Struktury automatizace průmyslového podniku

Struktury automatizace průmyslového podniku Struktury automatizace průmyslového podniku

30.9.2013 Identifying a Module Type Several characteristics: RSLogix 5000 Software I/O Configuration Module Slot Number I or O for Input or Output A for AC, B for DC, F for Fast Response Analog 1756 - O B 16 D Number of Points or Channels Suffix – (Diagnostic, Electronic Fusing, Individually Isolated, Voltage Only, Current Only, etc.) 32 Identifying an I/O Module Tag I/O format: Location:Slot:Type.Member.Bit “Local” or Module Name for Remote I/O Point (Optional) “Data” (I/O values), “Fault,” etc. “I” for Input, “O” for Output, “C” for Configuration Module Slot Number 33 16

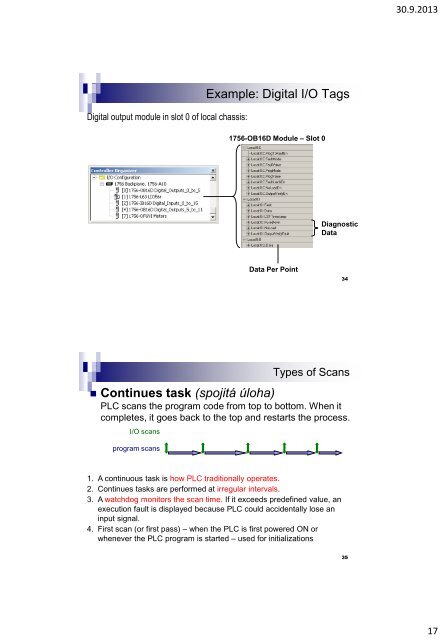

30.9.2013 Example: Digital I/O Tags Digital output module in slot 0 of local chassis: 1756-OB16D Module – Slot 0 Diagnostic Data Data Per Point 34 Types of Scans • Continues task (spojitá úloha) PLC scans the program code from top to bottom. When it completes, it goes back to the top and restarts the process. I/O scans program scans 1. A continuous task is how PLC traditionally operates. 2. Continues tasks are performed at irregular intervals. 3. A watchdog monitors the scan time. If it exceeds predefined value, an execution fault is displayed because PLC could accidentally lose an input signal. 4. First scan (or first pass) – when the PLC is first powered ON or whenever the PLC program is started – used for initializations 35 17

- Page 1 and 2: 30.9.2013 Průmyslová informatika

- Page 3 and 4: 30.9.2013 Klasické PLC Vzorkován

- Page 5 and 6: 30.9.2013 Lokální / Distribuovan

- Page 7 and 8: 30.9.2013 ControlNet: Key Terms Loc

- Page 9 and 10: 30.9.2013 Logické I/O adresy Allen

- Page 11 and 12: 30.9.2013 Two-slot Addressing Logic

- Page 13 and 14: 30.9.2013 Tabulka vytvářena modul

- Page 15: 30.9.2013 Klasické PLC / ControlLo

- Page 19 and 20: 30.9.2013 Continues, Periodic, and

- Page 21 and 22: 30.9.2013 Therac 25 - těžká chyb

- Page 23 and 24: 30.9.2013 1 of 2 errors Error is cl

- Page 25 and 26: 30.9.2013 P2P komunikace communicat

- Page 27: 30.9.2013 Busses and processors in

30.9.2013<br />

Example: Digital I/O Tags<br />

Digital output module in slot 0 of local chassis:<br />

1756-OB16D Module – Slot 0<br />

Diagnostic<br />

Data<br />

Data Per Point<br />

34<br />

Types of Scans<br />

• Continues task (spojitá úloha)<br />

PLC scans the program code from top to bottom. When it<br />

completes, it goes back to the top and restarts the process.<br />

I/O scans<br />

program scans<br />

1. A continuous task is how PLC traditionally operates.<br />

2. Continues tasks are performed at irregular intervals.<br />

3. A watchdog monitors the scan time. If it exceeds predefined value, an<br />

execution fault is displayed because PLC could accidentally lose an<br />

input signal.<br />

4. First scan (or first pass) – when the PLC is first powered ON or<br />

whenever the PLC program is started – used for initializations<br />

35<br />

17