view - Herion Systemtechnik GmbH

view - Herion Systemtechnik GmbH

view - Herion Systemtechnik GmbH

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

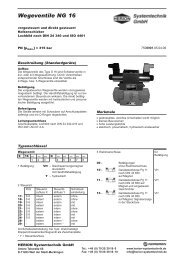

Hydraulic cylinder Type LHZ<br />

Double acting<br />

Diam. 25 - 200 mm<br />

PN [pmax.] = 250 bar<br />

Connecting dimensions<br />

Diam. 25 to 40 following CETOP R 58 H and ISO/DIS 6020/I<br />

Diam. 50 to 200 as per CETOP R 73 H and ISO/DIS 6022 7501336.06.04.08<br />

Symbol<br />

Description<br />

Mounting<br />

Line connection<br />

Installation position<br />

Damping, optional<br />

Fluid, optional<br />

see nominal sizes<br />

inside thread<br />

as per DIN ISO 228/1<br />

as required<br />

- without<br />

- adjustable on both end positions<br />

- hydraulic oil, filtered<br />

- water emulsion, filtered<br />

Temperature range for fluid hydraulic oil:<br />

[ o C] - 20 to + 80<br />

for fluid water emulsion:<br />

+ 4 to + 50<br />

Operating pressure min. 522<br />

static and dynamic [bar] max. 250<br />

Testing pressure [bar] max. 375<br />

Viscosity range<br />

cSt [mm 2 /s]<br />

3 to 300<br />

1) Other sealing materials on request.<br />

Materials: Flange: Steel<br />

Cylinder barrel:Steel<br />

Piston rod:<br />

Optional<br />

Tie rods,<br />

tie rod nuts:<br />

Seals: 1)<br />

(Chem. for fluid water emulsion)<br />

(Chem. for fluid water emulsion)<br />

- stainless-grade steel,<br />

1.4021<br />

- steel , 1.5217<br />

hard-chrome plated<br />

- steel, 1.7225<br />

hardened and<br />

hard-chrome plated<br />

steel<br />

Perbunan/polyurethane (PU)<br />

Cylinders delivered with base coat:<br />

Characteristics<br />

• Differential cylinder in tie rod design<br />

• Stroke length adjustable to customer specifications<br />

• Low stick-slip movement<br />

• Adjustable damping, optional<br />

• Optional hydraulic or water emulsion fluid<br />

• Choice of piston rod material<br />

• Accessories see Print 7501131.<br />

• Equipment as per request<br />

- ventilation<br />

- power-assisted design<br />

- piston seal static leak-free<br />

LHZ (250 bar)<br />

HERION <strong>Systemtechnik</strong> <strong>GmbH</strong><br />

Untere Talstraße 65<br />

D-71263 Weil der Stadt (Merklingen)<br />

Tel.: +49 (0) 70 33/30 18-0<br />

Fax: +49 (0) 70 33/30 18-10<br />

www.herion-systemtechnik.de<br />

info@herion-systemtechnik.de

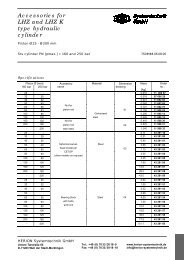

Nominal Sizes<br />

Piston Diam. [mm]<br />

Piston rod Diam. [mm]<br />

Line connection<br />

Piston area [cm 2 ]<br />

Ring area [cm 2 ]<br />

Damping stroke [mm]<br />

damping on<br />

both sides<br />

Base Nr.<br />

without<br />

damping<br />

Base design<br />

Stainless steel, 1.4021<br />

Foot mounting<br />

Centred swivel bearing<br />

Swivel bearing,<br />

spherical<br />

Tail flange<br />

Head flange<br />

Swivel bearing<br />

Piston rod material<br />

Steel,, 1.5217 (20 MnV6)<br />

hard-crome plated<br />

Base design<br />

Foot mounting<br />

Centred swivel bearing<br />

Swivel bearing,<br />

spherical<br />

Tail flange<br />

Head flange<br />

Swivel bearing<br />

Steel, 1.7225 (42 CrMo4)<br />

hardened and chromed<br />

Base design<br />

Foot mounting<br />

Centred swivel bearing<br />

Swivel bearing,<br />

spherical<br />

Tail flange<br />

Head flange<br />

Swivel bearing<br />

Fluid hydraulic oil [250 bar]<br />

25<br />

16<br />

G 1 /4<br />

4.91<br />

2.90<br />

23 44 843 4) 44 840<br />

10<br />

11<br />

12<br />

13<br />

14<br />

-<br />

16<br />

50<br />

51<br />

52<br />

53<br />

54<br />

-<br />

56<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

32<br />

20<br />

G 3 /8<br />

8.04<br />

4.90<br />

28 44 844 4) 44 841<br />

10<br />

11<br />

12<br />

13<br />

14<br />

-<br />

16<br />

50<br />

51<br />

52<br />

53<br />

54<br />

-<br />

56<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

40<br />

25<br />

G 1 /2<br />

12.56<br />

7.65<br />

35 44 845 4) 44 842<br />

10<br />

11<br />

12<br />

13<br />

14<br />

-<br />

16<br />

50<br />

51<br />

52<br />

53<br />

54<br />

-<br />

56<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

50<br />

32<br />

G 1 /2<br />

19.63<br />

11.59<br />

32 43 213<br />

43 223<br />

10<br />

11<br />

12<br />

13<br />

14<br />

15<br />

16<br />

50<br />

51<br />

52<br />

53<br />

54<br />

55<br />

56<br />

80<br />

81<br />

82<br />

83<br />

84<br />

85<br />

86<br />

63<br />

40<br />

G 3 /4<br />

31.17<br />

18.61<br />

39 43 214<br />

43 224<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

50<br />

51<br />

52<br />

53<br />

54<br />

55<br />

56<br />

80<br />

81<br />

82<br />

83<br />

84<br />

85<br />

86<br />

80<br />

50<br />

G 3 /4<br />

50.27<br />

30.63<br />

41 43 215<br />

43 225<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

50<br />

51<br />

52<br />

53<br />

54<br />

55<br />

56<br />

80<br />

81<br />

82<br />

83<br />

84<br />

85<br />

86<br />

100<br />

63<br />

G 1<br />

78.54<br />

47.37<br />

47 43 216<br />

43 226<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

50<br />

51<br />

52<br />

53<br />

54<br />

55<br />

56<br />

80<br />

81<br />

82<br />

83<br />

84<br />

85<br />

86<br />

125<br />

80<br />

G 1<br />

122.72<br />

72.45<br />

47 43 217<br />

43 227<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

50<br />

51<br />

52<br />

53<br />

54<br />

55<br />

56<br />

80<br />

81<br />

82<br />

83<br />

84<br />

85<br />

86<br />

160<br />

100<br />

G1 1 /4<br />

201.06 122.52<br />

51 43 218<br />

43 228<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

50<br />

51<br />

52<br />

53<br />

54<br />

55<br />

56<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

200<br />

125<br />

G1 1 /4<br />

314.16 191.44<br />

78 43 219<br />

43 229<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

50<br />

51<br />

52<br />

53<br />

54<br />

55<br />

56<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

Fluid water emulsion [250 bar]<br />

25<br />

16<br />

G 1 /4<br />

4.91<br />

2.90<br />

23 44 843 4) 44 840<br />

00<br />

01<br />

02<br />

03<br />

04<br />

-<br />

06<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

32<br />

20<br />

G 3 /8<br />

8.04<br />

4.90<br />

28 44 844 4) 44 841<br />

00<br />

01<br />

02<br />

03<br />

04<br />

-<br />

06<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

40<br />

25<br />

G 1 /2<br />

12.56<br />

7.65<br />

35 44 845 4) 44 842<br />

00<br />

01<br />

02<br />

03<br />

04<br />

-<br />

06<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

50<br />

32<br />

G 1 /2<br />

19.63<br />

11.59<br />

32 43 250<br />

43 257<br />

00<br />

01<br />

02<br />

03<br />

04<br />

05<br />

06<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

63<br />

40<br />

G 3 /4<br />

31.17<br />

18.61<br />

39 43 251<br />

43 258<br />

00<br />

01<br />

02<br />

03<br />

04<br />

05<br />

06<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

80<br />

50<br />

G 3 /4<br />

50.27<br />

30.63<br />

41 43 252<br />

43 259<br />

00<br />

01<br />

02<br />

03<br />

04<br />

05<br />

06<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

100<br />

