A N T I M O N Y : ITS HISTORY, CHEMISTRY, MINERALOGY ...

A N T I M O N Y : ITS HISTORY, CHEMISTRY, MINERALOGY ...

A N T I M O N Y : ITS HISTORY, CHEMISTRY, MINERALOGY ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

THE METALLURGY OF ANTIMONY. 117<br />

by the workmen. The flues generally require cleaning four times<br />

a year.<br />

In the process described above, the first operation of smelting the<br />

ore with iron is called "singling," the second operation, or resmelting<br />

the singles for the production of the bowl metal, is called "doubling,"<br />

and the last operation is called "refining" or "frenching."<br />

On an average, one man can smelt 10 to 11 cwts. of ore in twelve<br />

hours. It has been observed that a small quantity of the oxide<br />

mixed with the sulphide improves the appearance of the metal.<br />

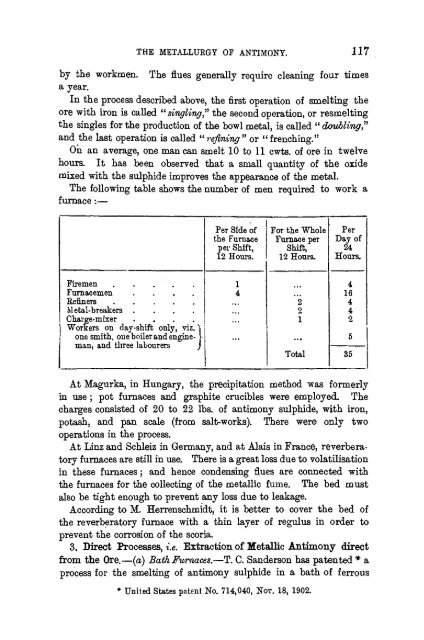

The following table shows the number of men required to work a<br />

furnace:—<br />

Firemen . . . ' .<br />

Furnacemen . . . .<br />

Refiners<br />

Metal-breakers . . . .<br />

Charge-mixer . . . .<br />

Workers on day-shift only, viz. \<br />

one smith, one boiler and engine- >man,<br />

and three labourers J<br />

Per Side of<br />

the Furnace<br />

per Shift,<br />

12 Hours.<br />

1<br />

4<br />

For the Whole<br />

Furnace per<br />

Shift,<br />

12 Hours.<br />

2<br />

2 1<br />

Total<br />

Per<br />

Day of<br />

24<br />

Hours.<br />

At Magurka, in Hungary, the precipitation method was formerly<br />

in use; pot furnaces and graphite crucibles were employed. The<br />

charges consisted of 20 to 22 lbs. of antimony sulphide, with iron,<br />

potash, and pan scale (from salt-works). There were only two<br />

operations in the process.<br />

At Linz and Schleiz in Germany, and at Alais in France, reverberatory<br />

furnaces are still in use. There is a great loss due to volatilisation<br />

in these furnaces; and hence condensing flues are connected with<br />

the furnaces for the collecting of the metallic fume. The bed must<br />

also be tight enough to prevent any loss due to leakage.<br />

According to M. Herrenschmidt, it is better to cover the bed of<br />

the reverberatory furnace with a thin layer of regulus in order to<br />

prevent the corrosion of the scoria.<br />

3. Direct Processes, i.e. Extraction of Metallic Antimony direct<br />

from the Ore.—(a) Bath Furnaces.—T. C. Sanderson has patented * a<br />

process for the smelting of antimony sulphide in a bath of ferrous<br />

* United States patent No. 714,040, Nov. 18, 1902.<br />

4<br />

16 442<br />

5<br />

35