Bond Strength Testing System HP 1000 - Herion Systemtechnik GmbH

Bond Strength Testing System HP 1000 - Herion Systemtechnik GmbH

Bond Strength Testing System HP 1000 - Herion Systemtechnik GmbH

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

ENGINEERINGADVANTAGE<br />

<strong>Bond</strong> <strong>Strength</strong> <strong>Testing</strong> <strong>System</strong> <strong>HP</strong> <strong>1000</strong><br />

Application of customers<br />

• the bond strength testing system <strong>HP</strong> <strong>1000</strong> serves for the<br />

determination of adhesive and/or tensile strength of coatings and<br />

materials, it is appropriate for the examinations according to DIN<br />

EN 24624 and DIN ISO 1048<br />

• experiences of many years, in close co-operation with users as<br />

well as important and prominent expert in the area of the tensile<br />

strength examination, led to the bond strength testing system<br />

<strong>HP</strong><strong>1000</strong> and the associated system components<br />

• a test plunger is stuck on the material which is to be examined and<br />

torn off by a piston with a pre-selected force rise rate. The tensile<br />

strength will be calculated by determining the retractile force<br />

Structure<br />

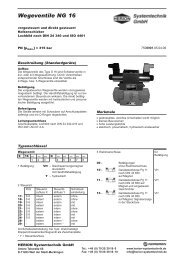

• principal item of the bond strength testing system <strong>HP</strong> <strong>1000</strong> is a bond<br />

strength control device, executed as a compact unit. According to<br />

requirements and application different standard pistons (0.6...20 kN)<br />

and test plungers can be mounted.<br />

Characteristics:<br />

• modular structure, optimally adaptable on respective targeted<br />

application by choice of the appropriate piston and test plunger.<br />

• logical arranged operating and display panel contains bilingual<br />

operating instructions (German and English).<br />

• simple operation in connection with electronic test sequence<br />

ensures a safe test execution and excludes process errors in a high<br />

degree.<br />

• equipment is portable and therefore suitable for the mobile<br />

application.<br />

• PC - supported control software in preparation.

The best of hydraulics and electronics combined in a single system<br />

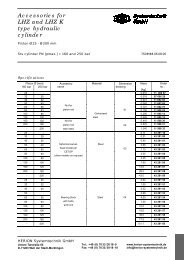

max<br />

kN<br />

N/s<br />

POWER ERROR<br />

kN<br />

ESC ENTER<br />

P1<br />

P2<br />

P3<br />

P4<br />

P5<br />

F[kN] A[cm²]<br />

0,6<br />

3,5<br />

9<br />

14<br />

20<br />

0,60<br />

3,78<br />

9,43<br />

14,73<br />

21,21<br />

Cont. Start<br />

Break Stop<br />

Steuertasten / control keys<br />

Zugkolben fährt aus zum Ankoppeln<br />

Thrust piston moves out ready for coupling<br />

Zugkolben fährt in Gestell ein<br />

Thrust piston moves into frame<br />

Prüfablauf beginnt, Kraftaufbau mit gewählter<br />

Kraftanstiegsgeschwindigkeit, LED ein<br />

Start Test sequence starts, force build-up with selected<br />

rate, LED on<br />

Prüfablauf wird beendet, Gerät geht in Grundstellung,<br />

Display zeigt “StoP”<br />

Stop Test sequence is ended, unit changes in basic<br />

position, Display shows “StoP”<br />

Kraftaufbau wird unterbrochen, Kraft am Prüfling<br />

wird gehalten, LED ein<br />

Break Force build-up is interrupted, test speciem<br />

remains under stress, LED on<br />

Kraftaufbau wird nach Unterbrechung fortgesetzt<br />

Cont. Force build-up is continued after interrupt<br />

Konfigurationstasten / setup keys<br />

max<br />

N/s<br />

kN<br />

ENTER<br />

ESC<br />

Display zeigt aktuelle Kraftanstiegsgeschw.<br />

Display shows actual rate of force increase<br />

Display zeigt aktuellen Maximalkraftwert<br />

LED meldet aktive Limitierung<br />

Display shows actual maximum force<br />

LED indicates activated limitation<br />

Display zeigt aktuellen Zugkolben<br />

Display shows actual thrust piston<br />

Eingabetasten / input keys<br />

Ermöglicht Eingabe der Konfigurationswerte,<br />

Display blinkt. Erneutes Drücken speichert Wert<br />

First press initiates input of setup values,<br />

display flashes. Second press stores value.<br />

Abbruch des Änderungsvorganges<br />

Input procedure is canceled<br />

Display<br />

kN<br />

8. 8. 8. 8.<br />

Next Service<br />

Display<br />

LED kN<br />

Grundstellung “StoP”<br />

aus<br />

basic position<br />

off<br />

Prüfablauf<br />

ansteigender Kraftwert ein<br />

test sequence increasing force value on<br />

Prüfende<br />

Endwert max. Kraft blinkend<br />

end of test sequence Result max. force flashing<br />

Konfiguration Eingabewert, blinkend aus<br />

Setup<br />

Set value, flashing off<br />

HERION <strong>System</strong>technik<br />

<strong>GmbH</strong><br />

Service: +49 (0) 7033 3018 0<br />

<strong>HP</strong> <strong>1000</strong><br />

Control panel<br />

<strong>System</strong> extent<br />

• compact bond strength testing unit consisting of hydraulically<br />

pressure supply with electronic test sequence and operating panel<br />

Technical data – <strong>Bond</strong> <strong>Strength</strong> <strong>Testing</strong> Unit<br />

• pump performance [l/min] 0,3<br />

• hydraulic operating pressure [bar] 100<br />

• motor performance [KW] 0,175<br />

• tank capacity [l] 0,7<br />

• weight [kg] approx.. 16<br />

• dimensions [mm] B 510, H 280, T 150<br />

• mains connection<br />

110...230 V / 50...60 Hz ; 240 W<br />

Accessories<br />

• different thrust pistons according to necessary traction power<br />

range selectable<br />

• hydraulic hoses with quick connection coupling<br />

• universal test rack for the mounting of the different pistons<br />

• various types of test plungers<br />

• further accessories such as cable remote control and PC -<br />

supported control software inpreparation<br />

Technical data – Accessories<br />

• piston traction power range [kN]<br />

size 0.6 0,06...0,6<br />

size 3.5 0,35...3,5<br />

size 9 0,90...9,0<br />

size 14 1,4...14,0<br />

size 20 2,0...20,0<br />

mass, depending on size [kg] 4...7<br />

• hydraulic hose<br />

filled with oil [m] 3,00<br />

• extension hose length [m] 3,00<br />

• test plunger size<br />

[mm]<br />

squarely 50 x 50<br />

round 20<br />

round 50<br />

round 100<br />

Drucknorm 7503553.02.03.04<br />

Contact:<br />

Technical consultation and order handling<br />

Mister Linhard Steeb<br />

Tel. +49 (0)70 33/30 18-441<br />

Fax +49 (0)70 33/30 18-30<br />

linhard.steeb@herion-systemtechnik.de<br />

HERION <strong>System</strong>technik <strong>GmbH</strong><br />

Untere Talstr. 65<br />

D – 71263 Weil der Stadt<br />

Tel. +49 (0)70 33/30 18-0<br />

Fax +49 (0)70 33/30 18-10<br />

info@herion-systemtechnik.de<br />

www.herion-systemtechnik.de