A N T I M O N Y : ITS HISTORY, CHEMISTRY, MINERALOGY ...

A N T I M O N Y : ITS HISTORY, CHEMISTRY, MINERALOGY ...

A N T I M O N Y : ITS HISTORY, CHEMISTRY, MINERALOGY ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

146 THE METALLURGY OF ANTIMONY.<br />

antimony, in variable proportions, with smaller quantities of copper,<br />

zinc, lead, bismuth, or other metals.<br />

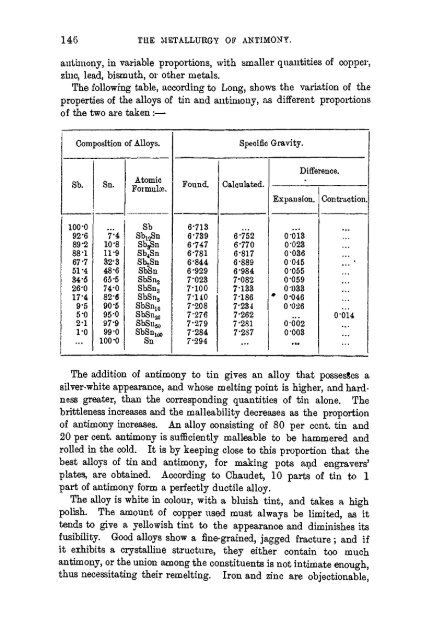

The following table, according to Long, shows the variation of the<br />

properties of the alloys of tin and antimony, as different proportions<br />

of the two are taken:—<br />

Composition of Alloys.<br />

Sb.<br />

100-0<br />

92*6<br />

89-2<br />

88*1<br />

67*7<br />

51*4<br />

34*5<br />

26-0<br />

17*4<br />

9*5<br />

5-0<br />

2*1<br />

1-0<br />

Sn.<br />

7 : 4<br />

10-8<br />

11-9<br />

32*3<br />

48-6<br />

65-5<br />

74*0<br />

82-6<br />

90*5<br />

95-0<br />

97*9<br />

99-0<br />

100-0<br />

Atomic<br />

Formulae.<br />

Sb<br />

SbjoSn<br />

SbgSn<br />

Sb4Sn<br />

Sb2Sn<br />

SbSn<br />

SbSn2<br />

SbSn3<br />

SbSn3<br />

SbSn10<br />

SbSnoo<br />

SbSugo<br />

SbSn100<br />

Sn<br />

Found.<br />

6-713<br />

6*739<br />

6747<br />

6-781<br />

6-844<br />

6-929<br />

7-023<br />

7*100<br />

7-110<br />

7-208<br />

7-276<br />

7-279<br />

7-284<br />

7-294<br />

Specific Gravity.<br />

Calculated.<br />

6-752<br />

6-770<br />

6*817<br />

6-889<br />

6*984<br />

7*082<br />

7-133<br />

7-186<br />

7*234<br />

7*262<br />

7-281<br />

7-287<br />

Expansion.<br />

0-013<br />

0*023<br />

0*036<br />

0 045<br />

0-055<br />

0-059<br />

0'033<br />

* 0-046<br />

0*026<br />

0-002<br />

0-003<br />

Difference.<br />

Contraction.<br />

o-314<br />

The addition of antimony to tin gives an alloy that possesses a<br />

silver-white appearance, and whose melting point is higher, and hardness<br />

greater, than the corresponding quantities of tin alone. The<br />

brittleness increases and the malleability decreases as the proportion<br />

of antimony increases. An alloy consisting of 80 per cent, tin and<br />

20 per cent, antimony is sufficiently malleable to be hammered and<br />

rolled in the cold. It is by keeping close to this proportion that the<br />

best alloys of tin and antimony, for making pots and engravers 7<br />

plates, are obtained. According to Chaudet, 10 parts of tin to 1<br />

part of antimony form a perfectly ductile alloy.<br />

The alloy is white in colour, with a bluish tint, and takes a high<br />

polish. The amount of copper used must always be limited, as it<br />

tends to give a yellowish tint to the appearance and diminishes its<br />

fusibility. Good alloys show a fine-grained, jagged fracture; and if<br />

it exhibits a crystalline structure, they either contain too much<br />

antimony, or the union among the constituents is not intimate enough,<br />

thus necessitating their remelting. Iron and zinc are objectionable,