63<br />

G 1<br />

78.54<br />

47.37<br />

47 43 253<br />

43 260<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

40<br />

41<br />

42<br />

43<br />

44<br />

45<br />

46<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

125<br />

80<br />

G 1<br />

122.72<br />

72.45<br />

47 43 254<br />

43 261<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

40<br />

41<br />

42<br />

43<br />

44<br />

45<br />

46<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

160<br />

100<br />

G1 1 /4<br />

201.06 122.52<br />

51 43 255<br />

43 262<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

40<br />

41<br />

42<br />

43<br />

44<br />

45<br />

46<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

200<br />

125<br />

G1 1 /4<br />

314.16 191.44<br />

78 43 256<br />

43 263<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

40<br />

41<br />

42<br />

43<br />

44<br />

45<br />

46<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

4)<br />

only delivered with one-sided<br />

damping on rear flange<br />

Base Nr.<br />

Piston rod material/Mounting type<br />

Sample Order:<br />

(see questionnaire on last page)<br />

Order Nr.:<br />

43 229 50 .0150<br />

Stroke length [mm]<br />

as per customer<br />

specification<br />

LHZ (250 bar)<br />

Dimensional Drawings<br />

Basic design<br />

L + Stroke<br />

2 Subject to alteration<br />

7501336.06.04.08

Dimensional Drawings<br />

Head flange<br />

Tail flange*<br />

L 5 + Stroke<br />

L 1 + Stroke<br />

Foot mounting<br />

L 4 + Stroke<br />

Swivel bearing<br />

Spherical<br />

<strong>view</strong> A<br />

L 3 + Stroke<br />

Swivel bearing<br />

<strong>view</strong> A<br />

Central swivel bearing<br />

L 2 + Stroke<br />

LHZ (250 bar)<br />

7501336.06.04.08 Subject to alteration<br />

3

Nominal Tables [measurements in mm]<br />

Tolerance<br />

f8<br />

js13<br />

H7<br />

f8<br />

DIN ISO<br />

228/1<br />

Piston Ø<br />

Ø d 1<br />

d 2<br />

Ø d 3<br />

Ø d 4<br />

Ø d 5<br />

Ø d 6<br />

Ø d 7<br />

Ø d 8<br />

Ø d 9<br />

d 10<br />

Ø d 11<br />

d 12<br />

Ø d 13<br />

A<br />

B<br />

C<br />

25<br />

16<br />

M 114x1.5<br />

-<br />

11<br />

90<br />

6,6<br />

75<br />

12<br />

12<br />

G 1 /4<br />

42<br />

M 16<br />

27<br />

18<br />

13<br />

-<br />

32<br />

20<br />

M 116x1.5<br />

-<br />

14<br />

115<br />

9,6<br />

92<br />

16<br />

16<br />

G 3 /8<br />

52<br />

M 18<br />

37<br />

22<br />

13<br />

-<br />

40<br />

25<br />

M 120x1.5<br />

-<br />

18<br />

130<br />

9,6<br />

106<br />

20<br />

20<br />

G 1 /2<br />

65<br />

M 10x1.25<br />

38<br />

28<br />

13<br />

-<br />

50<br />

32<br />

M 127x2<br />

63<br />

18<br />

160<br />

14,6<br />

132<br />

32<br />

32<br />

G 1 /2<br />

83<br />

M 12x1.25<br />

49<br />

36<br />

47<br />

29<br />

63<br />

40<br />

M 133x2<br />

75<br />

18<br />

180<br />

14,6<br />

150<br />

40<br />

40<br />

G 3 /4<br />

102<br />

M 16x1.5<br />

60<br />

45<br />

53<br />

32<br />

80<br />

50<br />

M 142x2<br />

90<br />

22<br />

215<br />

18,6<br />

180<br />

50<br />

50<br />

G 3 /4<br />

122<br />

M 20x1.5<br />

67<br />

56<br />

60<br />

36<br />

100<br />

63<br />

M 148x2<br />

110<br />

26<br />

250<br />

22,6<br />

212<br />

63<br />

63<br />

G 1<br />

152<br />

M 24x2<br />

79<br />

63<br />

63<br />

41<br />

125<br />

80<br />

M 164x3<br />

132<br />

26<br />

290<br />

22,6<br />

250<br />

80<br />

80<br />

G 1<br />

182<br />

M 27x2<br />

95<br />

85<br />

76<br />

45<br />

160<br />

100<br />

M 180x3<br />

160<br />

33<br />

360<br />

26,6<br />

315<br />

100<br />

100<br />

G 1 1 /4<br />

224<br />

M 30x2<br />

121<br />

95<br />

85<br />

50<br />

200<br />

125<br />

M 100x3<br />

200<br />

39<br />

445<br />

33,6<br />

385<br />

125<br />

125<br />

G 1 1 /4<br />

280<br />

M 33x2<br />

165<br />

112<br />

101<br />

61<br />

Tolerance<br />

Piston Ø<br />

D<br />

D 1<br />

E<br />

F<br />

G<br />

G 1<br />

* ± 0,3 * * * * * *<br />

G 2 H J K L L 1 L 2 L 3 L 4 L 5<br />

25<br />

C 1<br />

4<br />

48<br />

11<br />

2<br />

45<br />

168.5<br />

30<br />

9<br />

12<br />

-<br />

12<br />

147.5<br />

-<br />

178<br />

191.5<br />

100.5<br />

150<br />

32<br />

5<br />

46<br />

14<br />

3<br />

55<br />

179<br />

38<br />

12<br />

16<br />

-<br />

16<br />

169<br />

-<br />

206<br />

104.5<br />

111<br />

170<br />

40<br />

6<br />

59<br />

18<br />

4<br />

70<br />

189.5<br />

45<br />

15<br />

16<br />

-<br />

20<br />

190<br />

-<br />

231<br />

117.5<br />

120.5<br />

190<br />

50<br />

6<br />

50<br />

22<br />

8<br />

80<br />

183<br />

47<br />

18<br />

25<br />

22<br />

32<br />

238<br />

216<br />

305<br />

160<br />

147<br />

240<br />

63<br />

7<br />

55<br />

22<br />

10<br />

100<br />

194<br />

57<br />

24<br />

28<br />

25<br />

40<br />

268<br />

243<br />

348<br />

177<br />

166<br />

270<br />

80<br />

7<br />

64<br />

29<br />

10<br />

120<br />

109<br />

59<br />

30<br />

32<br />

28<br />

50<br />

295<br />

267<br />

395<br />

199<br />

179<br />

300<br />

100<br />

8<br />

73<br />

30<br />

10<br />

150<br />

123<br />

70<br />

36<br />

36<br />

32<br />

63<br />

333<br />

301<br />

442<br />

231<br />

200<br />

335<br />

125<br />

8<br />

96<br />

36<br />

13<br />

175<br />

145<br />

71<br />

40<br />

40<br />

36<br />

80<br />

386<br />

350<br />

520<br />

271<br />

240<br />

390<br />

160<br />

10<br />

103<br />

47<br />

13<br />

210<br />

163<br />

92<br />

45<br />

45<br />

40<br />

100<br />

456<br />

416<br />

617<br />

308<br />

291<br />

460<br />

200<br />

10<br />

118<br />

54<br />

13<br />

260<br />

188<br />

124<br />

50<br />

56<br />

45<br />

125<br />

535<br />

490<br />

756<br />

364<br />

342<br />

540<br />

LHZ (250 bar)<br />

Tolerance<br />

Piston Ø<br />

25<br />

32<br />

40<br />

50<br />

63<br />

80<br />

100<br />

125<br />

160<br />

200<br />

M<br />

* Installation lengths- / Stroke tolerances [mm]<br />

Stroke ≤ 1500<br />

20<br />

25<br />

30<br />

60<br />

60<br />

60<br />

80<br />

100<br />

120<br />

150<br />

Stroke > 1500 to 1250<br />

Stroke > 1250 to 2000<br />

N<br />

53<br />

65<br />

82<br />

100<br />

120<br />

145<br />

170<br />

205<br />

240<br />

295<br />

Stroke > 2000 on request<br />

h13<br />

O<br />

63<br />

75<br />

90<br />

112<br />

125<br />

150<br />

180<br />

224<br />

280<br />

335<br />

Stroke<br />

tolerance<br />

±1<br />

±1.5<br />

±2.5<br />

js16<br />

P<br />

10<br />

12<br />

16<br />

25<br />

32<br />

40<br />

50<br />

63<br />

80<br />

100<br />

R<br />

0.6<br />

1.0<br />

1.6<br />

2.5<br />

2.5<br />

3<br />

5<br />

5<br />

6<br />

6<br />

S<br />

22<br />

25<br />

32<br />

40<br />

40<br />

50<br />

60<br />

60<br />

70<br />

80<br />

T<br />

70<br />

80<br />

105<br />

125<br />

145<br />

177<br />

220<br />

245<br />

290<br />

348<br />

±1.5<br />

±2.0<br />

±3.0<br />

± 2<br />

U<br />

90<br />

105<br />

135<br />

160<br />

180<br />

220<br />

270<br />

295<br />

350<br />

420<br />

-0,3<br />

V<br />

28<br />

32<br />

40<br />

50<br />

63<br />

71<br />

90<br />

112<br />

125<br />

150<br />

W<br />

30<br />

40<br />

50<br />

65<br />

72<br />

78<br />

91<br />

140<br />

160<br />

188<br />

Installation length tolerance<br />

L+ Stroke L 1 + J + Stroke L 2 + Stroke L 5 + Stroke J L 3 L 4+ Y+Stroke<br />

X<br />

16<br />

20<br />

25<br />

38<br />

49<br />

59<br />

71<br />

90<br />

112<br />

145<br />

Y<br />

28<br />

33<br />

38<br />

64<br />

71<br />

80<br />

91<br />

100<br />

113<br />

134<br />

Z 1<br />

15<br />

20<br />

25<br />

17<br />

18<br />

20<br />

23<br />

24<br />

28<br />

33<br />

Z 2<br />

±2.0<br />

±2.8<br />

±4.0<br />

-<br />

-<br />

-<br />

31<br />

36<br />

38<br />

45<br />

2x46<br />

2x52<br />

2x61<br />

α [ o ]<br />

4<br />

4<br />

4<br />

4<br />

4<br />

4<br />

4<br />

4<br />

4<br />

4<br />

SW<br />

13<br />

16<br />

21<br />

27<br />

32<br />

41<br />

50<br />

65<br />

80<br />

100<br />

4 Subject to alteration<br />

7501336.06.04.08

Sectional Drawing<br />

Cross-section for piston diam.<br />

25 to 40 mm<br />

Drawn at 90°<br />

rotation<br />

Cross-section for piston diam.<br />

50 to 200 mm<br />

Drawn at 90°<br />

rotation<br />

1 Cylinder barrel<br />

2 Head flange<br />

3 Tail flange<br />

4 Piston rod<br />

5 Piston<br />

6 Bush<br />

* 17 Deflector<br />

* 19 Seal<br />

11 Damping bush<br />

12 Damping ring<br />

13 Damping ring<br />

14 Throttle<br />

* 15 O-ring<br />

* 16 O-ring<br />

* 17 Seal<br />

* 18 Tail ring<br />

19 Damping ring<br />

20 Tie rod<br />

All parts marked with * are included the respective wearing parts product line.<br />

Indicate full "name plate information" (order nr. and delivery date) when ordering other parts.<br />

* 21 Guide ring<br />

* 22 O-ring<br />

23 Nut<br />

24 Bolt<br />

34 Thread piece<br />

35 Clamping sleeve<br />

Wearing parts product lines<br />

Piston<br />

diam.<br />

[mm]<br />

25<br />

32<br />

40<br />

50<br />

63<br />

80<br />

100<br />

125<br />

160<br />

200<br />

Product line order numbers for Type LHZ (250 bar)<br />

Fluid hydraulic oil<br />

seals Perbunan / PU<br />

11 019 29<br />

11 019 30<br />

11 019 31<br />

11 013 80<br />

11 013 81<br />

11 013 82<br />

11 013 83<br />

11 013 84<br />

11 013 85<br />

11 013 86<br />

Fluid water emulsion<br />

seals Perbunan / PU<br />

11 019 32<br />

11 019 33<br />

11 019 35<br />

11 017 74<br />

11 017 75<br />

11 017 76<br />

11 017 77<br />

11 017 78<br />

11 017 79<br />

11 017 80<br />

Tightening torque [Nm]<br />

Pos. 23 3)<br />

1138.5<br />

1121<br />

1138<br />

1170<br />

1150<br />

1300<br />

1500<br />

1660<br />

1350<br />

2100<br />

3)<br />

For large strokes ensure equal distances<br />

between cylinder pipe/tie-rod.<br />

Tighten alternately (cross-wise) when<br />

mounting.<br />

LHZ (250 bar)<br />

7501336.06.04.08 Subject to alteration<br />

5

Note when Ordering<br />

Information required when specifying ventilation<br />

1. Ventilation requested for<br />

- head flange<br />

- tail flange<br />

- head and tail flanges<br />

2. Position of ventilation screw (pos. 1 to 4)<br />

3. Cylinder orientation<br />

View of piston rod<br />

= standard position of<br />

connecting bores<br />

Position of<br />

damping<br />

throttle<br />

When ordering or making inquiries about modified series cylinders or special hydraulic cylinders, please<br />

complete and attach questionnaire (Print 7501387).<br />

LHZ (250 bar)<br />

6 Subject to alteration<br />

7501336.06.04.08