <strong>of</strong> fish plates,<br />

bolts/Nuts & repairing after laying <strong>of</strong> service panels<br />

and aligning proper so that train movement can be<br />

allowed. This includes lifting <strong>of</strong> track with Kutcha<br />

packing.<br />

10.<br />

Post attention <strong>of</strong> newly laid PRC track which will<br />

include complete squaring, spacing and gauging<br />

after TRR with S.Rail to 20 Rail panel and boxing<br />

<strong>of</strong> exiting ballast in crib and shoulder.<br />

11. Complete Through Rail renewal <strong>of</strong> existing<br />

90R/52Kg service rails with new/SH 52Kg/60Kg,<br />

39 mtrs. rail to 20 rail panels i.e. dismantling <strong>of</strong><br />

existing 90R/52Kg rails by opening fish plates,<br />

Fittings & fastenings and putting<br />

new/SH52kg/60Kg. rails/panels on PRC sleepers &<br />

providing all fittings, fastening & fish plating<br />

complete.<br />

12. Execution <strong>of</strong> pre, post and during all works<br />

associated with BCM machine working including<br />

attention to low joints, pulling <strong>of</strong> ballast ahead &<br />

back, removal <strong>of</strong> all infringements on ahead and<br />

back <strong>of</strong> BCM machine, dressing <strong>of</strong> ballast to<br />

proper pr<strong>of</strong>ile, dressing the full width <strong>of</strong> cess after<br />

removing muck behind the BCM working, refixing<br />

<strong>of</strong> reference posts (which were removed<br />

prior to machine working), cleaning jungle on the<br />

cess, fixing <strong>of</strong> broken/fallen fittings etc. and<br />

including supply <strong>of</strong> adequate labour along with<br />

BCM machine for smooth operation <strong>of</strong> BCM<br />

during block period. The rate also includes<br />

fixing/shifting <strong>of</strong> cutter bar <strong>of</strong> BCM at suitable<br />

locations as advised by Engineer-in-charge,<br />

provision <strong>of</strong> ramp at the end <strong>of</strong> the work , removal<br />

<strong>of</strong> cutter bar when ever advised and fixation <strong>of</strong> PSC<br />

Sleepers at the location and fixing up sleepers<br />

which were dropped during operation <strong>of</strong> BCM<br />

machine including tightening <strong>of</strong> all fittings etc. and<br />

deep screening <strong>of</strong> shoulder ballast up to full depth<br />

& width (i.e. ballast section not screened by BCM)<br />

through approved sieves and putting back screened<br />

ballast on the track to the required pr<strong>of</strong>ile and<br />

8150<br />

T/Mtrs<br />

13529<br />

Sleepe<br />

rs<br />

8150<br />

T/Mtr.<br />

7750<br />

T/Mtrs<br />

T/Mtrs<br />

Per sleeper<br />

T/Mtr.<br />

T/Mtrs<br />

DEN(2)/DHN<br />

Signature <strong>of</strong> Tenders<br />

Date: